Академический Документы

Профессиональный Документы

Культура Документы

Screw Gauge

Загружено:

GyanRaj ChavanИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Screw Gauge

Загружено:

GyanRaj ChavanАвторское право:

Доступные форматы

18/02/2009

Screw Gauge

Filed under: Experiments,Screw Gauge gyaunnrraje @ 9:44 am Edit This Tags: Measurements, Screw Gauge Experiment No :2 Aim: To measure the i)Thickness of the Glass Plate ii) Diameter of the metal wire iii) Volume of the given Glass Plate. Apparatus : Screw Gauge , Glass Plate and Metal wire . Description : Screw Gauge consists of U shaped metallic frame. To one side of this U frame a long hallow cylindrical tube with a nut inside it, the inner side of cylindrical nut contains a uniform thread cut in it. On the other side of U frame a fixed stud with a plane face is attached.

A screw is fitted in the cylindrical nut. One side of the screw has a plane face similar to that of stud . The faces of and are plane and parallel to one another. The other end of the screw carries a milled head H attached to a cap C with a sloping edge. When the head H is rotated, the screw moves to and fro in the nut. The milled head H is provided with a safety device D to rotate the head H. When the object is held between the stud and screw and the head H is rotated using the safety device (D), it produces crackling sound when optimum pressure is applied on the object. The outer surface of long cylindrical nut consists of a thick horizontal line P parallel to the axis of cylindrical tube. This line P is called Index line. Along the index line a scale is graduated in millimeters. This scale is called Pitch Scale. On the sloping edge of the cap C a circular scale is graduated, which consists of 100 equal divisions, this scale is called Head scale.

Theory : The screw gauge works on the principle of screw. When we rotate the head H by means of safety device D through one complete rotation, the distance moved by the screw for every complete rotation is constant. This constant distance moved by the screw for one complete rotation of head H is called Pitch of the screw. If the head scale has 100 equal divisions, then the distance moved by the screw for even 1/100 of a complete rotation can be measured accurately, this is called Least count of screw gauge. Therefore Least count (L.C) = .

Procedure :First we have to determine the least count of the given Screw gauge. To determine the least count of the screw gauge, the head H is rotated through certain (say 5) number of complete rotations. The distance moved by the sloped edge over the pitch scale is measured. Now substitute these values in the formula of pitch of the screw = . Least count L.C = .

Now check whether the given screw gauge has any ZERO ERROR or not. To determine the ZERO ERROR, the head H is rotated until the flat end of the screw touches the plane surface of the stud (do not apply excess pressure) i.e we have to rotate the head only by means of safety device D only.

When and are in contact,the zero of the head scale perfectly coincides with the index line as in Fig-(a). In such case there will be no ZERO ERROR and no correction is required. When and are in contact, the zero of the head scale is below the index line as in Fig(b), such ZERO ERROR is called positive ZERO ERROR, and the correction is negative.

When and are in contact, the zero of the head scale is above the index line as in Fig(c) , such ZERO ERROR is called negative ZERO ERROR, and the correction is positive. a) Determine the thickness of glass plate : The given object glass plate is held between the two parallel surfaces of fix stud and screw tip . Note the completed number of divisions on pitch scale, which is called PITCH SCALE READING (P.S.R). The number of the head scale division coinciding with the index line is noted, which is called OBSERVED HEAD SCALE READING n. If the given screw gauge has ZERO ERROR (x) the correction is made by adding or subtracting the ZERO ERROR (x) from the OBSERVED HEAD SCALE READING n. The corrected value (n-x) or (n+x) is called the HEAD SCALE READING (H.S.R) n. To calculate the fraction the H.S.R (n) is multiplied by the least count (L.C). Thickness of the Glass plate = Total reading = P.S.R + - - - (1)

Changing the position of glass plate , 5 readings should be taken, and recorded in the table-1. Every time calculate the total thickness of the glass plate using equation (1). Average of the 5 readings of the glass plate should be calculated, to get the average thickness(t) of the given glass plate. b) Determine the radius(r) of the given metal wire :The given object metal wire is held between the two parallel surfaces of fix stud and screw tip . Note the completed number of divisions on pitch scale, which is called PITCH SCALE READING (P.S.R). The number of the head scale division coinciding with the index line is noted, which is called OBSERVED HEAD SCALE READING n. If the given screw gauge has ZERO ERROR (x) the correction is made by adding or subtracting the ZERO ERROR (x) from the OBSERVED HEAD SCALE READING n. The corrected value (n-x) or (n+x) is called the HEAD SCALE READING (H.S.R) n. To calculate the fraction the H.S.R (n) is multiplied by the least count (L.C). Diameter of the given wire = Total reading = P.S.R + Changing the position of metal wire, 5 readings should be taken, and recorded in the table-2. Every time calculate the total diameter (d) of the metal wire using equation (1). Average of the 5 diameter of the metal wire should be calculated, to get the average diameter(d) of the given metal wire. Radius (r) of the metal wire = mm.

Precautions : i ) Pitch scale reading (P.S.R) should be taken carefully without parallax error ii ) Head scale reading (H.S.R) should be taken carefully without parallax error iii ) Screw must be rotated by holding the safety device D iv ) Do not apply excess pressure on the object held between the surfaces and . v ) The screw is rotated in only one direction either clock wise or anti-clock wise to avoid the back lash error. Observations : i ) Zero error = ii) Zero correction = mm

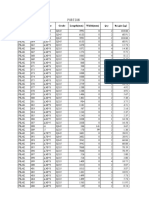

iii ) Distance moved by the head for 5 complete revolutions = mm iv ) Number of head scale divisions = v) Pitch of the screw = vi) Least count (L.C) = Table -1 ( Thickness of glass plate ) : Pitch Observed Scale H.S.R Reading (n) (P.S.R) amm Correction (x) Corrected H.S.R n=n-x Fraction Total reading b=n*L.C (a+b) mm . .

S.No

1. 2. 3. 4. 5. Average thickness of the glass plate (t) = mm

Table 2 (Diameter of the metal wire): Pitch Observed Scale H.S.R Reading (n) (P.S.R) amm Correction (x) Corrected Fraction Total H.S.R n=n- b=n*L.C reading x (a+b) mm

S.No

1. 2. 3. 4. 5. Average diameter d = Average radius r = = mm mm .

c ) Volume of Glass plate (v) : The length ( l ) , breadth ( b) are determined using vernier calipers and thickness ( t ) of the glass plate is determined using screw gauge. The values of l ,b and t are substituted in the equation of volume V = ( l )( b )( t )

Вам также может понравиться

- Find The Volume of The Given Rectangular Glass Plate Using Vernier Calipers and Screw GaugeДокумент5 страницFind The Volume of The Given Rectangular Glass Plate Using Vernier Calipers and Screw GaugeGyanRaj Chavan100% (1)

- Exp - 2 Screw Gauge PDFДокумент3 страницыExp - 2 Screw Gauge PDFyaswanthОценок пока нет

- Screw GuageДокумент3 страницыScrew GuageHarini PriyaОценок пока нет

- Screw GaugeДокумент4 страницыScrew GaugeManjeet SinghОценок пока нет

- Physics Manual XIДокумент23 страницыPhysics Manual XIAnonymous ExAwm00UPОценок пока нет

- Screw GaugeДокумент2 страницыScrew GaugeABHISEK SAHUОценок пока нет

- 1 MeasurementДокумент8 страниц1 MeasurementUvvj RajuОценок пока нет

- Compare The Radii of Three Given Wires Using Screw GaugeДокумент5 страницCompare The Radii of Three Given Wires Using Screw GaugeGyanRaj ChavanОценок пока нет

- Dynamics LabДокумент31 страницаDynamics LabỮΜΔIŘ ҜĦΔŇОценок пока нет

- Dcep 112 & Dmep 112Документ21 страницаDcep 112 & Dmep 112aneeqОценок пока нет

- Ship Hydrodynamics Lecture Notes Part 2 Propeller GeometryДокумент10 страницShip Hydrodynamics Lecture Notes Part 2 Propeller Geometryborhec123Оценок пока нет

- LAB ContentДокумент24 страницыLAB Contenttrantienson2707Оценок пока нет

- Experiment 3Документ4 страницыExperiment 3Shubhra Nil DeyОценок пока нет

- Dynamics LabДокумент3 страницыDynamics LabỮΜΔIŘ ҜĦΔŇОценок пока нет

- Angle MeasurementДокумент10 страницAngle MeasurementsumikannuОценок пока нет

- DATE:8 JUNE 2022 Screw Gauge 1Документ4 страницыDATE:8 JUNE 2022 Screw Gauge 1Anuj KiniОценок пока нет

- Screw GaugeДокумент19 страницScrew GaugeMohammad Rashik ZamanОценок пока нет

- LAB Content - PH1016Документ24 страницыLAB Content - PH1016son caoОценок пока нет

- Chapter 3: Angular Measurements: Definition of AngleДокумент10 страницChapter 3: Angular Measurements: Definition of AngleMohsin Munawar100% (1)

- 11th Experiment 2Документ4 страницы11th Experiment 2BeAsT HYdrA GamingОценок пока нет

- Screw GaugeДокумент7 страницScrew GaugeSURESH SURAGANIОценок пока нет

- Elearning - Vtu.ac - in 18 Enotes 10ME42 Unit3-PRVДокумент10 страницElearning - Vtu.ac - in 18 Enotes 10ME42 Unit3-PRVLokesh NarasimhaiahОценок пока нет

- AP Lab 01Документ4 страницыAP Lab 01muhammad arslanОценок пока нет

- Physics XI Experiment 2Документ3 страницыPhysics XI Experiment 2saumyayayОценок пока нет

- 1.0 Job/Experiment No.: Me594/05 2.0 NAME OF EXPERIMENT: Angle Measurement Using Sine Bar & SlipДокумент6 страниц1.0 Job/Experiment No.: Me594/05 2.0 NAME OF EXPERIMENT: Angle Measurement Using Sine Bar & SlipHimanshu Vasistha0% (1)

- Practical File Class XIДокумент7 страницPractical File Class XIISHITVA JOSHIОценок пока нет

- Physics - Practical Record Writing - Class XIДокумент83 страницыPhysics - Practical Record Writing - Class XISara Wolf100% (1)

- Angle Measurement: Instruments Used For Angular MeasurementДокумент8 страницAngle Measurement: Instruments Used For Angular MeasurementSayanSanyalОценок пока нет

- Physics Screw Guage 2-8 - 17 Copy 2Документ24 страницыPhysics Screw Guage 2-8 - 17 Copy 2PoorvaBakshiОценок пока нет

- Metrology Univ QP Discussion-April 2018Документ50 страницMetrology Univ QP Discussion-April 2018kannanОценок пока нет

- Understanding Vernier Calliper Screw Gauge and SpherometerДокумент6 страницUnderstanding Vernier Calliper Screw Gauge and SpherometerAnonymous vRpzQ2BLОценок пока нет

- Physics Lab Manual Diploma PDFДокумент39 страницPhysics Lab Manual Diploma PDFSriОценок пока нет

- 36Документ60 страниц36Fathi MaseeОценок пока нет

- Parametric Spur GearДокумент11 страницParametric Spur GearGoutam AcharjeeОценок пока нет

- Final Lab Report For Phy 112 and 110Документ28 страницFinal Lab Report For Phy 112 and 110fireballhunter646Оценок пока нет

- Physics BasicsДокумент106 страницPhysics Basicsjeroldscd100% (1)

- Exp - 3 Spherometer PDFДокумент3 страницыExp - 3 Spherometer PDFyaswanth100% (2)

- Youngs Modulus 2016Документ4 страницыYoungs Modulus 2016Darshan BhansaliОценок пока нет

- Volume CentroidДокумент6 страницVolume CentroidZsaneen Mariz Tulabut100% (1)

- Rotary KilnДокумент58 страницRotary KilnFrancisco Uribe Parra100% (7)

- Unit 11 Layout Work and Safety Issues: StructureДокумент11 страницUnit 11 Layout Work and Safety Issues: StructureakashkumardevОценок пока нет

- Tacheometry - Stadia System: KS SinДокумент48 страницTacheometry - Stadia System: KS SindoggyОценок пока нет

- Youngs Modulus PDFДокумент8 страницYoungs Modulus PDFSambit PatraОценок пока нет

- Screw Gauge Practicals CorrectedДокумент4 страницыScrew Gauge Practicals CorrectedeloelОценок пока нет

- Screw Gauge: ConstructionДокумент3 страницыScrew Gauge: ConstructionAdnan QureshiОценок пока нет

- Exp 02 Screw GaugeДокумент5 страницExp 02 Screw GaugeGaming baseОценок пока нет

- Lab Manual (Screw Gauge) PDFДокумент4 страницыLab Manual (Screw Gauge) PDFKashif Ali100% (2)

- Physics Experiment 2Документ4 страницыPhysics Experiment 2Kashif LiaqatОценок пока нет

- Screw GuageДокумент3 страницыScrew GuageMurtaza NaeemОценок пока нет

- Stereo NetsДокумент8 страницStereo NetsvishnuОценок пока нет

- SpherometerДокумент6 страницSpherometerLankarie ChamodaОценок пока нет

- Angular MeasurementДокумент46 страницAngular Measurementavutu_kunduruОценок пока нет

- SP Hero MeterДокумент6 страницSP Hero MeterReshan ChowdhuryОценок пока нет

- Vernier CalipersДокумент6 страницVernier CalipersRani JahnaviОценок пока нет

- Anik Sarkar - Lab Manual XI PDFДокумент34 страницыAnik Sarkar - Lab Manual XI PDFKousik SarkarОценок пока нет

- Watch and Clock Escapements A Complete Study in Theory and Practice of the Lever, Cylinder and Chronometer Escapements, Together with a Brief Account of the Origin and Evolution of the Escapement in HorologyОт EverandWatch and Clock Escapements A Complete Study in Theory and Practice of the Lever, Cylinder and Chronometer Escapements, Together with a Brief Account of the Origin and Evolution of the Escapement in HorologyОценок пока нет

- gr2 wk3 How Things MoveДокумент2 страницыgr2 wk3 How Things Moveapi-247570111100% (1)

- Viscous Fluid Flow Problem Set No. 3 Dr. A. Kebriaee Due Date: Sat.31 FarvardinДокумент2 страницыViscous Fluid Flow Problem Set No. 3 Dr. A. Kebriaee Due Date: Sat.31 FarvardinmohammadtariОценок пока нет

- Classification of Painting StyleДокумент9 страницClassification of Painting StyleCahyarani ParamestiОценок пока нет

- RSSI Informed Phase Method For Distance CalculationsДокумент5 страницRSSI Informed Phase Method For Distance CalculationsAndre AzevedoОценок пока нет

- Kinematics Lab ReportДокумент24 страницыKinematics Lab ReportNate Bocker0% (1)

- Surface Area of DuctsДокумент6 страницSurface Area of Ductsanwerquadri40% (5)

- IGCSE Physics Lesson PlanДокумент3 страницыIGCSE Physics Lesson Plangdsuta92% (12)

- Q3 - Science5 - Week 1Документ13 страницQ3 - Science5 - Week 1Maria Ronavie Davalos MantesОценок пока нет

- Math10 - Q2 - Module 9 - Preliminary Pages - v2Документ12 страницMath10 - Q2 - Module 9 - Preliminary Pages - v2He He0% (1)

- 5) - M1-Moments TryДокумент22 страницы5) - M1-Moments TryisamalhassanОценок пока нет

- Applicability of Using GIN Method, by ConsideringДокумент18 страницApplicability of Using GIN Method, by Considering张三疯Оценок пока нет

- Vehicle Impact Velocity Prediction From Pedestrian Throw DistanceДокумент14 страницVehicle Impact Velocity Prediction From Pedestrian Throw Distancenenad milutinovicОценок пока нет

- LR 11 Maths E3 Distance and LengthДокумент11 страницLR 11 Maths E3 Distance and LengthadaldanОценок пока нет

- Rule Images in Supervised Classification From ENVIДокумент2 страницыRule Images in Supervised Classification From ENVIArsip TGeomatika ITSОценок пока нет

- Willett, Nora S - Shin, Hijung Valentina - Jin, Zeyu - Li, Wilmot - Pose2Pose - Pose Selection and Transfer For 2D Character Animation (2020, ACM)Документ12 страницWillett, Nora S - Shin, Hijung Valentina - Jin, Zeyu - Li, Wilmot - Pose2Pose - Pose Selection and Transfer For 2D Character Animation (2020, ACM)booksОценок пока нет

- 411D ManualДокумент8 страниц411D ManualMadison AvenueОценок пока нет

- Record of Inspection: PSP Job No. Report No Page: of Project Name Item Name Item No. Customer OwnerДокумент34 страницыRecord of Inspection: PSP Job No. Report No Page: of Project Name Item Name Item No. Customer OwnerMuhammad Auliya AlamsyahОценок пока нет

- Lab 1 The Physics LaboratoryДокумент4 страницыLab 1 The Physics LaboratoryHolly ShankinОценок пока нет

- Speed Distance and TimeДокумент7 страницSpeed Distance and TimeNamaeОценок пока нет

- Teacher Guide Activity 2 AccelerationДокумент4 страницыTeacher Guide Activity 2 AccelerationCanada Railway TimesОценок пока нет

- The Elements of Non-Euclidean GeometryДокумент322 страницыThe Elements of Non-Euclidean Geometrybladieboe67% (3)

- AA-Bolt +AA Portion + SummaryДокумент45 страницAA-Bolt +AA Portion + SummaryJosep AdiyonoОценок пока нет

- Speed Distance Time ScienceДокумент5 страницSpeed Distance Time Scienceaby251188Оценок пока нет

- Geometry of Shape and Size: What You Are Expected To Learn?Документ145 страницGeometry of Shape and Size: What You Are Expected To Learn?Mhavy Pabanil Dela CruzОценок пока нет

- 4 The Definite IntegralДокумент58 страниц4 The Definite IntegralBinderya UsukhbayarОценок пока нет

- Method of Delinating Planning RegionsДокумент18 страницMethod of Delinating Planning RegionsanjaliОценок пока нет

- What Is MIME?: MIME As An Internet ProtocolДокумент8 страницWhat Is MIME?: MIME As An Internet Protocolmyprofile0225Оценок пока нет

- 2015 Summer Model Answer PaperДокумент21 страница2015 Summer Model Answer Paperabdul rehman syed parvez100% (1)

- The Gravity Tunnel in A Non-Uniform EarthДокумент8 страницThe Gravity Tunnel in A Non-Uniform EarthAlain RiverosОценок пока нет

- Egstar Manual PDFДокумент90 страницEgstar Manual PDFrufuelОценок пока нет