Академический Документы

Профессиональный Документы

Культура Документы

B. Tech. III

Загружено:

Shubham GuptaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

B. Tech. III

Загружено:

Shubham GuptaАвторское право:

Доступные форматы

Sr. No.

Course

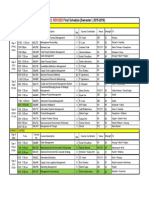

Scheme for Teaching & Examination B. Tech. - III (Mechanical) Fifth Semester Exam Scheme Teaching Total Scheme Code Credits Theory Tuto. Pract. Marks L T P Hrs. Marks Marks Marks ME 301 ME 303 ME 305 PR 301 3 3 3 3 1 1 1 1 2 2 2 2 2 2 2 2 100 100 100 100 25 25 25 25 50 50 50 50 175 175 175 175 5 5 5 5 3 23

1 2 3 4 5

Dynamics of Machines Heat & Mass Transfer Fluid Machines Machining Processes

Institute Elective I* 3 0 0 2 100 100 TOTAL 15 4 8 500 100 200 800 Total contact Hrs. per week (27) Total Credits =23 Total Marks = 800

Sr. No. 1 2 3 4 5

B. Tech. III (Production) Fifth Semester Teaching Exam Scheme Scheme Theory Tuto. Pract. Total Credits Course Code Marks L T P Hrs. Marks Marks Marks Dynamics of Machines Machining Processes Industrial Instrumentation & Control Industrial Engineering & Ergonomics Institute Elective - I* ME 301 PR 301 PR 303 PR 305 3 3 3 3 3 1 1 1 1 0 2 2 0 2 0 2 2 2 2 2 100 100 100 100 100 25 25 25 25 50 50 50 175 175 125 175 100 5 5 4 5 3 22

TOTAL 15 4 6 500 100 150 750 Total contact Hrs. per week (25) Total Credits =22 Total Marks = 750 Institute Elective - I* ME 309 : Applied Therm odynamics ME 311 : Experimental Stress Analysis PR 307 : Industrial Tribology & Vibration (Not for Mech anical) ME 313 : Plastics & Ceramics ME 315 : Theory of Elasticity

B. Tech. (MECHANICAL) Semester - 5 ME 301 DYNAMICS OF MACHINES

L 3

T 1

P 2

C 5

INTRODUCTION (10 Hours) Forces, couples, conditions of static equilibrium, free body diagrams, analysis of mechanisms, spur gears, worm gears. DYNAMIC FORCE ANALYSIS (12 Hours) Inertia forces, analysis of a floating link, rotation, method of virtual work. Dy namic analysis of Four-link mechanism, combined static and inertia force analysis of different mechanisms, turning moment diagrams, fluctuation of energy, flywheels. BALANCING (10 Hours) Introduction, static balancing, dynamic balancing of several masses in different planes. Balancing of inline engines, V-engines, radial engines, balancing machines. GOVERNORS (08 Hours) Introduction, types of governors, sensitiveness of a governor, hunting, isochronisms, stability, effort and power of a governor, controlling force. GYROSCOPE (05 Hours) Angular velocity, angular acceleration, gyroscopic couple, g yroscopic effect on naval ships, stability of an automobile, stability of a two wheel vehicle. (Total Lecture Hours: 45 + Tutorial Hrs: 15) PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. Slider crank mechanism Four bar chain mechanism Quick Return mechanism Hookes joint Cam Mechanism Balancing of rotors Governors Experiment on gear generation

BOOKS RECOMMENDED 1. 2. 3. 4. 5. 6. Thomas Bevan, Theory of Machines, CBS Publishers, New Delhi, 1984. Rattan S.S., Theory of Machines, Tata McGraw Hill, 2005. Rao J. S. and Dukkipati R.V., Mechanism and Machine Theory, Wiley Eastern, 1992. Shigley J. E. and Uicker J.J. , Theory of Machines and Mechanism s, McGraw Hill, 1995. Ballaney P. L., Theory of Machines, Khanna Publishers, 1999. Singh V. P., Theory of Machines, Dhanpat Rai & Sons, 2001.

B. Tech. (MECHANICAL) Semester 5 ME 303 HEAT & MASS TRANSFER INTRODUCTION Modes of heat transfer, conduction, convection and radiation.

L 3

T 1

P 2 (02 Hours)

C 5

CONDUCTION (10 Hours) Fouriers law. General three dimensional heat conduction equation in cartesion, cylindrical and spherical co ordinates. One dimensional steady conduction through plane wall, cylinder and sphere. Heat source systems in plane wall and cylinder. Heat transfer from fins of uniform cross section. Two dimensional steady state conduction through plane wall. One dimensional unsteady state heat conduction. CONVECTION (14 Hours) Free and forced convection. o Forced Convection: Energy integral equation of the boundary layer on a flat plate and integral solution for evaluation of heat transfer from a fluid friction and heat transfer, Similarity conditions in heat transfer, processes, and dimensional analysis. o Free Convection from a vertical flat plate, Grashoff number, Empirical relations and their use. Fundamentals of boiling & condensation heat transfer. RADIATION (08 Hours) Thermal radiation, monochromatic a nd total emissive power. basic laws of radiation. Radiation shape factors, black and grey surfaces, heat transfer in presence of re -radiating surfaces. HEAT EXCHANGERS (06 Hours) Basic types of heat exchangers, fouling factors, LMTD, Effectivene ss NTU methods of design. MASS TRANSFER (05 Hours) Ficks laws of diffusion, diffusion in dilute solutions in stationary media, one dimensional diffusion in gases with one component stationary. Convective mass transfer: Forced diffusion from a flat plate. Simulation of heat and mass transfer. (Total Lecture Hours: 45 + Tutorial Hrs: 15) PRACTICALS 1. Calibration of the thermocouple 2. Heat transfer through composite wall 3. Thermal conductivity of insulating powder 4. Heat transfer in Natural convection 5. Emissivity Measurement 6. Heat transfer in Force convection. 7. Determine the Stefan-Boltzmen constant 8. Heat transfer from pin fin 9.To determine LMTD, heat transfer rate and overall heat transfer coefficient of shell and tube type heat exchanger. BOOKS RECOMMENDED 1. 2. 3. 4. 5. S.P. Sukhatme, Heat Transfer, Universities Press (India), 2005. J.P. Holman, Heat Transfer, McGraw Hill, 2003. E.R.G. Eckert and Robert M. Drake, Heat and Mass Transfer, McGraw Hill, 1996. Chapman A.J., Heat Transfer, Macmillan, New York, 2000. Kothandraman. C.P., Fundamentals of Heat and Mass transfer , New Age International, 2006.

B. Tech. (MECHANICAL) Semester 5 ME 305 FLUID MACHINES

L 3

T 1

P 2

C 5

IMPULSE TURBINES (08 Hours) Working principle, impact of jet on vanes, construction details of Pelton wheel, c lassification, Specific speed, velocity triangles, various losses, p erformance characteristics curves, governing of impulse turbine, unit quantities and specific quantities . REACTION TURBINES (07 Hours) Working principle, construction details of Francis & Kaplan turbine, draft tube theory, cavitations, performance characteristic curves, governing of reaction turbine, Unit quantities & Spec ific quantities. FLOW OVER THE IMMERSED BODIES (05 Hours) Introduction, lift & drag, concept of stream line bodies & bluff bodies, flow over cylinder & aerofoil. FANS AND BLOWERS Construction details, governing equation, losses, performance curves. (05 Hours)

PUMPS (12 Hours) Classification of different type of pump, principle of dynamic action & positive displacement type of pump, various parts of centrifugal pump & their function, t heoretical analysis of energy transfer b etween fluid & rotor, losses , various efficiencies of the pum p, performance characteristics, m atching of pump & system characteristics, model analysis of centrifugal pum p & specific speed , cavitation in pump & maximum suction lift., special purpose pumps MISCELLANEOUS FLUID SYSTEMS (08 Hours) Hydraulic accumulator, hydraulic intensifier, hydraulic crane, hydraulic ram, hydraulic lift, fluid coupling & torque converter. (Total Lecture Hours: 45 + Tutorial Hrs: 15) PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. 9. Performance test on Pelton Turbine Performance test on Francis Turbine. Performance test on Kaplan Turbine Impact of jet on vanes Performance test on centrifugal pump Performance test on gear oil pump. Performance test on jet pump Performance test on hydraulic ram Cavitation in fluid machines

BOOKS RECOMMENDED 1. 2. 3. 4. 5. Som S. K., Biswas. G., Introduction to Fluid Mechanics and Fluid Machines, McGraw Hill, 2006. Lal Jagdish, Hydraulic Machines, Metropolitan, 2006. Gupta Vijay and Gupta Santosh K., Fluid Mechanics and its Applications, New Age International , 2005. Yahya S.M., Turbines, Compressors and Fans, Tata McGraw Hill, 2005. Pillai Narayana N. and Ramakrishnan C. R. Principles of Fluid Mechanics and Fluid Machine s, Universities Press (India), 2006.

B. Tech. (MECHANICAL) Semester 5 PR 301 MACHINING PROCESSES

L 3

T 1

P 2

C 5

INTRODUCTION (05 Hours) Introduction, classification, primary cutting motions, feed and auxiliary motion, gearing diagram, transmission ratio of drives. TURNING (06 Hours) Classification of turning machines, kinematic diagram of Engine lathe, capstan and turret , mechanisms, operations, tools, tool angles, setting of machines for various jobs, special attachments , and accessories. SURFACE MACHINING (06 Hours) Principles, processes, kinematics diagram, mechanisms, cutting parameters, work holding methods, Tools and tool angles. DRILLING AND BORING Classification, Kinematics diagrams, mechanisms, attachments, accessories, tools. (06 Hours)

MILLING (08 Hours) Classification, kinematics diagram of column and knee type milling machine, types of milling operations, holding of tool and work, cutters and a ngles, attachments. ABRASSIVE MACHINING (06 Hours) Importance of finishing process, types of machines and operations, kinematics diagram, mechanisms, dressing and trueing, blazing, loading, mounting and balancing , designating system & selection of grinding wheel. BROACHING Purpose, processes, classification, attachments, tools. GEAR CUTTING Gear milling, gear hobbing, gear finishing. (03 Hours)

(05 Hours)

(Total Lecture Hours: 45 + Tutorial Hrs: 15) PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Turning Practices for step and turning and machining time calculation. Drilling Practices and machining time calculation. Surface Machining practices (shagging) and time calculation Milling Practices and machining time calculation. Turning practices for thread cut ting and thread cutting calculation Milling practices using inducing teachings. Milling practices and spur gear cutting calculation Milling practices for helical gear & calculation Demonstration of Capstan & Single Automat spindle Demonstration of cylindrical surface & tool and cutter grinders.

BOOKS RECOMMENDED 1. H.M.T, Production Technology, Tata McGraw Hill, 1980. 2. Bawa H.S., Workshop Technology, Tata McGraw Hill, 1995. 3. Hajra Choudhary S.K. and Hajra Choudhary A.K ., Workshop Technology, Media Promotors and Publishers,1992. 4. Arora B.D., Workshop Technology, Satya Prakashan,1988. 5. Kalpakjain S. and Schmid Steven R., Manufacturing Processes for Engineering Materials , Pearson Publication, 2007.

B. Tech. (PRODUCTION) Semester 5 ME 301 DYNAMICS OF MACHINES

L 3

T 1

P 2

C 5

INTRODUCTION (10 Hours) Forces, couples, conditions of static equilibrium, free body diagrams, analysis of mechanisms, spur gears, worm gears. DYNAMIC FORCE ANALYSIS (12 Hours) Inertia forces, analysis of a floating link, rotation, method of virtual work. dynamic analysis of four-link mechanism, combined static and inertia force analysis of different mechanisms, turning moment diagrams, fluctuation of energy, flywheels. BALANCING (10 Hours) Introduction, static balancing, dynamic balancing of several masses in different planes. Balancing of inline engines, V-engines, radial engines, balancing machines. GOVERNORS (08 Hours) Introduction, types of governors, sensitiveness of a governor, hunting, isochronisms, stability, effort and power of a governor, controlling force. GYROSCOPE (05 Hours) Angular velocity, angular acceleration, g yroscopic couple, gyroscopic effect on naval ships, stabilit y of an automobile, stability of a two wheel vehicle. (Total Lecture Hours: 45 + Tutorial Hrs: 15) PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. Slider crank mechanism Four bar chain mechanism Quick return mechanism Hookes joint Cam Mechanism Balancing of rotors Governors Experiment on gear generation

BOOKS RECOMMENDED 1. 2. 3. 4. 5. 6. Thomas Bevan, Theory of Machines, CBS publishers, New Delhi , 1984. Rattan, S.S., Theory of Machines, Tata McGraw Hill, 2005. Rao J. S. and Dukkipati R.V., Mechanism and Machine Th eory, Wiley Eastern, 1992. Shigley J. E. and Uicker J.J., Theory of Machines and Mechanism s, McGraw Hill, 1995. Ballaney P. L., Theory of Machines, Khanna Publishers, 1999. Singh V. P. Theory of Machines, Dhanpat Rai & Sons, 2001.

B. Tech. (PRODUCTION) Semester 5 PR 301 MACHINING PROCESSES

L 3

T 1

P 2

C 5

INTRODUCTION (05 Hours) Introduction, classification, primary cutting motions, feed and auxiliary motion, gearing diagram, transmission ratio of drives. TURNING (06 Hours) Classification of turning machine kinematics diagram of Engine lathe, capstan and turret , mechanisms, operations, tools, tool angles, setting of machines for various jobs, special attachments and accessories. SURFACE MACHINING (06 Hours) Principles, processes, kinematics diagram, mechanisms, cutting parameters, work holding methods, tools and tool angles. DRILLING AND BORING Classification, kinematics diagrams, mechanisms, attachments, accessories, tools. (06 Hours)

MILLING (08 Hours) Classification, kinematics diagram of column and knee type milling machine, types of milling operations, holding of tool and work, cutters and angles, attachments. ABRASSIVE MACHINING (06 Hours) Importance of finishing process, types of machines and ope rations, kinematics diagram, mechanisms, dressing and trueing, blazing, loading, mounting and balancing . Designating system & selection of grinding wheel. BROACHING Purpose, processes, classification, attachments, tools. GEAR CUTTING Gear milling, gear hobbing, gear finishing. (03 Hours)

(05 Hours) (Total Lecture Hours: 45 + Tutorial Hrs: 15)

PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Turning Practices for step and turning and machining time calculation. Drilling Practices and machining time calculation. Surface Machining practices (shagging) and time calculation Milling Practices and machining time calculation. Turning practices for thread cutting and thread cutting calculation Milling practices using inducing teachings. Milling practices and spur gear cuttin g calculation Milling practices for helical gear & calculation Demonstration of Capstan & Single Automat spindle Demonstration of cylindrical surface & tool and cutter grinders.

BOOKS RECOMMENDED 1. H.M.T, Production Technology, Tata McGraw Hill, 1980. 2. Bawa H.S., Workshop Technology, Tata McGraw Hill, 1995. 3. Hajra Choudhary S.K. and Hajra Choudhary A.K., Workshop Technology, Media Promotors and Publishers, 1992. 4. Arora B.D., Workshop Technology, Satya Prakashan,1988. 5. Kalpakjain S. and Schmid Steven R., Manufacturing Processes for Engineering Materials , Pearson Publication, 2007.

B. Tech. (PRODUCTION) Semester 5 PR 303 INDUSTRIAL INSTRUMENTATION & CONTROL

L 3

T 1

P 0

C 4

FUNDAMENTALS OF CONTROL SYSTEM (07 Hours) Basic concepts of control system, Classification, System modeling, Transfer function, Block diagram representation, Signal flow graph. COMPONENTS AND TYPES OF CONTROLLERS (07 Hours) Control system components, Derivative, Proportional and Integral controllers and their combinations, Hydraulic and Pneumatic control systems, Industrial applications of control systems. TIME RESPONSE AND STABILITY ANALYSIS (07 Hours) Response characteristic of components and systems by classical laplace transformation and Analog computer stability criteria, Root locus method and Routh stability criterion. EXPERIMENTAL DATA ANALYSIS (09 Hours) Uncertainty analysis, Chi -square test, method of least squares, Charivenets criterion. Generalized performance characteristics, Transfer function -zero, first and second order instruments, performance prediction of measuring instruments, Response of a general form of instrument of periodic input loading effect under static and dynamic conditions. Experim ental determination of measurement, system parameters. DATA ACQUISITION SYSTEM (06 Hours) Data acquisition and processing, Si gnal conditioning, Data transmission, Data storage & Display. TRANSDUCERS Introduction, classification of transducers , Photo emissive cells, Hall effect transducers. (04 Hours)

MICROPROCESSOR AND CONTROL (05 Hours) 8085 microprocessor & 8051 micro controller, Architecture, Assembly language programming, Instruction se t, addressing modes. Applications of microprocessors and microcontrollers to mechanical & production engineering such as data acquisition systems etc. (Total Lecture Hours: 45 + Tutorial Hrs: 15) BOOKS RECOMMENDED 1. 2. 3. 4. Holman J. P. and Gajda W. J., Experimental Methods for Engineers , Tata McGraw Hill, New Delhi, 2004. Doebalin E.O., Measurement System Application and Design, McGraw Hill, 2005. Mazidi M.A., 8051 Microcontroller and Embedded Systems, Pearson Education, 2003. Gaonkar R. S., Microprocessor Architecture, Programming and Applications with the 8085, Penram International, Mumbai, 2007. 5. Ogata K., Modern Control Engineering , Prentice Hall India, 2003. 6. Nagrath I.J. and Gopal M., Control Systems Engineering , Wiley Eastern, New Delhi. 2006. 7. Dransfield Peter, Engineering Systems and Automatic Control , Prentice Hall India, 1994.

B. Tech. (PRODUCTION) Semester 5 PR 305 INDUSTRIAL ENGINEERING & ERGONOMICS

L 3

T 1

P 2

C 5

INDUSTRIAL ENGINEERING (01 Hour) Introduction, history, activities & techniques of Industrial Engineering, Organization of Industrial Engineering Department. PRODUCTIVITY (04Hours) Production & productivity, factors influencing productivity technological advancement & human factors, measurement of productivity (Productivity Index) , causes of low productivity and techniques of their elimination, improving productivity by reducing work content & ineffective time. WORK STUDY (14 Hours) Work content, excess work content & ineffective time , Method study objectives, steps, selection of job, process charts, micro-motion & memo-motion studies, principles of motion economy Therbligs, Workplace layout, Work Measurement objectives, steps, techniques, perform ance rating, allowances of standard time, techniques of work measurement , Work Sampling confidence levels, methods of work sampling, Computation of machines utilization & standard time , Predetermined Motion Time & Systems (PMTS) , Work Factor System, Method Time measurement (MTM) - MTM basic motion elements, Production study, Physiological work measurement. PRODUCT DESIGN AND DEVELOPMENT (04 Hours) Product life cycle, selection of a profitable product, product design & development, process, p roduct analysis Tools for product development viz. Standardization, Simplification, diversification, specialization etc. concurrent design, Design for Manufacturing & Assembly (DFMA), Reverse engineering, Manufacturability, Ergonomic considerations in Pro duct design, Process design . VALUE ENGINEERING (03 Hours) Value analysis & value engineering, reasons for unnecessary costs, Function Analysis System Technique (FAST), Techniques of value analysis & value engineering, value analysis procedure & questionnaire. PRODUCT COST CONCEPTS & BREAK -EVEN ANYLSIS (03 Hours) Costs of production, classification of costs, analysis of production costs, Break -even analysis graphical as well as mathematical analysis, costs volume Profit (CVP) analysis, managerial uses of Break even chart, Applications of Break-even analysis. Engineering Economy and Engineering Process requirements of an economy study of an engineering project ERGONOMICS (Human Factor Engineering) (06 Hours) Objectives of human engineering, Ergonomics, productivity and working environment, man - machine systems, design of controls & information displays, working environment factors such as illumination, noise & vibrations, ventilation, air-conditioning & temperature control , Anthropometry, Human activities, Biomechanics, nature of movements, expenditure of energy for movements, strength & maintenance of muscular force, Layout of working space layout design, working space required by worker, seating arrangements for providing maximum comfort. MANPOWER PLANNING (02 Hours) Features and importance, manpower planning process - organizational objectives & plans, forecasting of manpower requirement, factors affecting manpower planning , data and allowances, techniques of manpower planning such as work measurement and work sampling techniques. DECISION MAKING (03 Hours) Characteristics and classification of decision making, administrative problems and stages in decision making, techniques of decision making such as scientific management, human relations, mathematical model, decision support system; decision making under certainty, risk, un certainty etc.

LOCATION ECONOMICS & PLANT LAYOUT (03 Hours) Plant location factors affecting plant location, design of f actory plant building, plant layout importance & principles, types of layout such as product or line layout, process or functional layout, fixed position layout, techniques for layout planning. Quantitative methods for evaluation of plant location. MATERIAL HANDLING (02 Hours) Objectives, engineering & economic considerations, principles of material handling, selection & classification of material handling equipments.

(Total Lecture Hours: 45+ Tutorial Hrs: 15)

PRACTICALS 1. Construction of operation process chart, flow process chart (man type and material type) and flow diagram for a given component to be fabricated in Workshop , SVNIT. (a) Study of hand motions: a. Pin board study under given conditions b. Pin board study under constraints. (b) Study of hand motions with the help of a hand motion model. 2. Conducting method study of a given objects / assemblies. 3. Conducting time study of a. Turning operation. b. Drilling operation 4. Rating exercise (rating factor) for following activity: a. To fill a pin board having 30 holes by pins. b. Walking 5. Rating exercise for dealing of playing cards, mathematical as well as graphical analysis of performance and errors. 6. Study of principles of ergonomics: a. Measurement of illumination by using a Luxmeter. b. Measurement of a noise level by using a sound level meter. c. Measurement of Vibration by using human vibration meter. 7. Use of Ergomaster Software. BOOKS RECOMMENDED 1. 2. 3. 4. 5. Telsang M., Industrial Engineering and Production Management, S. Chand & Co., New Delhi, 2005. International Labour Organization, Geneva, Introduction to Work Study, 2004. Sharma S.K. and Sharma Savita, Work Study and Ergonomics, S.K. Kataria & Sons, Delhi, 2007. Mahajan M., Industrial Engineering and Production Management, Dhanpat Rai & Sons, Delhi, 2005. Sharma S. K., Sharma Savita and Sharma Tushar, Industrial Engineering and Operations Management, S.K. Kataria & Sons, New Delhi, 2004. 6. Paneerselvam R., Production and Operations Management, Prentice Hall India 2005.

10

B. Tech. (MECHANICAL) Semester 5 (INST. ELECTIVE I) ME 309 APPLIED THERMODYNAMICS

L 3

T 0

P 0

C 3

STEAM POWER CYCLES (08 Hours) Simple steam power cycle, Rankine cycle, Ranki ne cycle efficiency, Comparison of Rankine & Carnot cycles. Reheat cycle, Regenerative cycle, Reheat -regenerative cycle. GAS POWER CYCLES (08 Hours) Stiring cycle, Ericsson cycle, Otto Cycle, Diesel cycle, Dual Cycle, Brayton cycle, Air standard cycle for jet propulsions, Inter cooling, Reheating, Regeneration. REFRIGERATION CYCLES (06 Hours) Simple vapour compression cycle, Cycles with superheat & subcooling, Basic vapour absorption cycle. EXERGY: A MEASURE OF WORK POTENTI AL (10 Hours) Basic concepts, Available and unavailable energy for a cycle, Different form of E xergy, Exergy balance for closed system and open system, Decrease of Exergy principle, Difference between first law & second law efficiency, Second law efficiency for steady flow devices. REACTIVE MIXTURE (COMBUSTION ) (07 Hours) Combustion equations, Stoichiometric air, Excess air, Air -fuel ratio by volume & weight, Enthalpy of formation, Enthalpy and internal energy of combustion, Adiabatic flam e temperature, Equilibrium constants. THERMODYNAMIC RELATIONS & EQUILIBRIUM (06 Hours) The Maxwell relations, Clausis clapeyron equation, JouleThomson coefficient, Relationships involving specific heats, enthalpy, entropy. (Total Lecture Hours: 45)

BOOKS RECOMMENDED 1. Wylen Van, Sonnetag and Borgnakke, Fundamental of Classical Thermodynamics, John Wiley & sons, New York, 2005. 2. Cengel Yunus A. and Boles Michael A., Thermodynamics, Tata McGraw Hill, New Delhi, 2004. 3. Kothandaraman C.P., Khajuria P.R. and Domkundrar S., A Course in Thermal Engineering, Dhanpat Rai & Sons, 2004. 4. Dossat R.J., Principles of Refrigeration, John Wiley & S ons, 2003. 5. Ballaney P.L., Thermal Engineering , Khanna Publishers 2000. 6. Baukal C.E., Heat Transfer in Ind ustrial Combustion, CRC Press, 2000. 7. Rogus & Lewis, Combustion Technology, Prentice Hall, 2000. 8. Kuo K. K., Principles of Combustion, CHIPS, Texas, 2005.

11

B. Tech. (PRODUCTION) Semester 5 (INST. ELECTIVE I) ME 311 EXPERIMENTAL STRESS ANALYSIS

L 3

T 0

P 0

C 3

INTRODUCTION (20 Hours) Stress at a point, Stress equations of e quilibrium, Principal stresses in a two-dimensional stress system., Definitions of displacement and strain, Principal strain, Compatibility, Stress -strain Relations. Airys Stress function, Two-dimensional problems in polar coordinates. THEORY OF BRITTLE COATING Coating method, Brittle-coating, Crack patterns, Types of brittle coating. (06 Hours)

BEHAVIOR OF STRESSCOAT AND ITS APPLICATION (08 Hours) Composition of stresscoat, Coating cure and coating Thickness, Influence of Atmospheric Conditions, A Typical Application of the Brittle -coating Method. PHOTOELASTICITY (08 Hours) Theory of Photoelasitcity, Photoelastic Model Materials for Two -Dimensional Applications, Applications of Photoelastic Methods. INTORDUCTION TO STRAIN MEASUREMENTS Electrical-resistance Strain Gages, Rosette Analysis. (03 Hours)

(Total Lecture Hours: 45)

BOOKS RECOMMENDED 1. Dove R.C. and Adams P.H., Experimental Stress Analysis and Motion Measurements , Prentice Hall India, 2000. 2. Singh Sadhu, Experimental Stress Analysis , Khanna Publishers, 2003. 3. Frocht M.M., Photoelasticity, John Wiley & Sons, 2003. 4. Dally James W. and Riley William F., Experimental Stress Analysis, Tata McGraw Hill Pub. Co.,1984. 5. Srinath L.S., Experimental Stress Analysis , Tata McGraw Hill Publishing Co. Ltd., 1984.

12

B. Tech. (PRODUCTION) Semester 5 (INST. ELECTIVE I) PR 307 INDUSTRIAL TRIBOLOGY & VIBRATION INTRODUCTION Introduction to tribology and surface to pography. FRICTION & WEAR Theories of friction, wear and measurement techniques. LUBRICANTS Properties and testing of lu bricants.

L 3

T 0

P 0 (02 Hours)

C 3

(04 Hours)

(03 Hours)

REGIMES OF LUBRICATION (10 Hours) Application of lubrication mechanism in bearing design. Basic concepts o f hydrodynamic lubrication theory. Hydrostatic and boundary lubrication. TRIBOLOGY APPLIED TO METAL CUTTING AND M ETAL WORKING PROCESSES. (04 Hours)

FUNDAMENTALS OF VIBRATIONS (01 Hours) Introduction, definition, SHM, beats phenomenon, complex method of representing harmonic vibrations. UNDAMPED FREE VIBRATIONS OF SINGLE DEGREE OF FREEDOM SYSTEM (06 Hours) Introduction, derivation of differential equations and solutions, equivalent stiffness of spring combinations, Newtons method and energy method for problem solutions. DAMPED FREE VIBRATIONS OF SINGLE DEGREE OF FREEDOM SYSTEM Different types of dampings, free vibrations with viscous dampers. (06 Hours)

FORCED VIBRATION OF SINGLE DEGREE OF FREEDOM SYSTEMS (07 Hours) Forced vibration with constant harmonic excitation, with rotating and reciprocating unbalance, due to the support, vibration isolation and transmissibility, measuring instruments, displacement, velocity, acceleration, frequency measuring instruments. WHIRLING AND CRITICAL SPEED OF SHAFTS Introduction to multi degree of freedom system. (02 Hours)

(Total Lecture Hours: 45) BOOKS RECOMMENDED 1. 2. 3. 4. 5. 6. Cameron A., Basic Lubrication Theory, Wiley Eastern, New Delhi, 1987. Rao J, & Gupta K., Theory and Practice of Mechanical Vibration , Wiley Eastern, New Delhi, 1987. Halling J. & Arnell R.D., Fundamentals of Tribology, Springer Verlag, 1991. Grover G. K., Mechanical Vibrations, Nemchand & Bros., 1995. Kelly Graham S., Mechanical Vibrations, McGraw Hill, 1995. Majmudar B. C., Introduction to Tribology of Bearings , A.H. Wheeler and Co., 1986.

13

B. Tech. ( PRODUCTION) Semester 5 (INST. ELECTIVE I) ME 313 PLASTICS AND CERAMICS

L 3

T 0

P 0

C 3

INTRODUCTION (04 Hours) Polymeric materials and comparison with other engineering materials. Plastic, Thermoplast ic and Thermosets, Elastomers and polymers COMPOSITE MATERIAL S (08 Hours) Merits & demerits of composites, a pplication of composite, manufacturing processes of composites, Pro perty evaluation of composites. PROCESSING OF PLASTICS AND RUBBERS (08 Hours) Introduction to injection moulding, rotational moulding, extrusion, blow moulding, plastic film blowing, compound moulding, resin transfer moulding, resin injection moulding, designing with plastics and rubbers. FABRICATION AND DECO RATING OF PLASTICS (08 Hours) Machining of plastics, turning, drilling, sawing, threading, post -moulding techniques , hot stamping, metallic coatings, electroplating, printing, vacuum metalizing and some case studies. CERAMIC MATERIALS (09 Hours) Atomic bonding and crystal structure in ceramics, conventional ceramics and glass structure, refractory and insulating materials, physical, thermal, electrical, m agnetic, optical and piezoelectric properties, Differentiation from other engineering materials, Time temperature and environmental effect on properties of ceramics. . PROCESSING OF CERAMICS (08 Hours) Phase Equilibrium Diagram, Gibbs phase rule, advanced structural ceramics, syn thesis and processing of ceramics, sintering process, powder pressing and sintering fabrication processes, Sintering defects, slip casting, ceramic injection moulding, tape casting, properties & applications of ceramics and material selection. . (Total Lecture Hours: 45) BOOKS RECOMMENDED 1. Throne James L., Plastic Process Engineer, Marcel Dekker, New York, 1979 . 2. Crawfard R.J, Engineering Design of Plastics and Rubber, Woodhead Publication, U.K, 1985. 3. Richerson David, Modern Ceramic Engineer ing, Properties, Processing and Use in Design, Marcel Dekker, 1987. 4. Flinn R.A. and Trojan P.K, Engineering Materials and their Applications , Jaico Publishing House, 1999. 5. Kingery W.D, Bowen H. K and Uhlman D.R, Introduction to Ceramics, John Wiley & Sons, 1975.

14

B. Tech. (PRODUCTION) Semester 5 (INST. ELECTIVE I) ME 315 THEORY OF ELASTICITY

L 3

T 0

P 0

C 3

BASIC EQUATION OF ELASTICITY (09 Hours) The state of stress and strain at a point , plane stress & strain, Basic equation of Elas ticity in Cartesian coordinate, Method of solution 0f Elasticity problems. TWO DIMENSIONAL PROBLEMS IN THEORY OF ELASTICITY Basic equation, Airys stress function, in Cartesian co -ordinates & polar co-ordinates. NUMERICAL SOLUTION Finite difference methods, solution of finite difference equation , Theorm of Elasticity. THERMAL STRESSES Introduction and basic equation and field application. HERTZS CONTACT STRESSES Introduction, pressure between two parallel cylinders & two -spherical bodies in contact. (09 Hours)

(09 Hours)

(09 Hours)

(09 Hours)

(Total Lecture Hours: 45)

BOOKS RECOMMENDED 1. 2. 3. 4. 5. 6. Timoshenko S.P., Theory of Elasticity McGraw Hill , 1970. Patel R.C., Advanced Strength of Materials, C. Jamnadas & Co. , 1987. Gowda R.M.S., Theory of Elasticity , IIT Madras,1976. Budynas R. G., Advanced Strength and Applied Stress, McGraw Hill, 1977. Singh Sadhu, Theory of Elasticity, Khanna Publishers, New Delhi, 2000. Shrinath L.S., Experimental Stress Analysis, Tata McGraw Hill , 1984.

15

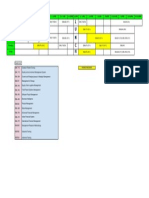

Sr. No. 1

Course

Scheme for Teaching & Examination B. Tech. - III (Mechanical) Sixth Semester Teaching Exam Scheme Scheme Code Theory Tuto. Pract. L T P Hrs. Marks Marks Marks ME 302 3 1 2 2 100 25 50

Total Marks 175

Credits

Machine Design-I Internal Combustion Engines & Automobile Engineering Refrigeration & Air Conditioning Tribology & Machine Dynamics Institute Elective-II*

ME 304

100

25

50

175

3 4 5

ME 306 ME 308

3 3 3

1 1 0

2 2 0

2 2 2

100 100 100

25 25 -

50 50 -

175 175 100 800

5 5 3 23

TOTAL 15 4 8 500 100 200 Total contact Hrs. per week (27) Total Credits =23 Total Marks = 800 B. Tech. III (Production) Sixth Semester Exam Scheme Teaching Scheme Theory Tuto. Pract. Code L 1 2 3 4 Theory of Metal Cutting Machine Design Computer Aided Design Product Measurement & Quality Control Institute Elective-II* PR 302 PR 304 PR 306 PR 308 3 3 3 3 T 1 1 0 1 P 2 2 2 2 Hrs. 2 2 2 2 Marks 100 100 100 100 Marks 25 25 25 Marks 50 50 50 50

Sr. No.

Course

Total Marks

Credits

175 175 150 175

5 5 4 5

100

100 775

3 22

TOTAL 15 3 8 500 75 200 Total contact Hrs. per week (2 6) Total Credits =22 Total Marks = 7 75 Institute Elective-II* ME 312 : Industrial Engineering (Not for Production) ME 314 : Plant Layout & Material Handling ME 316 : Microprocessors & Applications PR 312 : Elements of Automobile Engineering (Not for Mechanical) ME 318 : Corrosion Engineering

16

B. Tech. (MECHANICAL) Semester 6 ME 302 MACHINE DESIGN I

L 3

T 1

P 2

C 5

INTRODUCTION The design process, morphology of design, designing methods, concurrent engineering.

(03 Hours)

DESIGN ANALYSIS (05 Hours) Types of loads and stresses. Factor of safety types of failure, theories of failure, fatigue failure analysis, Soderberg and Goodman methods, estimation of life of a component. Wear failure , introduction to creep failure. SELECTION OF MATERIAL (02 Hours) Factors affecting material selection. f errous, non-ferrous metals and alloys, plastics for machine parts. MACHINE COMPONENTS (06 Hours) Parts subjected to tension, compression, shear, bending and torsion such as tie rods, push rods, levers, axels etc. Parts subjected to combined loads. Design of helical compression and extension springs, leaf springs. JOINTS AND CONNECTIONS Pin Joints and cottered joints, riveted connections, welded joints. (06 Hours)

SCREWS AND THREADED FASTNESS (06 Hours) Types of Screw threads, Indian standard proportions, design of power screws, Threaded fastness types of bolts and connections, stresses and preloading of bolts. Flanged connections bolted connections. SHAFTS (04 Hours) Types of shafts, ASME code for design of shafts, deflection of shafts, critical speed, Design of keys and splines. SIMPLE MACHINES (06 Hours) Design of rigid and flexible couplings, screw jack, screw p ress, toggle jack, bearing puller, I.C. Engines connecting rod, I.C. engine valve gear. THICK AND THIN CYLINDERS Shrink fitted and pressfitted connections. (04 Hours)

MANUFACTURING CONSIDERATIONS (03 Hours) Standardization, limits, fits and tolerance as per I.S. Specification, factors to be considered in design of castings, forgings and welded components. (Total Lecture Hours: 45 +Tutorial Hrs: 15) PRACTICALS 1. Design and drawing of cotter j oint 2. Design and drawing of Knuckle joint 3. Design and drawing of any type of coupling a. Flange coupling b. Bush pin type coupling c. Rigid coupling 4. Design and drawing of screw jack 5. Design of Spring 6. Design of fasteners 7. Design of Levers 8. Design of transmission shaft BOOKS RECOMMENDED 1. Bhandari V.B., Design of Machine Elements , Tata McGraw Hill, 1994. 2. Shigley Jospeh, Mechanical Engineering Design , McGraw Hill, 1989. 3. Patel R.C. and others, Machine Design, C. Jamnadas & Co., 1992. 4. Design Data (PSG College of Engg. & Tech.), DPV Printers, Coimbatore, 2000. 5. Nortan R.L., Machine Design: An Integrated Approach , Prentice Hall, 2005.

17

B. Tech. (MECHANICAL) Semester 6 ME 304 INTERNAL COMBUSTION ENGINES & AUTOMO BILE ENGINEERING INTRODUCTION Introduction of I. C. Engines.

L 3

T 1

P 2

C 5

(02 Hours)

ANALYSIS OF AIR STANDARD CYCLES AND FUEL AIR CYLCES (07 Hours) Air standard cycles, Ideal air standard cycles, Fuel air cycles, Characteristics of fuel - air mixtures, Variation of specific heat. Actual cycles and actual processes taking place in engines. COMBUSTION IN I.C. ENGINE (07 Hours) Combustion in S.I. Engine and C.I. Engines: Stages of combustion in S.I. Engine, Detonation and its Control of detonation. Stages of combustion in C.I. Engines, Delay period, Factor s influencing delay period, Diesel knock, Control of diesel knock. ELEMENTS OF FUEL SYSTEM IN S.I. ENGINE (07 Hours) Requirements of a good carburetor, Simple carburetor, Complex carburetor, Calculation of air -fuel ratio for a simple carburetor. Electronic fuel injection in S.I. Engine. ELEMENTS OF FUEL SYSTEM IN C.I. ENGINE Requirements of Diesel Injection System, Types of injection systems, Fuel pumps. LUBRICATION AND COOLING SYSTEM Lubrication and cooling system of I. C. Engine: Functions and Types. TESTING AND PERFORMANCE OF I. C. ENGINE Testing and performance of S. I. Engine & C. I. Engine (03 Hours) (03 Hours) (05 Hours)

ENGINE EMISSIONS AND CONTROL (02 Hours) Pollutants and their ill effects, Pollutants from Gasoline and Diesel Engines and their control. MODERN DEVELOPMENTS IN I C ENGINES Alternate fueled engines, Alcohol, hydrogen etc. (02 Hours)

TRANSMISSION SYSTEM OF AUTOMOTIVE VEHICLE (07 Hours) Types & its components and Braking and Suspension system of automotive vehicle, Function of Steering systems and their types, Electrical systems of automotive vehicle, Chasis, Wheels, Types of tyres, Functions of tyres, Tread design etc. (Total Lecture Hours: 45 +Tutorial Hrs: 15) PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. 9. S. I. & C.I. Engine System Valve Timing Diagram and Port Timing Diagram Morse Test A Constant Speed Load Test Heat Balance Test on a 4-Stroke Diesel Engine Transmission System of Automobile Principle of Steering Wheel Alignment and Wheel Balancing of automobile vehicle. Ignition and brake system.

BOOKS RECOMMENDED 1. 2. 3. 4. 5. 6. Ganeshan V., Internal Combustion Engines , McGraw Hill, New Delhi, 2007. Heywood J.B., Internal Combustion Engine Fundamentals McGraw Hill, Sing apore, 2002. H.N. Gupta, Fundamentals of Internal Combustion Engines, Prentice Hall India, 2006. Shyam K. Agrawal, Internal Combustion Engines New Age International Ltd., New Delhi, 2006. Narang G.B.S., Automobile Engineering, Khanna Publishers, New Delhi, 2002. Mathur M.L. and Sharma R.P. , A Course in Internal Combustion Engines, Dhanpat Rai & Sons, 1992.

18

B. Tech. (MECHANICAL) Semester 6 ME 306 REFRIGERATION & AIR CONDITIONING

L 3

T 1

P 2

C 5

GAS CYCLE REFRIGERATION (06 Hours) Air refrigeration system, Bell Colleman air cycle, Boot strap system, Aircraft refrigeration systems, Actual cycle, Ramming, Compression and Turbine efficiencies, Coefficient of performance. VAPOUR COMPRESSION REFRIGERATION (09 Hours) Analysis of vapour compression cycle, Losses and efficiencies of components, Factors affecting the performance of a simple vapour compression system, Heat balance, Multistage vapour compression system with flash intercooler, Multi evaporation system, Cascade refrigeration system ABSORPTION REFRIGERATION (06 Hours) Desirable properties of refrigerants and solvents, Thermodynamics analysis of vapour absorption System, Comparison between vapour absorption and vapour compression s ystem, Aqua-Ammonia and Lithium Bromide absorption system. PSYCHROMETRY AND PSYCHROMETRIC PROCESSES (10 Hours) Psychrometric properties, Psychrometers, Preparation of psychrometric charts, Enthalpy deviation, Psychrometric Processes - Mixing process, Sensible heating, Sensible cooling, Humidification, Dehumidification, Cooling and Dehumidification, Heating and humidification, Bypass factor, Apparatus dew point, Sensible heat factor, Air washer, Adiabatic humidification, Efficiency of h umidification, Summer and Winter air conditioning system. LOAD CALCULATION (08 Hours) Calculation of summer and winter loads, Heat gain through walls, roofs, floors, windows, and doors. AIR CONDITIONING SYSTEMS AND EQUIPMENTS (06 Hours) Humidifiers, Air coolers, Dehumidifiers, Air cleaners, Impurities in air and air cleaners, Ducts, Pressure drop in ducts. (Total Lecture Hours: 45 +Tutorial Hrs: 15) PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. To conduct performance test on vapour compression refrigeration system. To study tools and instruments used in refrigeration and air conditioning To determine psychrometric properties of air. To conduct performance test on air conditioning system to find C.O. P and to determine the by pass factor of coil. To conduct performance test on Ice plant. To conduct performance test on Cold storage plant. To conduct performance test on vapour absorption system - Electrolux- Domestic type. To conduct performance test on desert cooler. To study the domestic refrigerator. To study the charging, testing, evacuating and pumping down to a refrigerant plant

BOOKS RECOMMENDED 1. 2. 3. 4. 5. 6. Arora S.C. and Domkundwar S., A Course in Refri geration and Air Conditioning, Dhanpat Rai & Sons, 2006. Thrakeld J. L., Thermal Environmental Engineering, Prentice Hall, 2002. Stoeaker W. F., Refrigeration and Air conditioning, Tata McGraw Hill, 2004. Dossat R.J., Principles of Refrigeration, J ohn Wiley and Sons, 2000. Arora C. P., Refrigeration and Air conditioning, Tata McGraw Hill, 2004. Ananthanarayanan P. N., Basic Refrigeration and Air Conditioning, Tata McGraw-Hill, 2005.

19

B. Tech. (MECHANICAL) Semester 6 ME 308 TRIBOLOGY AND MACHINE DYNAMICS INTRODUCTION Introduction to tribology and surface topography. FRICTION & WEAR Theories of friction and wear and measurement techniques. LUBRICANTS Properties and testing of lubricants.

L 3

T 1

P 2 (02 Hours) (04 Hours) (04 Hours)

C 5

REGIMES OF LUBRICATION (10 Hours) Application of lubrication mechanism in bearing design. Basic concepts o f hydrodynamic lubrication theory. Hydrostatic and boundary lubrication. FUNDAMENTALS OF VIBRATIONS (01 Hours) Introduction, definition, SHM, beats phenomenon, complex method of representing harmonic vibrations. UNDAMPED FREE VIBRATIONS OF SINGLE DEGREE OF FREEDOM SYSTEM (06 Hours) Introduction, deviation of differenti al equations and resolution, equivalent stiffness of spring combinations, Newtons method and energy method for problem solutions. DAMPED FREE VIBRATIONS OF SINGLE DEGREE OF FREEDOM SYSTEM Different types of dampings, free vibratio ns with viscous dampers. (06 Hours)

FORCED VIBRATION OF SINGLE DEGREE OF FREEDOM SYSTEMS (06 Hours) Forced vibration with constant harmonic excitation, with rotating and reciprocating unbalance, due to the support, vibration isolation and transmissibili ty, measuring instruments, displacement, velocity, acceleration, frequency measuring instruments. WHIRLING AND CRITICAL SPEED OF SHAFTS Introduction to multi degree of freedom system. (02 Hours)

CAM DYNAMICS (04 Hours) Forces in rigid systems, follower response by phase -plane method, jump and cross -over, Johnsons numerical method. (Total Lecture Hours: 45 +Tutorial Hrs: 15) PRACTICALS 1. Tuned rectilinear vibration absorber 2. Free damped vibration 3. Fixed free three rotor system 4. Semi definite system 5. Variable port opening dash pot 6. Rectilinear vibration of cantilever beam 7. Tuned torsional vibration absorber 8. Viscosity measurement 9. Wear measurement BOOKS RECOMMENDED 1. Arnell R. D., Davies P.B., Halling J. and Whomes T.L., Tribology Principles and Design Application , Springer Verlag, 1991. 2. Majmudar B. C., Introduction to Tribology of Bearings , A.H. Wheeler and Co., 1986. 3. Cameron A., Basic Lubrication Theory, Wiley Eastern, 1987. 4. Grover G. K., Mechanical Vibrations, Nemchand & Bros. 1995. 5. Kelly Graham S., Mechanical Vibrations, McGraw Hill, 1995. 6. Shigley J.E., Theory of Machines and Mechanism , Tata McGraw Hill, 1992.

20

B. Tech. (PRODUCTION) Semester 6 PR 302 THEORY OF METAL CUTTING

L 3

T 1

P 2

C 5

SINGLE POINT CUTTING TOOL (12 Hours) Geometry of single point cutting tool, Mechanism of chip formation, Orthogonal and oblique cutting, Type of chips, chip breaking and control, Machining parameters, Cutting force and power requirement in single poi nt turning process, Merchants circle , Shear angle relationships, Friction an d thermal aspects of machining, Dynamometry. MULTI-POINT CUTTING TOOLS (16 Hours) Nature of cutting with multi-point cutting tools, Mechanism of chip formation in drillin g and milling, Metal cutting theory for milling, Dynamometry. TOOL WEAR & TOOL LIFE (09 Hours) Types of tool wear, Affecting parameters, Tool materials, Tool life, Definition & factors affecting tool life, Taylors tool life equation, Cutting flu ids - their characteristics & applications, Factors affecting machinability. Factors influencing surface quality and material removal rate in machining, Calculation of economic cutting speed, high efficiency zone. SURFACE FINISHING PROCESSES (08 Hours) Chip formation mechanism for grinding, factor influencing surface quality & MRR, super finishing processes like lapping, honing, buffing. (Total Lecture Hours: 45 +Tutorial Hrs: 15) PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Measurement of tool angles for single point cutti ng tool Measurement of Shear plane angle during shaping operation Measurement of power and forces under various cutting conditions during machining operations Measurement of torque and th rust under various cutting conditions during drilling operation. Measurement of cutting force during milling operation Measurement of tool chip interface temperature during drilling. Demonstration of Alignment Tests Demonstration of effect of cutting parameters on surface quality in grinding process Experiment to measure Cutting angles of a single point turning tool, Measurement of Tool Chip Interface temperature.

BOOKS RECOMMENDED 1. 2. 3. 4. 5. Ghosh A. and Mallik A.K., Manufacturing Science, East - West Press, New Delhi, 2002. Lissaman A.J. and Martin S.J., Principles of Engineering Production, Universities Press, UK, 1984. Armarego E.J.A. and Brown R.M., The Machining of Metals, Prentice Hall, U.S.A., 1975 Bawa H. S., Manufacturing Processes II, Tata McGraw Hill, 2004. Donaldson Cyrll, Tool Design, Tata McGraw Hill, 2000.

21

B. Tech. (PRODUCTION) Semester 6 PR 304 MACHINE DESIGN

L 3

T 1

P 2 (02Hours)

C 5

INTRODUCTION The design process, morphology of design, designing methods, concurrent engineering.

DESIGN ANALYSIS (04Hours) Types of loads and stresses , theories of failure, fatigue failure Soderberg and G oodman methods. SELECTION OF MATERIAL Factors affecting material selection , ferrous and non-ferrous metals and alloys, plastics . (03Hours)

MACHINE COMPONENTS (06Hours) Design of parts subjected to tension, compression, shear and bending such as tie rods, push rods, levers etc. Design of shafts, keys, splines and couplings, Design of the fasteners. Design of power screws. Design of helical compression springs. JOINTS AND CONNECTIONS Knuckle joint, rivertted joint, welded connections. (06Hours)

MECHANICAL POWER TRANSMISSION SYSTEM (08Hours) Selection of V and flat belts and design of belt drives. Design of sp ur gears. Selection of ball bearings. CAMS Types and design of eccentric and spiral cams. THICK AND THIN CYLINDERS Shrink fitted and pressfitted connections. (04Hours)

(04Hours)

MANUFACTURING CONSIDERATIONS IN DESIG N (04Hours) Limits, fits and tolerances, standardization, modular design, factors influencing the design of castings and welded machine frames. PRODUCT DESIGN (04Hours) (Total Lecture Hours: 45 +Tutorial Hrs: 15) PRACTICALS 1. 2. 3. Design and drawing of cotter joint Design and drawing of Knuckle joint Design and drawing of any type of coupling a. Flange coupling b. Bush pin type coupling c. Rigid coupling Design and drawing of screw ja ck Design of Spring Design of fastners Design of Levers Design of transmission shaft

4. 5. 6. 7. 8.

BOOKS RECOMMENDED 1. 2. 3. 4. 5. Bhandari V.B., Design of Machine Elements , Tata McGraw Hill, 1994. Shigley Jospeh, Mechanical Engineering Design , McGraw Hill, 1989. Patel R.C. and others, Machine Design, C. Jamnadas & Co., 1992. Nortan R.L., Machine Design: An Integrated Approach , Prentice Hall, 2005. Design Data (PSG College of Engg. & Tech.), DPV Printers, Coimbatore, 2000.

22

B. Tech. (PRODUCTION) Semester 6 PR 306 COMPUTER AIDED DESIGN

L 3

T 0

P 2

C 4

INTRODUCTION (03 Hours) Computer configuration for CAD applications, Computer peripherals for CAD programming technique using computer graphics software . COMPUTER GRAPHICS Transformation Two dimensional, three dimensional transformatio n. PLANE CURVES AND SPACE CURVES Parametric non parametric curves cubic splines Bezier curves, d spline curves. (12 Hours)

(08 Hours)

3-D MODELLING (08 Hours) Solid modeling-modelling approaches-coordinate system-basic features-viewing/visualization-hidden line removal. Introduction to Computer Aided Drafting and Analysis using software approach NUMERICAL ANALYSIS Finite Difference Method and Finite Element Method (14 Hours)

(Total Lecture Hours: 45)

PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. 9. Drafting practice using drafting package for drawing option. Drafting practice using drafting package for modify option. Drafting practice using drafting package for dimensional approach. Programming practice for a given problem. Programming practice for grap hic application. Practice for data exchange from draft package. Drafting of design component Demonstration of 3D modeling using CAD Packages. Demonstration of stress analysis using FEA package.

BOOKS RECOMMENDED 1. Rogers David F. and Alan Adams J., Mathematical Elements for Computer Graphics , McGraw Hill, 1990. 2. Kundra T. K., Rao P. N. and Tewari M. K., Numerical Control and Computer Aided Manufact uring, Tata McGraw Hill, 1990. 3. Krishnamoorthy C.S. and Rajeev S., Computer Aided Design, Narosa Publishing House, 1991. 4. Groover M.P. and Zimmers E.W., Computer Aided Design and Manufacturing , Prentice Hall India, 1997. 5. Vera B. Anand, Computer Graphics and Geometric Modeling for Engineers, John Wiley & Sons, 1993. 6. P N. Rao, CAD/CAM Principles and Applications, Tata McGraw Hill, 2006.

23

B. Tech. (PRODUCTION) Semester 6 PR 308 PRODUCT MEASUREMENT & QUALITY CONTROL

L 3

T 1

P 2

C 5

PRODUCT MEASUREMENT (08 Hours) Measuring-gauging, performance characteristics of instruments errors and er ror analysis in measurement, standards of measurement. Limit -fit-tolerance analysis, limit gauge, Taylors principle, gauge design as per ISI. EXTERNAL AND INTERNAL SCREW THREADS MEASUREMENTS (07 Hours) Errors in screw threads, direct and indirect methods of measuring screw threads parameters, wire methods, best wire size. SPUR GEAR MEASUREMENTS (07 Hours) Rolling test, tooth thickness measurements, base tangent method for getting module, test plug method, profile checking. SURFACE ROUGHNESS MEASUREMENT (07 Hours) Roughness measuring instruments, use of inferrometry, use of optical instruments. Comparators -principle of working and useful applications . QUALITY CONTROL (08 Hours) Concept of quality, quality characteristics, value of quality, quality of design and confo rmance, process capability, concept of TQM quality circle, quality improvement technique, ISO -9000. ACCEPTANCE SAMPLING P LANS (08 Hours) Single, double and sequential, AQL -LTPD concepts and AOQ -AOQL. Process control charts, SPC, control charts for variables and attributes, X , R, P, C, V and multi characteristics control charts. Use of computer software for quality control systems. (Total Lecture Hours: 45 + Tutorial Hrs: 15) PRACTICALS: based on the above syllabus each student has to perform at least eight experiments. 1. Calibration of passometer 2. Angle and radius measurement a. V-block b. Internal dove tail c. External dovetail d. Radius measurement 3. Gear measurement 4. Sphere and bore measurement Sphere measurement a. Bore measurement-two balls method b. Bore measurement-four balls method c. Measurement of taper using rings 5. Screw thread measurement 6. Taper measurement a. Taper of tail stock centre b. Taper of taper hole c. Taper of taper ring gauge d. Taper of tapered plug gauge 7. Control charts for a variables 8. Optical method a. Parameters of screw threads by microscope b. Parameters of screw threads by profile projector c. Parameters of screw threads by traveling microscope BOOKS RECOMMENDED 1. 2. 3. 4. 5. Jain R.K., Engineering Metrology, Khanna Publishers, 2005. Gupta I.C., A Text Book of Engineering Metrology, Dhanpat Rai and Sons, 1996. Hasen, Bertrand L. and Chare, Prabhakar M., Quality Control and Application, Prentice Hall India, 1999. Mitra Amitava, Fundamentals of Quality Control and Improvement, Pearson Education, 2004. Mahajan M., Statistical Quality Control, Dhanpat Rai and Sons, 2000.

24

B. Tech. (MECHANICAL) Semester 6 (INST. ELECTIVE- II) ME 312 INDUSTRIAL ENGINEERING

L 3

T 0

P 0

C 3

INDUSTRIAL ENGINEERING (01 Hour) Introduction, history, activities & techniques of Industrial Engineering, Organization of Industrial Engineering Department. PRODUCTIVITY (03 Hours) Production & productivity, factors influencing productivity technological advancement & human factors, measurement of productivity (Productivity Index) , causes of low productivity and techniques of their elimination, improving productivity by reducing work content & ineffective time. WORK STUDY (11 Hours) Work content, excess work content & ineffective time , Method study objectives, steps, selection of job, process charts, micro-motion & memo-motion studies, principles of motion economy Therbligs, Workplace layout, Work Measurement objectives, steps, techniques, performance rating, allowances of standard time, techniques of work measurement , Work Sampling confidence levels, methods of work sampling, Computation of machines utilization & standard time , Predetermined Motion Time Systems (PMTS) , Work Factor System, Method Time measurement (MTM) - MTM basic motion elements, Production study, Physiological work measurement. PRODUCT RESEARCH, DEVELOPMENT AN D DESIGN (02 Hours) Product life cycle, selection of a profitable product, product design & development, process, product analysis Tools for product development viz. Standardization, Simplification, diversification, specialization etc. concurrent design, Design for Manufacturing & Assembly (DFMA), Reverse engineering, Manufacturability, Ergonomic considerations in Product design, Process design. MATERIALS MANAGEMENT & INVENTORY CONTROL (06 Hours) Materials management, inventory, costs selective inventory control ABC analysis, safety stock, inventory models such as basic EOQ model, inventory with planned shortages, inventory with quantity discount, inventory with finite replenishment, ideal & real inventory management systems, inventory cont rol systems. DEMAND (SALES) FORECASTING (06 Hours) Quantitative forecasting techniques such as time series analysis, method of least squares, simple moving & weighted moving average regression & correlation; exponential smoothing methods, economic indicators method, qualitative forecasting techniques such as collective opinion method, Delphi technique etc, measures of forecast accuracy, selecting a forecasting method, costs and accuracy of forecasts . VALUE ENGINEERING (04 Hours) Value analysis & value engineering, reasons for unnecessary costs, Function Analysis System Technique (FAST), Techniques of value analysis & value engineering, value analysis procedure & questionnaire. PRODUCT COST CONCEPTS & BREAK -EVEN ANYLSIS (02 Hours) Costs of production, classification of costs, analysis of production costs, Break -even analysis graphical as well as mathematical analysis, costs volume Profit (CVP) analysis, managerial uses of Break even chart, Applications of Break -even analysis. ERGONOMICS (Human Factor Engineering) (03 Hours) Objectives of human engineering, Ergonomics, productivity and working environment, man -machine systems, design of controls & information displays, working environment factors , Anthropometry, Human activities. Biomechanics, nature of movements, expenditure of energy for movements, Layout of working space , seating arrangements for providing maximum comfort. ADVANCED INDUSTRIAL ENGINEERING TECHNIQUES (07 Hours) Total Quality Management (TQM), Business Process Reengineering (BPR), Just -in-time (JIT) manufacturing, Lean management, Total Productive Maintenance (TPM), World Class manufacturing (WCM) etc.

(Total Lecture Hours: 45)

25

BOOKS RECOMMENDED 1. 2. 3. 4. Mahajan M., Industrial Engineering and Production Management, Dhanpat Rai & Sons, Delhi, 2005. Telsang M., Industrial Engineering and Production Management, S. Chand & Co., New Delhi, 2005. Sharma S.K. and Sharma Savita, Work Study and Ergonomics, S.K. Kataria & Sons, De lhi, 2007. Sharma S. K., Sharma Savita and Sharma Tushar, Industrial Engineering and Operations Management, S.K. Kataria & Sons, New Delhi, 2004. 5. International Labour Organization, Geneva, Introduction to Work Study, 2005. 6. Paneerselvam R., Production and Operations Management, Prentice Hall India, 2005.

26

B. Tech. (MECHANICAL) Semester 6 (INST. ELECTIVE- II) ME 314 PLANT LAYOUT & MATERIAL HANDLING INTRODUCTION Plant design, types of manufacturing pro cess-plant design.

L 3

T 0

P 0 (04 Hours)

C 3

PLANT LOCATION (06 Hours) Influence of location on plant layout-location factors-plant size selection guide-location theory and models. INDUSTRIAL BUILDING (07 Hours) Relationship between the building and layout, building design and construction bays-floors-walls and windows-roots and ceiling. Types of building single story building and multi story building -constructional material. PLANT LAYOUT PROBLEM S (08 Hours) Why layout problems develop, classes of plant layout problems -objectives-classification of layout-product layout-process layout and fixed position layout -organization layout. Employee services-working conditions-the influence of organization and wage incentives -human relations DATA COLLECTION Use of work study in plant layout -plant layout tools and techniques. EVALUATION OF LAYOUT Measurement of effectiveness-systematic evaluation-optimizing evaluation. (06 Hours)

(06 Hours)

MATERIAL HANDLING (08 Hours) Types of material handling equipments, hoists, different types hand and power drives, different types of conveyers, elevators, etc. (Total Lecture Hours: 45)

BOOKS RECOMMENDED 1. 2. 3. 4. 5. Joseph S. Martinich, Production and Operation Management, John Wiley and Sons, 2002. Adams E.E., and Ebert R.J., Production and Operation Management, Prentice Hall India, 2000. Mahapatra P.B., Computer Aided Production Management , Prentice Hall India, 2001. Manocha R.C., Production and Operation Management, Excel books, New Delhi, 2003. Allegr Thodore H., Material Handling, Principles and Practice, CBS Publishers, New Delhi , 1987.

27

B. Tech. (MECHANICAL) Semester 6 (INST. ELECTIVE- II) ME 316 MICROPROCESSOR & APPLICATIONS

L 3

T 0

P 0

C 3

INTRODUCTION (07 Hours) Microprocessors and microcomputers, review of digital logic, boolean algebra and numbering systems. COMBINATIONAL AND SEQUENTIAL LOGIC (10 Hours) Boolean functions of two, three and four variables, karnaugh maps, elementary ideas about logic circuits of interest such as half and ful l adder, magnitude comparator, d ecoders, encoders, multiplexers, demultiplexers, flip-flops, counters and timers. 8085 MICROPROCESSOR ARCH ITECTURE (10 Hours) Memory interfacing, interfacing of input -output devices, microcomputer system based on 8085. 8051 MICROCONTROLLER ARCHITECTURE (10 Hours) Assembly language programming for 8051, instruction set, addressing modes, p eripherals of 8051, embedded C programming for 8051. APPLICATIONS OF MICROPROCESSORS AND MICROCONTROLLERS (08 Hours) Applications in mechanical and production engineering such as motion control, data acquisition systems , process control, etc.

(Total Lecture Hours: 45) BOOKS RECOMMENDED 1. Gaonkar R.S., Microprocessor Architecture, Programming and Applications with the 8085, Penram International, Mumbai, 2007. 2. Malvino A.P. and Leach D.P., Digital Principles and Applications, Tata McGraw Hill, New Delhi, 1991. 3. Mazidi M.A., 8051 Microcontroller and Embedded Systems, Pearson Education, 2003. 4. Ayala K., The 8051 Microcontroller, Thomson Delmar Learning, 2005. 5. Kent Stiffler A., Design with Microprocessors for Mechanical Engineers, Mc Graw Hill, 1992.

28

B. Tech. (MECHANICAL) Semester 6 (INST. ELECTIVE- II) PR 312 ELEMENTS OF AUTOMOBILE ENGINEERING INTRODUCTION Introduction of I. C. Engines. BASIC CONCEPTS OF AIR STANDARD CYCLE AN D FUEL AIR CYCLES Air & fuel standard cycles, Fuel - air mixtures, Ideal & actual cycles. COMBUSTION AND ITS FACTORS IN IC ENGINE I.C. Engine Combustion processes, Detonation, Delay period, Diesel knock.

L 3

T 0

P 0 (02Hours) (07Hours) (07Hours)

C 3

FUEL INJECTION SYSTEM IN AUTOMOBILE ENGINE (10Hours) Carburetors, Fuel injection systems in S.I. and C.I. engines, Electronic fuel injection systems. ADVANCED LUBRICATION AND HEAT REJECTION SYSTEM Function and Types of Lubrication and cooling system of automobile engines. PERFORMANCE PARAMETERS IN AUTO MOBILE ENGINES Testing and performance of S. I. Engine & C. I. Engine ENGINE EMISSIONS AND THEIR CONTROLS Pollutants and their related problems, Emission Control from Gasoline and Diesel Engines. ADVANCES IN IC ENGINES Alternate fueled engines, Alcohol, hydrogen , biofuels, hybrid vehicles. (03Hours) (05Hours) (02Hours) (02Hours)

CONCEPTS OF AUTOMOBILE TRANSMISSION AND TRANSAXLES (07Hours) Types of transmission systems used in automotive vehicles, Braking and Suspension system , Steering systems and their types, Electrical systems , Chasis, Wheels, Tyres. (Total Lecture Hours: 45) PRACTICALS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. A General Study of I. C. Engines. Study of S. I. & C.I. Engine System Valve Timing Diagram and Port Timing Diagram Morse Test A Constant Speed Load Test Heat Balance Test on a 4-Stroke Diesel Engine Study of Transmission System of Automobile Study of Principle of Steering Wheel Alignment and Wheel Balancing of automobile vehicle. Ignition and brake system.

BOOKS RECOMMENDED 1. 2. 3. 4. 5. 6. 7. Ganeshan V., Internal Combustion Engines , McGraw Hill, New Delhi, 2007. Heywood J.B., Internal Combustion Engine F undamentals, McGraw Hill, Singapore, 2002. Gupta H.N., Fundamentals of Internal Combustion Engines, Prentice Hall India, 2006. Agrawal Shyam K., Internal Combustion Engines, New Age International, New Delhi, 2006. Narang G.B.S., Automobile Engineering, Khanna Publishers, New Delhi, 2002. Mathur M.L. and Sharma R.P., A Course in Internal Combustion Engines, Dhanpat Rai and Sons, 1992. Ferguson C.R. and Kirkpatrick A.T., Internal Combustion Engines Applied Thermosciences, John Wiley, New York, 2001

29

B. Tech. (MECHANICAL) Semester 6 (INST. ELECTIVE- II) ME 318 CORROSION ENGINEERING

L 3

T 0

P 0

C 3

INTRODUCTION TO CORROSION (05 Hours) Cost of corrosion, Corrosion damage, Corrosion rate expressions, electrochemical corrosion of metals , origin of Pourbaix diagram. NACE Terminology Importance of corrosion control. CORROSION & ITS CONTOL (08 Hours) General corrosion, galvanic corrosion, crevice corrosion, pitting corrosion, intergranular corrosion, selective leaching, erosion corrosion, stress corrosion, overview of hydrogen cracking. High temperature corrosion. CORROSION OF VARIOUS MATERIALS (07 Hours) Corrosion of Steels, Stainless steels, Aluminium alloys, Copper alloys, Nickel and Titanium alloys ,Corrosion of polymers, Ceramics and composite materials and their control. CORROSION IN SELECTED ENVIRONMENTS & ITS CONTROL (09 Hours) Atmospheric Corrosion, Corrosion of Automobiles, Corrosion of Steel in Concrete, Corrosion in Sea water, Microbiologically Induced Corrosion, overview of corrosion in body, overview of corrosion in aircraft, Corrosion in the Petrochemical Industry, Corrosion in Paper and pulp industry and its control. CORROSION TESTING (08 Hours) Purpose Importance of testing, laboratory, semi-plant and field tests, ASTM standards for testing , stress corrosion cracking and pitting, sequential procedure for laboratory and on -site corrosion investigations. CORROSION PREVENTION (08 Hours) Purification & alloying of metal, Material selection, Alteration of Environment, Design modification, Cathodic and Anodic protection, Coatings (metallic ,inorganic ,non metallic and organic) (Total Lecture Hours: 45) BOOKS RECOMMENDED 1. 2. 3. 4. 5. Fontana G., "Corrosion Engineering ", McGraw -Hill, 1985. Schweitzer P.A., "Corrosion Engineering Hand Book ", Marcel Dec ker, 1996. Winston Revie and R, Uhlig, "Corrosion Hand Book ", John Wiley, 2000. Raj Narayan, An Introduction to Metallic Corrosion and its Prevention , Oxford and IBH, 1983. ASM International, Metals Handbook", 1996.

30

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Minor 2 - REVISED Final Schedule 5 OctДокумент2 страницыMinor 2 - REVISED Final Schedule 5 OctRohan PaliwalОценок пока нет

- MlearningДокумент1 страницаMlearningRohan PaliwalОценок пока нет

- Sem3 - Time Table - MBA'16 - Sheet1Документ1 страницаSem3 - Time Table - MBA'16 - Sheet1Rohan PaliwalОценок пока нет

- MlearningДокумент1 страницаMlearningRohan PaliwalОценок пока нет

- Ports & PlantsДокумент2 страницыPorts & PlantsRohan PaliwalОценок пока нет

- Segmentation Targeting and Positioning of Nestle Marketing EssayДокумент15 страницSegmentation Targeting and Positioning of Nestle Marketing EssayRohan PaliwalОценок пока нет

- Cokingcoal SampleДокумент18 страницCokingcoal SampleRohan PaliwalОценок пока нет

- 10 Grammar Mistakes That Make You Look Stupid PDFДокумент3 страницы10 Grammar Mistakes That Make You Look Stupid PDFPrachi MahajanОценок пока нет

- Tata SoulДокумент4 страницыTata SoulAshish RebornОценок пока нет

- Payment Details Transaction ID AHDF3514552551 Idea Number 7351954665 Transaction Date 11-10-2014 06:18:10 Amount 150.00Документ1 страницаPayment Details Transaction ID AHDF3514552551 Idea Number 7351954665 Transaction Date 11-10-2014 06:18:10 Amount 150.00Rohan PaliwalОценок пока нет

- Mark e Diction Quiz AnswersДокумент2 страницыMark e Diction Quiz AnswersRohan PaliwalОценок пока нет

- BtechДокумент61 страницаBtechRohan PaliwalОценок пока нет

- CL Mock Xat - 3Документ28 страницCL Mock Xat - 3v2k5Оценок пока нет

- Gaurav Seminar ReportДокумент29 страницGaurav Seminar ReportRohan PaliwalОценок пока нет