Академический Документы

Профессиональный Документы

Культура Документы

AN2459 Application Note

Загружено:

AmrRassemИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

AN2459 Application Note

Загружено:

AmrRassemАвторское право:

Доступные форматы

AN2459 Application note

Digital Power Factor Correction for Tube Lamp Ballasts and other digital power supplies controlled by an 8-bit microcontroller

Introduction

The electronic ballast market has undergone dramatic changes over the last few years. It has moved from full analog, very differentiated applications made by a collection of drivers and controllers, where use of custom ASICs was widespread, to a couple of standard platforms. The basic building blocks are still the same. They include a power factor corrector stage and an inverting high voltage stage (Figure 1). On the one hand, analog platforms are targeting the low cost/basic performance applications. Their main drivers and controllers are widely used and well known ICs such as Power Factor Correctors (L6561/2/3) and High Voltage Ballast Controllers (L6569x/ L6571x/ L6574). On the other hand, a new digital platform concept has gained more interest and acceptance. A microcontroller with a simple Half Bridge Driver (L638x) has replaced the ballast controller. The Half Bridge Driver is used mainly for high-end applications, especially where the microcontroller has to deal with communication tasks (e.g. using the Dali protocol). STMicroelectronics' digital ballast reference design STEVAL-ILB002V1 introduces a safe operating Power Factor Controller (PFC) and Ballast Controller. Even with relatively simple microcontroller firmware routines, the results for power control and ballast protection are in line with advanced analog controlled ballasts, while adding flexibility, for example, the possibility to drive a wide variety of lamps, or to easily introduce different protection schemes. This application note deals in detail with the first block of the digital ballast, which provides stable DC bus voltage for the halfbridge in all load conditions, as well as controlling the input current shape which fulfills IEC standards (6.: IEC 61000-3-2 "Electromagnetic compatibility".). The final description of the digital ballast - the lamp control block - will be described in detail in a separate application note.

Figure 1.

Digital ballast scheme

Input Filter

8- Bit Microcontroller ST7FLITE19B

Power Management Unit L6382D5

January 2007

Rev 1

1/35

www.st.com

Contents

AN2459 - Application note

Contents

1 2 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Power Factor Correction (PFC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 2.2 Transition Mode operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Digital implementation - Enhanced One Pulse Mode . . . . . . . . . . . . . . . . . 6

Power circuits design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 3.2 3.3 Power components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Bill of material (STEVAL-ILB002V1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Signals measurement, processing & control . . . . . . . . . . . . . . . . . . . . 15

4.1 4.2 4.3 4.4 Input voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Output voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Zero Current Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 MOSFET current measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5 6

Conclusion and outlook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 References and related materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Appendix A Components calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

A.1 A.2 A.3 A.4 A.5 Input capacitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Output capacitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Boost inductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 Power MOSFET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Boost Diode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2/35

AN2459 - Application note

List of tables

List of tables

Table 1. Table 2. Table 3. Table 4. Bill of material - PFC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Bill of material - Lamp Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 Bill of material - general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14 Document revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3/35

List of figures

AN2459 - Application note

List of figures

Figure 1. Figure 2. Figure 3. Figure 4. Figure 5. Figure 6. Figure 7. Figure 8. Figure 9. Figure 10. Figure 11. Figure 12. Figure 13. Figure 14. Figure 15. Figure 16. Figure 17. Figure 18. Figure 19. Digital ballast scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 PFC Transition Mode principle (frequency is not to scale) . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Principle of the Enhanced One Pulse Mode, inside the ST7Lite1B . . . . . . . . . . . . . . . . . . . 7 Input voltage & current with modified EMI filter (compared to STEVAL-ILB002V1) PF = 0.994 THD = 10.3% . . . . . . . . . . . . . . . . . . . . . . . 8 Input voltage & current measured on STEVAL-ILB002V1 (old EMI filter) PF = 0.991 THD = 10.4% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Schematics of STEVAL-ILB002V1 reference design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Modified EMI filter (not included in STEVAL-ILB002V1 reference design . . . . . . . . . . . . . 11 General flowchart of PFC software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Input voltage sensing circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Input voltage sensing circuit output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 The mains turn-on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Output voltage sensing circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Output voltage control loop flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 Application start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 Lamp restart - behavior of the control loop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Zero current crossing detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 PFC MOSFET overcurrent detection circuit and zero coil current detection circuit with indicated testing connection and microcontroller inner structure . . . . . . . . . . . . . . . . . . . . 24 Maximum MOSFET's TON protection routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Overcurrent reaction demonstration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4/35

AN2459 - Application note

Power Factor Correction (PFC)

Power Factor Correction (PFC)

Theoretically, any switching topology can be used to achieve a high power factor but, in practice, the boost topology has become the most popular because of the advantages it offers. These include:

Circuit requires the least external parts, thus it is the cheapest available. Boost inductor, located between the bridge and the switch, lowers the input di/dt, thus minimizing noise generated at the input and consequently reducing the EMI filter input requirements. Switch is source-grounded and therefore easy to drive. The Fixed Frequency Average Current Mode PWM. The Transition Mode (TM) PWM (fixed on-time, variable frequency). The peak current mode with fixed off-time.

Three methods of controlling the PFC preregulator are currently widely used. They are:

Control of the first method is complicated and requires a sophisticated IC controller (e.g. either ST's L4981A or STs L4981B which offers frequency modulation) and a considerable component count. Control of the second method is simpler (e.g. ST's L6561/2/3 family) and requires fewer external parts. It is therefore much less expensive. With the Fixed Frequency Average Current Mode method, the boost inductor operates in continuous conduction mode, while the TM method causes the inductor to work on the boundary between continuous and discontinuous modes. Thus, for a given throughput power, TM operation involves higher peak currents, suggesting it is more efficient at lower power ranges (typically below 200W). In contrast, the Fixed Frequency Average Current Mode is recommended for higher power levels. A third method of control, that of applying constant. Toff control, results in continuous conduction mode. The same simple TM-controllers may be used, as may a small RC network to set the off-time. This method is described in AN1792 (7) It is optimal for an input power of between 200 and 400W.

2.1

Transition Mode operation

As mentioned above, the typical PFC topology used in electronic ballasts is a step-up (boost) regulator (Figure 1) working in transition conduction mode. Figure 2 outlines the Transition Mode principles. When the MOSFET is turned on, the inductor is charged from the input voltage source. When the MOSFET is turned off, the boost inductor discharges its energy into the load until its current falls to zero. When the latter occurs, the boost inductor has no energy and a zero current (ZCD) signal is detected, due to a demagnetization change on the auxiliary winding. This drives the MOSFET on again, whereby another conversion cycle starts. As the drain voltage drops before turn-on, the turn-on switching losses are minimized. Figure 2 indicates the geometric relationship of average and peak currents. Due to the triangular shape of the inductor current, the peak current is twice the average current.

5/35

Power Factor Correction (PFC)

AN2459 - Application note

Figure 2.

PFC Transition Mode principle (frequency is not to scale)

Peak current enveloppe Inductor current

Average current

On

MOSFET

On

AI12647

2.2

Digital implementation - Enhanced One Pulse Mode

To provide good switch control, as described in Chapter 2.1 above, a simple 8-bit microcontroller may be used and a special PWM timer mode has been introduced. The timer mode, called "Enhanced One Pulse Mode" of the PWM generator (12-bit autoreload timer) is found inside the ST7FLITE19B microcontroller. It is explained in Figure 3 and in datasheet ST7Lite1xB (4). In principle, when a zero current event occurs the microcontroller will reset the timer and turn-on the PFC MOSFET. If there is no signal from ZCD, the timer will overflow and turn-on the MOSFET anyway (it means a minimum switching frequency is secured). The on-time of the MOSFET is set by a software control routine and is constant during the mains half-cycle (this is detailed below in Chapter 4). The control routine executed by the MCU alters the on-time depending on the input voltage level and the load current.

6/35

AN2459 - Application note

Power Factor Correction (PFC)

Figure 3.

Principle of the Enhanced One Pulse Mode, inside the ST7Lite1B

Timer reset caused by ZCD

Timer reset caused by autoreload value match

Compare event

Timer

Events ignored, because MOSFET is turned-on Event Event No event occured

ZCD

On

MOSFET

Off

AI12651

}

7/35

Power circuits design

AN2459 - Application note

3

3.1

Power circuits design

Power components

All components have been calculated following application note AN966 (3). A full description of the design and selection of each component, based on the analog TM PFC controller L6561, is also given in Appendix A. At the moment, input voltage is limited for European mains. Future Software updates will include wide range input capability. Besides the passive and discrete components of the microcontroller, the most important part is the power management unit, L6382D5, which helps control the power. It provides a stable (2%) 5V supply for the microcontroller during the whole operation. It also supplies a high voltage start-up. In addition, one of the general purpose gate drivers integrated inside L6382D5 is used to translate TTL PWM signals from the microcontroller to the boost converter gate of the MOSFET. Figure 4. Input voltage & current with modified EMI filter (compared to STEVAL-ILB002V1) PF = 0.994 THD = 10.3%

Note:

Brown = Mains voltage, Blue = Input current.

8/35

AN2459 - Application note

Power circuits design

Figure 5.

Input voltage & current measured on STEVAL-ILB002V1 (old EMI filter) PF = 0.991 THD = 10.4%

Note:

Brown = Mains voltage, Blue = Input current.

Reference board design measurements of STEVAL-ILB002V1(Figure 5) show a THD value of 10.4% and a PF value of 0.991. Between the manufacturing of the STEVAL-ILB002V1 reference design and publication of this application note, design work has continued and some improvements have been made. For example, EMI filter parameters have been changed from C-L-C to C-L filters, which give better results for waveform, power factor, and THD .This optimized version is given in Figure 7 and result in the measured waveforms shown in Figure 4 with THD = 10.3% and PF = 0.994.

9/35

3.2

R1 1M 350V + BRIDGE RB156 DC400V D2 1N4007 Not assembled TRANSFORMER

10/35

D12

F1

2 4

D7

Figure 6.

FUSE

3 3 1 3

Vcap STTH1R06 NTC1 10 R11 750k C7 22F 22uF 450V STP5NK60Z PFC VOUT Sense 1k R10 1k PFC OC R9 0.5 C6 C5 2n7 AverageLampVoltage 4n7 R13 10k R8 47k DC5V R14 R38 240k R37 240k

T1

J1

1 2 1 2 8 T2

C3 R3 750k

L N PE 2

100n 275VAC R6 PFC Zero Current Detect R4 750k 27k Q1 2 R7 PFC VinWaveform Vi 10 R5 20k R41 2k4 C4 10n PFC Mosfet Gate R12 750k +

C1 100n 275VAC

1 CM C hoke 2

R2 1M 350V

C29 100n

AC

275VAC

C2

1n 275VAC

Power circuits design

1 3

R24

Schematics

AverageCurrent

RsenseCurrent

R39 240k

C22 2 470n

10k

C18 470n

R40 2k4

R25 RsenseCurrent BAT46 C25 C8 Out pin 2.2nF 1000V PFC Mosfet Gate R16 R46 D3 Low Side Input High Side Input CSI CSO R19 10 0 10p 0.6W 0 U2 C26 10p DC5V R18 C27 10p

D5

PFC Gate Driver

PeakCurrent

4k7

R26 4k7 7

C21 470n

Q2 STP5NK60Z

Out pin

Vcap

R27 0.6W RsenseCurrent 18 C11 + 47F L6382 C13 50V 100nF 25V C12 100nF 0.6W 18

CSI

1

D13 STTH1R06A

1 2 3 4 5 6 7 8 9 10 PFI LSI HSI HEI PFG NC TPR GND LSG VCC

1N4148 SMD R20 33 Not assembled

VREF CSI CSO HEG NC HVSU NC OUT HSG BOOT

20 19 18 17 16 15 14 13 12 11

L1

C15 J2 1.8mH 100nF 400V Q3 STP5NK60Z C16 10n 1600V

3k9

R28 1k5

C20 1n

2

D4 DC5V R21 10 0

1 2 3 4

58W T8 lamp DC5V R22 33 1N4148 SMD Not assembled RsenseCurrent R29

DC5V

Schematics of STEVAL-ILB002V1 reference design

1M R30 10k LampDetection

R42 10k PFC Zero Current Detect C28 10p U1 CSO C14 High Side Input Low Side Input PFC Gate Driver LampDetection 10n

R43 10k

R44 10k

R45 10k

C9 220nF

R23 1 2W , ,1%

Vcap C17 10n R31 300k

VSS VDD

C10

10nF

RESET

PFC OC

1 2 3 4 5 6 7 8 9 10 OSC1/CLKIN/PC0 OSC2/PC1 PA0(HS)/LTIC PA1(HS)/ATIC PA2(HS)/ATPWM0 PA3(HS)/ATPWM1 PA4(HS)/ATPWM2 PA5(HS)/ATPWM3/ICCDATA PA6/MCO/ICCCLK/BREAK PA7(HS)/COMPOUT

ST7LITE1B 20pin

RESET COMPIN+/SS/AIN0/PB0 SCK/AIN1/PB1 MISO/AIN2/PB2 MOSI/AIN3/PB3 COMP-/CLKIN/AIN4/PB4 AIN5/PB5 AIN6/PB6

20 19 18 17 16 15 14 13 12 11

R32 300k

PFC Vout Sense

PFC VinW aveform

AverageCurrent R35 PeakLampVoltage 75k C23 68n R36 24k D6

R33 300k

PeakCurrent

PeakLampVoltage 1N4148 SMD C19 4n7 100V R34 100k

AverageLampVoltage

AN2459 - Application note

AI12648

AN2459 - Application note Figure 7.

Power circuits design

Modified EMI filter (not included in STEVAL-ILB002V1 reference design

F1 FUSE R1 1M 3 350V R2 1M 350V 1 CM Choke 45m +4 T1 4 1 2 H C3 2 100n 275VAC D7 BRIDGERB156 3

J1 L N PE AC C2

C1 100n 275VAC

1n 275VAC

AI12646

11/35

Power circuits design

AN2459 - Application note

3.3

Table 1.

Bill of material (STEVAL-ILB002V1)

Bill of material - PFC

Part 2.2n 100n 400V 10n 2n7 4n7 22F 10p Bridge 1N4007 FUSE 10 STP5NK60Z 1M 200V 750k 20k 27k 10 47k 0.5 1k 10k Common mode choke Transformer Connector Description X1,Y2 ceramic capacitor X2 capacitor SMD 0805 SMD 0805 SMD 0805 Elyt 450V SMD 1206 1.5A 600V Not assembled Roundfuse 2A 250V NTC 5R TO 220 SMD 1206 SMD 1206 200V SMD 1206 0.6W, THT 0207 SMD 1206 SMD 1206 SMD 2512 2W 1% SMD 1206 SMD 1206 Murata 0.8mH primary ARK500/3 Vogt 5753201600 STMicroelectronics STP5NK60Z Supplier Order code

Reference C2 C1, C3 C4 C5 C6 C7 C27 D7 D12 F1 NTC1 Q1 R1,R2 R3, R4, R11, R12 R5 R6 R7 R8 R9 R10, R14 R13 T1 T2 J1

12/35

AN2459 - Application note Table 2. Bill of material - Lamp Control

Part 10nF 100nF 10n 100nF 10n 10n 470n 4n7 100V 10p 1n 68n STTH1R06 1N4148 1N4148 BAT46 Connector 1.8m STP5NK60Z 1M 200V 10k 33 33 1 10k 4k7 3k9 1k5 300k 100k 75k 24k 2k4 2k4 240k Description SMD 0805 SMD 1206 50V SMD 0805 400V open case 1600V SMD 1206 SMD 0805, 16V SMD 1206 SMD 0805 SMD 0805 SMD 0805 DO-41 ultrafast diode Not assembled SMD SOD80 SOD 323 ARK500/2 COIL TO 220 SMD 1206 SMD 1206 SMD 1206 Not assembled 1W, SMD 2512, 5% SMD 0805 SMD 0805 SMD 0805 SMD 0805 0.6W, THT 0207, 300V 0.6W, THT 0207, 300V SMD 1206, 200V SMD 1206 0.6W, THT 0207, 300V SMD 1206 0.6W, THT 0207, 300V Vogt Supplier

Power circuits design

Reference C10 C13 C14 C15 C16 C17 C18, C21, C22 C19 C25, C26, C28 C20 C23 D2 D3, D4 D6 D5 J2 L1 Q2, Q3 R29 R30 R19, R21 R20, R22 R23 R24, R42, R43, R44, R45 R25,R26 R27 R28 R31,R32,R33, R34, R35 R36 R40 R41 R37,R38, R39

Order code

STMicroelectronics

STTH1R06

STMicroelectronics

BAT46J

SL 041 123 31 02 STP5NK60Z

STMicroelectronics

13/35

Power circuits design Table 3. Bill of material - general

Part 2.2nF 18 0 STTH1R06A 47F 100nF ST7LITE1B 20pin L6382D5 Description Y1 0.6W, THT 0207 0.6W, THT 0207 SM-A Elyt 35V SMD 1206 DIP 20 SO 20

AN2459 - Application note

Reference C8 R16,R46 R18 D13 C11 C12 U1 U2

Supplier

Order code

STMicroelectronics

STTH1R06A

STMicroelectronics STMicroelectronics

ST7FLIT19BF1B6 L6382D5

14/35

AN2459 - Application note

Signals measurement, processing & control

Signals measurement, processing & control

Figure 8 shows the general flow diagram of the PFC Software. It is described in a step by step fashion in the following paragraphs. Figure 8. General flowchart of PFC software

Power-on

Interrupts and peripheral init

PFC Init (PWM off)

PFC starting

PFC running

Iswitch > IPFCMAX (interrupt) N

Y PFC error

Ballast error

Wait for lamp insertion or mains restart

Reset

AI12649

15/35

Signals measurement, processing & control

AN2459 - Application note

4.1

Input voltage

The first signal used by the microcontroller is a voltage connected to the input connector. This voltage is first divided and filtered by the circuitry shown in Figure 9. Then it is measured by an analog to digital converter (ADC) inside the microcontroller. This signal has several uses. The first is to avoid connecting the wrong input voltage at the beginning (i.e. only European mains are allowed) and second to guard input over-voltage during normal operation. The whole operation is stopped if the microcontroller detects any problems. If an application is stopped due to a fail condition, it could be restarted only by re-lamping (insertion of the lamp) or by mains recycling. The third use of the input voltage measurement is to detect this recycling (disconnection and reconnection of the mains). A fourth use of the input voltage is when it works in conjunction with the main control loop (described in Chapter 4.2) to recognize a zero mains voltage crossing. Figure 9. Input voltage sensing circuit

750k 100n 750k Vin 20k 10n +

AI12652

16/35

AN2459 - Application note

Signals measurement, processing & control

Figure 10. Input voltage sensing circuit output

Note:

Brown = mains voltage, Green = voltage on ADC pin.

17/35

Signals measurement, processing & control Figure 11. The mains turn-on

AN2459 - Application note

Mains turn-on

Input voltage check Input voltage OK

start switching

Note:

Brown = mains, Green = DC output, Purple = PFC MOSFET gate.

4.2

Output voltage

The DC bus voltage (PFC output voltage) is measured by a high voltage divider with a lowpass filter (Figure 12). It is used by the software as an input for a PID regulator to calculate the MOSFET on-time. Parameters for the regulator are not fixed but change depending on the lamp state. This is because the electronic ballast behaves like a load with strongly changing conditions (preheating / ignition / normal operation). Figure 13 outlines one control cycle, and clearly shows that the regulator changes the MOSFET on-time at the synchronization event with the mains voltage zero crossing.

18/35

AN2459 - Application note

Signals measurement, processing & control

Figure 12. Output voltage sensing circuit

DC BUS

750k

750k DC BUS Voltage 1k

4n7

10k

AI12653

Figure 13. Output voltage control loop flowchart

PFC running

Measure VDCBUS Change regulator constants following the load state N VDCBUS within limits? Y

Lamp Control routines

Mains voltage zero crossing?

N Next loop

New TON PID regulator

Set new TON

410V

STOP - Failure

AI12650

19/35

Signals measurement, processing & control

AN2459 - Application note

Figure 14 shows a DC bus voltage waveform during ballast turn-on. The precision of regulation during normal operation (lamp is on) is 5%. The only moment when this accuracy is breached is at ignition phase, when there is a relative fast load change (lamp voltage and current rise quickly). It is assumed that by improving the regulation parameters, the ballast will also work from wide range mains (without any component change). Figure 14. Application start-up

Note:

Brown = VDC BUS; Yellow = lamp current.

Beside the main control loop, output voltage is also used for protection. The software is continuously supervising the output voltage value and when it reaches the upper or lower threshold an error is detected. Overvoltage above the higher threshold could mean that there is an unexpected fast load reduction. Alternatively, breaking the lower threshold means a fast increase of the load. Both situation are considered dangerous and are recognized as faults.

20/35

AN2459 - Application note

Signals measurement, processing & control

Figure 15. Lamp restart - behavior of the control loop

Lamp removed

Lamp inserted

Note:

Brown = DC bus voltage; Blue = lamp filament current.

4.3

Zero Current Detection

Detection of a zero current crossing the PFC inductor is extremely important. As described in Section 2: Power Factor Correction (PFC), a ZCD defines the moment when the switch should be turned-on again. A well-known method used in other analog PFC applications has been implemented for the digital ballast. The secondary winding of PFC inductor (1:10 winding ratio) gives a correct signal for the autoreload timer (Chapter 2.2). Typical signals are shown in Figure 16.

21/35

Signals measurement, processing & control

AN2459 - Application note

Figure 16. Zero current crossing detection

ZDC Event

ZD C

Note:

Green = microcontroller's input pin 18, Blue = inductor current.

22/35

AN2459 - Application note

Signals measurement, processing & control

4.4

MOSFET current measurement

The main reason for measuring a current flowing through the PFC MOSFET is to prevent exceeding the maximum current rating and so saturating the boost inductor which results in damaging components. The software routines in general are too slow to perform fast reaction. For this reason, only hardware peripherals are used, and the software is excluded from the detection of overcurrent. Two extra features of the ST7LITE19B are important for this protection:

the analog comparator; the break function.

The comparator integrated inside the microcontroller (datasheet ST7Lite1xB, 4 section 11.6) is a general purpose analog comparator with either an external or internal reference. Output can be seen on an external pin (Port PA7 - pin 11), or as it is in this case used only internally as an input for the second peripheral - the Break. The Break function is an emergency shutdown used to stop all PWM outputs (i.e. MOSFET gate signals). A detailed description of it may be found in the ST7FLITE19B datasheet, 4 section 11.2.3.3.

23/35

Signals measurement, processing & control

AN2459 - Application note

Figure 17. PFC MOSFET overcurrent detection circuit and zero coil current detection circuit with indicated testing connection and microcontroller inner structure

PFC Coil DC BUS 22F 450V + 27k Zero Current Detect 0.5 2n7

Voltage reference Interrupt generation on rising edge

STPP5NK60Z 1k PFC OC

PB0 (pin 4) +

ST7FLITE19B

BREAK active on rising edge PWM0 PWM1 PWM3 PA2 (pin 16) PA3 (pin 17) PA5 (pin 13) Halfbridge high side Halfbridge low side PFC

DC

Running SW

Over current testing

AI12654

In order to simulate the PFC MOSFET overcurrent without stressing other components of the digital ballast, an external DC source has to be connected in parallel with the sense resistor R9 (0.5). Afterwards, the MOSFETs gate signal is measured, and the protection response time may be obtained, as shown in Figure 19. Such a response time was measured in less than 500ns, which is fast enough to prevent coil saturation and thereby protect the MOSFET from damage. Figure 18. Maximum MOSFET's TON protection routine

Set new TON

TONnew TONMAX Y

N N=0 Use new TON Next loop

TON = TONMAX

N++

Y Error N > NMAX

AI12655

24/35

AN2459 - Application note

Signals measurement, processing & control

In addition to the aforementioned hardware protections, another safety feature (Maximum TON increase protection) is implemented in the software and outlined in Figure 18. During normal operation, the PFC routine counts the number of times the pre-set MOSFET's ontime maximum (TONMAX) is reached. If the maximum count( N MAX) is exceeded an error is introduced and the application is stopped. This condition indicates that the boost converter is unable to reach the required output voltage. Figure 19. Overcurrent reaction demonstration

Microcontroller stops all PWM outputs

Overcurrent introduced

Reaction time < 500ns

Note:

Brown = sense resistor voltage, Green = digital signal for driving MOSFET's gate.

25/35

Conclusion and outlook

AN2459 - Application note

Conclusion and outlook

This application note explains the power factor correction (PFC) stage of the new digital ballast reference design. It demonstrates a synergy between the power management unit L6382D5 and the 8-bit microcontroller ST7FLITE19B in a fully digitally controlled application. The reference design STEVAL-ILB002V1 is introduced with all the features and protections required for high performance digital power supplies/ electronic ballasts. Additional flexibility through the use of a digital approach has been highlighted as well. The document AN1971 (2) could be referred for more information on first implementation of a digital ballast with control based on the ST7Lite09. Other application notes for full digital ballast (reference design STEVAL ILB002V1) are published in two further application notes.

26/35

AN2459 - Application note

References and related materials

References and related materials

1. 2. 3. 4. 5. 6. 7. A. Loidl: "Digital ballast with PFC for Fluorescent Tube Lamps fully digitally controlled by 8-bit microcontroller", PCIM 2006. STMicroelectronics, AN1971 ST7LITE0 Microcontrolled ballast, http://www.st.com/stonline/products/literature/an/10534.pdf. STMicroelectronics, AN966 L6561, Enhanced Transition Mode Power Factor Corrector, http://www.st.com/stonline/products/literature/an/5408.pdf. STMicroelectronics, ST7Lite1xB datasheet, http://www.st.com/stonline/products/literature/ds/11929/st7lit19bf1.pdf. STMicroelectronics, L6382D5 datasheet, http://www.st.com/stonline/products/literature/ds/11138/L6382d5.pdf. IEC 61000-3-2 "Electromagnetic compatibility". STMicroelectronics, AN1792 Design of fixed-off-time-controlled PFC pre-regulators with the L6562, http://www.st.com/stonline/products/literature/an/10238.pdf.

27/35

Components calculation

AN2459 - Application note

Appendix A

Components calculation

This appendix presents guidelines for the calculation of power components. The content is based on the design process defined in AN966 (3).

A.1

Input capacitor

The input high frequency filter capacitor (C3) has to attenuate the switching noise due to the high frequency inductor current ripple (twice the average line current, Figure 9). The worst conditions occur on the peak of the minimum rated input voltage. The maximum high frequency voltage ripple is usually imposed between 1% and 10% of the minimum rated input voltage. This is expressed by a coefficient r (typically, r = 0.01 to 0.1):

High values of C 3 alleviate the burden to the EMI filter but cause the power factor and the harmonic contents of the mains current to worsen, especially at high line and light load. On the other hand, low values of C3 improve power factor and reduce mains current distortion but require heavier EMI filtering and increase power dissipation in the input bridge. It is up to the designer to find the right trade-off in their application.

A.2

Output capacitor

The output bulk capacitor (Co) selection depends on:

the DC output voltage; the admitted overvoltage; the output power; the desired voltage ripple.

A voltage ripple (Vo = 1/2 ripple peak-to-peak value) of 100 to 120Hz (twice the mains frequency) is a function of the capacitor impedance and the peak capacitor current (IC(2f)pk = Io):

With a low ESR capacitor the capacitive reactance is dominant, therefore:

28/35

AN2459 - Application note

Components calculation

Vo is usually selected in the range 1 to 5% of the output voltage. Although ESR usually does not affect the output ripple, it has to be taken into account for power loss calculations. The total RMS capacitor ripple current, including mains frequency and switching frequency components, is:

If the application has to guarantee a specified hold-up time, the selection criterion of the capacitance will change: C o has to deliver the output power for a certain time (tHold) with a specified maximum dropout voltage:

where Vo_min is the minimum output voltage value (which takes load regulation and output ripple into account) and Vop_min is the minimum output operating voltage before the 'power fail' detection from the downstream system supplied by the PFC.

A.3

Boost inductor

Designing the boost inductor involves several parameters and different approaches can be followed. First, the inductance value must be defined. The inductance (L) is usually determined so that the minimum switching frequency is greater than the maximum frequency of the internal starter, to ensure a correct TM operation. Assuming unity PF, it is possible to write:

Ton being the ON-time and Toff the OFF-time of the power MOSFET, ILpk the maximum peak inductor current in a line cycle and the instantaneous line phase ( (0,)). Note that the ON-time is constant over a line cycle. As previously mentioned, ILpk is twice the line-frequency peak current, which is related to the input power and the line voltage:

29/35

Components calculation

AN2459 - Application note

Substituting this relationship in the expressions of Ton and Toff, after some algebra it is possible to find the instantaneous switching frequency along a line cycle:

The switching frequency will be minimum at the top of the sinusoid ( = /2 sin() =1 ), maximum at the zero crossings of the line voltage ( = 0 or sin () = 0) where Toff = 0. The absolute minimum frequency fsw(min) can occur at either the maximum or the minimum mains voltage, thus the inductor value is defined by:

where V irms can be either Virms(min) or Virms(max), whichever gives the lower value for L. Once the value of L is defined, the real design of the inductor can start. Standard high frequency ferrite (gapped core-set with bobbin) is the usual choice in PFC applications. Selection of the most suitable one, among the various types offered by manufacturers, will depend on technical and economic considerations. The next step is to estimate the core size. To calculate an approximate value of the minimum core size, the following practical equation may be used:

Volume 4K L Irms

where Volume is expressed in cm3, L in mH and the specific energy constant K depends on the ratio of the gap length (lgap) and the effective magnetic length (le) of the ferrite core:

K 14 103

The ratio le/lgap is fixed by the designer.

Ie Igap

Next, the winding has to be specified. Quantities to be defined include the turn number and the wire cross-section. The (maximum) instantaneous energy inside the boost inductor (1/2 L ILpk^2) can be expressed in terms of energy stored in the magnetic field, given by the maximum energy density times and the effective core volume Ve:

1 2

2 L ILpk =

1 2

H B Ve

1 2

H B Ae Ie

where: Ae is the effective area of the core cross-section, H is the swing of the magnetic field strength and B is the swing of the magnetic flux density.

30/35

AN2459 - Application note

Components calculation

An air gap needs to be introduced to prevent the core from saturating because of its high permeability and to allow an adequate H. Despite the fact that gap length lgap is only a small per cent of le, the permeability of ferrite is so high (for power ferrites the typical value of r is 2500) that it is possible to assume, with good approximation (H Hgap), that the whole magnetic field is concentrated in the air gap. For instance, with an lgap/le value of 1% (which is the minimum suggested value) the error caused by the above assumption is approximately 4%. The error is smaller if the lgap/le ratio is larger. As a result, the fringing flux in the air gap region may be neglected and the energy balance can be re-written as:

2 L ILpk Hgap B Ae Igap

The flux density B, is the same throughout the core and the air gap, and is related to the field strength inside the air gap by the well-known relationship:

= 0 Hgap

Then, taking Ampere's law into account (but applying it only to the air gap region):

Igap Hgap N ILpk

it is possible to obtain the following equation from the energy balance equation :

where N is the turn number of the winding. Because N is defined, it is recommended to check the core saturation. If the core saturation result is too close to the rated limit, it will be necessary to increase the value of lgap and make a new calculation. The wire gauge selection is based on limiting the copper losses to an acceptable value:

4 PCU = 3

Irms RCU

Due to the high ripple frequency, the effective wire resistance RCU, increases by skin and proximity effects. For this reason litz wire or multi-wire solutions are recommended. Finally, the space occupied by the winding needs to be evaluated. If it does not fit the winding area of the bobbin, a bigger core set needs to be considered and the winding calculation repeated. It is also necessary to add an auxiliary winding to the inductor, in order for the ZCD pin to recognize at what point the current flowing through the inductor has fallen to zero. The winding is a low cost thin wire and the turn number is the only parameter to be defined.

31/35

Components calculation

AN2459 - Application note

A.4

Power MOSFET

The choice of MOSFET mainly concerns the R DSon, which depends on the output power. The breakdown voltage is fixed by sum of the output voltage, the overvoltage and a safety margin . The MOSFET's power dissipation depends on conduction and switching losses. The conduction losses are given by:

PON = IQrms RDSon

where:

Switching losses due to current-voltage cross occur only at turn-off because of the TM operation:

PCROSS = VO Irms tfall fsw

where tfall is the crossover time at turn-off. At turn-on, loss is due to the discharge of the total drain capacitance inside the MOSFET itself. In general, these losses are given by:

PCAP =

1.5 (3.3 COSS VDRAIN + 1

Cd VDRAIN

) fsw

where C oss is the internal drain capacitance of the MOSFET (at VDS = 25V), C d is the total external drain parasitic capacitance and VDRAIN is the drain voltage at MOSFET turn-on. In practice, it is possible to give only a rough estimate of the total switching losses because both fsw and VDRAIN change along a given line half-cycle. V DRAIN, in particular, is affected not only by the sinusoidal change of the input voltage but also by the drop due to the resonance of the boost inductor with the total drain capacitance. At low mains voltage, this causes VDRAIN to be zero during a significant portion of each line half-cycle. It is possible to show that "Zero-Voltage-Switching" occurs as long as the instantaneous line voltage is less than half the output voltage.

32/35

AN2459 - Application note

Components calculation

A.5

Boost Diode

The boost freewheeling diode is a fast recovery one. Its respective DC and RMS current values, which are useful for loss computations, are given below:

The conduction losses can be estimated as follows:

PDON = Vto IDO + Rd IDrms

where V to (threshold voltage) and Rd (differential resistance) are parameters of the diode. The breakdown voltage is fixed with the same criterion as the MOSFET.

33/35

Revision history

AN2459 - Application note

Revision history

Table 4.

Date 17-Jan-2007

Document revision history

Revision 1 Initial release. Changes

34/35

AN2459 - Application note

Please Read Carefully:

Information in this document is provided solely in connection with ST products. STMicroelectronics NV and its subsidiaries (ST) reserve the right to make changes, corrections, modifications or improvements, to this document, and the products and services described herein at any time, without notice. All ST products are sold pursuant to STs terms and conditions of sale. Purchasers are solely responsible for the choice, selection and use of the ST products and services described herein, and ST assumes no liability whatsoever relating to the choice, selection or use of the ST products and services described herein. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted under this document. If any part of this document refers to any third party products or services it shall not be deemed a license grant by ST for the use of such third party products or services, or any intellectual property contained therein or considered as a warranty covering the use in any manner whatsoever of such third party products or services or any intellectual property contained therein.

UNLESS OTHERWISE SET FORTH IN STS TERMS AND CONDITIONS OF SALE ST DISCLAIMS ANY EXPRESS OR IMPLIED WARRANTY WITH RESPECT TO THE USE AND/OR SALE OF ST PRODUCTS INCLUDING WITHOUT LIMITATION IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE (AND THEIR EQUIVALENTS UNDER THE LAWS OF ANY JURISDICTION), OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL PROPERTY RIGHT. UNLESS EXPRESSLY APPROVED IN WRITING BY AN AUTHORIZED ST REPRESENTATIVE, ST PRODUCTS ARE NOT RECOMMENDED, AUTHORIZED OR WARRANTED FOR USE IN MILITARY, AIR CRAFT, SPACE, LIFE SAVING, OR LIFE SUSTAINING APPLICATIONS, NOR IN PRODUCTS OR SYSTEMS WHERE FAILURE OR MALFUNCTION MAY RESULT IN PERSONAL INJURY, DEATH, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE. ST PRODUCTS WHICH ARE NOT SPECIFIED AS "AUTOMOTIVE GRADE" MAY ONLY BE USED IN AUTOMOTIVE APPLICATIONS AT USERS OWN RISK.

Resale of ST products with provisions different from the statements and/or technical features set forth in this document shall immediately void any warranty granted by ST for the ST product or service described herein and shall not create or extend in any manner whatsoever, any liability of ST.

ST and the ST logo are trademarks or registered trademarks of ST in various countries. Information in this document supersedes and replaces all information previously supplied. The ST logo is a registered trademark of STMicroelectronics. All other names are the property of their respective owners.

2007 STMicroelectronics - All rights reserved STMicroelectronics group of companies Australia - Belgium - Brazil - Canada - China - Czech Republic - Finland - France - Germany - Hong Kong - India - Israel - Italy - Japan Malaysia - Malta - Morocco - Singapore - Spain - Sweden - Switzerland - United Kingdom - United States of America www.st.com

35/35

Вам также может понравиться

- S7 400 CPU DataДокумент370 страницS7 400 CPU DataAmrRassemОценок пока нет

- FLOWTITE Install Guide Abb VersionДокумент16 страницFLOWTITE Install Guide Abb VersionAmrRassemОценок пока нет

- Simatic ET200Документ60 страницSimatic ET200AmrRassemОценок пока нет

- Raw Water GRP PipeДокумент48 страницRaw Water GRP PipeAmrRassemОценок пока нет

- FPI Technical CharacteristicsДокумент36 страницFPI Technical Characteristicsfahimshah1301Оценок пока нет

- "Smart Grid" Preview (ISBN 1587331624)Документ114 страниц"Smart Grid" Preview (ISBN 1587331624)TheCapitol.Net100% (6)

- 3bse056248 en Ac 800m and s800 I o - Getting StartedДокумент68 страниц3bse056248 en Ac 800m and s800 I o - Getting StartedDoc_LACОценок пока нет

- TotGuard Install Released DraftДокумент36 страницTotGuard Install Released DraftAmrRassemОценок пока нет

- Designing Embedded Communications SoftwareДокумент239 страницDesigning Embedded Communications SoftwareAmrRassemОценок пока нет

- TriLine R Flatpack CustomerДокумент6 страницTriLine R Flatpack CustomerAmrRassemОценок пока нет

- Power Cables - El Sewedy CablesДокумент118 страницPower Cables - El Sewedy CablesSherif Eltoukhi100% (1)

- AC500Документ68 страницAC500AmrRassem100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

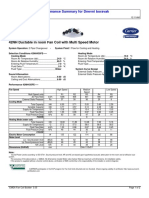

- Performance Summary For Dnevni Boravak: 42NH Ductable in Room Fan Coil With Multi Speed MotorДокумент2 страницыPerformance Summary For Dnevni Boravak: 42NH Ductable in Room Fan Coil With Multi Speed Motorvelikimag87Оценок пока нет

- Revision Notes On Current ElectricityДокумент7 страницRevision Notes On Current ElectricitySUSHMA100% (1)

- Chapterwise Notes QNA Icse 9 Physics ICSE PDFДокумент25 страницChapterwise Notes QNA Icse 9 Physics ICSE PDFisequaltoklasses.navneetОценок пока нет

- Half Wave RectifiersДокумент7 страницHalf Wave RectifiersVed PrakashОценок пока нет

- Unit 2nd McqsДокумент26 страницUnit 2nd McqsManav LekhiОценок пока нет

- Distribution Transformer Main HandbookДокумент84 страницыDistribution Transformer Main HandbookmellymoyoОценок пока нет

- Activity 10 Speed, Velocity and Acceleration - Answer To ExercisesДокумент1 страницаActivity 10 Speed, Velocity and Acceleration - Answer To ExercisesmarkflianceОценок пока нет

- Super Efficient AC - DaikinДокумент35 страницSuper Efficient AC - DaikinSaravanan SengazhaniОценок пока нет

- FinnedTubeCFD Final DraftДокумент17 страницFinnedTubeCFD Final DraftHai Nguyen CongОценок пока нет

- Air Conditioning ProcessesДокумент40 страницAir Conditioning ProcessesAmerul izwan AmiruddinОценок пока нет

- PDFДокумент19 страницPDFGabriel Bolívar100% (1)

- Angles and DirectionsДокумент24 страницыAngles and DirectionsSera Lee100% (1)

- Pre Fire Planning QuizДокумент2 страницыPre Fire Planning QuizJane MorilloОценок пока нет

- Power Quality Improvement TechniqueДокумент21 страницаPower Quality Improvement TechniquesravankotlasОценок пока нет

- Relay OmronДокумент18 страницRelay Omrondarwis_idОценок пока нет

- Assignment 12Документ4 страницыAssignment 12NandhalalОценок пока нет

- Technical Description 115 KV Submarine Cables (240mm2 and 400mm2) Rev. 4-Jun-10Документ36 страницTechnical Description 115 KV Submarine Cables (240mm2 and 400mm2) Rev. 4-Jun-10Bhuvanes Waran100% (1)

- Andaz Jihatullah Al Ramadan, 2018, Study of Load Shedding Schemes and NetworkДокумент3 страницыAndaz Jihatullah Al Ramadan, 2018, Study of Load Shedding Schemes and NetworkDery TriОценок пока нет

- Capacitor - Solutions FileДокумент21 страницаCapacitor - Solutions FileDhruv KuchhalОценок пока нет

- Manual 4MДокумент118 страницManual 4MJoão Manoel Bruna GarciaОценок пока нет

- Experiment 5Документ3 страницыExperiment 5Farhana LisaОценок пока нет

- Review of Owon B41TДокумент17 страницReview of Owon B41TAsistencia Técnica JLFОценок пока нет

- Power Quality - Kevin LoucksДокумент35 страницPower Quality - Kevin LoucksMohan KrishnaОценок пока нет

- 2 Gas Mixture ExerciseДокумент6 страниц2 Gas Mixture ExerciseSurenderan LoganОценок пока нет

- ACSRДокумент3 страницыACSRWeber HahnОценок пока нет

- Assignment #1 - Themro II - Spring 2024Документ3 страницыAssignment #1 - Themro II - Spring 2024Mai DweikatОценок пока нет

- Unit 1 Assignment Power DistributionДокумент2 страницыUnit 1 Assignment Power Distributionapi-296582578Оценок пока нет

- CT - IMB - 36 To 300 KVДокумент12 страницCT - IMB - 36 To 300 KVRaharjo YakinОценок пока нет

- Chapter 11 RefrigerationДокумент23 страницыChapter 11 Refrigerationmuru0105Оценок пока нет

- Fabrication of Self Balancing Two Wheeler Using Gysroscope.02Документ20 страницFabrication of Self Balancing Two Wheeler Using Gysroscope.02milan mottaОценок пока нет