Академический Документы

Профессиональный Документы

Культура Документы

Finishes 5th Level

Загружено:

Ganesh ReddimiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Finishes 5th Level

Загружено:

Ganesh ReddimiАвторское право:

Доступные форматы

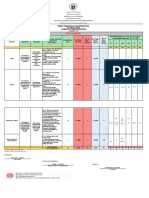

Zikreet Office Building - MJ154

Activity ID A001 Activity description Block work 1 Preparation of area and materials arrangement 2 Layout of block wall and fixing of rebar dowels from concrete slab 3 4 5 6 Fixing of blocks with all anchor and tie system up to bottom of the stiffener beam level Preparation of reinforcement and formwork for cast in-situ stiffener/lintel beams and stiffener columns Inspection of formwork and rebar prior to concreting Concrete pouring for lintles/stiffner beams and stiffener columns OPC 60N

Start date Finish date

Office Building Finishes

Total Days 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 1 2 3 4 5 6 7 8 9 Jul-10 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Medgulf Construction Co. W.L.L

Remarks

A002

7 Water curing concrete up to 7 days 8 Fixing of blocks up to bottom of the suspended slab level 9 Curing of the block work up to 3 days 10 Installation of the electromechanical services 11 Inspection of electromechanical services prior to plaster works Plaster works for internal walls 1 Preparation for plaster work Installation of corner beads, plaster stop and joint lath 2 Applying of the rash coat over the block wall surface 24 hours prior to applying the plaster 3 Applying of plaster 25 mm thick to made smooth finish surface

A003

4 Water curing for plastered surface for 3 days Plaster works for external walls 1 Preparation for plaster work Installation of corner beads, plaster stop and joint lath 2 Applying of the rash coat over the block wall surface 24 hours prior to applying the plaster 3 Applying of plaster 25 mm thick to made smooth finish surface

A004

A005

A006

A007

4 Water curing for plastered surface for 3 days Window fins 1 Marking location of windows fins 2 Installation of GRC window fins and alignment 3 Installation of embedded conduits 4 Inspection of fins prior to applying the shining sand Shining sand application 1 Surface preparation and sanding 2 Inspection of surface and survey report 3 Application of undercoat 4 Application of shining sand 5 Final inspection Waterproofing (roofs) 1 Preparation of structural surface and soaking 2 Installation of floor drains and testing 3 Pouring of screed concrete to slope 4 Application of primer 5 Installation of waterproofing membrane 6 Water leak test 7 Installation of polystyrene board 8 Installation of geo-textile cloth 9 Laying of aggregate 10 Installation of aluminum wall base and sealant application Ceramic tiles for walls (toilets and pantries) 1 Surface preparation, tile layout and vertical alignment prior to fixing the ceramic tiles 2 3 Installation of the wall ceramic tiles by using of Nitotile-489 manufactured by M/s Fosroc Grouting of tile joints by using of Nitotile epoxy grout manufactured by M/s Fosroc

A008

4 Cleaning and protection of the tiles 5 Inspection of the ceramic tiles Waterproofing wet areas 1 Preparation of structural surface 2 Inspection of structural surface 3 Application of two coats Masterseal SP 120 PF and set for drying 4 5 6 Filling of water and water leak test prior to proceeding the screed works Inspection of water leak test Preparation of elevations and pouring of the screed concrete up to bottom of the floor tiles in slope as per mentioned drawings

A009

7 Water curing for screed concrete up to 7 days Ceramic tiles for floors (toilets and pantries) Surface preparation, tile layout and alignment prior to fixing the ceramic tiles Installation of the floor ceramic tiles by using of Nitotile-489 manufactured by M/s Fosroc Grouting of tile joints by using of Nitotile epoxy grout manufactured by M/s Fosroc 9 Installation of floor drains and clean-outs

Ganesh

1 of 6

66047846.xls

Zikreet Office Building - MJ154

Activity ID Activity description 10 Grouting of ceramic tiles by using of Nitotile epoxy grout manufactured by M/s Fosroc A010 11 Cleaning and protection of the tiles Gypsum wall cladding (Internal) 1 Area preparation and marking for gypsum wall cladding 2 Installation of the floor and ceiling runners 3 Installation of the vertical studs at required spacing 4 Installation of the concealed electromechanical services 5 Inspection of the electromechanical services prior to closing the wall board 6 Inspection of the wall framing system 7 Fixing of the hardboard 10mm thick 8 Fixing of the gypsum board over the hardboard Paint woks (Internal) over gypsum and plaster surfaces 1 Preparation of wall surfaces (plaster/gypsum) 2 Inspection of the wall surfaces prior to applying the primer 3 Application of the primer one coat 4 Application of the filler and made smooth finish 5 Inspection of the filler prior to first finish coat 6 Application of the first finish coat 7 Application of the second finish coat 8 Inspection of the final surface Suspended ceiling (Mineral fiber, linear metal and gypsum) 1 Transportation and arrangement of the materials 2 Layout and marking of center lines for suspension system hangers 3 4 5 6 7 8 9 Installation of the suspension hangers on concrete slab Marking and installation of the perimeter angles Installation of the electromechanical services prior to fixing the suspension system Inspection of the electromechanical services prior to closing the ceiling High level clearance by electromechanical trades Installation of the suspension system main grid T runners and cross T runners Alignment and leveling of the suspension system at required elevation

Start date Finish date

Office Building Finishes

Total Days 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 1 2 3 4 5 6 7 8 9 Jul-10 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Medgulf Construction Co. W.L.L

Remarks

A011

A012

10 Laying of the ceiling tiles with cut-outs where required for sprinkler system and fire detectors A013 Blast resistant and metal doors 1 Area preparation and marking 2 Transportation and handling of doors to location 3 Installation of door frames 4 Installation of door leafs 5 Fixing of door hardware 6 Installation access control system 7 Alignment and grouting for doors 8 Final inspection Marble flooring 1 Area preparation and marking layout 2 Transportation and handling of marble tiles 3 Soaking of concrete slab 4 Placing of mortar bedding and application of sealer behind tiles 5 Installation of marble tiles/treads/raisers 6 Cleaning and filling the grout 7 Surface buffing/grinding 8 Polishing and application of wax 9 Final inspection Terrazzo flooring at service staircases 1 Area preparation and marking layout 2 Transportation and handling of terrazzo tiles 3 Soaking of concrete slab 4 Placing of mortar bedding 5 Installation of terrazzo tiles/treads/raisers 6 Cleaning and filling the grout 7 Surface buffing/grinding 8 Polishing and application of wax 9 Final inspection Wooden doors 1 Area preparation and marking 2 Transportation and handling of doors to location 3 Installation of door frames 4 Installation of door leafs 5 Paint touchup and protection 6 Final inspection Pantry units 1 Marking of location for wall and floor units 2 Installation of pantry units 3 Fixing of hardware 4 Cleaning and touchup 5 Final inspection and protection Aluminum windows and curtain walls

A014

A015

A016

A017

A018

Ganesh

2 of 6

66047846.xls

Zikreet Office Building - MJ154

Activity ID Activity description 1 Site survey for actual measurements and verticality 2 Area preparation and marking of windows and curtain walls 3 Transportation and handling of the materials 4 Installation of the framing system and alignment 5 Application of the blast resistant film over the glass panels 6 Installation of the glass panels and final fix of the frames 7 Application of the sealant all around the windows and curtain walls 8 Installation of the integrated aluminum doors in curtain walls 9 Installation of the hardware for doors and windows 11 Final cleaning of the all aluminum works 12 Final inspection and testing Installation of Revolving door 1 Floor preparation and cutting knock outs 2 Installation of floor tracks and floor spring 3 Installation of enclosure 4 Installation of swing leafs 5 Installation of hardware 6 Installation of door lighting 7 Installation of access control system 8 Testing and commissioning 9 Final inspection Demountable partition 1 Site preparation and marking layout for top and bottom runners 2 Materials handling and transportation to site 3 Instillation of the metal framing system 4 Installation of electrical and network conduits & services 5 Inspection of the metal framing system 6 Instillation of the gypsum boards and filling the joints 7 Surface preparation and installation of the wall cloth 8 Installation of the external trims and skirting 9 Installation of the wooden doors and hardware 10 Final alignment and cleaning prior to inspection 11 Final inspection and testing Free standing partition 1 Marking of location 2 Installation of bottom track 3 Installation of wall frames and top rails 4 Alignment and final fix 5 Final inspection Vinyl tiles 1 Site cleaning and preparation for vinyl tile area 2 Inspection of the surface 3 Installation of the vinyl tiles 4 Installation of the vinyl wall base 5 Cleaning and application of wax 6 Final inspection Carpet 1 Surface cleaning and preparation for carpet area 2 Inspection of the surface 3 Transpiration and storage of the carpet tiles to site 4 Installation of the carpet 5 Installation of floor boxes 6 Installation of the edge guards and carpet gripper 7 Final inspection of carpet works 8 Protection of the carpet works Handrails 1 Transportation of materials and handling 2 Marking and fixing of the base plates 3 Installation of the handrails and railing 4 Joints welding 5 Grinding and polishing 6 Protection of handrails 7 Final inspection Toilet cubicles 1 Site preparation and marking layout for cubicles 2 Materials transportation and handling to site 3 Assembling and fixing of bottom framing system 4 Installation of the cubicle walls 5 Installation of hardware 6 Final alignment 7 Final inspection Sanitary items 1 Site preparation and marking 2 Materials handling and transportation to site 3 Installation of the sanitary ware and accessories 4 Testing commissioning 5 Protection of the sanitary works 6 Final inspection Internal signage 1 Preparation of room titles index 2 Marking and installation of signage Expansion joint covers 1 Materials transportation and handling 2 Installation of expansion joint covers on walls and floor

Start date Finish date

Office Building Finishes

Total Days 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 1 2 3 4 5 6 7 8 9 Jul-10 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Medgulf Construction Co. W.L.L

Remarks

A019

A020

A021

A021

A022

A023

A024

A025

A026

A027

Ganesh

3 of 6

66047846.xls

Zikreet Office Building - MJ154

Activity ID 3 Final inspection Testing Pre-commissioning Commissioning Snagging De-snagging Activity description

Start date Finish date

Office Building Finishes

Total Days 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 1 2 3 4 5 6 7 8 9 Jul-10 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Medgulf Construction Co. W.L.L

Remarks

A028 A029 A030 A031 A032

Ganesh

4 of 6

66047846.xls

Zikreet Office Building - MJ154

Activity ID Activity description Block work 1 Preparation of area and materials arrangement 2 Layout of block wall and fixing of rebar dowels from concrete slab 3 4 5 6 Fixing of blocks with all anchor and tie system up to bottom of the stiffener beam level Preparation of reinforcement and formwork for cast in-situ stiffener/lintel beams and stiffener columns Inspection of formwork and rebar prior to concreting Concrete pouring for lintles/stiffner beams and stiffener columns OPC 60N

Start date Finish date

Sub-Station Works up to GFL

Total Days 11 12 13 14 15 16 17 18 19 May-10 20 21 22 23 24 25 26 27 28 29 30 31 1 2 3 4 5 6 7 8 9 Jun-10 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 1 2 Jul-10 3 4 5

Medgulf Construction Co. W.L.L

Remarks

Excavators-2nos Loader and dump trucks Helpers 6 nos Surveyor with helper

Carpenter 4 nos RFI and inspection by RG Mason 5nos and labor 5nos Labor 2nos Surveyor and helper + carpenter 8nos RFI and inspection by RG Mason 5nos and labor 5nos Labor 2nos Surveyor with helper Carpenter 8nos Steel fixer 8nos RFI and inspection by RG Mason 5nos and labor 5nos Carpenter 8nos

7 Water curing concrete up to 7 days 8 Fixing of blocks up to bottom of the suspended slab level 9 Curing of the block work up to 3 days 10 Installation of the electromechanical services 11 Inspection of electromechanical services prior to plaster works Plaster works 1 Preparation for plaster work 2 Applying of the rash coat over the block wall surface 24 hours prior to applying the plaster 3 Applying of plaster 25 mm thick to made smooth finish surface

4 Water curing for plastered surface for 3 days Ceramic tiles for walls (toilets and pantries) 1 Surface preparation, tile layout and vertical alignment prior to fixing the ceramic tiles 2 3 Installation of the wall ceramic tiles by using of Nitotile-489 manufactured by M/s Fosroc Grouting of tile joints by using of Nitotile epoxy grout manufactured by M/s Fosroc

4 Cleaning and protection of the tiles 5 Inspection of the ceramic tiles Waterproofing and installation of floor ceramic tiles for toilets and pantries 1 2 3 4 5 6 Preparation of structural surface Inspection of structural surface Application of two coats Masterseal SP 120 PF and set for drying Filling of water and water leak test prior to proceeding the screed works Inspection of water leak test Preparation of elevations and pouring of the screed concrete up to bottom of the floor tiles in slope as per mentioned drawings Water curing for screed concrete up to 7 days Installation of floor ceramic tiles by using of Nitotile-489 manufactured by M/s Fosroc

Labor 2nos Surveyor with helper Carpenter 8nos Steel fixer 8nos RFI and inspection by RG Mason 5nos and labor 5nos + concrete order to plant

7 8

Labor 2nos Carpenter 8nos Surveyor with helper

9 Installation of floor drains and clean-outs 10 Grouting of ceramic tiles by using of Nitotile epoxy grout manufactured by M/s Fosroc 11 Cleaning and protection of the tiles Gypsum wall cladding Area preparation and marking for gypsum wall cladding Installation of the floor and ceiling runners Installation of the vertical studs at required spacing Installation of the concealed electriomechanical services Inspection of the electromechanical services prior to closing the wall board Inspection of the wall framing system Fixing of the hardboard 10mm thick Fixing of the gypsum board over the hardboard Paint woks (Internal) over gypsum and plaster surfaces Preparation of wall surfaces (plaster/gypsum) Inspection of the wall surfaces prior to applying the primer Application of the primer one coat Application of the filler and made smooth finish Inspection of the filler prior to first finish coat Application of the first finish coat Application of the second finish coat Inspection of the final surface Suspended ceiling Transportation and arrangement of the materials Layout and marking of center lines for suspension system hangers Installation of the suspension hangers on concrete slab Marking and installation of the perimeter angles Installation of the electromechanical services prior to fixing the suspension system Inspection of the electromechanical services prior to closing the ceiling High level clearance by electromechanical trades Installation of the suspension system main grid T runners and cross T runners

Steel fixers 8nos Carpenter 8nos

RFI and inspection by RG Carpenter 8nos Mason 5nos and labor 5nos + concrete order to plant Labor 2nos

Surveyor with helper

Ganesh

5 of 6

file:///opt/scribd/conversion/tmp/scratch2492/66047846.xls

Zikreet Office Building - MJ154

Activity ID Activity description Alignment and leveling of the suspension system at required elevation

Start date Finish date

Sub-Station Works up to GFL

Total Days 11 12 13 14 15 16 17 18 19 May-10 20 21 22 23 24 25 26 27 28 29 30 31 1 2 3 4 5 6 7 8 9 Jun-10 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 1 2 Jul-10 3 4 5

Medgulf Construction Co. W.L.L

Remarks

Steel fixers 8nos Laying of the ceiling tiles with cut-outs where required for sprinkler system Carpenter 8nos RFI and inspection by RG Mason 5nos and labor 5nos + concrete order to plant Carpenter 8nos Labor 2nos Mason 3nos + concrete repair materials Painter/Mason + Masterseal SP 120 Carpenter/Mason 4nos + polyethylene sheet Labor 6nos + Protection board Labor 8 no, backfill materials, loader, bobcat and compactors + lab technician RFI and inspection by RG + lab technician

Ganesh

6 of 6

file:///opt/scribd/conversion/tmp/scratch2492/66047846.xls

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Department of Education: Income Generating ProjectДокумент5 страницDepartment of Education: Income Generating ProjectMary Ann CorpuzОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Project Manager PMP PMO in Houston TX Resume Nicolaas JanssenДокумент4 страницыProject Manager PMP PMO in Houston TX Resume Nicolaas JanssenNicolaasJanssenОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Chapter Three: Tools For Exploring The World: Physical, Perceptual, and Motor DevelopmentДокумент43 страницыChapter Three: Tools For Exploring The World: Physical, Perceptual, and Motor DevelopmentHsieh Yun JuОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Ac221 and Ac211 CourseoutlineДокумент10 страницAc221 and Ac211 CourseoutlineLouis Maps MapangaОценок пока нет

- Internet Bill FormatДокумент1 страницаInternet Bill FormatGopal Singh100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Avid Final ProjectДокумент2 страницыAvid Final Projectapi-286463817Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Unit 4Документ15 страницUnit 4David Lopez LaraОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Revised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10Документ6 страницRevised Final Quarter 1 Tos-Rbt-Sy-2022-2023 Tle-Cookery 10May Ann GuintoОценок пока нет

- Mark Magazine#65Документ196 страницMark Magazine#65AndrewKanischevОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- List of Phrasal Verbs 1 ColumnДокумент12 страницList of Phrasal Verbs 1 ColumnmoiibdОценок пока нет

- Technical Data Sheet TR24-3-T USДокумент2 страницыTechnical Data Sheet TR24-3-T USDiogo CОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Christena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Документ293 страницыChristena Nippert-Eng - Watching Closely - A Guide To Ethnographic Observation-Oxford University Press (2015)Emiliano CalabazaОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- CEN and CENELEC Position Paper On The Proposal For CPR RevisionДокумент15 страницCEN and CENELEC Position Paper On The Proposal For CPR Revisionhalexing5957Оценок пока нет

- Chap9 PDFДокумент144 страницыChap9 PDFSwe Zin Zaw MyintОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Understanding The Marshall AttackДокумент6 страницUnderstanding The Marshall Attacks.for.saad8176Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Buss40004 - Balance of PowerДокумент3 страницыBuss40004 - Balance of PowerVishwa NirmalaОценок пока нет

- En 50124 1 2001Документ62 страницыEn 50124 1 2001Vivek Kumar BhandariОценок пока нет

- The Piano Lesson Companion Book: Level 1Документ17 страницThe Piano Lesson Companion Book: Level 1TsogtsaikhanEnerelОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Electric Vehicles PresentationДокумент10 страницElectric Vehicles PresentationVIBHU CHANDRANSH BHANOT100% (1)

- Uneb U.C.E Mathematics Paper 1 2018Документ4 страницыUneb U.C.E Mathematics Paper 1 2018shafickimera281Оценок пока нет

- Ubi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaДокумент8 страницUbi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaPatrick Glenn BalanzaОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- 3rd Page 5Документ1 страница3rd Page 5api-282737728Оценок пока нет

- Liquid Chlorine SdsДокумент7 страницLiquid Chlorine SdsIPKL RS BHAYANGKARA KEDIRIОценок пока нет

- BioremediationДокумент21 страницаBioremediationagung24864Оценок пока нет

- DIFFERENTIATING PERFORMANCE TASK FOR DIVERSE LEARNERS (Script)Документ2 страницыDIFFERENTIATING PERFORMANCE TASK FOR DIVERSE LEARNERS (Script)Laurice Carmel AgsoyОценок пока нет

- Eng21 (Story of Hamguchi Gohei)Документ9 страницEng21 (Story of Hamguchi Gohei)Alapan NandaОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Zygosaccharomyces James2011Документ11 страницZygosaccharomyces James2011edson escamillaОценок пока нет

- Specification Sheet: Case I Case Ii Operating ConditionsДокумент1 страницаSpecification Sheet: Case I Case Ii Operating ConditionsKailas NimbalkarОценок пока нет

- War at Sea Clarifications Aug 10Документ4 страницыWar at Sea Clarifications Aug 10jdageeОценок пока нет