Академический Документы

Профессиональный Документы

Культура Документы

Process Audit Checklist

Загружено:

zafeerИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Process Audit Checklist

Загружено:

zafeerАвторское право:

Доступные форматы

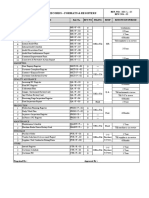

Process audit checklist

Major NC Remark

Action Plan Comment/Evidence Action Resp. Date

Status

Nr.

Expectation

Requested corrections follow up (claim, customer complain, last audit report,) & internal PPM

0 0 0

1 Supplier Corrective/Preventive actions Systems 2 Defect Analyses are deep enough to find root causes (of occurrence & not detection) 3 The action plan to correct the defect is correctly applied

4 Action plan are followed with reasonable timing(2 days for STAP , 2 weeks for MTAP) 5 Checking effectiveness of actions. (Result should be obvious)

Other

II

Survey Plan/SQA (ISAR) & Technical documents

0 0 0

1 Up-to-date and living documents

2 Drawings and Standards are available in latest version

NC

Page 1 of 6

MovahedC:\Documents and Settings\781085\Desktop\MPA - final.xls

Process audit checklist

Major NC Remark

Action Plan Comment/Evidence Action Resp. Date

Status

Nr.

Expectation

3 Customer(Sapco) verification after modification 4 The S/R parameters are clearly written on the surveyplan(SQA)

5 All involved people know these parameters

6 Plan of SPC (CPK review) specially for S/R parameters Other

III

Control Of Incoming (Materials, parts, Components,)

0 0 0

1 Product specification are clearly described in the purchase order for the sub contractor 2 Traceability of incoming material

3 Incoming storage and location and layout are suitable 4 Method of ensuring the quality of incoming by supplier

NC

Page 2 of 6

MovahedC:\Documents and Settings\781085\Desktop\MPA - final.xls

Process audit checklist

Major NC Remark

Action Plan Comment/Evidence Action Resp. Date

Status

Nr.

Expectation

5 The entrance checking is correctly done

6 The S/R parameters of incoming are clearly written on Documents and involved people know all S/R parameters

7 The control tools are calibrated

8 Quality record of incoming control based on control plan 9 Periodical process audit of subcontractors production line 9 FIFO is respected in entrance

Other

IV Production Line Audit

1 Measuring and control equipments: -Available in line ,according to control plan -Their calibration status

0 0 0

NC

Page 3 of 6

MovahedC:\Documents and Settings\781085\Desktop\MPA - final.xls

Process audit checklist

Major NC Remark

Action Plan Comment/Evidence Action Resp. Date

Status

Nr.

Expectation

2 Work instructions , control instructions : -Available and visual in each station -Are simple & clear for operators -Self control of the worker exist & is applied -The training of operators is defined and done 3 Setup & Maintenance: -Setup: production start up, line/material change , ,job setting , method of setup, initial setting , are defined and done. - Periodic Maintenance reports to shows PM effectiveness.

4 Identification & product Traceability during production 5 Production and control are done according to survey (control) plan and relative documents 6 The quality records are done according to control plan 7 The S/R parameters are clearly visualized in work stations and related documents 8 Implementation of SPC & Periodic review on CPK (improvement)

NC

Page 4 of 6

MovahedC:\Documents and Settings\781085\Desktop\MPA - final.xls

Process audit checklist

Major NC Remark

Action Plan Comment/Evidence Action Resp. Date

Status

Nr.

Expectation

9 Non conform (rejected) parts are blocked in a good manner Reactivity for N.C 11 Work environment: 5S, enough space and light (i.e. inspection zones) 12 The reworks are defined. The areas are specified and capable. The checking after rework are defined and done 13 Internal process audit by supplier's quality dept.: -The frequency of I. A. is respected -The quality alerts are included in the audit Other

V Final Product

1 Products storage locations and layout are suitable 2 FIFO is respected

0 0 0

3 Final inspection & test before dispatch & quality records & report in SCS system 4 The S/R parameters are clearly written in final control report The inspector knows all the S/R parameters

NC

Page 5 of 6

MovahedC:\Documents and Settings\781085\Desktop\MPA - final.xls

Process audit checklist

Major NC Remark

Action Plan Comment/Evidence Action Resp. Date

Status

Nr.

Expectation

5 In case of non conformity, corrective actions are done 6 The traceability is effective from entrance to dispatching 7 Packaging, marking and identification are defined and done

Sum

0 0 0

NC

Page 6 of 6

MovahedC:\Documents and Settings\781085\Desktop\MPA - final.xls

Вам также может понравиться

- Communication Control ProcedureДокумент2 страницыCommunication Control Procedurezafeer100% (2)

- Ncnda ImpfaДокумент11 страницNcnda ImpfaLionel Cerizo AseguradoОценок пока нет

- KEPL MR 06 - Management Review MeetingДокумент2 страницыKEPL MR 06 - Management Review MeetingAvijit SenОценок пока нет

- Apqp Check ListДокумент1 страницаApqp Check ListzafeerОценок пока нет

- Project Proposal Excel Template v2.0Документ6 страницProject Proposal Excel Template v2.0zafeerОценок пока нет

- Using WBS To Decompose Specific Project TasksДокумент9 страницUsing WBS To Decompose Specific Project TaskswinsomeОценок пока нет

- Supplier Assessment ChecklistДокумент2 страницыSupplier Assessment ChecklistCOLONEL ZIKRIA100% (1)

- 02 (SQ) Supplier System Audit SheetДокумент5 страниц02 (SQ) Supplier System Audit SheetDEVENDERОценок пока нет

- Sample Procedure FlowДокумент3 страницыSample Procedure Flowvyly1723Оценок пока нет

- CS P11 PurchasingДокумент4 страницыCS P11 PurchasingIdrus IsmailОценок пока нет

- Centurion Power Cables (P) LTD.: 1.0 PurposeДокумент4 страницыCenturion Power Cables (P) LTD.: 1.0 PurposetriveshОценок пока нет

- Process Audit Plan ScheduleДокумент4 страницыProcess Audit Plan ScheduleTravisОценок пока нет

- CS-P03-HR Recruitment TrainingДокумент5 страницCS-P03-HR Recruitment TrainingIdrus IsmailОценок пока нет

- NewPure-DB and KPI 22Документ5 страницNewPure-DB and KPI 22Senthilmani Muthuswamy0% (1)

- Departmental Wise Measurable Master - 2Документ13 страницDepartmental Wise Measurable Master - 2VenkatesanОценок пока нет

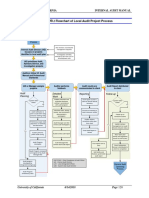

- 6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessДокумент1 страница6000 Appendix 6000.: 2 Flowchart of Local Audit Project ProcessNiken RindasariОценок пока нет

- MSP ProceduresДокумент18 страницMSP ProcedurestarunОценок пока нет

- MTC-IMS-PR-15-Procedure For Externally Provided ProductsДокумент5 страницMTC-IMS-PR-15-Procedure For Externally Provided ProductssouravrobinОценок пока нет

- QMS-F-15 Internal Audit ChecklistДокумент24 страницыQMS-F-15 Internal Audit Checklistmd quasid rabbaniОценок пока нет

- Internal Audit Check Sheet Ok 2016Документ11 страницInternal Audit Check Sheet Ok 2016manttupandeyОценок пока нет

- Turtle Diagrams - Stores + ShippingДокумент1 страницаTurtle Diagrams - Stores + Shippingcem electromechОценок пока нет

- Quality Records Examples ListДокумент6 страницQuality Records Examples ListJoel AlcantaraОценок пока нет

- Cis-Sp-18-Customer Complaints HandlingДокумент5 страницCis-Sp-18-Customer Complaints HandlingVaibhav Gadhawe100% (1)

- Cs-P06-Ca & PaДокумент3 страницыCs-P06-Ca & PaIdrus IsmailОценок пока нет

- Audit Evidence Evaluation Comments: Internal Audit Check List Mr/Cip/Training/Customer ComplaintsДокумент3 страницыAudit Evidence Evaluation Comments: Internal Audit Check List Mr/Cip/Training/Customer ComplaintsganrashОценок пока нет

- Training (HR) - QMP-HR-01Документ3 страницыTraining (HR) - QMP-HR-01Rohit VishwakarmaОценок пока нет

- Process Audit - Checklist - SCRIBDДокумент3 страницыProcess Audit - Checklist - SCRIBDcarryn1Оценок пока нет

- Self Audit Checklist PresentationДокумент20 страницSelf Audit Checklist Presentationnashwan mustafaОценок пока нет

- Internal Audit Check Sheet QualityДокумент6 страницInternal Audit Check Sheet QualityRamdas PaithankarОценок пока нет

- Check List - Product Realisation ProcessДокумент4 страницыCheck List - Product Realisation ProcessDisha ShahОценок пока нет

- List of Records - Formats & RegistersДокумент1 страницаList of Records - Formats & RegistersSuraj KadamОценок пока нет

- Internal Audit Check Sheet MKTGДокумент4 страницыInternal Audit Check Sheet MKTGRamdas PaithankarОценок пока нет

- Template - Management Review ReportДокумент2 страницыTemplate - Management Review ReportIslam WayОценок пока нет

- QMP 07 TrainingДокумент10 страницQMP 07 Trainingom cncОценок пока нет

- CS P09 Project ManagementДокумент4 страницыCS P09 Project ManagementIdrus IsmailОценок пока нет

- Design Process TurtleДокумент2 страницыDesign Process TurtleBAlaОценок пока нет

- Induction Training Text Format - StaffДокумент5 страницInduction Training Text Format - StaffJohnОценок пока нет

- Sample ISO TimelineДокумент2 страницыSample ISO TimelineEHashim Al MunawarahОценок пока нет

- 1 Recruitment: Sr. No Key Result AreaДокумент11 страниц1 Recruitment: Sr. No Key Result AreaJitendra GurjarОценок пока нет

- ASP-NPD-04 (Process of Product Safety)Документ5 страницASP-NPD-04 (Process of Product Safety)akash.vd.1603Оценок пока нет

- Blow Packaging India LTD: List of Approved SuppliersДокумент3 страницыBlow Packaging India LTD: List of Approved Suppliersvishvendan100% (1)

- Pt. Patco Elektronik Teknologi Standard Operating Procedure PurchasingДокумент8 страницPt. Patco Elektronik Teknologi Standard Operating Procedure Purchasingmochammad iqbal100% (1)

- AF-QMSP-14 Procedure For Machine Shop StoreДокумент16 страницAF-QMSP-14 Procedure For Machine Shop StoreSharif KhanОценок пока нет

- Vendor Registration Form (New) SHADABДокумент9 страницVendor Registration Form (New) SHADABChandan Thakur50% (2)

- Process Audit Check Sheet Cum ReportДокумент4 страницыProcess Audit Check Sheet Cum ReportLakshmanan Venkatesan100% (3)

- List of Mandatory Records For ISO 9001Документ2 страницыList of Mandatory Records For ISO 9001NC Rigor Luis100% (2)

- Control of RecordsДокумент3 страницыControl of Recordschahi100% (1)

- Employee Training Tracking Log 2Документ6 страницEmployee Training Tracking Log 2Hiko AdillaОценок пока нет

- Hardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistДокумент1 страницаHardrock Attachments Pvt. LTD.: Preventive Maintenance ChecklistSandeep KumarОценок пока нет

- 003 Corrective Action Report FormДокумент4 страницы003 Corrective Action Report FormRidwan100% (1)

- Supplier Self-Assessment SurveyДокумент15 страницSupplier Self-Assessment SurveyGuillermo AlfaroОценок пока нет

- MFG Process Audit ReportДокумент1 страницаMFG Process Audit ReportBASAVA ENGINEERINGОценок пока нет

- Sub Process: Purchased Parts, Pass Through, Material ManagementДокумент2 страницыSub Process: Purchased Parts, Pass Through, Material ManagementNikhilesh NaikОценок пока нет

- Department Name: Production Department Name: Production: Material ResourcesДокумент21 страницаDepartment Name: Production Department Name: Production: Material ResourcesLesly LesОценок пока нет

- Procedure For Material Requirement Planning & PurchasingДокумент1 страницаProcedure For Material Requirement Planning & PurchasingHarkesh KumarОценок пока нет

- Sharma Enterprises: Contingency Plan For Business ContinuityДокумент1 страницаSharma Enterprises: Contingency Plan For Business ContinuitytriveshОценок пока нет

- Purchasesop 140305221543 Phpapp01Документ11 страницPurchasesop 140305221543 Phpapp01Ankit RastogiОценок пока нет

- Balanced Scorecard Departemen Produksi PERIODE TAHUN .Документ7 страницBalanced Scorecard Departemen Produksi PERIODE TAHUN .mr mrОценок пока нет

- Manufacturing Process Audit Excel FormДокумент2 страницыManufacturing Process Audit Excel FormTri Hdyvtdt100% (1)

- Example of Using Pear FormДокумент2 страницыExample of Using Pear Formjohnoo7Оценок пока нет

- InternalAuditChecklistISO9001 2015Документ28 страницInternalAuditChecklistISO9001 2015syamimi balkhis100% (1)

- Skill Matrix MaterialsДокумент2 страницыSkill Matrix MaterialsRavikant PandeyОценок пока нет

- QMS Audit Check SheetДокумент7 страницQMS Audit Check Sheetaboo2uОценок пока нет

- ACE Silver 2015 PresentationДокумент20 страницACE Silver 2015 PresentationY BОценок пока нет

- QMS Audit Check SheetДокумент7 страницQMS Audit Check Sheetaboo2uОценок пока нет

- Contract ReviewДокумент3 страницыContract Reviewzafeer100% (1)

- PM ChecklistДокумент1 страницаPM ChecklistzafeerОценок пока нет

- NCR Monitoring: OP-002-0 NCR Monitoring From Control of Non-Conforming Products/Services ProcedureДокумент1 страницаNCR Monitoring: OP-002-0 NCR Monitoring From Control of Non-Conforming Products/Services ProcedurezafeerОценок пока нет

- Design Review ChecklistДокумент1 страницаDesign Review ChecklistzafeerОценок пока нет

- Project / Process Audited: .. Audit No.: Car No Date Action Comp. Date Follow-Up Date Car Close-Out DateДокумент1 страницаProject / Process Audited: .. Audit No.: Car No Date Action Comp. Date Follow-Up Date Car Close-Out DatezafeerОценок пока нет

- QM-004-0 Document Distribution, Retrieval and Disposal Form From Control of Documents ProcedureДокумент2 страницыQM-004-0 Document Distribution, Retrieval and Disposal Form From Control of Documents Procedurezafeer100% (1)

- MP-02 Document Control Rev1Документ9 страницMP-02 Document Control Rev1zafeerОценок пока нет

- Tooling Approval Report-0430Документ1 страницаTooling Approval Report-0430zafeerОценок пока нет

- Performance Plan EXCELДокумент4 страницыPerformance Plan EXCELFatih BodrumОценок пока нет

- Planned Preventive Maintenance - SOPДокумент6 страницPlanned Preventive Maintenance - SOPzafeer100% (2)

- Equipment Maintenance Checklist:::: Good Condition:: Needs RepairДокумент2 страницыEquipment Maintenance Checklist:::: Good Condition:: Needs RepairzafeerОценок пока нет

- Example Quality PlanДокумент11 страницExample Quality PlanzafeerОценок пока нет

- Training Effectiveness EvaluateДокумент1 страницаTraining Effectiveness Evaluatezafeer100% (1)

- FORMAT Daily Production ReportДокумент2 страницыFORMAT Daily Production ReportzafeerОценок пока нет

- Preventive Maintenace StatusДокумент1 страницаPreventive Maintenace StatuszafeerОценок пока нет

- Comprehensive MaintenanceДокумент38 страницComprehensive MaintenancezafeerОценок пока нет

- FMT ListДокумент1 страницаFMT ListzafeerОценок пока нет

- Basics Start A Vege GardenДокумент2 страницыBasics Start A Vege GardenzafeerОценок пока нет

- Savings Interest Calculator: Savings Plan Inputs Summary of ResultsДокумент1 страницаSavings Interest Calculator: Savings Plan Inputs Summary of ResultszafeerОценок пока нет

- Assessment To COBIT 4.1 Maturity ModelДокумент5 страницAssessment To COBIT 4.1 Maturity ModelReda El HaraouiОценок пока нет

- Lenovo Case AnalysisДокумент4 страницыLenovo Case AnalysisYasmin Gloria100% (1)

- 7Документ28 страниц7Alex liao0% (1)

- 20 AnnexureДокумент7 страниц20 AnnexureAfreen ShaikhОценок пока нет

- The Real Deal Polly PeckДокумент4 страницыThe Real Deal Polly PeckManda simz100% (1)

- Jmsab: Pengaruh Pajak, Exchange Rate Dan Kepemilikan Asing Terhadap Transfer PricingДокумент8 страницJmsab: Pengaruh Pajak, Exchange Rate Dan Kepemilikan Asing Terhadap Transfer PricingLukmanul HakimОценок пока нет

- Chap 1Документ5 страницChap 1Lệ Mẫn TrầnОценок пока нет

- Syncro Module Orders ExternalДокумент33 страницыSyncro Module Orders ExternalAhmed BouriОценок пока нет

- S4hana-Launch Mena Aborchert - FinalДокумент48 страницS4hana-Launch Mena Aborchert - FinalpilloleonОценок пока нет

- Ocp Ems2017Документ23 страницыOcp Ems2017LeonfungОценок пока нет

- Perancangan Bussiness Process Reenginering Perpustakaan Universitas WidyatamaДокумент23 страницыPerancangan Bussiness Process Reenginering Perpustakaan Universitas WidyatamaSurya NurdinОценок пока нет

- 2115 Human Resource Management Final Short Answer PracticeДокумент4 страницы2115 Human Resource Management Final Short Answer PracticeraymondОценок пока нет

- Customer RetentionДокумент18 страницCustomer RetentionHasnainОценок пока нет

- Six Sigma CH 4Документ26 страницSix Sigma CH 4Anil YadavОценок пока нет

- Acc426 2020Документ3 страницыAcc426 2020faithОценок пока нет

- 5,441 Atal Tinkering Labs $480 MNДокумент4 страницы5,441 Atal Tinkering Labs $480 MNParth Hemant PurandareОценок пока нет

- KFHG Gender Pay Gap Whitepaper PDFДокумент28 страницKFHG Gender Pay Gap Whitepaper PDFWinner#1Оценок пока нет

- BUSINESS FINANCE (Week 6)Документ4 страницыBUSINESS FINANCE (Week 6)elyra blythe salcedoОценок пока нет

- B4B Insight Forum Report (Final)Документ73 страницыB4B Insight Forum Report (Final)THAN HAN100% (1)

- AFAR Quiz Master S Copy FinalДокумент18 страницAFAR Quiz Master S Copy FinalPam G.Оценок пока нет

- AstroДокумент4 страницыAstroR PОценок пока нет

- Policy Theme Our Customers Effective April 14, 2008Документ28 страницPolicy Theme Our Customers Effective April 14, 2008Roshan FarsiwanОценок пока нет

- Quick Profitable Trader PDFДокумент6 страницQuick Profitable Trader PDFNitin GarjeОценок пока нет

- Porters 5Документ3 страницыPorters 5Maureen Joy Esguerra ZamudioОценок пока нет

- Barrett Business Services (BBSI) : A Tick-Tick-Ticking Time BombДокумент32 страницыBarrett Business Services (BBSI) : A Tick-Tick-Ticking Time BombCopperfield_Research100% (1)

- Case 2 - Bata Shweta EbizДокумент6 страницCase 2 - Bata Shweta EbizKavish JainОценок пока нет

- HANDOUT MRK2051 Lecture 13 - Organizational Buying BehaviourДокумент11 страницHANDOUT MRK2051 Lecture 13 - Organizational Buying BehaviourChristopher GauciОценок пока нет

- Real Property Tax Audit With Management Comment and ExhibitsДокумент29 страницReal Property Tax Audit With Management Comment and ExhibitsDaily FreemanОценок пока нет