Академический Документы

Профессиональный Документы

Культура Документы

HDD Catalogue

Загружено:

Múcio LimaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HDD Catalogue

Загружено:

Múcio LimaАвторское право:

Доступные форматы

Horizontal Directional Drilling

Application

Random Rock Hole Opener Specifications

Secoroc Rock Drilling Tools

Rotary Products HDD

Step 1 Drill Pilot Hole from one side of an obstruction (river, road, airport runway, etc.) to the other.

In soft soils, an angled bit is used. To steer, rotation is stopped, the angle of the bit is orientated to the desired direction and forward thrust is applied. The directed jet of the drilling fluid and the forward thrust acts to cut a path in the desired direction. To drill straight, the pipe is rotated and thrust is applied. In Rock Drilling, a mud motor with a bent sub is commonly used. The mud motor converts the hydraulic pressure of the drilling fluid into mechanical rotation. To steer, the bend of the sub is orientated in the desired direction and thrust is applied the drill string does not

rotate (only the bit rotates) and the bit progresses in the direction of the bend. To drill straight, the pipe and motor are rotated. In cases where the ground is unstable, a wash-over pipe or casing can be driven down the bore hole to prevent the collapse of the hole walls. The pilot bit is located with either a sonde or transmitter located near the mud motor or bit. The angle, rotation, direction and depth can be determined using a surface walk over locating system. In instances where a surface locator is not practical (river crossing, excessive depths) a wire line system is used to transmit data through the inside of the drill pipe.

Subjected to alterations without prior notice. Atlas Copco Secoroc AB. All rights reserved. 2006.08 9851 2400 01a

Conventional Hole Opener Specifications

Step 2 Pre-ream

One or more hole opening passes to enlarge the pilot hole to a diameter sufficient enough to accommodate the product which is to be pulled. Upon reaching the exit point, the bit is removed and a reamer (Hole Opener) is attached. The reamer is pulled back while rotating the drill pipe to enlarge the bore hole, with as many consecutive passes as required. Drill pipe is generally added behind the hole opener (trailed) so that there is always drill pipe in the hole (in case pipe failure occurs).

Step 3 Pullback

Once the hole has been enlarged, the final product is attached to the drill string and pulled through to the opposite side. Once the bore hole is at least 25% larger than the prod-

uct to be installed, the end of the pipe is attached to a reamer and then to a swivel connected to the product pipe. Drill fluid is pumped continuously for lubrication and the product pipe is pulled in while rotating the drill pipe and reamer. The swivel prevents rotation of the product pipe.

Atlas Copco Secoroc AB Box 521, SE-737 25 Fagersta, Sweden Phone: +46 223 461 00 E-mail: secoroc@se.atlascopco.com www.atlascopco.com

Bullseye Pilot Bits

Atlas Copco can provide a multitude of cutting structures, available in all common sizes to meet your HDD Pilot Bit requirements. Specifically designed for the rigors of HDD applications: - Proprietary carbide shapes and grades to prolong cutting structure integrity - Specific cutting structures designed for the rigors of HDD bore paths - Industry proven bearing and seal packages - Full Armor package to retard erosion at key locations on the pilot bit - Pressure compensated lubrication system Atlas Copco engineers have combined Hard Rock cutting structures with leading edge bearing and seal package technology. The result is an HDD pilot bit which will drill faster and stay in the hole longer thereby lowering your total drilling costs. We have a full range of Premium Quality HDD Rotary Pilot Bits 4 diameter and above (up to 17 ). Many of these products have been designed specifically for Horizontal Drilling and have many features that enable them to drill faster and stay in the hole longer.

Bullseye Random Rock Hole Openers

Atlas Copco Secoroc Random Rock Reamers are the first split bit type hole opener designed specifically for the HDD industry by a Rotary Rock Bit Manufacturer. These hole openers utilize common, random cutting structure bit thirds, precisely positioned to assure equal load distribution. Advantages: Better rock face coverage one rotation of the cone provides complete bottom hole coverage. Smaller Cuttings The random cutting structure produces small cuttings which are in turn easier to clear from the bore hole. Fewer inserts on the rock face at any given moment Fewer inserts produce a higher weight/insert ratio. Better utilization of available force results in better performance on undersized machine (improved penetration rate). Smoother Drilling Due to the one cone design typical in five (or more) places on the body, the tool runs smoother down hole. Our philosophy is to maximize both the cutter count and the cutter size for any given hole opener diameter. The result is a carefully balanced reamer which will produce optimized operating hours at exceptional rates of penetration. Available from 8 in diameter and up custom sizes available upon request.

Bullseye Replaceable Cutter Hole Openers

Atlas Copco Secoroc can also supply a complete line of

Atlas Copco Secoroc and Horizontal Directional Drilling

Atlas Copco HDD tooling has over the years set the standard on many Horizontal Directional Drilling projects involving Hard Rock and difficult drilling conditions. Our products are the result of decades of drilling research and development and are manufactured in our world class manufacturing facility in Grand Prairie, Texas, USA. The production plant is both ISO 9001 and API certified, and ensures that only world class quality products are delivered to the HDD market. Our HDD equipment range includes: - Pilot Bits in all sizes and types - Standard Hole Openers utilizing Field Replaceable cutters - Split Bit Hole Openers incorporating a common, random bit third With the Atlas Copco worldwide sales and service organization, there is always support and advice close at hand for any HDD project. In addition, we have a technical expertise and development team available to support requests for assistance - any time - any where. For enquiries and advise, please contact the nearest Atlas Copco Secoroc sales office. Futher information can also be obtained at www.atlascopco.com/HDD

Bit/Formation Selection Chart

replaceable cutter hole openers. These reamers utilize either Trojan B cutters (17 ) or Trojan H cutters (26 and up). Both cutters feature our unique random Tungsten Carbide cutting structure and are also available in a milled (steel) tooth version.

Reliability and durability have been enhanced with revised cutting structures as well as with a newly improved bearing system: Unique random cutting structure Replaceable, saddle mounted cutters Field Proven Load Pin fastening system Increased bearing capacity and improved seal reliability Compensated lubrication systems TCI and Milled Tooth cutting structures Custom designs available upon request

Вам также может понравиться

- Effect of Soil Plug Removal On The Load-Carrying Capacity of Symmetric and Non-Symmetric Pile GroupsДокумент25 страницEffect of Soil Plug Removal On The Load-Carrying Capacity of Symmetric and Non-Symmetric Pile GroupsChandra MouliОценок пока нет

- US5320019 Hammer JammerДокумент8 страницUS5320019 Hammer JammerDuane BlakeОценок пока нет

- Case 580f Tractor Loader Backhoe Operators ManualДокумент8 страницCase 580f Tractor Loader Backhoe Operators Manualأكرم تيجي100% (1)

- User Manual: HGM1780 Genset ControllerДокумент23 страницыUser Manual: HGM1780 Genset ControllerMas DomasОценок пока нет

- SPP2 - Siemens TXP HW ManualДокумент293 страницыSPP2 - Siemens TXP HW ManualMiguel CarpioОценок пока нет

- Ahu Room Size PDFДокумент7 страницAhu Room Size PDFMohammed AltafОценок пока нет

- Mid Term Problem 3 SolvedДокумент13 страницMid Term Problem 3 Solveddougie109Оценок пока нет

- ChargePerformanceData OWEN OIL TOOLSДокумент8 страницChargePerformanceData OWEN OIL TOOLSCuenta InformacionОценок пока нет

- Model 800 Viscometer Instruction ManualДокумент24 страницыModel 800 Viscometer Instruction ManualHewaОценок пока нет

- Manual Single Ended - Severing ToolsДокумент8 страницManual Single Ended - Severing Toolslow tech guyОценок пока нет

- Corrigendum1 T49 50Документ41 страницаCorrigendum1 T49 50Thirumalai DbkОценок пока нет

- C - Wellbore Cleaning Technology - H03280-BR PDFДокумент26 страницC - Wellbore Cleaning Technology - H03280-BR PDFAlexandru AndreiОценок пока нет

- Serie Age Formation Top OH M DJHN-3 0 Continental IntercalaireДокумент12 страницSerie Age Formation Top OH M DJHN-3 0 Continental IntercalaireAlexander KlmОценок пока нет

- E Tendering ProcedureДокумент5 страницE Tendering Procedurem_vamshikrishna22Оценок пока нет

- 12 Perforating SystemsДокумент79 страниц12 Perforating SystemsnazgultrОценок пока нет

- Trane Alert CodesДокумент16 страницTrane Alert CodesJESUS PENAОценок пока нет

- BMH Offering Guide 2010Документ15 страницBMH Offering Guide 2010Srini KumarОценок пока нет

- New Welltech 4X™ Systems Are Certified Class 1 Division 2 As A Standard Feature!Документ4 страницыNew Welltech 4X™ Systems Are Certified Class 1 Division 2 As A Standard Feature!Byron LvzОценок пока нет

- 2mm Vs 8mm Charpy Striker Edge RadiusДокумент26 страниц2mm Vs 8mm Charpy Striker Edge RadiusErick EaxОценок пока нет

- The Evolution, Not Revolution, of Digital Integration in Oil and GasДокумент159 страницThe Evolution, Not Revolution, of Digital Integration in Oil and GasBruno TelesОценок пока нет

- ROULUNDS RUBBER - Korea - JapanДокумент60 страницROULUNDS RUBBER - Korea - JapanВладимир АнаймановичОценок пока нет

- Nit For Drilling of Boreholes of Various Diameters at Hutti Gold MinesДокумент50 страницNit For Drilling of Boreholes of Various Diameters at Hutti Gold MinesSyed Qaisar ImamОценок пока нет

- RSS DirectoryДокумент11 страницRSS DirectoryNever MindОценок пока нет

- IDE Lec9 Canal Outlets&CDWДокумент79 страницIDE Lec9 Canal Outlets&CDWFortiter FysproОценок пока нет

- IFE ProductLineДокумент6 страницIFE ProductLineEnrique AssmannОценок пока нет

- SOW For OT & HDDДокумент9 страницSOW For OT & HDDSamanthanvi kОценок пока нет

- Designing Geo Technical Core Drilling ProgramДокумент2 страницыDesigning Geo Technical Core Drilling ProgramOumaima ChatouaneОценок пока нет

- Freemyer TWS600S IV - OR00059565 4,5 & 3.5Документ38 страницFreemyer TWS600S IV - OR00059565 4,5 & 3.5Carlos Martínez VelázquezОценок пока нет

- Api Spec 6a Gate Valves BRДокумент18 страницApi Spec 6a Gate Valves BRravikumarОценок пока нет

- Niengo Outsep North Papua 5 - 06 - 07rev2Документ20 страницNiengo Outsep North Papua 5 - 06 - 07rev2Prince DenhaagОценок пока нет

- Canal Lining ITRC Paper No. P 11-006Документ3 страницыCanal Lining ITRC Paper No. P 11-006Fiaz GujjarОценок пока нет

- Guideline 4306793 01Документ110 страницGuideline 4306793 01Tomson MaliyekkalОценок пока нет

- Vibration-Modal Analysis Model For Multi-Span Pipeline With Different Support ConditionsДокумент7 страницVibration-Modal Analysis Model For Multi-Span Pipeline With Different Support ConditionsLK AnhDungОценок пока нет

- Earth Dam LectureДокумент32 страницыEarth Dam Lecturejahid shohagОценок пока нет

- Drilling Engineering: Bottom Hole Assembly (BHA)Документ41 страницаDrilling Engineering: Bottom Hole Assembly (BHA)djeramОценок пока нет

- Intelliserv Product Catalog d392004875 MKT 001 Rev 01Документ12 страницIntelliserv Product Catalog d392004875 MKT 001 Rev 01carlosorizabaОценок пока нет

- Core OperationsДокумент10 страницCore Operationsdeyaa SadoonОценок пока нет

- CB Analysis of Shipping Container Emergency SheltersДокумент8 страницCB Analysis of Shipping Container Emergency SheltersVioleta MihajlovicОценок пока нет

- External Internal: Major Dia Pitch Dia Minor DiaДокумент5 страницExternal Internal: Major Dia Pitch Dia Minor DiaDenis StruggleОценок пока нет

- PET524 1c Porosity PDFДокумент12 страницPET524 1c Porosity PDFmhdstatОценок пока нет

- Drillcare: Atlas Copco Drilling SolutionsДокумент2 страницыDrillcare: Atlas Copco Drilling SolutionsAlexander Lopez100% (1)

- Design of Hydraulic Pressure Tunnels..Документ11 страницDesign of Hydraulic Pressure Tunnels..abrar ullahОценок пока нет

- DEE Brochure 16Документ20 страницDEE Brochure 16GabrielОценок пока нет

- Drilling Fluid ProgramДокумент434 страницыDrilling Fluid ProgramhakoubОценок пока нет

- Itungan DasarДокумент98 страницItungan DasarAqil AthoillahОценок пока нет

- 2009 - Chapter 4 Material BalanceДокумент25 страниц2009 - Chapter 4 Material BalanceNoelia Almanza GutierrezОценок пока нет

- Trapped Key Interlock For ValvesДокумент7 страницTrapped Key Interlock For Valvesra9622Оценок пока нет

- Geothermal Drilling and Well Design (SE-830-DR2) : CementingДокумент43 страницыGeothermal Drilling and Well Design (SE-830-DR2) : CementingERICK GUSTAVO QUINTANILLA GARCIAОценок пока нет

- معدات aДокумент55 страницمعدات aJaber AlbaajОценок пока нет

- Wang 2020Документ8 страницWang 2020Sachin SinghОценок пока нет

- Fibre Optic Leak DetectionДокумент57 страницFibre Optic Leak DetectionLance ArendseОценок пока нет

- Spex Ass 2 SKДокумент2 страницыSpex Ass 2 SKSiddhant KotakОценок пока нет

- Offer Letter: Ramacivil India Construction Pvt. LTDДокумент2 страницыOffer Letter: Ramacivil India Construction Pvt. LTDAshabul SkОценок пока нет

- TCB-X1005 Proposed Liner Running Tally 5''Документ8 страницTCB-X1005 Proposed Liner Running Tally 5''juan_ba777Оценок пока нет

- Construction - Piling - Construction Cycle TimingsДокумент4 страницыConstruction - Piling - Construction Cycle TimingsWee Kim GohОценок пока нет

- Is 14845-2000 (Air Relief Valves) PDFДокумент18 страницIs 14845-2000 (Air Relief Valves) PDFSarbendu PaulОценок пока нет

- U-064 - MSV50 - Hydraulic Components - FДокумент2 страницыU-064 - MSV50 - Hydraulic Components - FBerat DeğirmenciОценок пока нет

- Owen Performance DataДокумент8 страницOwen Performance Dataunduh100% (1)

- NITIEДокумент13 страницNITIESantosh DeshpandeОценок пока нет

- Third Party Dynamic Test ResultsДокумент20 страницThird Party Dynamic Test ResultsDevendra SinghОценок пока нет

- Close Interval Potential Survey: Orrosion Echnology ErvicesДокумент4 страницыClose Interval Potential Survey: Orrosion Echnology ErvicesAndika ChemEng100% (1)

- Overdrive Casing Running and Drilling System: ExpectДокумент25 страницOverdrive Casing Running and Drilling System: ExpectLuis Arreaza BelisarioОценок пока нет

- B+V-Manual - BVC75-200-Rev004-20052010 - ENGДокумент42 страницыB+V-Manual - BVC75-200-Rev004-20052010 - ENGZEESHAN ASHRAFОценок пока нет

- Training Manuals-Instruments: Preparation of Installation TenderДокумент9 страницTraining Manuals-Instruments: Preparation of Installation Tendermilton1987Оценок пока нет

- Casing DrillingДокумент59 страницCasing Drillingleonardosandoval100% (3)

- Bluetooth Mini Earbud s530 ManualДокумент3 страницыBluetooth Mini Earbud s530 ManualDavidОценок пока нет

- Computer Basic Answer KeysДокумент16 страницComputer Basic Answer KeysjagadeeshpersonaluseОценок пока нет

- Iom-Ball ValveДокумент10 страницIom-Ball ValveMohamadIbnuHassanОценок пока нет

- 6ED10521CC080BA1 Datasheet enДокумент2 страницы6ED10521CC080BA1 Datasheet envicky mОценок пока нет

- Crossmax Elite 29 2017 FRONTДокумент2 страницыCrossmax Elite 29 2017 FRONTlcesserОценок пока нет

- Service: Audi A3 1997Документ105 страницService: Audi A3 1997Luan SouzaОценок пока нет

- Using The TPS43061 Boost Evaluation Module (EVM) : User's GuideДокумент20 страницUsing The TPS43061 Boost Evaluation Module (EVM) : User's GuidePaulo chagas paulo ratoОценок пока нет

- SIEMENS - 1500 based - ET200SP PLC CPU 型錄Документ10 страницSIEMENS - 1500 based - ET200SP PLC CPU 型錄CHIENMAO WUОценок пока нет

- Tugas Si SadeДокумент25 страницTugas Si SadeNabil SatriaОценок пока нет

- N ® DT-466E D E: Avistar Iesel NgineДокумент1 страницаN ® DT-466E D E: Avistar Iesel NgineJUAN ERNESTO BETANCUR OSORIOОценок пока нет

- World Class Automation Training: PLC Scada Dcs VFD Hmi Control PanelsДокумент20 страницWorld Class Automation Training: PLC Scada Dcs VFD Hmi Control PanelsPronadeep BoraОценок пока нет

- 1900 ElectricFuel Schematic PDFДокумент2 страницы1900 ElectricFuel Schematic PDFHernan RomeroОценок пока нет

- Report Vocational TrainingДокумент43 страницыReport Vocational Traininghbyubuybiu ubbhybОценок пока нет

- Workshop Manual W3030EN1.pdf Workshop Manual W3030EN1 PDFДокумент43 страницыWorkshop Manual W3030EN1.pdf Workshop Manual W3030EN1 PDFAlexander LopezОценок пока нет

- TK10 Madoneservice 062309Документ27 страницTK10 Madoneservice 062309depuy01Оценок пока нет

- SEL-TBD-I-DS-021 - R0 - Data Sheet For MSAI Flow Transmitter - SignДокумент4 страницыSEL-TBD-I-DS-021 - R0 - Data Sheet For MSAI Flow Transmitter - SignhadiОценок пока нет

- Karcher 720 - MX PDFДокумент14 страницKarcher 720 - MX PDFIraklis100% (1)

- Instruction Sheet 735 3101: Industrial Frequency Converter 400 V (735 3101)Документ4 страницыInstruction Sheet 735 3101: Industrial Frequency Converter 400 V (735 3101)John Philip Rosario SabayleОценок пока нет

- Mainline PPR LT.21.DДокумент1 страницаMainline PPR LT.21.DVictor AfandiОценок пока нет

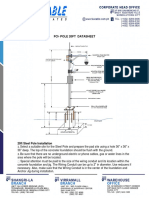

- 20ft Steel Pole DatasheetДокумент3 страницы20ft Steel Pole DatasheetDVTech EngineeringОценок пока нет

- Tasse Ron Measuring ElementsДокумент2 страницыTasse Ron Measuring ElementsRoger LozanoОценок пока нет

- P 1690 TBWДокумент104 страницыP 1690 TBWShoaib JadoonОценок пока нет

- RPC Manual (English)Документ23 страницыRPC Manual (English)Justice KОценок пока нет

- System Allocation: ABS Warning Lamp Right Brake LampДокумент5 страницSystem Allocation: ABS Warning Lamp Right Brake LampDadang Lukmanul HakimОценок пока нет

- aLLEN KEYДокумент9 страницaLLEN KEYpatrik710Оценок пока нет