Академический Документы

Профессиональный Документы

Культура Документы

Tai Lieu May Ep 70MN - 1

Загружено:

Biện Công ThếИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tai Lieu May Ep 70MN - 1

Загружено:

Biện Công ThếАвторское право:

Доступные форматы

-70MN

70MN Technical Parameters of 70MN Hydraulic Press for Building material

Tianjin Taipingyang Ultra-high pressure Equipment Co., Ltd

Add: Xumuyanjiusuo Road, Yixingbu Town, Beichen Dist. Tianjin, China E-mail: tj-tpy@163.net P.C. 300402 Tel: 0086-2226999463 Website: www. pacific-machine.com Fax: 0086-22-26995099

-70MN

Contents: 1. Function and special feature 2. Technical date 3. System components 3.1 Machinery system 3.2 Hydraulic system 3.3 Electrical control and safety system 4. Quality standard 5. Test method 6. Delivery 7. After sale services and relevant documents 7.1 Quality assurance 7.2 Service 7.3 Providing documents 7.4 List of spare parts

-70MN

50MN The 50MN hydraulic press for pressing building material manufactured by Tianjin Taipingyang Ultra-high Pressure Equipment Co., Ltd ranks first in quantity and takes leading positions in designed efficiency and property in China. Details are as follows:

. Function and special feature:

1.1 15 The safety factor is high. Pressing life will be more than 15 years. 1.2 0.1mm The working table has high rigid feature. The deformation under full working load is 0.1mm. 1.3 Pressure rising with double cylinders and the slides goes up placidly, no need to adjust the working status. 1.4 The seals can be replaced without major cylinder being moved away from its installed position. 1.5 4 Sliding blocks are respectively supported by 4 fast cylinders to go fleetly, greatly reducing ineffective time consumption. 1.6 , The hydraulic system adopts intensifier which can use lower system pressure, enhancing the reliability of hydraulic system. 1.7 The adjustable high pressure pump and large flow low pressure pump will work together in oil supplying, which can realize the pressing speed infinite variable control to save energy in fast going up procedures. 1.8 The spherical connection between working cylinder and slide can lessen the wearing of seals, and make the slide work accurately.

.

2.1 2.2 2.3

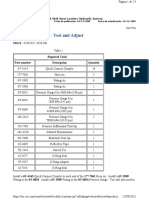

Technical data

Working force Working table(lengthwidth) Maximum opening MN mm mm 50 13002600 1200

-70MN

2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 2.15 2.16 2.17 2.18

Maximum stroke Empty speed Working speed Return speed Thickness of upper working table Thickness of lower working table * Operation window Diameter of main cylinder Number of main cylinder Diameter of return cylinder Number of return cylinder Pressure of the system Pressure of main cylinder Power of main motor Trailer bearing capacity Trailer power of motor with braking Speed of loading and unloading trailer

mm mm/s mm/s mm/s mm mm mm mm

400 30 0.05-0.4 30 600 600 18001200 860

2 160/110

mm

4 25 60 37 20

MPa MPa kW t

2.19

kW

3.7

2.20

mm/s

40

2.21

Total weight of the equipment

~125

-70MN

2.22

Outside measurement of the main equipment

Height above ground

mm

2570*2700*7000

2.23

mm

3800

. Composition and assortment 3.1 Machinery system

4 The equipment has the structure of double frames and main cylinders. The lower slide is driven to go up quickly by 4 fast cylinders. The oil tank (prefilling tank) is installed on the top of main cylinder to make the connection. Nos Name Bearing frame Semi-cycle beam Column winding steel wire Main oil cylinder Body of the cylinder lid of the cylinder Piston Winding steel wire 3 4 5 6 () Movable working table Fixed working table Seat Fastening screw and bolt 45# 4 45# ZG270-500 ZG270-500 65Mn Q235 Q235 HT200 20t 1 1 4 Q235 Q235 65Mn 2 4 4 28t Material Quantity

-70MN

7 Feeding trailer

Assembly

1 1set

3.2 Hydraulic system

The hydraulic system of the equipment is consisted of the major system, ultra high pressure control system and the supplementary control system. 1. The manual variable volume piston pump and low pressure hydraulic gear pump are used for oil supplying. 2. Reciprocating-type intensifiers are used in the ultra high pressure system to realize pressure increase and release with the help of the ultra high pressure valve assembly.. : Working principles of the hydraulic system: Empty fast going up: The low pressure gear pump supply oil for 4 sets of fast cylinder, which will bring the slide go up quickly. At the same time, the hydraulic oil in oil tank will go through ultra-high pressure prefill valve to fill into main cylinder. , Pressurization: When the fast rising material contact with upper working table, the limit switch will send signal (or by pressure sending signal) to change working status to pressurization. The gear pump will unload, and the variable plunger pump will begin to work by providing pressure directly to main cylinder with the help of controlling valve blocks. The pressure will be set and originated by pressure sensor. If the procedure is too fast, it can be changed to supply oil by booster. Pressure increase: When the pressure of the pump is up to set value, the pump will provide oil through reversing valve until the repeat working of intensifier, which will make the pressure to final value by the way of outputting ultra-high pressure oil to main cylinder Pressure keeping: Pressure keeping starts when the pressure reaches stipulated value and the pump enters load release status. When the pressure is released to set value at which the pressure will continue to raise, the pressure will keep a stable value in this way. The pressure keeping brings to an end the opening operation of the pressure release valve of both sides to facilitate steady and fast pressure release of the liquid in the cylinder.

-70MN

Return travel: With the opening of liquid filing valve and fast cylinder oil releasing valve at the bottom of the cylinder, the slide will realize quick stroke under the double action of gravity and return cylinders.

3.2.1 Nos. power devices Devices Quantity Model 37Kw 1500 r.p.m Double extension moto Supplier

1 Motor 1

Beijing B.J electric motor

Tianjin hydraulic

3 4 5

Variable piston pump(manual

Gear pump

63SCY14-1B

1 2 1

CBG2080 Tianjin TPY TPY Leemin hydraulic Leemin hydraulic Leemin hydraulic Tang valve Taifeng hydraulic Taifeng hydraulic Taifeng hydraulic

Shaft coupling

Seat

3.2.2 Oil tank assembly 1 body of oil tank 2 3 4 5 Air filter Liquid level meter Temperature sensor Connecting valve

1 2 2 1 2

~3000L QUQ3 YWZ-250T 0~100 DN65

3.2.3 () Cartridge valve block 1 Double pump pressure 1 NG25 adjustment valve block 2 1 NG25 Directional valve block 3 supporting speed adjustment valve block 3.2.4 Ultra pressure valve assembly 1 NG25

-70MN

1 2

Valve block Double check valve Hydraulic control pressure release valve Manual pressure release valve Ultra pressure liquid filling valve Body of ultra pressure cylinder Body of medium pressure piston Ultra pressure gasket High pressure gasket Signal giving device Connection flange and screw bolt

1 2

Dg12 Dg12

Taifeng hydraulic TPY TPY

Dg12

Dg12

TPY

Dg50

TPY

3.2.5 Double action intensifier 1 42CrMo TPY 1 45# TPY TPY Imported products Imported products TPY TPY 1

3 4 5 6

1 1 1 1 2 2 sets

45#

3.2.6 Oil filter and supplementary hydraulic parts 1 1

Oil filter

Leemin hydraulic Leemin hydraulic

On e lot 3.2.7 Hydraulic indicator, instrument and meter Joints and pipes

1 Ultra pressure touch point meter Vibration resistant pressure meter Pressure 1 2 1 0~160Mpa 0~40 0~60Mpa 0~100Mpa

Jinan Gauge Tianjin

2 3

-70MN

sensor 3.2.9 Oil cooling filtration device 1 1 Plate heat exchanger 2

2

SENEX TPY 1 2.2kW,80/min Tianjin Kaiquan

12m

Motor assembly of oil pump

3 4 5

Water pump Filter

Thermometer

1 1 1

1.5 kW

0~100

Leemin Hydraulic Leemin Hydraulic

Valv e Seat

DN65

Tianjin Jintang valve

TPY

3.3

Electric control and protection system Q PLC The electric system adopts Japanese Mitsubishi Q series PLC to realize control of every working position of the press. a. Operation system: Two-hand operation is maintained by two hands, safe and reliable. b. Safety protection system: The press is accompanied with safety relay, making the equipment reliable and safe. 0.1 Mpa For safety and reliability, the connection contact pressure meter, signal giving for ultra pressure alert and immediate pressure release are installed with the press in addition to pressure sensor. The precision is 0.1M pa. Emergency buttons accompanied with recovery functions are available with two sides of press, facilitating easy maintenance, repairing and operation. c. System for self inspection of operation status: The touch screen shows its position and the working status of the electromagnetic valve of the

-70MN

hydraulic system. The working pressure is shown on the touch screen as well as on the digital status indicator. The alarming device in the electric control system shows category of the alarm, giving an order the repairman for repairing and indicating the statistics of the number of maintenance and repairing. Temperature sensor is mounted in the oil tank gauge to check temperature of oil and start the plate heat exchanger automatically according to setting temperature. When the temperature excesses the setting value, press will shut down immediately. Oil flitting device are mounted in the oil inlet of pump, which have the check device for oil cleansing. When there is impurity, indicator will alarm and press shut down. Two hand operation button control box is installed beside the press which can be easily manipulated. 3.3.1. Electric motor starting box Device Nos. Model Quantity Brand 1 2 3 4 5 6 Body of box Automatic air switch Automatic air switch Thermal relay A C contactor DC voltage stabilized source Thermal relay 8 9 10 11 12 AC contactor AC ammeter Current transformer AC voltage meter LC1-D1810M7/220V BE-72/200/5 RCT-15-1/200/5 BE-72/600V MY2NJ/DC24V 3 3 3 3 30 Schneider Mack Mack Mack OMROM TS8/800*800*2000+100 NSX250HM1C2.2+exte ntion handle NSX250H/MA220 LR9-F5367/60-100A LC1/F185M7/220V SITOP 6EP1336-2 2 1 1 1 3 2 Rittal Schneider Schneider Schneider Schneider Siemens

LR97D25B/DC24V

Schneider

-70MN

Intermediate relay 13 Autoconnecte d transformer Control transformer Circuit breaker Circuit breaker Circuit breaker Circuit breaker Circuit breaker 380/220-75KVA 1 Shanghai Leipu Shanghai Schnerder Schneider Schneider Schneider Schnieder

14 15 16 17 18 19

380/220/JBK5-4KVA OSMC32ND6/1P GV2-ME16 OSMC32ND2/2P OSMC32ND10/2P OSMC32ND20/2P

1 18 3 2 4 4

3.3.2. Electric box for operation control Nos. 1 2 3 4 5 Device Body of box Programmable controller Touch screen Programming software Configuration software Indicator of pressure sensor Thermometer Button with light Button with light . Locking button with light Selection switch Model TP/600*400*875 Q03UDCPU/QX80/QY10 series GT1575-XTBA GX DEVRLOPER GT Designer Quanti ty 1 1 set 1 1 1 Brand Rittal Mitsubishi Mitrubishi Mitsubishi Mitsubishi Japanes e make Japanese make Schneider Schneider Schneider Schneider

RKC/RD900/4-2-mA

7 8 9 10 11

RKC/CD701 XB4BW33B1C/24V ZB4BW34C+ZB4BWB42 C/24V XB4BW36B1C=ZB4BZ2 1C/24V ZB4DD2C+ZB4 BZ105C

1 16+2 10 4 4

-70MN

12 13 14

Approach switch Emergency stop button Thermocouple Photoelectric displacement transducer Opto electronic swithc Approach switch

E2E-X5MEI XB4-BS542 E52-IC6D

2 3 1

Omron Schneider OMROM

15

1000mm

OMROM

16 17 18

E3JK-5M1 E2E-X10E1 FRN7.5G1S

1 1 1

OMROM OMROM FUJI

Trailer motor 3.3.3. transducer Safety protection system 1 Stroke control switch 2 3 Signal giving device Safety relay

HL5030 XVB+XVS series

4 1 5

OMROM Schneider OMROM

G7SA-4A2B/DC24V

3.3.4. Supplementary electric parts 1 Electric wire 2 Terminal

BVR25/BVR1 280-901/80

100/800 4

General Factory of Electric wire Wanke

Test and inspection method:

4.1 Inspect the press according to the parameters stipulated in t he contract. 4.2 5 Keep the pressure under full work capacity for 5 minutes and check the interior pressure of the major cylinder 3 times repeatedly and take the average value of the three as the standard. 4.3 100 Feasibility test report under full work capacity may result in 100 continuous pressing on bearer block without any problem.

Delivery

5.1 150 The buyer is supposed to come to the manufacturers factory site to conduct inspection for acceptance and delivery within 150 days after signing of contract and receipt of prepayment.

-70MN

. After sale services and relevant documents:

6.1 Quality Guarantee 6.1.1 15 Frame and main cylinders shall have a guarantee to be free from cracks in 15 years. 6.1.2 The whole press is guaranteed for 1 year 6.2 Services 6.2.1 24 The supplier will propose problem solution for user within 24 hours upon notice whether it is within or after expiration of the quality guarantee period. 6.2.2 Provide free repairmen and spare parts if the equipment has the quality problem in the guarantee period 6.3 providing documents 6.3.1 General drawing 6.3.2 Hydraulic principle drawing 6.3.3 Electronic system drawing 6.3.4

Wearing parts drawing

6.3.5 Detail list of bought-in components 6.3.6 Instruction book of operation a. Operation main point b. Content and time requirement of regular check and maintenance c. Replacement method of main seals d. Wearing parts list e. Problem judgment, maintenance and repairing 6.3.7 Instruction book for brought-in electronic control devices 6.3.8 Main spare parts material report and detection test report 6.3.9 Machine test report

-70MN

6.3.10 Quality certificate 6.3.11 Packing list 6.4 List of spare parts No.s Name 1 2 3 Pipeline seals Double check valve seat and spool Relief valve seat and spool

Unit set Set set

Quantity 2 2 2

Supplier China TPY TPY

. , Price and terms of payment:

7.1 Price of equipmentIncluding spare parts: --Ex work Equipment RMB (Unit: 10,000 Yuan) 70MN 270 Ex-work 70MN Hydraulic press for pressing building material 8.2 Cost for installation and test operation Equipment 70MN 70MN Hydraulic press for pressing building material RMB (Unit: 10,000 Yuan) 8

Except the fee for food accommodation of technical staff 8.4 Terms of payment: 8.4.1 30% Pay up 30% of the price of the equipment after signing of contract. 8.4.2 30% Pay up 30% of the price of the equipment in the winding period. 8.4.3 35% Pay up 35% of the price of the equipment after the FAT approved 8.4.4 Pay up all the freight cost after the equipment get to the factory site of buyer. 8.4.4 5% Pay all installation cost of the equipment within two weeks after test approved in buyers site, and the remaining 5% of the equipment within one year since approval.

Вам также может понравиться

- 使 用 说 明 书 Operation Manual: YM-160T 龙门液压机 Longmen YM-160T hydraulic machineДокумент18 страниц使 用 说 明 书 Operation Manual: YM-160T 龙门液压机 Longmen YM-160T hydraulic machineBALAОценок пока нет

- Auto Tension Device (1) AutoДокумент22 страницыAuto Tension Device (1) Autogaurav_2012Оценок пока нет

- 2021.12.24 R-ME-HC-S-020 Governor System Commissioning ProcedureДокумент12 страниц2021.12.24 R-ME-HC-S-020 Governor System Commissioning Procedurerotimi olalekan fataiОценок пока нет

- Relief Valve (Line) - Test and Adjust: Shutdown SIS Previous ScreenДокумент5 страницRelief Valve (Line) - Test and Adjust: Shutdown SIS Previous Screenchanlin0% (1)

- ReliefДокумент3 страницыReliefMohamed OmarОценок пока нет

- Electronic Expansion ValveДокумент5 страницElectronic Expansion Valveemongclooney11Оценок пока нет

- Oil Country 45000Документ70 страницOil Country 45000char_lyn100% (2)

- Hydraulic Pump - Test and Adjust: Pantalla AnteriorДокумент14 страницHydraulic Pump - Test and Adjust: Pantalla Anterioriver_millan100% (1)

- Oil Country WF Model 57802-100TK Hydraulic Tubing TongДокумент83 страницыOil Country WF Model 57802-100TK Hydraulic Tubing Tongwuillian barreto100% (1)

- Instruction For Shaft Jacking Device 141A.553SM (B) - 5Документ16 страницInstruction For Shaft Jacking Device 141A.553SM (B) - 5anbarasanОценок пока нет

- Fail Free Commissioning-Steam Turbine Hydraulic SystemДокумент36 страницFail Free Commissioning-Steam Turbine Hydraulic SystemPrabhudhasanОценок пока нет

- D8T Test Trans Relief ValДокумент7 страницD8T Test Trans Relief ValjaimeОценок пока нет

- Governing and Protection SystemДокумент15 страницGoverning and Protection SystemVamsikrishna Lakamsani100% (1)

- Piston Pump Pressure - Test and AdjustДокумент11 страницPiston Pump Pressure - Test and Adjustالبراق للتوريدات وصيانة المعداتОценок пока нет

- Jq-15 Ball Pump Operation Manual 300MW JQ-15 型胶球泵使用说明书: 2×300Mw Rosa Thermal Power ProjectДокумент9 страницJq-15 Ball Pump Operation Manual 300MW JQ-15 型胶球泵使用说明书: 2×300Mw Rosa Thermal Power ProjectASHXQ39WОценок пока нет

- Pilot Pressure - Test and AdjustДокумент4 страницыPilot Pressure - Test and AdjustAnthony Inca MaytaОценок пока нет

- Model 55000-100 Hydraulic Tubing TongДокумент75 страницModel 55000-100 Hydraulic Tubing TongPrejit Radhakrishna50% (2)

- Pressure Reducing Valve - Test and AdjustДокумент4 страницыPressure Reducing Valve - Test and AdjustHendra MonoОценок пока нет

- Pressure Reducing Valve (Pilot Oil) - Test and AdjustДокумент3 страницыPressure Reducing Valve (Pilot Oil) - Test and AdjustgeniusnetxxxxОценок пока нет

- ZQ127 25 Drill Pipe Power TongДокумент12 страницZQ127 25 Drill Pipe Power Tong刘巍Оценок пока нет

- HydrostaticДокумент21 страницаHydrostaticGuido Emanuel SteinbachОценок пока нет

- Oil Country - Llave Hidraulica 57853-100 (OSM-166 57853-100)Документ75 страницOil Country - Llave Hidraulica 57853-100 (OSM-166 57853-100)jhogs74100% (3)

- MANUAL BANCO DE PRUEBA NT2001& - NT3000 - PLCoperation - ManualДокумент19 страницMANUAL BANCO DE PRUEBA NT2001& - NT3000 - PLCoperation - ManualCarlos Alberto ErrobidartОценок пока нет

- Abs 14 Punching and Riveting MachineДокумент2 страницыAbs 14 Punching and Riveting MachineChockalingam AthilingamОценок пока нет

- Hydrostatic System - Test and AdjustДокумент23 страницыHydrostatic System - Test and AdjustSanchez Gamarra AndyОценок пока нет

- Flywheel Lubrication Oil Pressure - Test: D8T Track-Type Tractor Power TrainДокумент5 страницFlywheel Lubrication Oil Pressure - Test: D8T Track-Type Tractor Power TrainEdwin Julcamoro AquinoОценок пока нет

- Discharge Device: Nantong Yawei Machinery Manufacture Co., LTDДокумент8 страницDischarge Device: Nantong Yawei Machinery Manufacture Co., LTDNova HeriОценок пока нет

- NV MSTP 269 Multi Shot Tubing Punch TM 235 c207 003 09 ManualДокумент22 страницыNV MSTP 269 Multi Shot Tubing Punch TM 235 c207 003 09 ManualDiana Carolina Rojas TorresОценок пока нет

- M0627Документ24 страницыM0627subhransubaral1Оценок пока нет

- Hydrostatic TestДокумент22 страницыHydrostatic TestGuido Emanuel SteinbachОценок пока нет

- Steering Pump - Test and Adjust: Shutdown SIS Previous ScreenДокумент16 страницSteering Pump - Test and Adjust: Shutdown SIS Previous Screenardan fadilahОценок пока нет

- Hydrostatic System - Test and Adjust: Pruebas y AjustesДокумент22 страницыHydrostatic System - Test and Adjust: Pruebas y AjustesJose PichinteОценок пока нет

- Transmission 950gДокумент17 страницTransmission 950gAbi JithОценок пока нет

- Fuel System Pressure - Test: Testing and AdjustingДокумент4 страницыFuel System Pressure - Test: Testing and AdjustingAbdoulaye Boua BERTHEОценок пока нет

- Turret Swivel System Operation (Rev.00)Документ12 страницTurret Swivel System Operation (Rev.00)hai dang maiОценок пока нет

- Fabrication of Hydrauic Heavy Duty Vice Synopsis: Valve Will Open So The Piston Goes Back and Oil Again Moves To SumpДокумент4 страницыFabrication of Hydrauic Heavy Duty Vice Synopsis: Valve Will Open So The Piston Goes Back and Oil Again Moves To SumpANAND KRISHNANОценок пока нет

- CTS Operation Manual Rev1.0Документ13 страницCTS Operation Manual Rev1.0Juan Manuel VizosoОценок пока нет

- FlowMaster Models85676&85678 C8 319Документ20 страницFlowMaster Models85676&85678 C8 319Juan Santiago RojasОценок пока нет

- Volvo BM L50B Wheel LoaderДокумент21 страницаVolvo BM L50B Wheel Loaderangel primo100% (2)

- Relief Valve (Hoist Dual Stage) - Test and Adjust: Shutdown SIS Previous ScreenДокумент6 страницRelief Valve (Hoist Dual Stage) - Test and Adjust: Shutdown SIS Previous ScreenSofhan RanyОценок пока нет

- LS-TSZD - QJ005 Turbine Bypass System Commissioning ProcedureДокумент24 страницыLS-TSZD - QJ005 Turbine Bypass System Commissioning ProcedureBharath Nadimpalli100% (1)

- Speed Control Circuit Using MeteringДокумент10 страницSpeed Control Circuit Using MeteringPankaj GuravОценок пока нет

- Cheuqeo Cilindros Hidraulicos Del Cargador 988KДокумент5 страницCheuqeo Cilindros Hidraulicos Del Cargador 988KRAMON CALDERONОценок пока нет

- Governor System (Electrical Part)Документ142 страницыGovernor System (Electrical Part)የፐፐፐ ነገርОценок пока нет

- MZQ-B300-38-C Computer Control Push Down Valve Test Bench R.2Документ11 страницMZQ-B300-38-C Computer Control Push Down Valve Test Bench R.2ahsun habibОценок пока нет

- Manual de Operacion de ZQ127-IДокумент10 страницManual de Operacion de ZQ127-IEdwin Fernando Hernandez LadinoОценок пока нет

- VALVULA ALIVIO LINEAS 972G CatДокумент8 страницVALVULA ALIVIO LINEAS 972G CatEdin Raul Yalle RafaelОценок пока нет

- REXROTH Service Manual PVC PSSFДокумент6 страницREXROTH Service Manual PVC PSSFRaghavendra DeshpandeОценок пока нет

- Clutch ServiceДокумент44 страницыClutch ServiceTanmayОценок пока нет

- Hydraulic Systems: Operation, Maintenance, TroubleshootingДокумент68 страницHydraulic Systems: Operation, Maintenance, TroubleshootingGauthamОценок пока нет

- Pressure Limiter Valve - Test: Essai Et RéglageДокумент6 страницPressure Limiter Valve - Test: Essai Et RéglagechakrouneОценок пока нет

- Pilot Pressure To The Main Control Valve - CheckДокумент8 страницPilot Pressure To The Main Control Valve - CheckMiguel Angel Moreno100% (8)

- Osm-093 57800-100Документ86 страницOsm-093 57800-100Taller cncОценок пока нет

- 4×350 MW Kamalanga Thermal Power ProjectДокумент15 страниц4×350 MW Kamalanga Thermal Power ProjectK R Kumar RanjanОценок пока нет

- Hydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorДокумент18 страницHydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorjuampacervantesОценок пока нет

- Hydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorДокумент18 страницHydraulic Pump - Test and Adjust: Cerrar SIS Pantalla AnteriorjuampacervantesОценок пока нет

- Steam Turbine Over Speed Trip SystemsДокумент11 страницSteam Turbine Over Speed Trip SystemsPRASAD326100% (17)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Stan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineОт EverandStan Shiels on centrifugal pumps: Collected articles from 'World Pumps' magazineРейтинг: 5 из 5 звезд5/5 (1)

- Color Selector CL PDFДокумент1 страницаColor Selector CL PDFBiện Công Thế100% (1)

- Color Selector CL PDFДокумент1 страницаColor Selector CL PDFBiện Công ThếОценок пока нет

- Roast Log Sept 2013Документ1 страницаRoast Log Sept 2013Biện Công ThếОценок пока нет

- Tensile Strength of Paper (PSI) Calcium in Solution (PPM)Документ20 страницTensile Strength of Paper (PSI) Calcium in Solution (PPM)Biện Công ThếОценок пока нет

- TC FLS Sihi Leh 1200 1500 1800 enДокумент10 страницTC FLS Sihi Leh 1200 1500 1800 enGustavo ZavalaОценок пока нет

- BG Group - Casing Design ManualДокумент51 страницаBG Group - Casing Design ManualHamza Lahbiben100% (1)

- Heat Transfer Correlation of The Falling Film Evaporation On A Single Horizontal SmooДокумент10 страницHeat Transfer Correlation of The Falling Film Evaporation On A Single Horizontal SmooManuel ChavezОценок пока нет

- Ecole Polytechnique Federale de LausanneДокумент44 страницыEcole Polytechnique Federale de LausanneSyed Yahya HussainОценок пока нет

- Manual BombaДокумент15 страницManual BombaHector RamírezОценок пока нет

- 1.1.3 Exercise 2 - Titration CalculationsДокумент10 страниц1.1.3 Exercise 2 - Titration CalculationsNabee DoskiОценок пока нет

- S2 PHYSICS Unit-3 & 6 Revision NoteДокумент16 страницS2 PHYSICS Unit-3 & 6 Revision Noterayofthelight777100% (1)

- ASTM D572 04 - Standard Test Method For Rubber-Deterioration by Heat and OxygenДокумент4 страницыASTM D572 04 - Standard Test Method For Rubber-Deterioration by Heat and OxygenAndre SpirimОценок пока нет

- RF Energy HarvestingДокумент34 страницыRF Energy Harvestingjaymin915Оценок пока нет

- Bernoulli Equation Lab ReportДокумент8 страницBernoulli Equation Lab ReportnadjihahОценок пока нет

- Mission S and W Dims and Curve Chart PDFДокумент28 страницMission S and W Dims and Curve Chart PDFcaballero_tigreОценок пока нет

- Hubungan Karakteristik Aktivitas Dengan Tekanan DarahДокумент16 страницHubungan Karakteristik Aktivitas Dengan Tekanan DarahDhanis DharmaОценок пока нет

- CAT CS533E Engine Part 4Документ6 страницCAT CS533E Engine Part 4Oecox Cah DjadoelОценок пока нет

- Pic 1 SL2 N/A Tc1A N2 Secondary Barrier: Tag #Revision #Document NºДокумент2 страницыPic 1 SL2 N/A Tc1A N2 Secondary Barrier: Tag #Revision #Document NºRanchojiОценок пока нет

- Gravity Dam Analysis EXAMPLE PROBLEMSДокумент15 страницGravity Dam Analysis EXAMPLE PROBLEMSJiever AustriaОценок пока нет

- PTC31, PTP31, PTP35 Manual Eng PDFДокумент32 страницыPTC31, PTP31, PTP35 Manual Eng PDFkhangtrang83Оценок пока нет

- PHY07Документ190 страницPHY07sazliman100% (2)

- CHM 151 Lecture Note - 2023-2024Документ15 страницCHM 151 Lecture Note - 2023-2024jimisolaoluwayinkaОценок пока нет

- Leak Test Procedure PDFДокумент6 страницLeak Test Procedure PDFanon_456282505100% (3)

- Underwater Explosion (Part I) ©2008 Henry TanДокумент8 страницUnderwater Explosion (Part I) ©2008 Henry TanHariprasad K KotarathilОценок пока нет

- Effect of Hole Cleaning On Drilling Rate and PerformanceДокумент7 страницEffect of Hole Cleaning On Drilling Rate and PerformanceazeazeazeОценок пока нет

- Design CriteriaДокумент6 страницDesign CriteriaAllyssa Jane ErcillaОценок пока нет

- Cot-Dlp 1Документ2 страницыCot-Dlp 1Renando P. DueñasОценок пока нет

- Plate Load Test at InaruwaДокумент34 страницыPlate Load Test at InaruwaSushant Giri100% (1)

- Sist en 14067 2 2004Документ11 страницSist en 14067 2 2004leninОценок пока нет

- Appendix GДокумент22 страницыAppendix Gqwrtp79100% (1)

- Leak TestingДокумент27 страницLeak TestingNurulAtirahNoroziОценок пока нет

- Ocean Engineering: Xiuli Du, Piguang Wang, Mi ZhaoДокумент10 страницOcean Engineering: Xiuli Du, Piguang Wang, Mi ZhaoSuzon IkramОценок пока нет

- Chem ENgg Board Exam QuestionsДокумент42 страницыChem ENgg Board Exam QuestionsAllyana Marie TiemsimОценок пока нет

- Pruebas PDDДокумент36 страницPruebas PDDVaneZiita CarvajallОценок пока нет