Академический Документы

Профессиональный Документы

Культура Документы

Paper2 Turbulent Flow

Загружено:

zenondepazИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Paper2 Turbulent Flow

Загружено:

zenondepazАвторское право:

Доступные форматы

Journal of Membrane Science 201 (2002) 203212

Modeling of cross-ow osmotic pressure controlled membrane

separation processes under turbulent ow conditions

Kosaraju Sreenivas, P. Ragesh, Sunando DasGupta, Sirshendu De

Department of Chemical Engineering, Indian Institute of Technology, Kharagpur 721302, India

Received 30 March 2001; received in revised form 30 March 2001; accepted 2 November 2001

Abstract

A comprehensive predictive model for the osmotic pressure controlled turbulent cross-ow membrane separation process

is presented. A thin rectangular channel is selected as the system geometry. The model can handle solutes with wide range of

diffusivities (from sodium chloride to dextran) under different modes of membrane separations (RO, UF, etc.). It is not limited

to the condition that the mass transfer boundary layer lies within the viscous sublayer of the hydrodynamic boundary layer. The

governing equations are solved using an integral method. The performance characteristics of the system in terms of permeate

ux and permeate concentration can be predicted simultaneously. The experimental data available in the literature under

turbulent conditions [Ind. Eng. Chem. Fundam. 3 (1964) 210; J. Membr. Sci. 22 (1985) 117] are successfully compared with

the model predicted results. Aparametric study has been carried out to observe the effects of various operating conditions on the

permeate ux and permeate concentration (in terms of observed retention). 2002 Elsevier Science B.V. All rights reserved.

Keywords: Cross-ow; Diffusivities; Hydrodynamic boundary layer; Turbulent ow; Permeate ux

1. Introduction

One of the major problems associated with mem-

brane separation processes, which restricts the

widespread application of this process in the industry

is the decline in ux. This occurs due to the build up

of the solute concentration near the membrane sur-

face, which is dened as concentration polarization

[1]. The transport of species towards the membrane

is strongly inuenced by the conditions inside the

hydrodynamic and mass transfer boundary layers.

Therefore, the control of the boundary layers is cru-

cial for the optimization of the process. The conven-

tional method to reduce concentration polarization

Corresponding author. Tel.: 91-3222-83926 (Off)/83927 (Res);

fax: 91-3222-55303.

E-mail address: sde@che.iitkgp.ernet.in (S. De).

is to increase turbulence e.g. stirring the solution or

cross-ow of the feed. An accurate quantication

of concentration polarization as a function of pro-

cess conditions is necessary to estimate the system

performance satisfactorily.

Many researchers attempted modeling of UF/RO

systems in the past [25]. Initial models are based

on lm theory [1,6] where concentration boundary

layer is assumed to be fully developed. This led to

the under-prediction of ux. The models which con-

sider developing concentration boundary layer contain

assumptions like no axial variation of permeate ux

[7,8], surface concentration [9,10], and simplied hy-

drodynamics, etc. [11,12].

In order to solve the governing mass transfer equa-

tion one needs to evaluate the detailed velocity proles

in the particular system. There has been a considerable

effort towards developing a detailed transport model

0376-7388/02/$ see front matter 2002 Elsevier Science B.V. All rights reserved.

PII: S0376- 7388( 01) 00730- X

204 K. Sreenivas et al. / Journal of Membrane Science 201 (2002) 203212

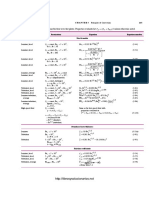

Nomenclature

A damping length constant

(26(

w

/)

1/2

)

B

1

, B

2

, B

3

viral coefcients

c solute concentration (kg/m

3

)

D diffusivity (m

2

/s)

d

e

equivalent diameter (=4 h) (m)

h Channel half height (m)

k Von Karmans constant (0.4)

l Prandtl mixing length (m)

L channel length (m)

L

p

membrane permeability (m/(Pa s))

P transmembrane pressure (Pa)

Re Reynolds number (u

o

d

e

/)

R

o

observed rejection

R

r

intrinsic rejection

u axial velocity (m/s)

u

friction velocity (

w

/) (m/s)

u

dimensionless axial velocity (u/u

)

u

o

time averaged axial velocity (m/s)

u

/

v

/

time averaged velocity uctuation

(m

2

/s

2

)

v vertical velocity (m/s)

v

w

permeate ux (m/s)

!v

w

) average permeate ux (m/s)

v

w

dimensionless suction velocity (v

w

/u

)

x axial coordinate (m)

y transverse coordinate (m)

y

dimensionless transverse coordinate

(yu

/)

Greek letters

1

,

2

,

3

,

4

coefcients in Eqs. (A.1)(A.4)

concentration boundary layer

thickness (m)

dimensionless concentration

boundary layer thickness, dened

as

= (/)u

kinematic viscosity (m

2

/s)

osmotic pressure (Pa)

osmotic pressure difference across

the membrane (Pa)

density (kg/m

3

)

total shear stress (N/m

2

)

w

wall shear stress (N/m

2

)

coefcient in Eq. (15)

Subscripts

m membrane surface

o feed bulk

p permeate

in a variety of channel geometries. Belfort and Klein-

streuer [13] have reviewed much of the analytical and

numerical work in this area. These provide insight

into the uid ow problems in the membrane systems.

Most of the work in modeling of UF/RO systems

has been undertaken in the laminar range [2,3,14,15].

This severely restricts their applicability, as these sys-

tems often operate under turbulent ow conditions or

employ turbulence promoters. Silva-freire [16], Sucec

and Oljaca [17] have undertaken detailed calculation

for turbulent transpiration ows. However, these so-

lutions are for the case of external ows and when

the free stream velocity is known as a function of the

axial distance. The transpiration considered in their

solution is injection and it is taken to be constant with

axial distance. The most common approach for mod-

eling turbulence in membrane separation processes is

to use empirical correlations for the mass transfer co-

efcients [18]. However, these correlations are system

specic and valid in certain ranges of the operating

conditions thereby limiting their applicability.

Recently, more fundamental modeling of turbulent

cross-ow UF was attempted [11,12]. These analyses

are valid for low diffusivity (e.g. dextran T70) solutes.

For these solutes, the concentration boundary layer

lies within the viscous sub-layer (of the hydrodynamic

boundary layer). Another simplied assumption re-

garding the hydrodynamics is that the x-component

velocity remains unaffected by membrane perme-

ation. Moreover, the turbulent mass transport terms

(Reynolds stresses) are neglected, which may not be

true outside the viscous sub-layer (of the hydrody-

namic boundary layer). Hence, such analysis cannot

account for the ltration of the high diffusivity so-

lutes (sodium chloride, sucrose, etc.) for which the

concentration boundary layer may grow beyond the

viscous sub-layer in to the buffer zone or even in to

the turbulent core.

In the present work, most of the above draw-

backs for the osmotic pressure controlled turbulent

cross-ow UF/RO have been taken care of. The axial

K. Sreenivas et al. / Journal of Membrane Science 201 (2002) 203212 205

Fig. 1. Schematic of the system.

velocity prole is developed using the van Driest mix-

ing length hypothesis. This is then coupled to the mass

conservation equation. The numerical solution of the

model equations predicts the system performance in

terms of permeate ux and permeate concentration.

The model predictions are compared with the experi-

mental data available in the literature [19,20].

1.1. Theory

The ow conguration is a rectangular channel as

shown in the Fig. 1. The uid ows axially over the

membrane surface. The process is assumed to be in

steady state with fully developed turbulent hydrody-

namic boundary layer. Physical properties of the com-

ponents are assumed to be constant.

1.1.1. Hydrodynamic considerations

The momentum equation for a two dimensional, in-

compressible, turbulent boundary layer with zero pres-

sure can be written as

u

u

x

v

u

y

=

1

y

(1)

where is the total shear stress and is expressed as

=

l

t

=

u

y

u

/

v

/

(2)

where

l

is the laminar and

t

the turbulent shear stress

[21].

The boundary conditions for Eq. (1) are

u = 0, v = v

w

: =

w

at y = 0 (3)

For the fully developed hydrodynamic boundary layer,

the Eq. (1) reduces to

v

w

u

y

=

y

(4)

Integrating the above equation yields the following

expression for the shear stress

=

w

uv

w

(5)

The turbulent shear stress term can be expressed ac-

cording to the Prandtl mixing length theory as [22,23]

t

= l

2

u

y

u

y

(6)

where l is the Prandtl mixing length. The Prandtl mix-

ing length can be expressed using the van Driest hy-

pothesis in the following way [23]:

l = ky

1 exp

y

A

(7)

where A is the damping length constant, dened as

26(

w

/)

1/2

. The modied value of A for suction

is given as A = 26(

w

/2)

1/2

exp(5.9v

w

) [23], with

k as Von Karmans constant (equal to 0.4) [23]. It

may be noted that the entire domain of the turbulent

hydrodynamic boundary layer is represented by the

expression of the mixing length given by Eq. (7).

On substitution of Eq. (7) into Eq. (6), the following

expression for the turbulent shear stress is obtained:

t

=

ky

1 exp

y

A

2

du

dy

2

(8)

Using the above expression of

t

, Eq. (5) may be writ-

ten as

=

l

t

=

du

dy

ky

1 exp

y

A

du

dy

2

=

w

uv

w

(9)

Simplifying the above expression, the velocity gradi-

ent may be expressed as

du

dy

=

2

4(

w

uv

w

)B

2B

(10)

where

B =

ky

1 exp

y

A

2

206 K. Sreenivas et al. / Journal of Membrane Science 201 (2002) 203212

The wall shear stress in turbulent ow can be ex-

pressed in terms of the time smoothed average veloc-

ity (u

0

) [24],

w

= 0.03325 u

2

o

2

d

e

u

o

0.25

(11)

Using the above expression for wall shear stress,

Eq. (10) can be expressed in an implicit form as

du

dy

= E(v

w

, y) (12)

The boundary condition for Eq. (12) is u = 0 at y = 0.

1.2. Mass transfer boundary layer

The steady state mass balance near the membrane

surface (within the concentration boundary layer) is

described by the governing species conservation equa-

tion:

u

c

x

c

y

= D

2

c

y

2

J

y

y

(13)

where

J

y

is a term representing turbulent mass trans-

port and is expressed using Prandtl analogy as [21]

J

y

= l

2

du

dy

c

y

(14)

Assuming = l

2

[du/dy[, Eq. (13) is modied as

u

c

x

v

y

c

y

= (D )

2

c

y

2

(15)

The boundary conditions for Eq. (15) are

c(0, y) = c

0

(16)

c(x, ) = c

0

(17)

The solute mass balance at the membrane surface, i.e.

at y = 0 gives the third boundary condition:

v(c c

p

) D

c

y

= 0 (18)

Since, the mass transfer boundary layer is very thin

compared to the half channel height, the transverse

velocity prole may be expressed as [11,12,25]

v = v

w

An integral method is employed for solving the gov-

erning mass balance equation (Eq. (15)), by assuming

the concentration prole is of the form

c = a

1

a

2

a

3

2

where =

y

The coefcients a

1

, a

2

, a

3

are evaluated using the

boundary conditions on the mass transfer governing

Eqs. (16) and (17) along with, the condition at the

edge of the boundary layer, (c/y)

y=

= 0. Evalu-

ating the constants, the concentration prole becomes

c

c

0

=

c

m

c

0

1

y

2

y

(19)

Substituting the above concentration prole into

Eq. (15), the following equation is obtained:

f

d

dx

g

dc

m

dx

= k

1

(20)

where

f = u

c

o

2

y

2c

m

1

y

g =

1

y

2

k

1

=2(D )

(c

m

c

0

)

v

w

y

2c

m

1

y

2

y

y

= l

2

d

2

u

dy

2

2l

du

dy

ky l

A

l

y

The expression for (d

2

u/dy

2

) can be obtained from

Eq. (10) (given in Appendix A).

1.3. Osmotic pressure model

Solvent ow through the membrane is quantied by

Darcys law for ow through a porous medium.

v

w

= L

p

(P ) (21)

Osmotic pressure of any macromolecular solution can

be expressed in the form of a viral expansion:

= B

1

c B

2

c

2

B

3

c

3

(22)

K. Sreenivas et al. / Journal of Membrane Science 201 (2002) 203212 207

Osmotic pressure difference can be estimated if the

concentration of the solute at the membrane surface

(c

m

) and the permeate concentration (c

p

) can be eval-

uated. These two concentrations are related by in-

trinsic retention (R

r

) which is constant for a specic

membranesolute system [26] dened as

R

r

= 1

c

p

c

m

(23)

The quality of permeate stream is characterized by the

observed retention (R

o

)

R

o

= 1

c

p

c

o

(24)

Using Eqs. (22) and (23), the osmotic pressure differ-

ence across the membrane can be expressed in terms

of the membrane surface concentration as

=B

1

c

m

R

r

B

2

c

2

m

(1 (1 R

r

)

2

)

B

3

c

3

m

(1 (1 R

r

)

3

) (25)

On substituting Eq. (25) into Eq. (21), the permeate

ux can be obtained as a function of the membrane

surface concentration:

v

w

=L

p

[P B

1

c

m

R

r

B

2

c

2

m

(1 (1 R

r

)

2

)

B

3

c

3

m

(1 (1 R

r

)

3

)] (26)

Combining Eqs. (18) and (19) the following expres-

sion for ux can be obtained:

v

w

=

2D(c

m

c

o

)

c

m

R

r

(27)

Combining Eqs. (26) and (27), we get an algebraic

equation containing surface concentration and concen-

tration boundary layer thickness, which can be given

as

(c

m

1)

2(/d

e

)

= [

1

c

m

2

c

2

m

3

c

3

m

4

c

4

m

] (28)

where c

m

= c

m

/c

o

and

1

,

2

,

3

,

4

are given in

Appendix A. Differentiating the above expression with

respect to x gives

dc

m

dx

=

2(c

m

c

o

)

F

d

dx

= f

1

d

dx

(29)

where F is a polynomial given in the Appendix A.

Substituting Eq. (29) in Eq. (20), results in a nonlin-

ear rst-order differential equation for the mass trans-

fer boundary layer:

(f gf

1

)

d

dx

= k

1

(30)

Integrating the above equation over the concentration

boundary layer thickness, the following equation is

obtained:

0

(f gf

1

)

d

dx

dy =

0

k

1

dy (31)

P

d

dx

= T (32)

where P and T are the functions of x, v

w

, and c

m

:

P =

0

(f gf

1

) dy (33)

T =

0

k

1

dy (34)

Eq. (32) has to be solved along with the Eqs. (12) and

(28) to obtain the prole of the concentration boundary

layer and in turn the axial variation of c

m

and v

w

.

The average permeate ux is obtained using

!v

w

) =

1

L

L

0

v

w

dx

(35)

Once the membrane surface concentration prole is

determined by the above method, the prole of ob-

served retention is obtained.

2. Numerical solution

The coupled differential and algebraic equations

(Eqs. (12), (28), (29) and (32)) are solved using a

fourth-order RungeKutta method. The governing hy-

drodynamic equation (Eq. (12)) becomes indetermi-

nate at y = 0. This problem is circumvented by the

following approach. As the velocity prole very close

to the wall is linear in nature and is given by u

= y

,

a very small value of y (10

9

m) and the correspond-

ing value of u (from the viscous sub-layer relation) are

chosen as the initial condition for the solution of the

velocity prole (Eq. (12)). The lattice spacing in the

transverse direction is taken as 10

8

m. No apprecia-

ble changes in the calculated values of the dependent

208 K. Sreenivas et al. / Journal of Membrane Science 201 (2002) 203212

variables are noticed by changing the y spacing and

the starting value of y.

The mass transfer governing equation (Eq. (32))

has been coupled with the differential Eq. (12) and is

solved using the fourth order RungeKutta method.

The coefcients P and T (Eq. (32)) are evaluated nu-

merically at each step of integration using Simpsons

one-thirds rule. It may be noted that the algebraic equa-

tion (Eq. (28)) is coupled with Eqs. (12) and (32) and

is solved using NewtonRaphsons method.

The initial condition for the solution of Eq. (32) is

= 0 at x = 0. This will make the solution inde-

terminate. Therefore, an asymptotic solution is sought

to the limit x 0, 0. Under these conditions,

the developing concentration boundary layer (near the

entrance) lies well within the viscous sub-layer. The

form of the asymptotic solution of Eq. (32) will be as

follows [11]:

d

dx

=

8h

3

Z

2

(36)

where

Z =

u

2

d

3

e

64Dv

(37)

The solution of Eq. (36) is

= h

24x

Z

1/3

(38)

The axial starting point for integration is taken as x =

10

10

m. Any further decrease in the initial point did

not result in any appreciable increase in accuracy. The

axial lattice spacing is reduced until the solution was

effectively independent of spacing. Variable step size

is employed with an initial axial spacing of 10

12

m

and it has been increased up to 10

4

m at the end of

the channel.

3. Results and discussion

3.1. Comparison of model predictions with the

experimental data

The model Eqs. (12), (28), (29) and (32) are solved

as outlined in the numerical solution section. The

solution provides the proles of the permeate ux

and the membrane surface concentration along the

Fig. 2. Comparison with the experimental data for NaCl [19]. The

predictions are the solid lines whereas the experimental data are

presented by the symbols.

channel length. The length averaged permeate ux is

obtained using Simpsons one-thirds rule. The exper-

imental data for two different solutessodium chlo-

ride (high diffusivity, order of magnitude 10

9

m

2

/s,

[19]) and dextran-70,000 (low diffusivity, order of

magnitude 10

11

m

2

/s [20]) are taken for compari-

son. The comparison of sodium chloride data under

turbulent ow conditions with the predicted values

is presented in Fig. 2. The predictions are the solid

lines whereas the experimental data are presented by

the symbols. The experiments were conducted [19]

in a cell of dimensions 75 mm 25 mm 2.5 mm.

The feed concentration was 4.2 wt.% and the op-

erating pressure was 103 atm. Cross-ow velocities

were varied from 0.08 to 0.5 m/s. Eastman E-398-3

cellulose acetate membrane was used with a mem-

brane permeability of 7.6 10

6

g/(cm

2

s atm). The

comparison for dextran-70,000 is presented in Fig. 3.

The ultra-ltration experiments [20] were carried out

in a thin channel of dimensions 100 mm 60 mm

5.9 mm. Kalle polysulphone membranes were used

with a permeability of 1.44 10

10

m

3

/(Ns). The

feed concentrations were varied from 0.43, 0.935

and 1.42 kg/m

3

; the operating pressure differences

were 200, 400 and 600 kPa; cross-ow velocities

were 1.06, 1.84, 2.75 m/s. It is clear from these two

gures that the predicted results are in good agree-

K. Sreenivas et al. / Journal of Membrane Science 201 (2002) 203212 209

Fig. 3. Comparison with the experimental ux (10

5

m

3

/(m

2

s))

data for dextran [20].

ment with the experimental data. This indicates that

the model presented herein is suitable for solutes of

widely varying diffusivities. The major advantage

of this model is that it can be successfully used,

with the assumptions inherent in the development

of the model (as described in the Section 1.1), for

high diffusivity solutes for which the concentration

boundary layer will denitely cross the viscous sub-

layer.

Fig. 4 represents the dimensionless concentration

boundary layer development along the channel length

for different solutes, namely, sodium chloride, sucrose

and dextran. The solutes are chosen in the decreas-

ing order of diffusivity (orders of magnitudes of 10

9

,

10

10

, 10

11

m

2

/s, respectively). Physical properties

of these solutes in aqueous solution are presented in

the Appendix B. As is evident from the gure, that

for the high diffusivity solutes (NaCl and sucrose,

curves 1 and 2), the concentration boundary layer de-

velops and goes beyond the viscous sub-layer into

the buffer region of the hydrodynamic boundary layer.

Only for dextran (curve 3), which is having the small-

est diffusivity (the highest Schmidt number) of the

three solutes, the concentration boundary layer lies

well within the viscous sub-layer. Thus, the present

model is more generalized compared to the existing

fundamental models of turbulent cross-ow ltration

[11,12].

Fig. 4. Variation of concentration boundary layer thickness along

the channel length. c

o

= 1 kg/m

3

, R

r

= 1, L = 1000 mm,

P = 800 kPa, Re = 4600. Curve: 1, NaCl; 2, sucrose; 3, dextran.

The axial velocity prole after incorporation of suc-

tion is expressed in Eq. (12). Fig. 5 represents a plot

of the x-component of the velocity prole as a func-

tion of the distance from the wall when the average

velocity in the channel is u

0

= 1 m/s. Curve 1 rep-

resents the velocity prole when there is no suction

(i.e. v

w

= 0). The effect of suction (v

w

= 0.001 m/s)

on the velocity prole is presented in curve 2. It can

be clearly observed from the gure that the velocity

decreases across the channel due to suction.

Fig. 5. Variation of x-component of velocity with suction. Curve:

1, v

w

= 0.0 m/s; 2, v

w

= 0.001 m/s.

210 K. Sreenivas et al. / Journal of Membrane Science 201 (2002) 203212

Fig. 6. Variation of membrane surface concentration along the

channel length for NaCl solution. c

o

= 42 kg/m

3

, P = 103 atm.

Curve: 1, Re = 4600; 2, Re = 9200; 3, Re = 13,800.

Since the major thrust of this work is to develop a

model that would be valid even for high diffusivity so-

lutes, a parametric study is undertaken with NaCl as

the solute. The aim of the study is to quantify the ef-

fects of various operating conditions (e.g. transmem-

brane pressure, R

r

, u

0

) on the permeate ux and the

observed retention.

Fig. 6 represents the variation of dimensionless

membrane surface concentration along the length of

the channel for various cross-ow velocities. Curve 1

is for the lowest and curve 3 is for the highest

cross-ow velocities. It is clear from the gure that in-

creased turbulence (high cross-ow velocity) impedes

the accumulation of the solutes on the membrane sur-

face. This would result in a lower value of membrane

surface concentration.

The relative decrease in membrane surface concen-

tration results in a reduction in the build up of osmotic

pressure, thereby, increasing the effective driving force

across the membrane. The consequent increases in the

permeate ux are presented in Fig. 7, where curves

13 are arranged in increasing order of cross-ow ve-

locity.

Fig. 8 presents the variation of quality in the form

of observed retention of the permeate along the chan-

nel for different cross-ow velocities. Curve 3 is for

the highest and curve 1 is for the lowest cross-ow ve-

locity. It can be observed that the quality deteriorates

Fig. 7. Variation of permeate ux along the channel length for

NaCl solution. Operating conditions are same as in Fig. 6.

along the channel due to increase in the membrane sur-

face concentration (Fig. 6). As explained earlier, an in-

crease in cross-ow velocity decreases the membrane

surface concentration, thereby decreasing the chem-

ical potential difference across the membrane. This

would result in less solute transport through the mem-

brane (lower permeate concentration) and hence, the

observed retention will increase.

Fig. 8. Effect of cross-ow velocity on the prole of observed

retention along the channel length. Operating conditions are same

as in Fig. 6.

K. Sreenivas et al. / Journal of Membrane Science 201 (2002) 203212 211

Fig. 9. Effect of intrinsic retention on the prole of observed

retention along the channel length. c

o

= 42 kg/m

3

, P = 103 atm;

Re = 4600. Curve: 1, R

r

= 0.98; 2, R

r

= 0.95; 3, R

r

= 0.90.

Fig. 9 represents the effects of R

r

on the observed

retention. For a xed R

r

, R

o

decreases along the chan-

nel. This decrease appears less than the previous g-

ure (Fig. 8) due to the length scale for R

o

chosen here

to accommodate larger variation in R

o

. The axial vari-

ation (reduction) in R

o

is consistent with the relative

increases in C

m

(Fig. 6) for a xed value of R

r

. At a

xed location in the channel, R

o

is lower for smaller

values of R

r

. Low values of R

r

indicate that the mem-

brane is more porous and therefore, the solute concen-

tration in the permeate stream tends to increase. This

leads to a decrease in the values of R

o

with smaller R

r

.

4. Conclusions

A transport model for the osmotic pressure con-

trolled turbulent cross-ow membrane ltration pro-

cess is developed. The limitations of the previous

models, specially, for high diffusivity solutes have

been overcome in this work. Thus, the model is ap-

plicable for most of the solutes typically encountered

in membrane separation processes (from RO to UF).

An integral method is employed to solve the coupled

governing hydrodynamic and mass transfer equa-

tions. The solution simultaneously predicts the per-

meate ux and permeate concentration as a function

of the operating conditions. The results from the

model are successfully compared with the data avail-

able from literature for sodium chloride and dextran

under turbulent ow conditions.

Appendix A

1

= R

r

(A.1)

2

=

R

2

r

c

0

B

1

(P)

(A.2)

3

=

R

r

c

2

o

B

2

(P)

[1 (1 R

r

)

2

] (A.3)

4

=

R

r

c

3

o

B

3

(P)

[1 (1 R

r

)

3

] (A.4)

where

=

L

p

d

e

(P)

4D

(A.5)

F =2

1

2

1

(c

m

) 3

1

(c

m

)

2

4

1

(c

m

)

3

(A.6)

where

c

m

=

c

m

c

o

and

=

d

e

d

2

u

dy

2

=

2B

2

dB

dy

v

w

[B (dB/dy)]

MB

M

2B

2

dB

dy

(A.7)

where

M =

2

4(

w

uv

w

)B

B =

ky

1 exp

y

A

2

dB

dy

=

k

2

y

1 exp

y

A

2y exp(y/A)

A

1 exp

y

A

where

A = 26

1/2

exp(5.9v

w

)

212 K. Sreenivas et al. / Journal of Membrane Science 201 (2002) 203212

Appendix B. Physical properties of the solutes

(i) Diffusivity [19,20,27]: NaCl, 1.5 10

9

m

2

/s;

sucrose, 5.24 10

10

m

2

/s; dextran, 4

10

11

m

2

/s.

(ii) Viscosity: Viscosity of the solutions have been

taken as 0.001 Pa s.

(iii) Density: Density of the solutions have been taken

as 1 g/cm

3

.

(iv) Osmotic pressure: Osmotic pressure of macro-

molecular solutions can be expressed in a viral

form:

= B

1

C B

2

C

2

B

3

C

3

where is in Pa and C is in kg/m

3

.

For dextran T70 [20]: B

1

= 37.5; B

2

= 0.752;

B

3

= 0.00764.

For NaCl [19]: B

1

= 83086.5; B

2

= 0.0; B

3

= 0.0.

For sucrose [27]: B

1

= 3770; B

2

= 38.79; B

3

=

0.04.

References

[1] W.F. Blatt, A. Dravid, A.S. Michaels, L. Nelson, Solute

polarization and cake formation in membrane ultra-ltration:

causes, consequences and control techniques, in: J.E. Flinn

(Ed.), Membrane Science and Technology, Plenum Press, New

York, 1970.

[2] S. Srinivasan, C. Tien, W.N. Gill, simultaneous development

of velocity and concentration proles in reverse osmosis

systems, Chem. Eng. Sci. 22 (1967) 417.

[3] J.S. Shen, R.F. Probstein, On the prediction of limiting ux in

laminar ultra-ltration of macromolecular solutes, Ind. Eng.

Chem. Fundam. 16 (1977) 459.

[4] D.R. Trettin, M.R. Doshi, Ultra-ltration in an unstirred batch

cell, Ind. Eng. Chem. Fundam. 19 (1980) 189.

[5] J.G. Wijmans, S. Nakao, C.A. Smolders, Flux limitations in

ultra-ltration: osmotic pressure model and gel layer model,

J. Membr. Sci. 20 (1984) 115.

[6] R. Rautenbach, R. Albrecht, Membrane Processes, Academic

Press, New York, 1986.

[7] T.K. Sherwood, P.L.T. Brian, Salt concentration at phase

boundaries in desalination by reverse osmosis, Ind. Eng.

Chem. Fundam. 4 (1965) 113.

[8] L. Dresner, Boundary layer build-up in the demineralization of

salt water by reverse osmosis, Oak Ridge National Laboratory

Report, 1964, p. 3621.

[9] D.R. Trettin, M.R. Doshi, Pressure independent ultra-ltration

is it gel limited or osmotic pressure limited? in: A.F. Turbak

(Ed.), Synthetic Membranes. Part II. Hyper and Ultra-ltration

Uses, ACS Symposium Series, 1981, p. 154.

[10] P.L.T. Brian, Concentration polarization in reverse osmosis

desalination with variable ux and incomplete salt rejection,

Ind. Eng. Chem. Fundam. 4 (1965) 439.

[11] R. Prabhakar, S. DasGupta, S. De, Simultaneous prediction

of ux and retention for osmotic pressure controlled turbulent

cross-ow ultra-ltration, Sep. Purif. Technol. 18 (2000) 13.

[12] V.S. Minnikanti, S. DasGupta, S. De, Prediction of mass

transfer with suction for turbulent ow in cross-ow

ultra-ltration, J. Membr. Sci. 4079 (1999) 1.

[13] G. Belfort, C. Kleinstreuer, Mathematical modeling of uid

ow and solute distributions in pressure driven membrane

modules, in: G. Belfort (Ed.), Synthetic Membrane Processes:

Fundamentals and Water Applications, Academic Press, New

York, 1984.

[14] S. Ganguly, P.K. Bhattacharya, Development of concentration

prole and prediction of ux for ultra-ltration in a radial

cross-ow cell, J. Membr. Sci. 97 (1994) 185.

[15] L. Huang, M.T. Morrisey, Finite element analysis as a tool

for cross-ow membrane lter simulation, J. Membr. Sci. 155

(1999) 19.

[16] A.P. Silva-freire, An asymptotic solution for transpired

incompressible turbulent boundary layers, Int. J. Heat Mass

Transfer 31 (5) (1988) 1011.

[17] J. Sucec, M. Oljaca, Calculation of turbulent boundary layers

with transpiration and pressure gradient effects, Int. J. Heat

Mass Transfer 38 (15) (1995) 2855.

[18] V. Gekas, B. Hallstrom, Mass transfer in the membrane

concentration polarization layer under turbulent cross-ow.

Part I. Critical literature review and adaptation of existing

Sherwood correlations to membrane operations, J. Membr.

Sci. 80 (1987) 153.

[19] U. Merten, H.K. Lonsdale, R.L. Riley, Boundary layer effects

in reverse osmosis, Ind. Eng. Chem. Fundam. 3 (1964)

210.

[20] J.G. Wijmans, S. Nakao, J.W.A. van den Berg, F.R. Trolestra,

C.A. Smolders, Hydrodynamic resistance of concentration

polarization boundary layers in ultra-ltration, J. Membr. Sci.

22 (1985) 117.

[21] R.B. Bird, W.E. Stewart, E.N. Lightfoot, Transport

Phenomena, Wiley, New York, 1960.

[22] P. Bradshaw, T. Cebeci, Momentum Transfer in Boundary

Layers, Hemisphere, Washington, DC, 1977.

[23] T. Cebeci, A.M.O. Smith, Analysis of Turbulent Boundary

Layers, Academic Press, New York, 1975.

[24] R.W. Fox, A.T. McDonald, Introduction to Fluid Mechanics,

Wiley, New York, 1985.

[25] S. De, S. Bhattacharya, P.K. Bhattacharya, A. Sharma,

Generalized integral and similarity solutions for concentration

proles for ultra-ltration, J. Membr. Sci. 130 (1997) 99.

[26] W.S. Opong, A.L. Zydney, Diffusive and convective protein

transport through asymmetric membranes, AIChE J. 37 (1991)

1497.

[27] S. Sourirajan, Reverse Osmosis, Academic Press, New York,

1970.

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Integrity Test Services: View Our Tutorial Videos at Hallpyke - IeДокумент2 страницыIntegrity Test Services: View Our Tutorial Videos at Hallpyke - IeLam TranОценок пока нет

- Heat Loss From PipeДокумент11 страницHeat Loss From Pipemlarakahan100% (1)

- FM Part-4Документ190 страницFM Part-4Shivam PatidarОценок пока нет

- 44flow Through PipesДокумент42 страницы44flow Through PipesVenkata RamanaОценок пока нет

- Lyophilic and Lyophobic SolsДокумент7 страницLyophilic and Lyophobic Solssatvik guptaОценок пока нет

- What Is The Importance of Reynold Numbers in Flow of FluidДокумент10 страницWhat Is The Importance of Reynold Numbers in Flow of Fluidyowma33% (3)

- Metalworking BrochureДокумент6 страницMetalworking BrochurechayanunОценок пока нет

- Corre Laci OnesДокумент12 страницCorre Laci Onesjose antonioОценок пока нет

- Easa Part 66 Module 8 PDFДокумент2 страницыEasa Part 66 Module 8 PDFPRASAD100% (3)

- Final Project (Team)Документ5 страницFinal Project (Team)bintangОценок пока нет

- 1 L Power - Circulation and Mixing Time Tank Anchor AgitatorДокумент9 страниц1 L Power - Circulation and Mixing Time Tank Anchor Agitatornarayana reddyОценок пока нет

- Discrete Phase Modelling - CombustionДокумент63 страницыDiscrete Phase Modelling - CombustionFabian Andrey DiazОценок пока нет

- Exact Solution Tank DrainageДокумент8 страницExact Solution Tank DrainageFelipe CastОценок пока нет

- Sambungan CHAPTER 3Документ11 страницSambungan CHAPTER 3JuanCarlosJaplehОценок пока нет

- Engineering Fluid Mechanics: (8th Edition)Документ4 страницыEngineering Fluid Mechanics: (8th Edition)كرار عبدالحسين قاسمОценок пока нет

- M6b Water Surface Profiles PDFДокумент10 страницM6b Water Surface Profiles PDFEftima KredanОценок пока нет

- The Effect of Bubble Size On Fine Particle FlotationДокумент23 страницыThe Effect of Bubble Size On Fine Particle FlotationMiguel Sepúlveda MartinezОценок пока нет

- Application Manual Lubricating Greases For The Food Industry ENДокумент20 страницApplication Manual Lubricating Greases For The Food Industry ENAlfonso Florez MartinezОценок пока нет

- GEA Spray Drying: Small-Scale Solutions For R&D and ProductionДокумент20 страницGEA Spray Drying: Small-Scale Solutions For R&D and ProductionPatricio ValenciaОценок пока нет

- Interfacial 5 PDFДокумент12 страницInterfacial 5 PDFعلاء ابو سمكОценок пока нет

- Factors Affecting PermeabilityДокумент4 страницыFactors Affecting PermeabilityMahesh RamtekeОценок пока нет

- For Exchanger Tube Rupture PDFДокумент3 страницыFor Exchanger Tube Rupture PDFNikhil DivateОценок пока нет

- Assessment Exam 03 1Документ7 страницAssessment Exam 03 1Andrea Magtuto100% (1)

- Cavitation Guide For Control ValvesДокумент120 страницCavitation Guide For Control ValvesShivshankar Ghuge100% (1)

- Hydrostatic Force On Submerged and Semi-Submerged Rectangular AreaДокумент9 страницHydrostatic Force On Submerged and Semi-Submerged Rectangular AreaKevin P MendozaОценок пока нет

- Aiaa 1989 1319 451Документ12 страницAiaa 1989 1319 451joukendОценок пока нет

- Unit 3 - Thermal Engineering and Gas Dynamics - WWW - Rgpvnotes.inДокумент9 страницUnit 3 - Thermal Engineering and Gas Dynamics - WWW - Rgpvnotes.inFno FnoОценок пока нет

- Acta Astronautica: Zhongtao Kang, Zhen-Guo Wang, Qinglian Li, Peng ChengДокумент25 страницActa Astronautica: Zhongtao Kang, Zhen-Guo Wang, Qinglian Li, Peng Chengsaman kasmaieeОценок пока нет

- Properties of FluidДокумент4 страницыProperties of FluidAbdallah Hisham AdailehОценок пока нет

- Drew Plus TM 4507 A Foam Control DefoamerДокумент2 страницыDrew Plus TM 4507 A Foam Control DefoamerDara PishtazОценок пока нет