Академический Документы

Профессиональный Документы

Культура Документы

European Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02

Загружено:

Lenti TiborИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

European Patent Application: 22.06.2011 Bulletin 2011/25 A01D 45/02

Загружено:

Lenti TiborАвторское право:

Доступные форматы

Printed by Jouve, 75001 PARIS (FR)

(19)

E

P

2

3

3

5

4

7

2

A

1

1111LLT111111

(11) EP 2 335 472 A1

(12) EUROPEAN PATENT APPLICATION

(43) Date of publication:

22.06.2011 Bulletin 2011/25

(21) Application number: 09425514.8

(22) Date of filing: 18.12.2009

(51) Int Cl.:

A01D 45/02

(2006.01)

(84) Designated Contracting States:

AT BE BG CH CY CZ DE DK EE ES FI FR GB GR

HR HU IE IS IT LI LT LU LV MC MK MT NL NO PL

PT RO SE SI SK SM TR

Designated Extension States:

AL BA RS

(71) Applicant: Olimac S.r.l.

12081 Beinette (CN) (IT)

(72) Inventor: Carboni, Lorenzo

12081 Beinette (CN) (IT)

(74) Representative: Marchitelli, Mauro

Buzzi, Notaro & Antonielli dOulx Srl

Via Maria Vittoria 18

10123 Torino (IT)

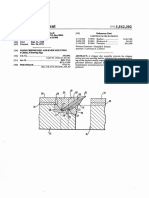

(54) Stalk-chopper and machine for harvesting maize equipped with such stalk-chopper

(57) A stalk-chopper, in particular for a machine for

harvesting maize, comprising:

- a hollow casing (124) having a central portion (126) and

two box-section arms (128) that extend in cantilever fash-

ion from the central portion (126) according to a U-shaped

configuration, the box-section arms (128) being set at a

distance from one another in a transverse direction and

having respective distal ends (128a) set at a distance

from the central portion (126) in a longitudinal direction

(A);

- two rotating output members (130) projecting on the

outside of said box-section arms (128) at the respective

distal ends (128a) of said box-section arms (128), the

output members (128) being carried in a rotatable way

by the respective arms (128) about respective mutually

parallel axes of rotation (E);

- two rotary cutting devices (132) connected to respective

output members (130) and having respective cutting di-

ameters (D) partially overlapping one another; and

- a transmission device (138) housed within said hollow

casing (124) and provided for driving said output mem-

bers (130) in rotation in concordant directions.

EP 2 335 472 A1

2

5

10

15

20

25

30

35

40

45

50

55

Description

BACKGROUND OF THE INVENTION

1. Field of the invention

[0001] The present invention relates to a stalk-chopper

designed to be mounted on a machine for harvesting

maize and a machine for harvesting maize equipped with

said stalk-chopper.

2. Description of the prior art

[0002] Machines for harvesting maize of the most

widely used type comprise a supporting structure de-

signed to be fixed to the combine harvester and carrying

a plurality of harvesting units set alongside one another

in a transverse direction. Each harvesting unit is dedicat-

ed to the harvesting of a row of maize plants. Each har-

vesting unit usually comprises a fixed framework carrying

two stripper plates. Said stripper plates have respective

edges facing one another that form a squeezing channel

for the maize stalks. Each harvesting unit comprises a

pair of counter-rotating traction rollers arranged under-

neath the squeezing channel. The traction rollers grip the

maize stalks and draw them downwards, passing the

stalks between the facing edges of the stripper plates.

The cobs of maize come into contact with the top surfaces

of the stripper plates and are detached from the stalks

as a result of the stalks being drawn down by the traction

rollers.

[0003] Machines for harvesting maize can be

equipped with integrated stalk-choppers designed to car-

ry out chopping of the maize stalks. In the most wide-

spread solutions, each harvesting unit comprises a stalk-

chopper of its own, which includes a rotary cutting device

set underneath the traction rollers.

SUMMARY OF THE INVENTION

[0004] The object of the present invention is to provide

a stalk-chopper, in particular for a machine for harvesting

maize, which will enable more effective chopping of the

stalks than stalk-choppers according to the prior art.

[0005] According to the present invention, this object

is achieved by a stalk-chopper having the characteristics

forming the subject of Claim 1.

[0006] The stalk-chopper according to the present in-

vention comprises a hollow casing having a U-shaped

configuration with the two arms that carry at their distal

ends two output members that are able to turn about

respective mutually parallel axes of rotation, the output

members carrying two rotary cutting devices having re-

spective cutting diameters partially overlapping one an-

other and driven in rotation in concordant directions.

[0007] With the stalk-chopper according to the present

invention, cutting of the stalks is performed between two

blades that move in opposite directions, according to a

shearing mode. The cutting of the stalks is more effective

as compared to the solutions of a known type, where

cutting is performed by a single rotor.

[0008] The present invention moreover relates to a ma-

chine for harvesting maize including a stalk-chopper of

the type referred to above.

DESCRIPTION OF THE DRAWINGS

[0009] The present invention will now be described in

detail with reference to the annexed drawings, which are

provided purely by way of non-limiting example and in

which:

- Figure 1 is a perspective view of a machine for har-

vesting maize according to the present invention;

- Figure 2 is a perspective view of a harvesting unit

indicated by the arrow II in Figure 1;

- Figure 3 is an exploded perspective view of the har-

vesting unit of Figure 2;

- Figure 4 is a perspective view at a larger scale of the

stalk-chopper indicated by the arrow IV in Figure 3;

and

- Figures 5 and 6 are respectively a plan view from

beneath and a side view of the harvesting unit of

Figure 2.

DESCRIPTION OF THE PREFERRED EMBODIMENT

[0010] With reference to Figure 1, designated by 10 is

a machine for harvesting maize designed to be applied

to the front part of a combine harvester of a conventional

type (not illustrated). The machine 10 comprises a sup-

porting structure 12 equipped with means (not illustrated)

for connection to the thresher. The supporting structure

12 has a transverse conveying channel 14, associated

to which is a worm conveyor 16.

[0011] The supporting structure 12 carries a plurality

of harvesting units 18 set alongside one another in a

transverse direction with respect to the direction of ad-

vance of the machine 10, indicated by the arrow A in

Figure 1. Separation prongs 20 are arranged between

adjacent harvesting units 18. The harvesting units 18 car-

ry out detachment of the cobs from the maize stalks in

the way that will be described in what follows. The har-

vesting units 18 convey the cobs towards the conveying

channel 14. The worm conveyor 16 conveys the cobs

contained in the conveying channel 14 towards openings

22 of the supporting structure 12, which face respective

loading mouths of the combine harvester.

[0012] With reference to Figures 2 and 3, each har-

vesting unit 18 comprises a framework 26 fixed with re-

spect to the supporting structure 12. The framework 26

comprises two box sections 28, preferably made of sheet

metal, set at a distance from one another in a transverse

direction by an empty space 30 elongated in a longitudi-

nal direction. The box sections 28 have respective mu-

tually coplanar plane top walls 32 that extend on opposite

1 2

EP 2 335 472 A1

3

5

10

15

20

25

30

35

40

45

50

55

sides of the empty space 30.

[0013] Each harvesting unit 18 comprises two stripper

plates 44 carried by the respective box sections 28 of the

fixed framework 26. The stripper plates 44 have respec-

tive preferably plane top surfaces 44a and respective

edges 46 facing one another. The stripper plates 44 ex-

tend within the respective box-section portions 28. The

parts of the stripper plates 44 adjacent to the edges 46

project on the outside of the box-section portions 28 and

extend on opposite sides in the empty space 30 defined

between the box sections 28. The facing edges 46 define

a squeezing channel 48 elongated in a longitudinal di-

rection A. The stripper plates 44 have respective append-

ages 50 that extend on the outside of the box section 28

on the opposite side of the squeezing channel 48.

[0014] Preferably, the stripper plates 44 are mobile in

a vertical direction with respect to the respective box sec-

tions 28 between a raised position and a lowered position

and are associated to respective spring devices (not vis-

ible in the drawings) that push the stripper plates 44 elas-

tically towards the respective raised positions.

[0015] Preferably, the stripper plates 44 are associat-

ed to an automatic adjustment mechanism 62 that auto-

matically adapts the width of the squeezing channel 48

to the size of the maize stalks. The adjustment mecha-

nism 62 comprises, for each stripper plate 44, a rocker

64 and an elastic device 66. Each rocker 64 is articulated

in a central part thereof to the respective box section 28.

The top end of each rocker 64 is articulated to a respec-

tive appendage 50 of a stripper plate. The bottom end of

each rocker 64 is articulated to a mobile element of the

elastic device 66. The forces produced by the elastic de-

vices 66 push the edges 46 of the stripper plates 44 to-

wards one another in such a way that the edges 46 are

constantly pressed against the maize stalks entering the

squeezing channel 48. The stripper plates 44 move in a

transverse direction according to the diameter of the

stalks entering the squeezing channel 48. Consequently,

the width of the squeezing channel 48 automatically

adapts to the diameter of the stalks.

[0016] With reference to Figure 3, each harvesting unit

18 comprises a pair of counter-rotating traction rollers 82

arranged underneath the squeezing channel 48. The

traction rollers 82 are carried in cantilever fashion by a

respective transmission assembly 86 fixed to the sup-

porting structure 12. The transmission assembly 86

drives the rollers 82 in rotation about respective mutually

parallel longitudinal axes 88. The traction rollers 82 are

preferably equipped with blades designed to grip the

stalks that are in the squeezing channel 48.

[0017] The rotation of the traction rollers 82 causes a

traction of the stalks in a vertical direction. The maize

stalks enter the squeezing channel 48 as a result of the

advance of the machine 10 in the direction A. The rollers

82 draw the stalks that are in the squeezing channel 48

downwards. The edges 46 of the stripper plates 44 are

pressed against the stalks so that the width of the squeez-

ing channel 48 is equal to the diameter of the stalks. The

cobs come into contact with the top surfaces 44a of the

stripper plates 44. The action of drawing downwards of

the stalks caused by the rotation of the traction rollers 82

brings about detachment of the cobs from the stalks. The

detached cobs remain on the top surface 44a of the strip-

per plates 44.

[0018] Each harvesting unit 18 comprises a pair of har-

vesting chains 24. The harvesting chains 24 are arranged

on top of the respective box sections 28 of the framework

26. Each harvesting chain 24 is wound in a closed loop

on a drive gear 90 and on a return gear 92. The drive

gears are driven in rotation about respective vertical axes

by the transmission assembly 86. The return gears 92

are preferably carried by respective spring tensioners 94

fixed to the top walls 32 of the box sections 28.

[0019] With reference to Figures 2 and 3, each har-

vesting chain 24 carries a plurality of thrust elements 96

that project from the outer side of the respective chain

24. The thrust elements 96 push the cobs that lie on the

top surfaces 44a of the stripper plates 44 in a direction

of harvesting F opposite to the direction of advance A.

The thrust elements 96 convey the cobs towards the

transverse conveying channel 14. Preferably, at least

one of the thrust elements 96 of each chain 24 carries a

member for gathering the grains 98 designed to convey

in the direction of harvesting F the loose grains of maize

G that lie on the top surfaces 44a of the stripper plates

44. Preferably, each member for gathering the grains 98

has a flexible contact portion 100 that slides against the

top surface 44a.

[0020] With reference to Figure 3, the transmission as-

sembly 86 of each harvesting unit 18 comprises a paral-

lelpipedal casing 102 having a top face 104, a bottom

face 106, a front face 108, two side faces 110, and a rear

face 112. The rear face 112 is fixed to the supporting

structure 12. The drive gears 90 that drive the harvesting

chains 24 are arranged on top of the top face 104. Pro-

vided on the front face 108 are rotating output members

114 coupled to which are the traction rollers 82. Provided

on the side faces 110 are coupling members 116 con-

nected to corresponding coupling members of adjacent

harvesting units. A coupling member 116 of one of the

harvesting units is connected to a transmission (not illus-

trated) designed to be connected to a power offtake of

the thresher. Housed within the casing 102 is a gear

mechanism that connects the coupling members 116,

the drive gears 90, and the output members 114 opera-

tively to one another.

[0021] With reference to Figures 3 and 4, each har-

vesting unit 18 comprises a respective stalk-chopper

118. The stalk-chopper 118 comprises a fixing plate 120

connected, for example by means of screws 122, to the

bottom face 106 of the transmission assembly 86. The

stalk-chopper 118 comprises a hollow casing 124 having

a general U shape. The hollow casing 124 comprises a

central portion 126 and two arms 128 that extend in can-

tilever fashion from the central portion 126. The arms 128

are set at a distance from one another in a transverse

3 4

EP 2 335 472 A1

4

5

10

15

20

25

30

35

40

45

50

55

direction and have respective distal ends 128a set at a

distance from the central portion 126 in the longitudinal

direction A so as to form an empty space 129 closed on

three sides by the arms 128 and by the central portion

126.

[0022] With reference to Figures 3 and 5, the arms 128

of the hollow casing 124 are arranged underneath the

box sections 28 and are shifted laterally outwards with

respect to the traction rollers 82. The squeezing channel

48 and the traction rollers are positioned above the empty

space 129.

[0023] The arms 128 carry two output members 130

that project on the outside of the box-section arms 128

at the respective distal ends 128a. The output members

130 are carried in a rotatable way by the respective arms

128 about respective mutually parallel axes of rotation E.

[0024] With reference to Figure 4, the stalk-chopper

118 comprises two rotary cutting devices 132 connected

to respective output members 130. Preferably, each cut-

ting device 132 comprises a hub 134 fixed to the respec-

tive output member 130, and two blades 136 fixed to the

hub 134 and diametrally opposite to one another with

respect to the axis of rotation E. The number of the blades

and their arrangement could vary with respect to what is

illustrated.

[0025] With reference to Figures 4 and 5, the cutting

devices 132 have respective cutting diameters D that par-

tially overlap one another. For the cutting diameters D to

partially overlap one another the distance between the

axes of rotation E must be smaller than the cutting diam-

eter D. In the case where the cutting diameters D are

different from one another, the distance between the ax-

es of rotation E must be less than the mean value of the

cutting diameters.

[0026] To avoid any interference the distance between

the axes of rotation must moreover be greater than the

cutting radius or greater than the largest cutting radius

in the case of different cutting diameters.

[0027] With reference to Figure 6, to avoid any inter-

ference the blades 136 of the cutting devices 132 are

staggered with respect to one another in a direction par-

allel to the axes of rotation E.

[0028] With reference to Figure 4, the stalk-chopper

18 comprises a transmission device 138 housed within

the hollow casing 124. The transmission device 138 is

provided for driving the cutting devices 132 in rotation in

concordant directions about the respective axes of rota-

tion E.

[0029] In other words, in operation the cutting devices

132 turn both in a clockwise and in a counterclockwise

direction.

[0030] In the embodiment illustrated, the transmission

device 138 comprises a central gear 140, two output

gears 142, and two series of return gears 144, cascaded

between the central gear 140 and the output gear 142.

The transmission device 138 could be made differently

from what has been illustrated, for example with chain

transmissions or transmissions of another type.

[0031] The output gears 142 are fixed to the respective

output members 130. The central gear 140 is fixed to an

input member 148 that projects on the outside of the hol-

low casing 124. With reference to Figure 3, the input

member 148 is connected to a corresponding output

member (not visible) of the transmission assembly 86

positioned on the bottom face 106 of the casing 102.

[0032] The rotation in concordant directions of the cut-

ting devices 132 means that, in the area of overlapping

of the cutting diameters D, the blades 136 move in op-

posite directions to one another. Consequently, in oper-

ation, the blades 136 carry out a shearing of the stalks

whilst these are pushed into the empty space 129 by the

traction rollers 82. The shearing performs a finer and

more effective chopping of the stalks as compared to

stalk-chopper of a known type.

[0033] The stalk-chopper according to the invention is

particularly suited for use in machines for harvesting

maize, but could also be used in agricultural machines

of another type.

Claims

1. A stalk-chopper, in particular for a machine for har-

vesting maize, comprising:

- a hollow casing (124) having a central portion

(126) and two box-section arms (128) that ex-

tend in cantilever fashion from the central portion

(126) according to a U-shaped configuration, the

box-section arms (128) being set at a distance

from one another in a transverse direction and

having respective distal ends (128a) set at a dis-

tance from the central portion (126) in a longitu-

dinal direction (A);

- two rotating output members (130) projecting

on the outside of said box-section arms (128) at

the respective distal ends (128a) of said box-

section arms (128), the output members (128)

being carried in a rotatable way by the respective

arms (128) about respective mutually parallel

axes of rotation (E);

- two rotary cutting devices (132) connected to

respective output members (130) and having re-

spective cutting diameters (D) partially overlap-

ping one another; and

- a transmission device (138) housed within said

hollow casing (124) and provided for driving said

output members (130) in rotation in concordant

directions.

2. The stalk-chopper according to Claim 1, wherein the

distance between said axes of rotation (E) is smaller

than the cutting diameter (D) or to the mean cutting

diameter of said rotary cutting devices (132).

3. The stalk-chopper according to Claim 2, wherein the

5 6

EP 2 335 472 A1

5

5

10

15

20

25

30

35

40

45

50

55

distance between said axes of rotation (E) is greater

than the cutting radius or than the greater cutting

radius of said rotary cutting devices (132).

4. The stalk-chopper according to Claim 1, wherein

said transmission device (138) comprises a central

gear (140), two output gears (142) connected to said

rotating output members (130), and two series of re-

turn gears (144) cascaded between the central gear

(140) and the output gears (142).

5. A machine for harvesting maize, comprising a sup-

porting structure (12) carrying a plurality of harvest-

ing units (18) set alongside one another in a trans-

verse direction, wherein each harvesting unit (18)

comprises:

- a framework (26), which is fixed with respect

to the supporting structure (12) and includes two

box sections (28) set at a distance from one an-

other in a transverse direction by an empty

space (30) elongated in a longitudinal direction

(A);

- two stripper plates (44) carried by respective

box sections (28), the stripper plates (44) having

respective top surfaces (44a) and respective

edges (46) facing one another that extend on

opposite sides in said empty space (30), the fac-

ing edges (46) of said stripper plates (44) form-

ing a squeezing channel (48);

- a pair of counter-rotating traction rollers (82)

arranged underneath said squeezing channel

(48), which are provided for drawing downwards

stalks of maize plants contained in said squeez-

ing channel (48) in such a way that, in operation,

the cobs of the maize plants contained in said

squeezing channel (48) are detached from the

respective stalks and gather on said top surfac-

es (44a) of said stripper plates (44);

- a pair of harvesting chains (24), which move

along respective closed-loop paths and are

equipped with respective thrust elements (96),

which move on top of respective top surfaces

(44a) of said stripper plates (44) for drawing in

a direction of harvesting (F) the cobs (C) that lie

on said stripper plates (44); and

- a stalk-chopper device (118) according to one

or more of Claims 1-4, set underneath said trac-

tion rollers (82).

7 8

EP 2 335 472 A1

6

EP 2 335 472 A1

7

EP 2 335 472 A1

8

EP 2 335 472 A1

9

EP 2 335 472 A1

10

EP 2 335 472 A1

11

EP 2 335 472 A1

12

EP 2 335 472 A1

13

Вам также может понравиться

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANДокумент6 страницWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaОценок пока нет

- Jurnal Bubut FixsafasfasfДокумент6 страницJurnal Bubut FixsafasfasfAdiBimaSanjaya100% (1)

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Документ3 страницыM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonОценок пока нет

- H. J. Smith: Potato Cutting Machine 28 Filed 00Документ3 страницыH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaОценок пока нет

- United States Patent - (191: Mayeux Et AlДокумент4 страницыUnited States Patent - (191: Mayeux Et AlRodrigoPomaОценок пока нет

- EP1321438B1Документ10 страницEP1321438B1Alessandro PatanèОценок пока нет

- US2099314Документ3 страницыUS2099314Jhonnatan E Avendaño Florez100% (1)

- TEPZZ 957 - 9ZB - T: European Patent SpecificationДокумент10 страницTEPZZ 957 - 9ZB - T: European Patent SpecificationAna LisaОценок пока нет

- Hypoid Gear CuttingДокумент9 страницHypoid Gear CuttingHano LourensОценок пока нет

- 19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Документ5 страниц19mg WK.: June 1, 1954 J. H. Breisch 2,579,786Azri LunduОценок пока нет

- ?T T T - FT ?: April 9, 1968Документ6 страниц?T T T - FT ?: April 9, 1968Pooria1989Оценок пока нет

- Us1223254 PDFДокумент7 страницUs1223254 PDFRodrigoPomaОценок пока нет

- United States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986Документ3 страницыUnited States Patent (191: Gray (45) Date of Patent: Mar. 25, 1986wahaha06Оценок пока нет

- United States Patent (19) : Miiller (45) Date of PatentДокумент8 страницUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaОценок пока нет

- Us2765819 PDFДокумент8 страницUs2765819 PDFAzri LunduОценок пока нет

- Us1955360 PDFДокумент8 страницUs1955360 PDFRodrigoPomaОценок пока нет

- The Line Boring MachineДокумент8 страницThe Line Boring MachineJinky L. LavegaОценок пока нет

- Coco Inven PDFДокумент4 страницыCoco Inven PDFsushil-funОценок пока нет

- United States Patent (191: OuelletteДокумент7 страницUnited States Patent (191: OuellettecxzczxОценок пока нет

- Us2935914 PDFДокумент14 страницUs2935914 PDFMichael LaneОценок пока нет

- Aug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1Документ4 страницыAug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1raseks1Оценок пока нет

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Документ13 страниц(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuОценок пока нет

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetДокумент7 страницCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitОценок пока нет

- Another Corn Dog Machine PatentДокумент14 страницAnother Corn Dog Machine PatentMinnesota Public RadioОценок пока нет

- Byfwf p41 ': March 7, 1961 O. Danyluke 2,973,909Документ5 страницByfwf p41 ': March 7, 1961 O. Danyluke 2,973,909KrozeОценок пока нет

- Us 8210068us 8210068us 8210068us 8210068Документ9 страницUs 8210068us 8210068us 8210068us 8210068JameszouqunОценок пока нет

- European Patent Application A46D 3/06Документ21 страницаEuropean Patent Application A46D 3/06AGUAVIVANJОценок пока нет

- A. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .Документ4 страницыA. Zahoransky 1,936,743: Filed March 2, 1931 2. Sheets-Sheet .AGUAVIVANJОценок пока нет

- April 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932Документ8 страницApril 25, 1933. J. 5. Finlay Et Al: Filed Feb 25, 1932jojaberiОценок пока нет

- Dual Acting ShaperДокумент30 страницDual Acting ShaperAbhijeet NaikОценок пока нет

- US4335764Документ7 страницUS4335764Jorge ArbelaezОценок пока нет

- United States Patent (191: Von Kale! Et AlДокумент18 страницUnited States Patent (191: Von Kale! Et AlJoão Paulo Canto RibeiroОценок пока нет

- Us4854065 PDFДокумент7 страницUs4854065 PDFJin SongОценок пока нет

- Us20030075626 PDFДокумент28 страницUs20030075626 PDFprouserdesigner77Оценок пока нет

- US2128620 - Bending MachineДокумент5 страницUS2128620 - Bending MachinedevheadbotОценок пока нет

- Ulllted States Patent (10) Patent N0.: US 7,610,957 B2Документ8 страницUlllted States Patent (10) Patent N0.: US 7,610,957 B2lfilippiniОценок пока нет

- W, B. Kidder. : Tree Climbing MotorДокумент4 страницыW, B. Kidder. : Tree Climbing Motormonem2014Оценок пока нет

- CN107860183A Claims 202106090012Документ2 страницыCN107860183A Claims 202106090012Nora LlenoОценок пока нет

- United States Patent (19) : HermannsДокумент3 страницыUnited States Patent (19) : HermannsIvan ReyesОценок пока нет

- Dau TomДокумент6 страницDau TomPham LoiОценок пока нет

- European Patent Application: Double-Barrelled Gun and Two-Row MagazineДокумент29 страницEuropean Patent Application: Double-Barrelled Gun and Two-Row Magazineala2356Оценок пока нет

- Nun M.: BC BM 0000Документ12 страницNun M.: BC BM 0000shdhsjkОценок пока нет

- Us 4207797Документ7 страницUs 4207797fghdfjerОценок пока нет

- European Patent Specification: Motor For Washing MachineДокумент16 страницEuropean Patent Specification: Motor For Washing MachineavalosheОценок пока нет

- Fieie) : ' Jan. 5, 1971 N. T. Fosse Etal 3,551,958Документ6 страницFieie) : ' Jan. 5, 1971 N. T. Fosse Etal 3,551,958adrianomc25Оценок пока нет

- Braiding MachineДокумент7 страницBraiding Machinejojaberi100% (1)

- June 23, 1925.: F . I: ZacherДокумент3 страницыJune 23, 1925.: F . I: ZachershamsОценок пока нет

- US3361235Документ3 страницыUS3361235Scaricatore92Оценок пока нет

- Us 5176330Документ7 страницUs 5176330ManivannanMudhaliarОценок пока нет

- EP1070663A2Документ4 страницыEP1070663A2atabОценок пока нет

- CN111284031A-Machine TranslationДокумент19 страницCN111284031A-Machine TranslationutkarshОценок пока нет

- United States Patent (19) (11) Patent Number: 5,243,873Документ10 страницUnited States Patent (19) (11) Patent Number: 5,243,873Nile_JockeyОценок пока нет

- Hwa M: March 16, 1911 - J, T. Del'Vecchm 3,570,129Документ8 страницHwa M: March 16, 1911 - J, T. Del'Vecchm 3,570,129diordesasОценок пока нет

- CGNT-209 ManualДокумент28 страницCGNT-209 Manualgabriel martinezОценок пока нет

- US20010024927A1Документ7 страницUS20010024927A1MahnooshОценок пока нет

- Title - Wood Chipper Disc and Knife MountingДокумент5 страницTitle - Wood Chipper Disc and Knife Mountingمحمد عبدالدايمОценок пока нет

- Mica DescrptionДокумент8 страницMica DescrptionmpkkbtechОценок пока нет

- Us4522105 PDFДокумент10 страницUs4522105 PDFJin SongОценок пока нет

- April 2, 1963 R. I. Lund: Mixing Mill Accumulating Shelf Filed Feb. 8. 1962Документ5 страницApril 2, 1963 R. I. Lund: Mixing Mill Accumulating Shelf Filed Feb. 8. 1962Eduardo Fernandez DazaОценок пока нет

- Celex 42012X0508 en TXTДокумент18 страницCelex 42012X0508 en TXTLenti TiborОценок пока нет

- SGG ECKELT Emalit Seralit Minta ENДокумент9 страницSGG ECKELT Emalit Seralit Minta ENLenti TiborОценок пока нет

- Systron Tools Esx ENДокумент2 страницыSystron Tools Esx ENLenti TiborОценок пока нет

- K-TEX 930 - Gloves - Honeywell SafetyДокумент1 страницаK-TEX 930 - Gloves - Honeywell SafetyLenti TiborОценок пока нет

- Systron Tools Esx Catalogue-Parameter-Guide ENДокумент7 страницSystron Tools Esx Catalogue-Parameter-Guide ENLenti TiborОценок пока нет

- Henniker Plasma Surface Testing OverviewДокумент7 страницHenniker Plasma Surface Testing OverviewLenti TiborОценок пока нет

- Surface Silicone Contamination Test Kit - Henniker Plasma TreatmentДокумент1 страницаSurface Silicone Contamination Test Kit - Henniker Plasma TreatmentLenti TiborОценок пока нет

- EN 62262-2002 - enДокумент12 страницEN 62262-2002 - enLenti Tibor100% (1)

- En SGG BiocleanДокумент4 страницыEn SGG BiocleanLenti TiborОценок пока нет

- Safety Data Sheet: HI 70300 Storage Solution, For PH and ORP ElectrodesДокумент4 страницыSafety Data Sheet: HI 70300 Storage Solution, For PH and ORP ElectrodesLenti TiborОценок пока нет

- 2016 - IFT Cekal PU 2Документ5 страниц2016 - IFT Cekal PU 2Lenti TiborОценок пока нет

- Bavelloni VE500 Water QualityДокумент1 страницаBavelloni VE500 Water QualityLenti TiborОценок пока нет

- Safety Data Sheet: HI 7007 Buffer Solution PH 7.01Документ3 страницыSafety Data Sheet: HI 7007 Buffer Solution PH 7.01Lenti TiborОценок пока нет

- Safety Data Sheet: HI 7032 TDS Calibration Solution, 1382 MG/L at 25°C/77°FДокумент3 страницыSafety Data Sheet: HI 7032 TDS Calibration Solution, 1382 MG/L at 25°C/77°FLenti TiborОценок пока нет

- Safety Data Sheet: HI 7031 Conductivity Calibration Solution, 1413 S/CM at 25°C/77°FДокумент3 страницыSafety Data Sheet: HI 7031 Conductivity Calibration Solution, 1413 S/CM at 25°C/77°FLenti TiborОценок пока нет

- Safety Data Sheet: HI 7010 Buffer Solution PH 10.01Документ3 страницыSafety Data Sheet: HI 7010 Buffer Solution PH 10.01Lenti TiborОценок пока нет

- Insulating Glass-Sealant GD 115: Solvent-Free, One-Component Primary SealantДокумент1 страницаInsulating Glass-Sealant GD 115: Solvent-Free, One-Component Primary SealantLenti TiborОценок пока нет

- 2016 - IFT Cekal PU 2Документ5 страниц2016 - IFT Cekal PU 2Lenti TiborОценок пока нет

- Glaston FC Series: The Masterpiece of IntelligenceДокумент12 страницGlaston FC Series: The Masterpiece of IntelligenceLenti TiborОценок пока нет

- Geometric Dimensioning and TolerancingДокумент30 страницGeometric Dimensioning and TolerancingLenti TiborОценок пока нет

- Bases Diseño TechnipДокумент13 страницBases Diseño TechnipJuan Roberto López BetanzosОценок пока нет

- BS 7910-2019 Guide To Methods For Assessing The Acceptabilty of Flaws in Metallic StructuresДокумент3 страницыBS 7910-2019 Guide To Methods For Assessing The Acceptabilty of Flaws in Metallic Structuresfarombimathew4Оценок пока нет

- DC GeneratorДокумент3 страницыDC GeneratorDurga SampathОценок пока нет

- Diesel Engine Rebuild Kits, Overhaul Kits and Parts For CAT, Detroit, Cummins PDFДокумент1 страницаDiesel Engine Rebuild Kits, Overhaul Kits and Parts For CAT, Detroit, Cummins PDFAndres AraqueОценок пока нет

- Mixed Mode VentilationДокумент6 страницMixed Mode VentilationdaveleyconsОценок пока нет

- Heavy Duty Flyer CatalogДокумент7 страницHeavy Duty Flyer CatalogJessie BechaydaОценок пока нет

- USA - Lindapter High Slip Resistance ClampsДокумент7 страницUSA - Lindapter High Slip Resistance ClampstckittuОценок пока нет

- Hardness Conversion Table: Tensile StrengthДокумент1 страницаHardness Conversion Table: Tensile StrengthMehdy HosseiniОценок пока нет

- Okuma OSP P300S Operation ManualДокумент415 страницOkuma OSP P300S Operation Manualsunhuynh100% (4)

- Vertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFДокумент4 страницыVertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFJhonnatan Fredy Gomez DominguezОценок пока нет

- PROSIS Part Information: 8/3/2011 1054905 20060 EC700B LC Volvo 10001-214/100 Valve MechanismДокумент3 страницыPROSIS Part Information: 8/3/2011 1054905 20060 EC700B LC Volvo 10001-214/100 Valve MechanismPower MobileОценок пока нет

- 18V2000G63-TB 0-10000hДокумент9 страниц18V2000G63-TB 0-10000hNabesterNajamОценок пока нет

- Betopom Arastirma 2Документ31 страницаBetopom Arastirma 2KvncGmz DzrОценок пока нет

- Specifications: INI Ydraulic XcavatorДокумент2 страницыSpecifications: INI Ydraulic XcavatorAchariya ParpromОценок пока нет

- Colony Corner 36" X 36" Shower StallДокумент2 страницыColony Corner 36" X 36" Shower Stalldenon95Оценок пока нет

- The Kinematics of Rigid Body Motion, GPS Ch. 4: Ijk IjkДокумент2 страницыThe Kinematics of Rigid Body Motion, GPS Ch. 4: Ijk IjkAmina IbrahimОценок пока нет

- Yamaha Model GuideДокумент8 страницYamaha Model GuideMohd Musa100% (3)

- Statistical Thermodynamics - An Engineering ApproachДокумент284 страницыStatistical Thermodynamics - An Engineering Approachhgutierrezcable0% (1)

- Introduction To ThermodynamicsДокумент45 страницIntroduction To ThermodynamicsHumberto Alejandro Lopez GarcesОценок пока нет

- Part Manual CondensersДокумент109 страницPart Manual CondensersEep Saepudin HambaliОценок пока нет

- R C C Beam DesignДокумент6 страницR C C Beam DesignediezelОценок пока нет

- Handout - Equation Sheet and Review For First MidtermДокумент8 страницHandout - Equation Sheet and Review For First MidtermRahul CRОценок пока нет

- Ships Spares CatalogueДокумент35 страницShips Spares CatalogueChittagong Port AgentОценок пока нет

- EIT Masters Engineering MIA BrochureДокумент28 страницEIT Masters Engineering MIA BrochureRichard AnarfiОценок пока нет

- Comparison of Effective Width Method, Pigeaud's Theory and Westergaad's Method With SAP2000 Fem ModelДокумент14 страницComparison of Effective Width Method, Pigeaud's Theory and Westergaad's Method With SAP2000 Fem ModelAkarshGowdaОценок пока нет

- MCQ Failure TheoriesДокумент46 страницMCQ Failure TheoriesfdsfsdfsdfsfsОценок пока нет

- Manual de Calibracion de Valvulas Del Daihatsu Toyota TeriosДокумент10 страницManual de Calibracion de Valvulas Del Daihatsu Toyota Teriosahmed zhranОценок пока нет

- Lec 6 Entropy and The Second Law of ThermodynamicsДокумент77 страницLec 6 Entropy and The Second Law of ThermodynamicsACCOUNT ONEОценок пока нет

- PipeFittings CatalogДокумент11 страницPipeFittings Catalogjimmy sadewaОценок пока нет

- Quick Start Guide: Operating & Maintenance InstructionsДокумент20 страницQuick Start Guide: Operating & Maintenance InstructionsEnrique CaboОценок пока нет