Академический Документы

Профессиональный Документы

Культура Документы

MC 162-163

Загружено:

Brandon MarshallИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MC 162-163

Загружено:

Brandon MarshallАвторское право:

Доступные форматы

162

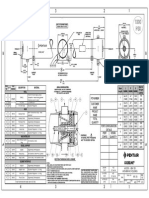

Cavity and Core Components

Air Poppet Valves Applications

Air Poppet Valves VA Features and Benefits

Prevents mold damage due to ejection problems with deep-draw or thin-walled parts More durable and precision-made than competitive units These precision-engineered valves are designed to remedy the vacuum problem often encountered during the molding of deep-draw (e.g., buckets) or thin-walled parts. Air flow, timed to coincide with the ejection cycle, opens the valve to break the vacuum and facilitate part ejection. A precisionground valve seat helps prevent flash from entering the assembly during injection. Each valve is matched to the body to further assure reliable performance.

Air Poppet Valves Applications

Typical Application

AIR LINE (PRESSURE OFF)

AIR LINE (PRESSURE ACTIVATED)

Mold Closed

L K

Mold Open

A T MAX APPROX VALVE TRAVEL

Cavity and Core Components

SPRING HOUSING

SPRING

VALVE

BODY A

INFORMATION KEY: D = Outside Diameter E = Housing Diameter F = Approx. Valve Diameter G = Hole Diameter H = Hole Diameter K = Body Length L = Overall Length N = Depth

T = Max Valve Travel Body Material: Stainless Steel Body Hardness: 53 3 HRC Valve Material: Stainless Steel Valve Surface Treatment: Titanium Nitrided Max. Temp: 120C (250F) Operating Air Pressure: 58 PSI min. 87 PSI max Dimensions: All dimensions are in mm

ITEM NUMBER

VA 01 VA 02 VA 03

D 8 12 18

(APPROX)

K

BODY LENGTH 11 18 22

L

OVERALL LENGTH 24 34 45.5 E 6 8 12

T

MAX TRAVEL 1.2 1.9 2.5

6.6 9.7 14.8

All dimensions shown are in mm.

Table of Contents

U.S. 800-626-6653

Canada 800-387-6600

www.dme.net

Index

Cavity and Core Components

163

Air Poppet Valves Typical Installations

Typical Installations

2mm MIN CLEARANCE RECOMMENDED

AIR LINE

Cavity and Core Components

AIR LINE

Standard A Series Mold Base Installation (Ejector pins required for part ejection) Pocket Machining Dimensions

X Series Stripper Plate Mold Base Installation (Stripper plate required for part ejection)

+0 0.03mm

Installation Information Press-fit installation required. Maintain a close tolerance press fit, as specified. Too loose a fit could allow the Air Poppet Valve to move out of position, while too tight a press fit could interfere with the movement of the valve.

NOTES: 1. Pressure to air line of Air Poppet Valve and machine ejection should be activated at the same time. This allows valve to relieve negative pressure build-up (vacuum) in the cavity during part ejection. 2. The air flow to the poppet valve must be fully relieved to the atmosphere after each cycle to ensure that the poppet valve closes before the next injection cycle. Material injected into a partially open poppet valve could cause damage to the valve and/or the mold. Control valves and limit switches to be supplied by moldmaker and/or molder. 3. The Air Poppet Valve should never be used as the sole means of part ejection. Material shrinkage and other factors will not allow it to be used as an alternative to ejector pins or stripper plates. 4. Do not position Air Poppet Valve directly under hot drop.

+0.2mm 0

0.05mm MAX RADIUS OR CHAMFER R RADIUS MAX

0.005mm

Air Poppet Valves Typical Installations

SHARP CORNER

2mm CLEARANCE MIN BELOW BOTTOM OF POPPET VALVE ITEM NUMBER VA 01 VA 02 VA 03 N DEPTH 11 18 22

L REF

G 8 12 18

H 6.75 9 14

R 0.1 0.2 0.3

L REF 24 34 45.5

All dimensions shown are in mm.

Quantity Discounts

8 to 15 valves . . . . . . . . . . . . . . . . . . . . . . . . Less 3% 16 or more valves . . . . . . . . . . . . . . . . . . . . Less 5% Discounts apply to current net prices. Sizes may be combined on one order for quantity discounts.

Table of Contents

U.S. 800-626-6653

Canada 800-387-6600

www.dme.net

Index

Next

Вам также может понравиться

- Waste-To-Energy Plant Process Safety ChallengesДокумент5 страницWaste-To-Energy Plant Process Safety Challengessomesh sharmaОценок пока нет

- Unique Single Seat Valve-Simply UniqueДокумент8 страницUnique Single Seat Valve-Simply UniquelggomezupbОценок пока нет

- 2660CE37-807 & 2660CGHI42-807: Compressor Field Service ManualДокумент24 страницы2660CE37-807 & 2660CGHI42-807: Compressor Field Service ManualHenry ArguettОценок пока нет

- Wilden PumpДокумент23 страницыWilden Pumpsunchit1986Оценок пока нет

- Wilden h800 EomДокумент28 страницWilden h800 Eomanon_819441268Оценок пока нет

- Apco Airvacuum Valves Avv Sales 601Документ8 страницApco Airvacuum Valves Avv Sales 601Jhony MedranoОценок пока нет

- 1776279Документ82 страницы1776279Tengku Nizarul AslamiОценок пока нет

- Wilden Pump - t2Документ0 страницWilden Pump - t2Absar MamunОценок пока нет

- Operating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpДокумент10 страницOperating Instructions & Service Manual Blue Max Ii Hydrostatic Test PumpdocrafiОценок пока нет

- SRC Alpha Version1 PDFДокумент26 страницSRC Alpha Version1 PDFRajat JainОценок пока нет

- Carrier 53ccd Installation ManualДокумент44 страницыCarrier 53ccd Installation ManualKarim Kassab100% (1)

- Manual Wilden t8 PDFДокумент31 страницаManual Wilden t8 PDFRoyalguard-exОценок пока нет

- Schrader VentiliДокумент8 страницSchrader VentiliSLANO77Оценок пока нет

- PRO Combination Air Valve For High Flow: DescriptionДокумент4 страницыPRO Combination Air Valve For High Flow: DescriptionVanderson LimaОценок пока нет

- Air System ComponentsДокумент6 страницAir System ComponentsEliasОценок пока нет

- Sauter B6R Three-Way Valve With Female Thread, PN 16Документ4 страницыSauter B6R Three-Way Valve With Female Thread, PN 16pitanje1991Оценок пока нет

- 20115272209Документ45 страниц20115272209Cristian TeodorescuОценок пока нет

- BaileyДокумент14 страницBaileyhecdomОценок пока нет

- Damper Guide BookДокумент21 страницаDamper Guide Booksbmmla100% (1)

- Crane - Series.rs Center LineДокумент23 страницыCrane - Series.rs Center LinenedwestОценок пока нет

- Unique SSV - Tank OutletДокумент6 страницUnique SSV - Tank OutletlggomezupbОценок пока нет

- Pneumatic VVДокумент20 страницPneumatic VVsaashadanОценок пока нет

- Auto Drain 70APADH4000Документ3 страницыAuto Drain 70APADH4000thomasoburОценок пока нет

- D-050 D-050-C D-052: Combination Air ValveДокумент6 страницD-050 D-050-C D-052: Combination Air Valve7erick7Оценок пока нет

- p177 02 PDFДокумент4 страницыp177 02 PDFJuan ZamoraОценок пока нет

- Process ValveДокумент38 страницProcess ValvetabiiОценок пока нет

- Ins Una 23-25-26 enДокумент20 страницIns Una 23-25-26 endarsh2001patelОценок пока нет

- H Series Valves-EnДокумент12 страницH Series Valves-EnWalther Ernesto Molina DominguezОценок пока нет

- Relief Valves: V SeriesДокумент8 страницRelief Valves: V SeriesRafael OrtizperezОценок пока нет

- AUTOMAX Supernova BrochureДокумент12 страницAUTOMAX Supernova BrochureEnrique Domingo RubioОценок пока нет

- Masoneilan - 78 Series Air Filter Regulators IOMДокумент8 страницMasoneilan - 78 Series Air Filter Regulators IOMNithyAОценок пока нет

- Eaton-Airflex Quick Release Valve IOMДокумент8 страницEaton-Airflex Quick Release Valve IOMIvan AcostaОценок пока нет

- 38hds Installation ManualДокумент8 страниц38hds Installation Manualdelmar02Оценок пока нет

- Topworx Position SwitchДокумент60 страницTopworx Position SwitchsarkaftОценок пока нет

- 459-475 Hose AssembliesДокумент17 страниц459-475 Hose Assembliesrobertito101Оценок пока нет

- Vertical Ammonia CompressorsДокумент41 страницаVertical Ammonia CompressorsIulian12345Оценок пока нет

- Convertidor Mechanical S108KДокумент8 страницConvertidor Mechanical S108KALBERTOОценок пока нет

- Book LayoutДокумент8 страницBook LayoutaamenaОценок пока нет

- (2012) Complete IELTS Bands 5-6.5 Student's BookДокумент3 страницы(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- DPB 280LHДокумент51 страницаDPB 280LHGuillermo Hernandez100% (1)

- Safety Relief ValvesДокумент52 страницыSafety Relief ValvesHamza NoumanОценок пока нет

- Bomba Neumatica Wilden P200 PlasticaДокумент28 страницBomba Neumatica Wilden P200 PlasticaPablo Enrique Hernandez ZavalaОценок пока нет

- Mooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasДокумент12 страницMooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasCarlos TarquinoОценок пока нет

- Dynaco c101 c102 Dump Pump PDFДокумент7 страницDynaco c101 c102 Dump Pump PDFnbgearsОценок пока нет

- Manual Soplador 3003 TuthillДокумент44 страницыManual Soplador 3003 TuthillIgnacio León CornejoОценок пока нет

- Automatic Air Vent Valve Spirax SarcoДокумент4 страницыAutomatic Air Vent Valve Spirax SarcosrshahОценок пока нет

- Samson PRV Mounting and Operating InstructionДокумент20 страницSamson PRV Mounting and Operating InstructionRick CalaguiОценок пока нет

- Bombas de Tinta - 1Документ3 страницыBombas de Tinta - 1leandrouniaОценок пока нет

- Es Acv 1116FMДокумент4 страницыEs Acv 1116FMWattsОценок пока нет

- 07 ValvesДокумент33 страницы07 Valvesshiva_ssk17Оценок пока нет

- Drivemaster 2speed Installation InstructionsДокумент17 страницDrivemaster 2speed Installation InstructionsAngel DlsgОценок пока нет

- AV-C Butterfly ValveДокумент20 страницAV-C Butterfly ValveSopon SrirattanapiboonОценок пока нет

- V 22 D 28Документ8 страницV 22 D 28EDDIN1960Оценок пока нет

- Blower TUTHILL ManualДокумент48 страницBlower TUTHILL ManualEd Ortiz100% (1)

- 390 InstructionsДокумент48 страниц390 InstructionsemaanazeemОценок пока нет

- Breather Valve - Pressure-Vaccuem Relief ValveДокумент2 страницыBreather Valve - Pressure-Vaccuem Relief Valvevphor85Оценок пока нет

- Control Valve FisherДокумент28 страницControl Valve FisherAndrés Camilo Velasquez PeñalozaОценок пока нет

- Tech 1183 Man StripperДокумент19 страницTech 1183 Man StripperDonna Gray100% (1)

- TORQMAXДокумент8 страницTORQMAXReddy SadhanaОценок пока нет

- Application of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaДокумент24 страницыApplication of ESP For Gas Cleaning in Cement Industry - With Reference To IndiaSJ ChuaОценок пока нет

- G10 - Handout - Organic - Makeup Handout - First WeekДокумент4 страницыG10 - Handout - Organic - Makeup Handout - First WeekSheela BatterywalaОценок пока нет

- Work Instructions (W.I.)Документ18 страницWork Instructions (W.I.)Shamsul Azhar MohdОценок пока нет

- CHM1 Structure & Bonding QДокумент115 страницCHM1 Structure & Bonding QGoutham SivagnanamОценок пока нет

- Test1 Goc & Poc Tough by S.K.sinha See Chemistry Animations atДокумент3 страницыTest1 Goc & Poc Tough by S.K.sinha See Chemistry Animations atmyiitchemistry100% (1)

- Machinability of BS S132Документ2 страницыMachinability of BS S132goggerОценок пока нет

- A Rapid Accurate Method For The Analysis of An Iron OreДокумент5 страницA Rapid Accurate Method For The Analysis of An Iron Oreilham_metallurgy6744Оценок пока нет

- Assignment On: Textiles in Agriculture (Agrotech)Документ6 страницAssignment On: Textiles in Agriculture (Agrotech)AmirParvezОценок пока нет

- Tds Chemical Resistant CoatingДокумент3 страницыTds Chemical Resistant CoatingUtilities2Оценок пока нет

- Aladin 2017Документ6 страницAladin 2017Dwi ermawatiОценок пока нет

- Principles of Topical Therapy: Presented By: DR .Anjali Singh Junior Resident Department of DermatologyДокумент25 страницPrinciples of Topical Therapy: Presented By: DR .Anjali Singh Junior Resident Department of DermatologyRiyaSinghОценок пока нет

- CADD Unit 4 TPДокумент7 страницCADD Unit 4 TPmohitОценок пока нет

- Reduction of Environmental ImpactДокумент16 страницReduction of Environmental ImpactJohn Vincent MalvarОценок пока нет

- Multiparticulate Delayed Release Drug Delivery SystemДокумент24 страницыMultiparticulate Delayed Release Drug Delivery SystemAarti koramОценок пока нет

- Redox Regulation, Thioredoxins, and Glutaredoxins (Review 2023)Документ15 страницRedox Regulation, Thioredoxins, and Glutaredoxins (Review 2023)Hatem BoubakriОценок пока нет

- DELTA-FC 1022 Tds - EngДокумент2 страницыDELTA-FC 1022 Tds - EngAhmed HassanОценок пока нет

- Phyton 27 MSDSДокумент2 страницыPhyton 27 MSDSBernardo UenoОценок пока нет

- Effect of W/C Ratio On Self Compacting Concrete of M70 Grade With Fly Ash and Micro Silica As Filler MaterialДокумент76 страницEffect of W/C Ratio On Self Compacting Concrete of M70 Grade With Fly Ash and Micro Silica As Filler MaterialbenhasidОценок пока нет

- Omega 600S Manual PDFДокумент36 страницOmega 600S Manual PDFjosebernal_mzaОценок пока нет

- E - 2 - Effect of Casting Shape and Size On Solidification TimeДокумент6 страницE - 2 - Effect of Casting Shape and Size On Solidification Timeoğuz kağanОценок пока нет

- Cci Valve 100DSVДокумент8 страницCci Valve 100DSVyg89Оценок пока нет

- Antinociceptive Activity of Buddleja Globosa (Matico)Документ6 страницAntinociceptive Activity of Buddleja Globosa (Matico)alinumlОценок пока нет

- Spesifikasi Material Finishing Unit ApartemenДокумент34 страницыSpesifikasi Material Finishing Unit ApartemenArif GumelarОценок пока нет

- Nepro PVC PipesДокумент11 страницNepro PVC PipesAhrian BenaОценок пока нет

- Rotary PumpsДокумент31 страницаRotary PumpsalbertОценок пока нет

- Lecture 3 GlycosidesДокумент18 страницLecture 3 Glycosidessami ullahОценок пока нет

- Installation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyДокумент28 страницInstallation and Operating Instructions: Busch Produktions GMBH Schauinslandstr. 1 79689 Maulburg GermanyRenārs BērtiņšОценок пока нет

- National Waste Management Strategy 2019-2023Документ64 страницыNational Waste Management Strategy 2019-2023Chikondi KanamaОценок пока нет