Академический Документы

Профессиональный Документы

Культура Документы

Johnson Industries

Загружено:

Priya NawaleИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Johnson Industries

Загружено:

Priya NawaleАвторское право:

Доступные форматы

Erp and case analysis On Johnson and johnson Presented by Hepsy verghese Tracy H imanshu sati

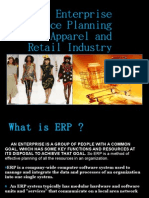

ERP SYSTEM Stands for Enterprise Recourse Planning. Way to integrate data and processes of an organization into a single system. ERP major components are Hardware and Soft ware. Uses a unified database to store data for various functions of organizatio n. Functions such as HR, Supply Chain Management(SCM) and Warehouse Management f un are integrated under ERP.

Integration is a key for ERP ERPs main goal is to integrate data and processes from all the areas of the organ ization. Provide easy access to data and workflow in the organization. It create s a single database that employs multiple software providing different areas of organization with various functions.

ERP System Concept

Advantages of an ERP system A totally integrated system. The ability to streamline various processes and wor kflows. The ability to easily share data among various departments in an organiz ation. Improved efficiency and productivity levels. Better tracking and forecast ing. Lower cost. Improved customer service.

Disadvantages of ERP system Time consuming. Expensive. Conformity to the modules. Vendor dependence. Feature s and complexity. Scalability and global outreach.

Some of the ERP modules are Accounting Management. Financial management. Manufacturing management. Productio n Management. Transportation Management. Sales and Distribution Management. Huma n Resource Management. Supply Chain Management. E-Business.

COMPANY OVERVIEW Originated in. 1920s. Corporate headquarters-Atlanta 1988-Genuine parts /NAPA acquir ed Johnson industries. Largest OEM auto parts distributer in the country. Annual s ales-$150m It now serves automotive repair facilities throughout the United State s. Largest distributers of acdalco, motorcraft

CHALLENGES FACED Johnson industries procured businesses in similar markets. Cont ract with JD Edwards software implementation. C.D groups audit discovered follow ing problems in the implementation. Only the general ledger module was implemente d with the entire

Functions and duties across the organization were not consolidated. No clear strat egy or solution were defined with regard to centralization of business processes . Critical business practices were distributed across several DCs.

Job duties were duplicated creating inefficiencies. Created high degree of complex ity. Generation of multiple statements creating multiple identities.

DRAWBACKS OF CURRENT LEGACY SYSTEM No longer supported its needs.duplicate and inconsistent business practices and rules No support for multi-warehousing functionality. Limited ability to smooth slower moving inventory between distribution centers. Absence of automation crea ted

Solution New business model implemented by CD Group which represented Johnson Industries as a single entity. The new model used JD Edwards OneWorld in a centralized foot print, using an NT operating system and a SQL database to support multiple wareh ouses as a standard for all distribution centers.

Changes brought in Incorporated centralized, critical business processes (i.e. journal entries, pur chasing, paying suppliers, etc.) in all DCs to ensure consistent Best Practices ac ross the organization. Benefits enabled customers to receive one statement for all purchases Ability to forward al l payments to a single location. Standardizing customer and item numbers

Step 1 RF technology was leveraged to automate the tracking of inventory movement withi n a DC Benefits Inventory balances updated immediately Eliminating of paper trail and human inte rvention required to manually update inventory.

Step 2 Implemented a warehouse location system to improve inventory tracking. Be nefits - provided visibility to inventory on the receiving dock, in a staging ar ea, in product overflow, or on the shelf. Step 3 Applied a consistent cycle count program that validated and maintained in ventory accuracy. Benefits - Rebuilt confidence among management regarding inven tory accuracy

Business Benefits Streamline future acquisitions Increase inventory turns and im prove cash flow Ensure the consistent and timely application of price changes Pr esent a single company image to its customer base Defer the need for warehouse e xpansions Close the month earlier

Increased inventory visibility across DCs and among customer service personnel. Johnson Industries received a one-time reduction in inventory estimated at $7.6M in annual inventory carrying costs. Consolidation of the different IT systems c aused reduced hardware and software maintenance expenses. Incorporation of Best Practices standards model reduced employee training costs. and

THANK-YOU

Вам также может понравиться

- Johnson IndustriesДокумент21 страницаJohnson Industriesaarun01Оценок пока нет

- 2 - Erp GeneralДокумент31 страница2 - Erp Generalpujakumari_niam10Оценок пока нет

- Phases of Erp ImplementationДокумент20 страницPhases of Erp ImplementationSuda Aravindnath ReddyОценок пока нет

- Case Study Emerson and Sanofi: Data Stewards Seek Data Conformi TYДокумент28 страницCase Study Emerson and Sanofi: Data Stewards Seek Data Conformi TYTaimoorAdilОценок пока нет

- Enterprise Resource and Planning - ERPДокумент20 страницEnterprise Resource and Planning - ERPyogendra reddyОценок пока нет

- Constructing An E-Supply Chain at Eastman Chemical CompanyДокумент37 страницConstructing An E-Supply Chain at Eastman Chemical CompanyrronyyОценок пока нет

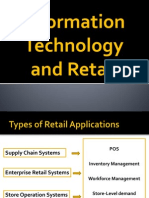

- It and RetailДокумент49 страницIt and RetailchetnachhabraОценок пока нет

- Enterprise Resource Planning: The Rising: Organizational Value SystemsДокумент6 страницEnterprise Resource Planning: The Rising: Organizational Value SystemsSudhaОценок пока нет

- ERP Basics, Business Functions and ProcessesДокумент69 страницERP Basics, Business Functions and ProcessesRahul Abhishek MehraОценок пока нет

- Bhupesh Negi (OM Articles)Документ6 страницBhupesh Negi (OM Articles)Bhupesh NegiОценок пока нет

- ERP OverviewДокумент16 страницERP OverviewAtanu GhoshОценок пока нет

- Unit 1 Part AДокумент42 страницыUnit 1 Part AShanthiОценок пока нет

- LectraДокумент38 страницLectraNiharika SinhaОценок пока нет

- Implementing an ERP System at Rolls-RoyceДокумент15 страницImplementing an ERP System at Rolls-RoyceAbhinav SrivastavaОценок пока нет

- Enterprise Resource Planning in Apparel and Retail IndustryДокумент36 страницEnterprise Resource Planning in Apparel and Retail IndustrypankhuripalОценок пока нет

- Bab 3.1Документ20 страницBab 3.1SYED AHMAD SHAUQI BIN SYED SHUHAIMIОценок пока нет

- Implementing An ERP SystemДокумент6 страницImplementing An ERP SystemTayyaba IshtiaqОценок пока нет

- Name: Roll No: Department: Section:: Madhusmita Mishra 1006247081 M.B.A (First Year) "B"Документ17 страницName: Roll No: Department: Section:: Madhusmita Mishra 1006247081 M.B.A (First Year) "B"Vivek KumarОценок пока нет

- Enterprise Resource Planning ERPДокумент16 страницEnterprise Resource Planning ERPsaifОценок пока нет

- Chapter 1Документ52 страницыChapter 1Suresh VenkateshwaranОценок пока нет

- Business Process Reengineering: ERP-Lecture 16319Документ6 страницBusiness Process Reengineering: ERP-Lecture 16319neeraj sainiОценок пока нет

- Enterprise Resource Planing SystemsДокумент70 страницEnterprise Resource Planing Systemsaagrawal3Оценок пока нет

- Enterprise Resource PlanningДокумент6 страницEnterprise Resource PlanningLucaОценок пока нет

- Chapter 3Документ26 страницChapter 3Mira Nayrouz50% (2)

- Q-A SCMДокумент4 страницыQ-A SCMDil FarzanaОценок пока нет

- ERP-40Документ14 страницERP-40Arunima BanerjeeОценок пока нет

- IT Management in Supply Chains - Omkar Khairmode - HPGDJL213544Документ15 страницIT Management in Supply Chains - Omkar Khairmode - HPGDJL213544Venkatesh KamathОценок пока нет

- Dell's Supply Chain & Operations Management Case StudyДокумент29 страницDell's Supply Chain & Operations Management Case StudySavan BhattОценок пока нет

- CH 1 Introduction To Enterprise Resource Planning SystemsДокумент20 страницCH 1 Introduction To Enterprise Resource Planning SystemsPurdianta YoОценок пока нет

- CHAPTER10 - Resource PlanningДокумент18 страницCHAPTER10 - Resource PlanningGeni AshuraОценок пока нет

- Enterprise Resource Planning June 2023 Assignment SolutionДокумент10 страницEnterprise Resource Planning June 2023 Assignment SolutionAnket SinghОценок пока нет

- Enterprise Resource PlanningДокумент20 страницEnterprise Resource PlanningAishwarya SinghОценок пока нет

- ERP Implementation FundamentalsДокумент22 страницыERP Implementation Fundamentalssowmithra4uОценок пока нет

- Erp ImplementationДокумент57 страницErp Implementationchakradhar_yenigallaОценок пока нет

- Management Information SystemДокумент33 страницыManagement Information SystemTrần Huỳnh NhưОценок пока нет

- Basic Introduction About SAP ERP ECC and FICOДокумент12 страницBasic Introduction About SAP ERP ECC and FICOsurnis4onkarОценок пока нет

- Erp An OverviewДокумент19 страницErp An OverviewPradeesh Kumar.AОценок пока нет

- ERP Implementation Fundamentals: Richard Byrom Oracle Consultant, Speaker and AuthorДокумент23 страницыERP Implementation Fundamentals: Richard Byrom Oracle Consultant, Speaker and AuthorsajidschannelОценок пока нет

- Erp Complete FileДокумент179 страницErp Complete FileShanthiОценок пока нет

- ERP Explained: What is ERP SoftwareДокумент7 страницERP Explained: What is ERP SoftwareSaleh AlgdaryОценок пока нет

- Advantages Disadvantages of ERPДокумент14 страницAdvantages Disadvantages of ERPKundan Singh100% (1)

- Enterprise Resource Planning (Unit-1) Alish Patel: Overview of ERP Software SolutionsДокумент9 страницEnterprise Resource Planning (Unit-1) Alish Patel: Overview of ERP Software SolutionsKrishna KantОценок пока нет

- Enterprise Resource PlanningДокумент26 страницEnterprise Resource PlanningHemal Patel SamОценок пока нет

- Storyboard Data Warehouse Planning GuestДокумент15 страницStoryboard Data Warehouse Planning GuestHani SalemmОценок пока нет

- An Overview - Enterprise: Prepare By: Dr. Usman Tariq 08 January 2020Документ26 страницAn Overview - Enterprise: Prepare By: Dr. Usman Tariq 08 January 2020Faisal AlharbiОценок пока нет

- Logistics Management System Complete DocumentationДокумент99 страницLogistics Management System Complete DocumentationDrapeeto33% (9)

- Business Case - Item Master EnrichmentДокумент12 страницBusiness Case - Item Master EnrichmentMohamed AzarudeenОценок пока нет

- Questions From Chapter 9Документ3 страницыQuestions From Chapter 9Syeda Wahida SabrinaОценок пока нет

- Class PresentationДокумент142 страницыClass PresentationFaisal RashidОценок пока нет

- Information System Unit 4 NotesДокумент33 страницыInformation System Unit 4 NotesNithya KarthikОценок пока нет

- ERP Implementation Challenges at Pantaloons and Overstock.comДокумент34 страницыERP Implementation Challenges at Pantaloons and Overstock.comGURNOOR KAURОценок пока нет

- ErpmДокумент19 страницErpmakshay kushОценок пока нет

- ITM7-Group2 PepsiAmericasДокумент11 страницITM7-Group2 PepsiAmericasSneha Lundia AgrawalОценок пока нет

- Lecture 4 Achiving Strategy Through TechnologyДокумент9 страницLecture 4 Achiving Strategy Through TechnologyKatongo ChisakutaОценок пока нет

- SCM & ErpДокумент31 страницаSCM & ErpVrinda MadhuОценок пока нет

- Case Study Analsys of International Trade Logistics: Prof. K K K ChandДокумент6 страницCase Study Analsys of International Trade Logistics: Prof. K K K Chandsuchanda87Оценок пока нет

- Casestudy03 Pemeco-Implements-Optimize v3Документ5 страницCasestudy03 Pemeco-Implements-Optimize v3alaric7nurmОценок пока нет

- Supply Chain Optimization ForecastingДокумент4 страницыSupply Chain Optimization Forecastingहुडदंग हास्य कवि सम्मलेनОценок пока нет

- A Study of the Supply Chain and Financial Parameters of a Small BusinessОт EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessОценок пока нет

- CyberTech - Cisco VoIP Recording MethodsДокумент17 страницCyberTech - Cisco VoIP Recording MethodsImtiaz AhmadОценок пока нет

- Spaulding Lighting New Yorker Spec Sheet 8-84Документ2 страницыSpaulding Lighting New Yorker Spec Sheet 8-84Alan MastersОценок пока нет

- Case Study Sheet - 01Документ6 страницCase Study Sheet - 01Irfan PashaОценок пока нет

- Viewguide 1Документ2 страницыViewguide 1api-424173654Оценок пока нет

- Project Title:: Checklist For PlasteringДокумент2 страницыProject Title:: Checklist For Plasteringalfie100% (6)

- Glasgow Library Facade OverhaulДокумент9 страницGlasgow Library Facade OverhaulSubhishasri A K VОценок пока нет

- Chapter 4 Hotel ReservationДокумент61 страницаChapter 4 Hotel ReservationEni Syafina RoslanОценок пока нет

- Pneumatic StructuresДокумент7 страницPneumatic StructuresMicah EuropaОценок пока нет

- Data Presentation PDFДокумент2 страницыData Presentation PDFGP Priela100% (1)

- Exam Management System NotesДокумент24 страницыExam Management System NotesRanganathan NagendranОценок пока нет

- Mac Operating SystemДокумент12 страницMac Operating SystemMaham100% (1)

- Modern Network Security Threats EvolutionДокумент143 страницыModern Network Security Threats EvolutionNabila Fauzi100% (1)

- Quiz Paper Concrete QuestionsДокумент5 страницQuiz Paper Concrete QuestionsNeha ChauhanОценок пока нет

- Chapter 1 Sample ThesisДокумент6 страницChapter 1 Sample ThesisIan Ignacio AgngarayngayОценок пока нет

- Air Handling Units GuidelineДокумент5 страницAir Handling Units GuidelineImam MansyurОценок пока нет

- Intel 22nm SoC BriefingДокумент11 страницIntel 22nm SoC BriefingAnuradha PatilОценок пока нет

- SWIMMING POOL HYDRAULIC ANALYSISДокумент6 страницSWIMMING POOL HYDRAULIC ANALYSISdcoveОценок пока нет

- Vti FpxploitationДокумент52 страницыVti FpxploitationMoshe ZioniОценок пока нет

- Data Domain DD OS 5.4 Hardware Installation: Student GuideДокумент83 страницыData Domain DD OS 5.4 Hardware Installation: Student GuideLouis Thierry Ekwa Bekok0% (1)

- WTX Product OverviewДокумент3 страницыWTX Product OverviewRavi DingariОценок пока нет

- Computer Graphics Second Module SecondДокумент19 страницComputer Graphics Second Module Seconddgk84_idОценок пока нет

- Troubleshooting RPC Endpoint Mapper Errors Using The Windows Server 2003 Support Tools From The Product CDДокумент17 страницTroubleshooting RPC Endpoint Mapper Errors Using The Windows Server 2003 Support Tools From The Product CDAnderson SilvaОценок пока нет

- JK Cement ISIN Numbers ListДокумент621 страницаJK Cement ISIN Numbers ListkenindiОценок пока нет

- Preparing A Technical Report: SHAC Judging CriteriaДокумент4 страницыPreparing A Technical Report: SHAC Judging CriteriatzmtzmОценок пока нет

- LSI Starbeam Series Brochure 1994Документ6 страницLSI Starbeam Series Brochure 1994Alan MastersОценок пока нет

- SWE321 - Data Centered DesignДокумент19 страницSWE321 - Data Centered DesignZeeshan RasoolОценок пока нет

- Prequalified Seismic Moment ConnectionsДокумент2 страницыPrequalified Seismic Moment Connectionssymon ellimacОценок пока нет

- Project Name: 4G1-MW Project Number: 77075: Swlhrraa Swlhrraa Swlhrraa Swlhrraa SwlhrraaДокумент61 страницаProject Name: 4G1-MW Project Number: 77075: Swlhrraa Swlhrraa Swlhrraa Swlhrraa SwlhrraaAbdallahMohmmedОценок пока нет

- Terminology of Valves Used PDFДокумент11 страницTerminology of Valves Used PDFglazetmОценок пока нет

- ALPHA Script - PresentationДокумент13 страницALPHA Script - PresentationGeorge DelaportasОценок пока нет