Академический Документы

Профессиональный Документы

Культура Документы

專業術語

Загружено:

Tsun-Wu LiuИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

專業術語

Загружено:

Tsun-Wu LiuАвторское право:

Доступные форматы

http://www.dison.com/chinese/pro.

htm

No.

1 2 3 4 5 6 7 8 9

1.

abrasion add lubricating oil air pipe alcohol container analog-mode device argon welding Assembly line automatic screwdriver automation

No.

1.

No.

1.

() () ()

36 D/C Date Code 37 defective product box 38 defective product label 39 defective to staking 40 defective upsiding down 41 defective-products,/ not up-to-grade products

71 excesssive gap 72 exposed metal/bare metal 73 factory director 74 failure, trouble 75 fasten 76 feature change 77 feeder 78 feeding is not in place 79 final inspection 80 fit together 81 fixture 82 flow board 83 fold of pakaging belt 84 forefinger 85 forklift 86 front plate 87 fuse machine 88 fuse together 89 garbage bag 90 garbage can 91 garbage container 92 gauge(or jig) 93 general manager 94 glove(s) with exposed fingers 95 grease/oil stains 96 grinder 97 group leader/supervisor 98 head of screwdriver 99 Hi-pot test of SPS 100 human resource department 101 hydraulic handjack 102 hydraulic machine

42 deficient manufacturing procedure 43 deficient purchase 44 delivery deadline 45 delivery, to deliver 46 demand and supply 47 dents 48 department director 49 deputy manager =vice manager 50

10 band-aid 11 barcode 12 barcode scanner 13 basket 14 bezel panel 15 bottom stop 16 breaking.(be)broken,(be)cracked 17 buzzle 18 career card 19 carton 20 chain 21 character die 22 chassis 23 classification 24 cleaning cloth 25 cleanness 26 common equipment 27 conservation 28 consume, consumption 29 conveyer 30 conveyer belt 31 cosmetic defect 32 cosmetic inspect 33 critical defect 34 CTN Carton 35 culture

deputy section supervisor =vice section superisor ()

51 die (mould)change 52 die (mould)worker 53 die lifter 54 die locker 55 die(mould) repair 56 dimension/size is a little bigger 57 discoloration 58 driller 59 easily damaged parts 60 education and training 61 electric screw driver 62 electrical sparkle 63 embedded lump 64 EMI gasket 65 engineering 66 engineering, project difficulty 67 enterprise plan = enterprise expansion 68 equipment 69 evaluation 70 excessive defects

103 ID/C Identification Code 104 identifying sheet list 105 inch

No.

1.

No.

1.

No.

1.

()

106 inclusion 107 inner parts inspect 108 inquiry, search for 109 isolating plate baffle plate; barricade

141 not up to standard 142 one stroke 143 operation procedure 144 operator 145 oxidation

176 projects 177 proposal improvement 178 PRS Pairs 179 punch press, dieing out press 180 punching machine

110 iudustrial alcohol

121

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

111 L/N Lot Number 112 lack of painting 113 lamp holder 114 lathe 115 lbs. Inch 116 left fork /fork lift 117 line supervisor 118 linear(wire) cutting 119 little finger 120 location lump, locating piece, block stop

(/)

146 P/N Part Number 147 packaging tool 148 painting factory 149 painting make-up 150 painting peel off 151 PAL Pallet/skid 152 pallet 153 PCS Pieces 154 pedal 155 planning department 156 plastic basket 157 plastic parts 158 Pneumatic screw driver 159 PO Purchasing Order 160 polishing/surface processing 161 poor incoming part 162 poor processing 163 poor staking 164 position 165 power button 166 power wire 167 prepare for, make preparations for 168 president 169 pressure plate=plate pinch 170 processing, to process 171 production capacity 172 production department 173 production line 174 production unit 175 production, to produce

(,)

181

qualified-products,/up-to-grade products

182 rack, shelf, stack 183 rag 184 rear plate 185 receive 186 registration 187 registration card 188 regulation 189 repair 190 reset 191 reset button 192 reverse angle = chamfer 193 ring finger 194 Rivet gun 195 Rivet table 196 roll material 197 rotating speed, revolution 198 rust 199 safe stock 200 safety 201 scraped 202 scratch 203 screwdriver holder 204 section supervisor 205 sheet metal parts 206 shrinking/shrinkage 207 shut die 208 shut height of a die 209 sliding rack slipped screwhead/shippery 210 screw thread

121 lots of production 122 magnetizer 123 major defect 124 manufacture management 125 manufacture procedure 126 material (/stock) change, 127 material check list 128 ME 129 midfinger 130 mildewed=moldy=mouldy 131 miller 132 minor defect 133 missing part 134 mixed color 135 MO Manufacture Order 136 molding factory 137 mop 138 MT 139 name of a department 140 not up to grade, not qualified

No.

1.

No.

1.

() ()

No.

1.

slipped screwhead/slippery screw 211 head 212 smoothly 213 speckle 214 stage die 215 staker=reviting machine 216 stamping factory 217 stamping, press 218 stamping-missing 219 standard parts 220 statistics 221 steel plate 222 stop/switch off a press 223 sub-line

246 to impose lines 247 to load a die 248 to load material 249 to looser a bolt 250 to lubricate 251 to mop (the floor) 252 to move away (a die plate) 253 to move, to carry, to handle 254 to notice 255 to pull and stretch 256 to put forward and hand in 257

281 water spots 282 welder 283 wet station 284 work cell 285 worktable 286 wrong part

1 2 3 4 5 BS: BD: PD: Board Split Boart Check Program Download PCBA

to put material in place, to cut material, to / input

SDB: Serial&Data Burn In PT: PCBA Test

258 to repair a die(mould)

221

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

224 Supervisor 225 sweeper 226 SWR Special Work Request 227 taker 228 thickness gauge 229 thumb 230 thumb screw 231 Tiana 232 to apply oil 233 to clean a table 234 to clean the floor 235 to collect, to gather 236 to compress, compressing 237 to connect material 238 to continue, cont. 239 to control 240 to draw holes 241 to feed, feeding 242 to file burr 243 to fill in 244 to fix a die 245 to grip(material)

259 to return delivenry to. 260 to return material/stock to 261 to reverse material 262 to revise, modify 263 to send delinery back to retrn of goods 264 to stake, staking, reviting 265 to stock, storage, in stock 266 to storage 267

6 7 8 9

PFT:

PCBA Functin Test

PCBA LEN LENS

FHA: Front Housing Assy RHA: Rear Housing Assy PA: PCB Assy Close & Screw Function Advance Test Moblie Test Final Check Test LENS Assy LENS Press Surface & Function Test Surface & Function Test Surface & Function Test

10 CS: 11 FAT: 12 MT: 13 FCT: 14 LA: 15 LP: 16 SFT: 17 SFT: 18 SFT:

to switch over to, switch---to throw--over switching over

268 to take apart a die(mould) 269 to tight a bolt 270 to unload material 271 top stop 272 trailer=long vehicle 273 transmission rack 274 transportation 275 trolley 276 uncoiler and straightener 277 vaccum cleaner 278 vocabulary for stamping 279 voltage switch of SPS 280 waste

19 Packing 20 FQA: 21 AC FQA Alloting Center

No.

1 2 3 4 5 6 7 8 9 barreling belling bending blanking bulging burring

2.-

No.

2.-

/

No.

15 punch set 16 stripper pad 17 stripping plate 18 top block 19 top plate 20 up stripper 21 upper plate

2.-

( )

39 progressive blanking 40 progressive drawing 41 progressive forming 42 reaming 43 restriking 44 riveting 45 roll bending 46 roll finishing 47 rolling 48 roughing 49 scrapless machining 50 seaming 51 shaving 52 shearing 53 sizing 54 slitting 55 spinning 56 staking 57 stamping

cam die bending caulking coining

No.

1 2 3 4 5 6 7 8 9

2.-

air cushion plate bending block deburring punch guide pad located block lower sliding plate reel-stretch punch ribbon punch roller

10 compressing 11 compression bending 12 crowning 13 curl bending 14 curling 15 dinking 16 double shearing 17 drawing 18 drawing with ironing 19 embossing

10 round punch 11 sliding dowel block

321

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

20 extrusion 21 filing 22 fine blanking 23 finish blanking 24 finishing 25 flanging 26 folding 27 forming 28 impact extrusion 29 indenting 30 ironing 31 knurling 32 lock seaming 33 louvering 34 marking 35 notching 36 parting 37 piercing 38 progressive bending

58 swaging 59 trimming 60 upsetting 61 wiring

12 special shape punch 13 spring box 14 spring-box eject-rod 15 stamped punch 16 stiffening rib punch = stinger

No.

1 2 3 4 5 6 7 8 9 bottom block bottom plate die holder die pad die set feature die female die inner stripper lower plate

2.-

( ) () ()

17 supporting block for location 18 trimming punch 19 upper holder block 20 upper mid plate

No.

1 2 3 4 5 6 7 8 9

2.-

eq-height sleeves=spool inner guiding post inner hexagon screw lifter guide pin outer bush outer guiding post pin stop screw wire spring

10 lower stripper 11 male die 12 outer stripper 13 punch holder 14 punch pad

No.

1 blanking

2.-

No.

11 edge gate 12 eject pin 13 eject rod (bar)

3.&

No.

43 spindle 44 sprue 45 sprue gate

3.&

; ( ) ()

2 deburr or coin 3 dome

4 draw hole

14 encapsulation molding

46 sprue less

5 emboss 6 forming die 7 gang dies 8 groove 9 pierce 10 pierce die 11 plain die 12 punch riveting 13 reel stretch 14 riveting die 15 semi-shearing 16 shearing die 17 side stretch 18 stamp letter 19 stamp mark 20 tick-mark far side 21 tick-mark nearside

15 fan gate 16 film gate 17 flash gate 18 flash mold 19 handle mold 20 hot runner 21 insert core 22 insulated runner 23 knock pin 24 leather cloak 25 long nozzle 26 orientation 27 pin gate 28 piston 29 plsitive mold 30 post screw insert 31 return pin 32 Runner less

47 sprue lock pin 48 stress crack 49 striper plate 50 stripper plate 51 submarine gate 52 tab gate 53 taper 54 three plate 55 tunnel gate 56 two plate 57 valve gate 58 welding line 59 welding mark 60 well type

No.

1 2 3

4.

bismuth mold blank through dies burnishing die

No.

3.&

421

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

1 air vent

33 runner plat

button die

2 band heater 3 CAV Cavity 4 chip 5 cold slag 6 compre sion molding 7 core 8 cylinder 9 diaphragm gate 10 dish gate

34 runner stripper plate 35 runner system 36 self tapping screw 37 shiver 38 side gate 39 slag well 40 sleeve 41 slit gate 42 spear head

5 6 7 8 9

center-gated mold chill mold clod hobbing composite dies counter punch

10 double stack mold 11 duplicated cavity plate 12 electroformed mold 13 expander die

No.

4.

No.

4.

No.

5.

14 extrusion die 15 family mold 16 fantail die 17 fishtail die 18 gypsum mol 19 hot-runner mold 20 ingot mold 21 lancing die 22 landed plunger mold

51 solid forging die 52 split forging die 53 split mold 54 sprueless mold 55 squeezing die 56 stretch form die 57 sweeping mold 58 swing die 59 three plates mol

23 press forging 24 rocking die forging 25 rotary forging 26 rotational molding 27 rubber molding 28 sand mold casting 29 shell casting 30 sinter forging 31 six sides forging

23 landed positive mold 24 loading shoe mold 25 loose detail mold 26 loose mold 27 louvering die 28 manifold die 29 modular mold 30 multi-cavity mold 31 multi-gate mold 32 offswt bending die 33 palletizing die 34 plaster mold 35 porous mold 36 positive mold 37 pressure die 38 profile die 39 progressive die, follow (-on)die 40 protable mold 41 prototype mold 42 punching die 43 raising(embossing)

60 trimming die 61 unit mold 62 universal mold 63 unscrewing mold 64 yoke type die

32 slush molding 33 squeeze casting 34 transfer molding 35 warm forging

No.

1

6.

active plate air-cushion eject-rod alkalidipping alkaline etch alloy anodize approved by approved by / checked by / prepared by assembly //

No.

1 2 3 4 5 6 7 8 9

5.

accurate die casting calendaring molding cold chamber die casting cold forging compacting molding compound molding compression molding dip mold extrusion molding

2 3 4 5 6 7 8 9

10 augular offset 11 auxiliary fuction 12 available material

10 foam forming 11 gravity casting 12 hollow(blow) molding 13 hot chamber die casting 14 hot forging 15 injection molding

() 13 beacon 14 bezel 15 blanking 16 blush

521

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

44 re-entrant mold 45 runless injection mold 46 sectional die 47 segment mold 48 semi-positive mold 49 shaper 50 single cavity mold

16 investment casting 17 laminating method 18 lost wax casting 19 low pressure casting 20 matched mould thermal forming 21 powder forming 22 powder metal forging

17 bolt 18 boring 19 bushing block 20 cam block 21 cam driver 22 carbonization 23 casing = containerazation

No.

24 chromate 25 club car 26 coil stock

6.

;

No.

60 folded block 61 form block 62 gas mark 63 gouge

6.

;

No.

96 plate

6.

97 pocket for the punch head 98 poly-line 99 punched hole 100 quenching 101 ram 102 raw materials 103 resistance 104 response=reaction=interaction 105 rinse 106 round pierce punch=die button 107 sand blasting 108 satin texture 109 score=groove 110 scraped products 111 Seal 112 shape punch=die insert 113 sheet stock 114 shim(wedge) 115 shine 116 skid/pallet 117 sliding block 118 spare dies 119 spare molds location 120 spare tools location 121 speck 122 splay 123 spline=the multiple keys 124 spring 125 spring-box eject-plate 126 steel/rolled steel 127 stepping bar 128 stock locater block 129 through-hole form 130 titrator

27 compound die 28 concave 29 convex 30 coolant 31 coordinate 32 cover plate 33 crank shaft 34 crusher 35 cutting die, blanking die 36 D.I. rinse 37 degate 38 degrease 39 dejecting 40 delamination 41 demagnetization 42 derusting machine 43 desmut 44 die block 45 die plate, front board 46 die(mould) 47 dismantle the die 48 drag form 49 drill 50 dryer 51 edge finder 52 EDM 53

64 granule=peuet=grain 65 grind 66 grit 67 grit maker 68 groove punch 69 heat dissipation 70 heater band 71 high-speed transmission 72 incoming material to be inspected 73 induction 74 induction light 75 ion 76 ISA Industry Standard Architecture 77 Line streching, line pulling 78 location pin 79 lower die base 80 magnalium 81 magnesium 82 main manifold 83 material for engineering mold testing 84 material statistics sheet 85 metal plate 86 mill 87 molding 88 molding/injection 89 moly high speed steel 90 organic solvent 91 padding block 92 panel board 93 phosphate 94 pilot

EISA Extended Industry Standard Architecture

54 engraving, to engrave 55 equipment 56 expansion dwg 57 factor 58 figure file, chart file

621

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

59 fillet

95 plane

131 to be inspected or reworked

No.

132 to bending

6.

No.

7.

No.

3 4 5 6 7 8

8.

air hardening air patenting annealing anode effect anodizing atomloy treatment /

11 drilling machine 12 engraving E.D.M. 13 engraving machine 14 form grinding machine 15 graphite machine 16 horizontal boring machine

133 to cutedges=side cut=side scrap 134 tolerance 135 torch-flame cut 136 torque 137 tox machine

138 trim

17 horizontal machine center

austempering

139 tungsten high speed steel 140 type 141 under cut=scrap chopper 142 upper die base 143 upper padding plate blank 144 upper supporting blank 145 upsiding down edges 146 velocity 147 viscosity 148 volatile 149 voller pin formality 150 wire EDM

18 internal cylindrical machine 19 jig boring machine 20 jig grinding machine 21 lap machine 22 machine center 23 multi model miller 24 NC drilling machine NC 25 NC grinding machine NC 26 NC lathe NC 27 NC programming system NC 28 planer 29 profile grinding machine 30 projection grinder

10 austenite 11 bainite 12 banded structure 13 barrel plating 14 barrel tumbling 15 blackening 16 blue shortness 17 bonderizing 18 box annealing 19 box carburizing 20 bright electroplating 21 bright heat treatment 22 bypass heat treatment 23 carbide 24 carburized case depth 25 carburizing 26 cementite 27 chemical plating 28 chemical vapor deposition 29 coarsening 30 coating 31 cold shortness 32 comemtite 33 controlled atmosphere

No.

1 2 3 4 5 6 7 8 9

7.

3D coordinate measurement boring machine cnc milling machine CNC contouring machine copy grinding machine copy lathe copy milling machine copy shaping machine cylindrical grinding machine

31 radial drilling machine 32 shaper 33 surface grinder 34 try machine 35 turret lathe 36 universal tool grinding machine 37 vertical machine center 38 wire E.D.M.

No.

1 2

8.

age hardening ageing

10 die spotting machine

No.

8.

No.

67 martensite 68 metallikon 69 metallizing 70 nitriding

8.

/

No.

8.

34 corner effect 35 creeping discharge 36 decarburization 37 decarburizing 38 depth of hardening 39 diffusion 40 diffusion annealing

100 secular distortion 101 segregation 102 selective hardening 103 shot blast 104 shot peening 105 single stage nitriding 106 sintering

71 nitrocarburizing 72 normalizing 73 oil quenching

721

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

41 electrolytic hardening 42 etching 43 first stage annealing 44 flame hardening 45 flame treatment 46 full annealing 47 gaseous cyaniding 48 globular cementite 49 grain size 50 granolite treatment 51 graphitizing 52 hardenability 53 hardenability curve 54 hardening 55 heat treatment 56 hot bath quenching 57 hot dipping 58 induction hardening 59 ion carbonitriding 60 ion carburizing 61 ion plating 62 isothermal annealing 63 liquid honing 64 low temperature annealing 65 malleablizing 66 martempering

74 overageing 75 overheating 76 pearlite 77 phosphating 78 physical vapor deposition 79 plasma nitriding 80 pre-annealing 81 precipitation 82 precipitation hardening 83 press quenching 84 process annealing 85 quench ageing 86 quench hardening 87 quenching crack 88 quenching distortion 89 quenching stress 90 reconditioning 91 recrystallization 92 red shortness 93 residual stress 94 retained austenite 95 rust prevention 96 salt bath quenching 97 sand blast 98 seasoning 99 second stage annealing

107 soaking 108 softening 109 solution treatment 110 spheroidizing 111 stabilizing treatment 112 straightening annealing 113 strain ageing 114 stress relieving annealing 115 subzero treatment 116 supercooling 117 surface hardening 118 temper brittleness 119 temper colour 120 tempering 121 tempering crack 122 texture 123 thermal refining 124 thermoechanical treatment 125 time quenching 126 transformation 127 tufftride process 128 under annealing 129 vacuum carbonitriding 130 vacuum carburizing 131 vacuum hardening 132 vacuum heat treatment

No.

8.

No.

5 6 7 8

10.

bonderized steel sheet carbon tool steel clad sheet clod work die steel emery

No.

8 9

11.

ball slider binder plate

133 vacuum nitriding 134 water quenching 135 wetout

10 blank holder 11 blanking die 12 bolster 13 bottom board 14 bracket 15 bumper block 16 buster 17 casting ladle 18 casting lug 19 cavity retainer plate 20 center pin 21 clamping block 22 coil spring 23 cold punched nut

No.

1 2 3 4 5 6 7 8 9 barrel broaching centering cutting

9.

()

10 ferrostatic pressure 11 forging die steel 12 galvanized steel sheet 13 hard alloy steel 14 high speed tool steel 15 hot work die steel 16 low alloy tool steel 17 low manganese casting steel 18 marging steel 19 martrix alloy 20 meehanite cast iron

cylindrical lathe cutting electric discharge machine electrolytic grinding facing hand finishing

10 hemming 11 hobbing 12 joggling

821

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

13 lapping 14 laser beam machining 16 lathe cutting 15 planning 17 polishing 18 rough machining 19 rounding 20 sawing 21 scaling 22 shaping 23 skiving 24 slotting 25 taper turning 26 thread cutting 27 ultrasonic machining 28 up cut milling

21 meehanite metal 22 merchant iron 23 molybdenum high speed steel 24 molybdenum steel 25 nickel chromium steel 26 prehardened steel 27 silicon steel sheet 28 stainless steel 29 tin plated steel sheet 30 tough pitch copper 31 troostite 32 tungsten steel 33 vinyl tapped steel sheet

24 cooling spiral 25 core pin 26 cotter 27 cross 28 cushion pin 29 die bed 30 die body 31 die bush 32 die button 33 die clamper 34 die fastener 35 die lip 36 direct gate 37 dog chuck 38 dowel 39 dowel hole 40 dowel pin 41 dozzle 42 draft 43 draw bead 44 drive bearing

No.

1 2 3

11.

air vent vale anchor pin angular pin baffle baffle plate ball button ball plunger /

No.

1 2 3 4 alloy tool steel aluminium alloy bearing alloy blister steel

10.

4 5 6 7

No.

11.

pin

No.

11.

No.

11.

45 ejection pad 46 ejector 47 ejector guide pin 48 ejector leader busher 49 ejector pad 50 ejector pin 51 ejector plate 52 ejector rod 53 ejector sleeve 54 ejector valve 55 eye bolt 56 finger pin 57 finish machined plate 58 finish machined round plate 59 fixed bolster plate 60 flanged pin 61 flask 62 floating punch 63 gate 64 gate land 65 goose neck

82 king pin bush 83 knockout bar 84 land area 85 leader busher 86 lifting pin 87 lining 88 locating center punch 89 locating pilot pin 90 locating ring 91 lock block 92 locking block 93 locking plate 94 loose bush 95 making die 96 manifold block 97 master plate 98 match plate 99 mold base 100 mold clamp 101 mold platen 102 moving bolster

119 riding stripper 120 ring gate 121 runner 122 runner ejector set 123 runner lock pin 124 screw plug 125 set screw 126 shedder 127 shim 128 shoe 129 shoot 130 shoulder bolt 131 skeleton 132 slag riser 133 slide(slide core) 134 slip joint 135 spacer block 136 spacer ring 137 spider 138 sprue bushing 139 sprue bushing guide

921

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

66 guide bushing 67 guide pin 68 guide plate 69 guide post 70 guide rail 71 head punch 72 headless punch 73 heavily tapered solid 74 hose nippler 75 impact damper 76 inlay busher 77 inner plunger 78 inner punch 79 insert 80 insert pin 81 king pin

103 moving bolster plate 104 one piece casting 105 parallel block 106 paring line 107 parting lock set 108 pass guide 109 peened head punch 110 pilot pin 111 plate 112 pre extrusion punch 113 punch 114 puncher 115 pusher pin 116 rapping rod 117 retainer pin 118 retainer plate

140 sprue lock bushing 141 sprue puller 142 spue line 143 square key 144 square nut 145 square thread 146 stop collar 147 stop pin 148 stop ring 149 stopper 150 straight pin 151 stripper bolt 152 stripper bushing 153 stroke end block 154 support pillar 153 stroke end block

No.

11.

/ /

No.

26 index head 27 jack 28 jig 29 kit 30 metal saw 31 nose angle 32 pinchers 33 pliers 34 plug 35 polisher

12.

No.

7 8 9 butt welding cascade clad weld

13.

154 support pillar 155 support pin 156 supporting plate 157 sweep templete 158 taper key 159 taper pin 160 teeming 161 three start screw 162 thrust pin 163 vent 164 wortle plate

10 crator 11 excess metal 12 filler rod 13 fillet weld 14 gas shield 15 groove welding 16 hand face shield 17 hard facing 18 jig welding 19 laser beam welding 20 metal electrode insert gas welding MIG

36 protable driller 37 sand paper 38 scraper 39 screw driver 40 scribing 41 second out file 42 spanner 43 spline broach 44 square 45 square sleeker 46 square trowel 47 stripping 48 tool for lathe 49 tool point angle 50 tool post 51 tosecan

No.

1 2 3 4 5 6 7 8 9

12.

adjustable spanner angle cutter anvil arbour backing belt sander buffing chamfering machine chamfering tool

21 nugget 22 overlaying 23 peening of welding 24 plug welding 25 positioned welding 26 pressure welding 27 propane gas cutting 28 pure nickel electrode 29 reinforcement of weld 30 resist 31 root running 32 seam

10 chisel 11 chuck 12 compass 13 concave cutter 14 convex cutter

1021

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

15 cross joint 16 cutting edge clearance 17 drill stand 18 edge file 19 file 20 flange joint 21 grinder 22 hammer 23 hand brace 24 hexagon headed bolt 25 hexagon nut

52 T-slot T 53 waffle die flattening 54 wiper 55 wrench

33 seam welding 34 seaming 35 series seam welding 36 skip welding process 37 spark

No.

1 2 3 4 5 6 acetylene ampere angle welding arc argon arc welding bare electrode

13.

38 spot welding 39 stitch welding 40 stud arc welding 41 under laying 42 void 43 weld flow mark

No.

44 weld flush 45 weld line

13.

No.

14.

No.

14.

26 camlachie cramp 27 cast blade 28 casting flange 29 casting on flat 30 chamotte sand 31 charging hopper 32 cleaning of casting 33 closed-die forging 34 core compound 35 core template 36 core vent 37 corner gate 38 counter blow hammer 39 counter lock 40 depression 41 die approach 42 draw out 43 draw plate 44 draw spike 45 dummying 46 embedded core 47 erosion 48 fettling 50 filling core 51 filling in 52 film play 53 finishing slag 49 flash gutter 54 flask molding 55 forging roll 56 formboard 57 gutter

65 investment casting 66 isothermal forging 67 loose piece 68 molding pit 69 pouring process 70 recasting 71 roll forging 72 rolled surface 73 rough sand 74 roughing forge 75 sand crushing 76 seamless forging 77 shave 79 shrinkage fit 80 sieve mesh 81 sintering of sand 82 slag 83 slag inclusion 84 stickness 85 strip layout 86 tap casting 87 top gate 88 unworked casting 89 upender 90 upending 91 uphill casting 92 white cast iron

46 weld penetration 47 weld zone 48 welding 49 welding bead 50 welding direction 51 welding distortion 52 welding flux 53 welding ground 54 welding interval 55 welding stress 56 welding torch

No.

1 2 3 4 5 6 7 8 9 accretion

14.

acid converter acid lining cupola acid open-hearth furnace aerator air set mold airless blasting cleaning all core molding all round die holder

10 assembly mark 11 back pouring 12 backing sand 13 base bullion 14 base permeability 16 billet 15 bleed 17 blocker 18 blocking

1121

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

19 blow hole 20 bottom pour mold 21 bottom pouring 22 boxless mold 23 break-off core 24 brick molding 25 buckle

58 hammer man 59 heading machine 60 impacter 61 inblock cast 62 ingot 63 ingot blank 64 inlay casting

No.

1 2 acrylic

15.

PMMA CAB

No.

24 polyamide

15.

PA PBT PC PFG PEO PETP POM PPO PP PTFE PE PU PVAC PVA PVB PVC PVF PVDC PS S1

No.

47 thermosetting

15.

CA cellulose acetate butyrate

25 polybutyleneterephthalate

48 thermosetting plastic

3 4 5

casein cellulose acetate composite material

26 polycarbonate 27 polyethyleneglycol 28 polyethyleneoxide

49 unsaturated polyester

No.

1 activator

16.

cresol resin

CF EP - EVA EPS / HDPE HIPS MF

29 polyethyleneterephthalate

dially phthalate

30 polymetylmethacrylate

bag moulding

8 9

disperse reinforcement engineering plastics

31 polyoxymethylene 32 polyphenyleneoxide 33 polypropylene 34 Polytetrafluoroethylene

3 4 5 6

bonding strength breathing caulking compound cell

10 epoxy resin 11 ethyl cellulose

12 ethylene vinylacetate copolymer

35 Polythene

color masterbatch

13 EVA expanded polystyrene

36 polyurethane

color matching

14 fiber reinforcement

37 polyvinylacetate

colorant

15 high density polyethylene

38 polyvinylalcohol

10 compound

16 high impact polystyrene

39 polyvinylbutyral

11 copolymer

17 high impact polystyrene rigidity

40 polyvinylchloride

12 cryptometer

18 LDPE melamine resin

41 polyvinylfuoride

13 cull

19 low density polyethylene 20 nitrocellulose 21 phenolic resin

42 polyvinylidenechloride 43 PP polystyrene 44 prepolymer

14 cure 15 daylight 16 dry cycle time

22 plastic 23 polyacrylic acid

PAP

45 silicone resin 46 thermoplastic

17 ductility 18 elastomer

No.

16.

No.

16.

No.

36 galling 37 glazing 38 gloss 39 grease pits

17.

19 extruded bead sealing 20 feed filler 21 film blowing 22 floating platen 23 foaming agent

58 torpedo spreader 59 transparency 60 void content

No.

1 aberration

17.

40 grinding defect

1221

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

24 gunk 25 hot mark 26 hot stamping 27 injection nozzle 28 injection plunger 29 injection ram 30 isomer 31 kneader 32 leveling agent 33 lubricant 34 matched die method 35 mould clamping force 36 mould release agent 37 nozzle 38 oriented film 39 parison 40 pellet 41 plasticizer 42 plunger 43 porosity 44 post cure 45 premix 46 purging 47 reciprocating screw 48 resilience 49 resin injection 50 rheology 51 sheet 52 shot 53 shot cycle 54 slip agent 55 take out device 56 tie bar 57 toggle type mould clamping system

2 3 4 5 6 7 8 9

atomization bank mark bite blacking hole blacking scab blister blooming blushing

( )

41 haircrack 42 haze 43 incrustation 44 indentation 45 internal porosity 46 mismatch 47 mottle 48 necking 49 nick 50 orange peel 51 overflow 52 peeling 53 pit 54 pitting corrosion 55 plate mark 56 pock 57 pock mark 58 resin streak 59 resin wear 60 riding 61 sagging 62 saponification 63 scar 64 scrap 65 scrap jam 66 scratch 67 scuffing 68 seam 69 shock line 70 short shot 71 shrinkage pool 72 sink mark 73 skin inclusion 74 straightening

/ /

10 body wrinkle 11 breaking-in 12 bubble 13 burn mark 14 burr 15 burr() flash() 16 camber 17 center buckle 18 check 19 checking 20 chipping 21 clamp-off 22 collapse 23 color mottle 24 corrosion 25 crack 26 crazing 27 deformation 28 edge 29 edge crack 30 fading 31 filler speak 32 fissure 33 flange wrinkle 34 flaw 35 flow mark

No.

75 streak

17.

No.

18.

No.

18.

21 DIA Diameter 22 DIM Dimension 23 distortion 24 DQA Design Quality Assurance 25 draft taper 26 EMI Electrical-Music Industry

55 surface roughness 56 tapping 57 thermocouple 58 torsion load 59 toughness 60 tracing TVR

76 surface check 77 surface roughening 78 surging 79 sweat out 80 torsion

81 warpage

27 EMI Electronic Magnetron Inspect

61

verification report

1321

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

82 waviness 83 webbing 84 weld mark 85 whitening 86 wrinkle

28 first check 29 fit tolerance 30 flexible rigidity 31 flow chart 32 FMI Frequency Modula Tim Inspect 33 gas vent

62 under cut

No.

1 2 3 4

19.

back shaft blank determination board drop hammer bottom slide press

No.

1

18.

assembly drawing

34 hatching

35 heater cooler

brake

2 3 4 5 6 7 8 9

auto tool change cycle beam bending moment bending stress bottoming buckling capability chamfering

36 hook cavity 37 lug 38 maintenance 39 metallurgy 40 notch effect 41 out of roughness 42 plane strain 43 plug mill 44 repeated load 45 revision 46 riveted joint 47 shift 48 shrink fit 49 shrinkage hole 50 sinking 51 sketch 52 spalling 53 straightness 54 submarine

6 7 8 9

burr clearance clump clutch

10 clutch boss 11 clutch brake

12 clutch lining 13 coil car 14 coil cradle 15 coil reel stand 16 column 17 connection screw 18 cradle 19 crank 20 crankless 21 cross crank 22 cushion 23 dial feed 24 die assembly

10 channel 11 chattering 12 chip conveyor 13 CHK Check 14 coefficient of friction 15 cooling pipe 16 coupon 17 D/C Drawing Change 18 deflection 19 design modification(change) 20 designing, to design

No.

19.

No.

19.

No.

19.

25 die cushion 26 die height 27 die height 28 die height range 29 die height range 30 die life 31 die opening 32 die spotting press 33 die structure dwg 34 double crank press 35 downward 36 draght angle 37 edging

58 idle stage 59 inching 60 key clutch 61 knockout 62 knuckle mechanic 63 land 64 level 65 loader 66 loop controller 67 lower die 68 material 69 material thickness 70 micro inching device

91 roll forming machine 92 roll release 93 roller feed 94 roller leveler 95 rotary bender 96 safety guard 97 scrap cutter 98 scrap press 99 separate 100 shear angle 101 sheet loader 102 shut height 103 slide balancer

1421

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

38 extension dwg 39 feed length 40 feed level 41 fine blanking press 42 fly wheel 43 fly wheel brake 44 foot press 45 frame 46 friction 47 friction brake 48 gap shear 49 gear 50 gib 51 gripper 52 gripper feed 53 gripper feeder 54 hand press 55 hand rack pinion press

71 microinching equipment 72 motor 73 notching press 74 opening 75 overload protection device 76 pinch roll 77 pinion 78 pitch 79 press specification 80 pressfit 81 procedure dwg 82 progressive 83 punch wt. 84 pusher feed 85 pusher feeder 86 quick die change system 87 regrinding 88 releasing

104 slug hole 105 spin forming machine 106 spotting 107 stack feeder 108 stickness 109 straight side frame 110 stretcher leveler 111 strip feeder 112 stripping pressure 113 stroke 114 take out device 115 toggle press

() 116 total wt. 117 transfer 118 transfer feed 119 turrent punch press 120 two speed clutch 121 uncoiler

56 hand screw press 57 hopper feed

89 reversed blanking 90 robot

122 unloader 123 upward

No.

19.

No.

20.

No.

6 7 8 9

21.

7QCTools 7 Quality Controls Tools 8 disciplines abnormal handling ACC Accept 8

124 vibration feeder 125 weight wt. 126 wiring press

18 magnetic base 19 master graphite 20 pipe graphite 21 pulse

No.

1 2 3 4 5

20.

abnormal glow arc discharge belt centreless chrome bronze

22 rib working 23 roller electrode 24 rotary surface 25 shank 26 sharp edge 27 tough bronze

10 acceptance = receive 11 ADM Absolute Dimension Measurement Artical Inspection report

12 AIR

13 AOD Accept On Deviation 14 AOQ Average Output Quality 15 AOQL Average Output Quality Level

,,

6 7 8 9

clearance angle corner shear drop discharge energy dressing

28 traverse 29 tungsten bronze 30 work 31 working allowance 32 working dischard

16 APP Approve 17 AQL Acceptable Quality Level 18 AR Averary Range

19 Bending 20 C=0 Critical=0 CAR 21 Corrective action request CP 22 index CPK 23 index of process 24 CR Critical

10 dwell 11 flange

12 gap

No.

1

21.

(be) qualfied, up to grade 3B

13 graphite

14 graphite contraction allowance

1521

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

15 graphite holder

5M Man/Machine/Material/Method /Measurement

/ / / / / / / /

25

defective product/non-good parts

16 horn

5S

26 defective products

17 jump

/ / 5WIH When/Where/Who/What/Why/How / / 27 DFR Defect Failure Rate to /

No.

28 Down Load Box FA 29 audit FAA 30 article assurance FAI article inspection

21.

No.

51 NG Not Good 52 No. Number OOBA 53 of box audit OQA 54

21.

, ()final

No.

21.

74 QIT Quality Improvement Team 75 QP Quality Policy

first

76 QT Quality Target

out

31

first quality assurance OQC quality control On going Reliability Qualit failure

77 quality

output

32 FC Function check FMEA 33 model effectiveness analysis FPIR First Piece Inspection 34 Report FQC 35 quality control

55

78 R Range

output

56 ORT

79 REE Reject 80 RMA Return Material Audit

57 P/O Waive Purchase Order Waive final

58 Packing

81 RQT Reliability Quality Test

36 FREQ Frequency

59 PDCA Plan/ Do /Check /Action POC

/ / /

82 S I-S IV Special I-Special IV

37

good product , accepted goods, accepted parts, good parts

60

quality control

passage 83 S/S Sample size

38

GRR Gauge Reproducibility & Repeatability IPQC

61 PPM Parts Per Million

84 SPC Statistical Process Control

39

process quality control IQC quality control

in 62 Product Control List

85 SQC Statistical Quality Control

40

incoming 63 Q/R/S Quality/Reliability/Service

/ /

SSQA 86 supplier quality TQC

41 Japanese Industrial Standard

(JIS)

QA 64 assurance 65 QAN Quality Ameliorate Notice QC 66 control 67 QC Quality Control 68 QC Quality System 69 QC Section 70 QCC Quality Control Circle QE 71 engineering QFD

87

quality control

quality

42 LCL Lower Central Limit 43 LQL Limiting Quality Level 44 LRR Lot Reject Rate 45 MAJ Major 46 MAX Maximum 47 MIL-STD Military-Standard 48 MIN Minimum

88 TQM Total Quality Management 89 UAI Use As It 90 UCL Upper Central Limit 91 ZD Zero Defect 91 ZD Zero Defect

quality

49 MIN Minor 50 MRB Material Reject Bill

72 function deployment 73 QI Quality Improvement

No.

1 2 3

22.

autocollimator bench comparator block gauge

No.

29 optical flat

22.

No.

13 ferrite

23.

30 optical parallel 31 pass meter

14 gantt chart 16 heat cycle test

1621

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

4 5

bore check calibration

32 position scale 33 profile projector

15 histogram 17 hot bend test

6 7 8

caliper gauge check gauge clearance gauge

34 protractor 35 radius 36 ring gauge

18 izod impact test 19 loop tenacity 20 martens heat distortion temperature test

clinoretee

37 sine bar 38 snap gauge 39 square master 40 stylus 41 telescopic gauge 42 working gauge

21 mullen bursting strength tester 22 nol ring test 23 normal distribution 24 ozone resistance test 25 pareto diagram 26 peeling test 27 pinhole test

10 comparator 11 cylinder square 12 depth gauge 13 dial indicator 14 dial snap gauge 15 digital micrometer 16 feeler gauge 17 gauge plate 18 height gauge 19 inside calipers

No.

1 2 3

23.

air permeability test austenitic steel brinell hardness test

28 rattler test 29 rockweel hardness 30 rockweel hardness test 31 rolinx process

20 inside micrometer 21 interferometer 22 leveling block 23 limit gauge 24 micrometer

4 5 6 7 8

charpy impact test conical cup test cup flow test dart drop impact test Elmendorf test

32 rossi-peakes flow test 33 sampling inspection 34 scratch hardness 35 shore hardness 36 spiral flow test

25 mil

environmental stress cracking test

37 surface abrasion test

26 monometer

10 ericessen test 11 falling ball impact test 12 fatigue test

38 taber abraser 39 tensile impact test 40 tensile strength

27 morse taper gauge

28 nonius /caliper

No.

23.

No.

27 CLF 28 commision

24.

No.

24.

41 tension test 42 thermal shock test 43 torsion test 44 ubbelohde viscometer

64 no payment 65 odd item 66 offer 67 offer sheet

29 commission 30 complain

45 vicat indentation test 46 Vickers hardness test 47 warpage test 48 weatherometer

31 container 32 correspondence bank 33 cost 34 cost and freight; C&F

68 open account 69 order 70 over looked 71 packing

49 weissenberg effect

35 custom broker 36 customer

72 pamphlet 73 partial shipment 74 patent 75 paying price

No.

1

24.

accept order

37 D/A 38 D/P

1721

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

2 3 4 5 6 7 8 9

account after service agent sale annual sales at sight attached balance bank draft

39 deferred payment 40 deferred shipment 41 delivery on spot 42 delivery order 43 delivery time 44 discount 45 discount on draft 46 documentary draft 47 down payment 48 enclosure 49 endorsement 50 enquete 51 exhibition 52 export 53 factory visiy 54 favourable price 55 foreign exchange 56 free on board 57 idea price 58 import 59 invoice 60 L/C 61 margin 62 market 63 net weight

76 payment method 77 port of destination 78 port of trans-shipment 79 price 80 price descending 81 price rising 82 procurement 83 prompt delivery 84 purchase 85 purchasing agent 86 quotation 87 rebate 88 reference 89 remittance 90 repeat order 91 request letter 92 RFQ Request For Quotation 93 rumor 94 sample order 95 second hand goods 96 shipment 97 shipper 98 shipping 99 shipping mark 100 sold out

10 bargain goods 11 batch 12 bid 13 bid sales 14 bill of landing 15 bills receivable 16 brand 17 bulk cargo 18 business transaction 19 buyer 20 carbon copy 21 cargo collection 22 cash in advance 23 catalogue 24 cheque 25 claim 26 clearance goods

No.

24.

No.

1 2 3 4 5 6 7 8 9 3D modeling access application board bug bus CAD

25.

No.

25.

/

101 special discount 102 specification 103 standing 104 storage charge 105 subcontract 106 subject to final confirmation 107 supplier 108 T/T 109 tie-in sale 110 trade fair 111 transferred 112 trans-shipment 113 wharf

41 microprocessor 42 modeling 43 module 44 monitor 45 mouse 46 need 47 network 48 new version 49 on line 50 option 51 PC 52 plotter 53 program 54 scanning 55 simulation 56 software 57 solid model

CAE Computer AID Engineering CAM Computer AID Manufacturing

10 cassette 11 CD Compact Disk 12 color display 13 command 14 communication 15 compact 16 computer 17 copy

1821

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

18 CPU Central Processing Unit 19 cursor 20 curve modeling 21 database 22 design 23 digitizing 24 disk 25 dot 26 E-MAIL Electrical-Mail 27 eyelet 28 FDD Floppy Disk Drive 29 floppy 30 format 31 graphic 32 hardware 33 HDD Hard Disk Drive 34 honeycomb 35 interface 36 know how 37 laser printer 38 lay out 39 memory 40 memory swap

58 system 59 tape 57 solid model 58 system 59 tape 60 terminal 61 trim 62 venter 63 word processor

No.

1

26.

3C Computer , Commumcation , Consumer electronics 4M1H Man/Material/Money /Method/Time A.S.A.P As Sooner As Possible A/C Accountant Dept ABIOS Achanced Basic in put/output system abrasive / / / / () /

No.

26 cause description

26.

No.

26.

51 ESD Electric-static Discharge

27 CC Carbon Copy CD-ROM Compact Disk Read-Only Memory

52 F/C Flat Cable

3 4 5 6 7 8 9

28

53 file folder filed by accounting department 54 for reference 55 finished products 56 GS General Specification 57 I/O Input/Output 58 IC Integrated Circuit 59 IE Industrial Engineering 60 IS Inspection Specification 61 ISO International Standard Organization

29 chairman 30 check point 31 checked by 32 CMOS Complemeruary Metoll Oxide Semiconductor

administration/general affairs dept allround die holder AM Ante Meridian

33 conclusion 34 CONN Connector 35 DC Document Center 36 decision items 37 department

10 amendment 11 animation 12 application form for purchase Application status records of 13 year-end physical inventory List and physical inventory card 14 approval examine and verify

62 item/group/class IWS International Workman Standard

38 description

63

39 difference quantity

64 JIT Just In Time

, ( )

15 ASS'Y Assembly 16 ATTN Attention

40 DIMM Dual in-line Memory Module 41 disposed goods / disposed products

65 L/T Lead Time 66 LAB Laboratory

1921

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

17 B/M Boar/Molding(flat cable) 18 bill name 19 blank and waste sheet NO. 20 BOM Bill Of Material 21 BS Brain storming 22 C/P Connector of PC 23 C/T Cycle Time 24 CAD Computer Aid Design 25 cause analysis

42 distribution department 43 document folder 44 DT Desk Top 45 DVD Digital Video Disk 46 DWG Drawing 47 ECN Engineering Change Notes 48 ECO Engineering Change Order 49 end-user/using unit(department) 50 ES Engineering Standardization

()

67 LCD Liquid Crystal Display 68 LED Light-Emitting Diode 69 liaison 70 LMC Least Material Condition

71 LMS Least Material Size 72 location 73 materials 74 MC Material Control MCA Micro Channel 75 Architecture

No.

76 meeting minutes

26.

( ) ()

No.

101

26.

PCE assembly production schedule sheet

No.

126 REV Revision

26.

77 meeting type 78 MMC Maximum Material Condition

102 PCN Process Change Notice 103 PD Product Department 104 PDA Personal Digital Assistant 105 PE Product Engineering 106 performance 107 physical count quantity 108 physical inventory 109 PM Post Meridian 110 PMC Production & Material Control 111 PMP Product Management Plan 112 PPC Production Plan Control 113 pre-fixed finishing date 114 prepared by 115 present members 116 production control confirmation 117 production tempo 118 PS Package Specification

127 RFI Read Frequency Input 128 S/T Standard Time 129 sample 130 SECC SECC` 131 second check 132 second count 133 semi-finished product 134 SGCC SGCC 135 SIMM Single in-line memory module Specification In Process

79 MMS Maximum Material Size 80 Model MQA Manufacture Quality 81 Assurance MRP Material Requirement 82 Planning 83 MT Mini-Tower 84 MTL Material 85 N/A Not Applicable

86 not included in physical inventory 87 notes 88 obsolete material 89 OC Operation System OEM Original Equipment 90 Manufacture 91 OK 92 on way location 93 on-hand inventory

136 SIP

SOP Standard Operation 137 Procedure spare parts physical inventory 138 list 139 spare parts=buffer 140 SPEC Specification 141 SPS Switching power supply 142 143 SQA Strategy Quality Assurance

SSQA Sales and service Quality Assurance () )

94 oversea location

119 QTY Quantity

144 stock age analysis sheet

95 P&P Plans & Procedure

120 quantity of customs count quantity of physical invetory second count

145 subject summary of year-end physical inventory bills

96 P/A Personal & Administration 97 P/M Product Market 98 packing materials 99 PCB Printed Circuit Board PCE Personal Computer Enclosure

121

146

122 R&D Research & Design 123 REF Reference 124 remark

147 T/P True Position 148 TBD To Be Discuss 149 the first page This sheet and physical inventory list will be sent to 150 accounting department and financial department)

100

125 responsible department

No.

151 to put file in order 152 total 153

26.

TPM Total Production Maintenance

154 TYP Type

2021

2011/2/17 05:00

http://www.dison.com/chinese/pro.htm

155 VCD Video Compact Disk 156 VS 157 W/H Wire Harness 158 warehouse/hub 159 waste materials WDR Weekly Delivery 160 Requirement 161 witness line 162 work in progress product 163 work order 164 year-end physical inventory difference analysis sheet

2121

2011/2/17 05:00

Вам также может понравиться

- Welding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement ConsumablesДокумент10 страницWelding Consumable Calculation (WCC) : Doc. No Project Client Project Details Technical Requirement Consumableskeymal9195Оценок пока нет

- 造纸英语Документ360 страниц造纸英语Bruce GОценок пока нет

- Prefabricated Building Size 81'x27' Thallian Camp FWOДокумент3 страницыPrefabricated Building Size 81'x27' Thallian Camp FWOSagheer Ahmed100% (1)

- Profile WEIGHT calculation: Q.ty (M) 규 격 total weight 품 명 unit weightДокумент55 страницProfile WEIGHT calculation: Q.ty (M) 규 격 total weight 품 명 unit weightM Zahran KhairyОценок пока нет

- CONE Plate ReqdДокумент2 страницыCONE Plate ReqdneelОценок пока нет

- 5.0 First-Order Second Moment (Fosm)Документ20 страниц5.0 First-Order Second Moment (Fosm)YasirMahmoodОценок пока нет

- Topic 1 - Mechanical Fastening 2Документ11 страницTopic 1 - Mechanical Fastening 2nazirulhakimОценок пока нет

- Lifting Lug Weld DesignR1aДокумент1 страницаLifting Lug Weld DesignR1aJohnclaude ChamandiОценок пока нет

- 數學式和數學用語的英文讀法Документ13 страниц數學式和數學用語的英文讀法quantalcat100% (2)

- HeatExchanger Drawing PDFДокумент7 страницHeatExchanger Drawing PDFssierroОценок пока нет

- SCG Catalog LowДокумент42 страницыSCG Catalog LowNisay ArchineerОценок пока нет

- Perdele Economic B 2VVДокумент4 страницыPerdele Economic B 2VVakitainupufОценок пока нет

- 1 Beam Fails Ub305x165x54Документ4 страницы1 Beam Fails Ub305x165x54Elencheliyan PandeeyanОценок пока нет

- Duct Take Off-ModelДокумент11 страницDuct Take Off-ModelAbdul RaheemОценок пока нет

- Grundfos SololiftДокумент2 страницыGrundfos Sololiftptopic10Оценок пока нет

- Table 2 Est. Sheet EqptДокумент7 страницTable 2 Est. Sheet EqptKevinDataHilaОценок пока нет

- ASME CheckДокумент14 страницASME Checkfuransu777Оценок пока нет

- Document Transmittal Form (External) : Technics Offshore Engineering Pte LTDДокумент3 страницыDocument Transmittal Form (External) : Technics Offshore Engineering Pte LTDHanuman RaoОценок пока нет

- CCK VNT DuplexДокумент4 страницыCCK VNT DuplexNikki RobertsОценок пока нет

- Minimum Orifice Plate Thickness To Avoid Plastic Deformation (Buckling)Документ10 страницMinimum Orifice Plate Thickness To Avoid Plastic Deformation (Buckling)Hadi VeyseОценок пока нет

- Vessel Data Sheet Process Specification Sheet FormДокумент1 страницаVessel Data Sheet Process Specification Sheet FormunitedmanticoreОценок пока нет

- Secondary ScreenДокумент1 страницаSecondary ScreenVivek SakthiОценок пока нет

- Minimum Two Way Slab Thickness V 1.1Документ3 страницыMinimum Two Way Slab Thickness V 1.1engr_waqarОценок пока нет

- Air Curtain SpecificationsДокумент1 страницаAir Curtain SpecificationsJames Pitts100% (1)

- Ldo Storage Tank Calculation 170Документ6 страницLdo Storage Tank Calculation 170م.ذكى فضل ذكى100% (1)

- Preparation Before Machine Setup: (Sample)Документ2 страницыPreparation Before Machine Setup: (Sample)sciucОценок пока нет

- Demo Asme PWHT PreheatДокумент54 страницыDemo Asme PWHT PreheatWalter TrajadaОценок пока нет

- Plate & RectangularДокумент7 страницPlate & RectangularibicengОценок пока нет

- Emirates National Oil Co. LTD: Belleli Energy SRLДокумент7 страницEmirates National Oil Co. LTD: Belleli Energy SRLKhairul JaggerОценок пока нет

- Piping Rate ListДокумент12 страницPiping Rate Listshawanqureshi1706160Оценок пока нет

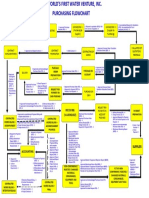

- Purchasing Flowchart FinalДокумент1 страницаPurchasing Flowchart FinalSpex AbrogarОценок пока нет

- Mechanical TerminlogyДокумент166 страницMechanical Terminlogyjoechengsh100% (1)

- Partsbook Zoje ZJ953 13H ED2 PDFДокумент55 страницPartsbook Zoje ZJ953 13H ED2 PDFMaskusyaniОценок пока нет

- 6754465782Документ2 страницы6754465782Coalsa IngenieríaОценок пока нет

- Drilling Design ManualДокумент230 страницDrilling Design Manualtarang_tushar100% (1)

- Bharat Petroleum Bid With UOP SpecificationДокумент395 страницBharat Petroleum Bid With UOP SpecificationBilal RasheedОценок пока нет

- Systematic Analysis of Gear Failures PDFДокумент241 страницаSystematic Analysis of Gear Failures PDFtheerapat patkaew100% (1)

- Auto Back TackДокумент14 страницAuto Back TackRicardo PirelaОценок пока нет

- CRV Air Valve Catalogue PDFДокумент10 страницCRV Air Valve Catalogue PDFsathishОценок пока нет

- Project: Landmark Macapagal Project DATE: OCTOBER 21, 2018 Subject: Haulout of Cut PilesДокумент6 страницProject: Landmark Macapagal Project DATE: OCTOBER 21, 2018 Subject: Haulout of Cut PilesJOHN KEVINОценок пока нет

- Malwi Marine: Inspection Report CrankshaftДокумент1 страницаMalwi Marine: Inspection Report CrankshaftBurak AldemirОценок пока нет

- Manual 1213896570Документ14 страницManual 1213896570Aroni AlejoОценок пока нет

- Singer: From The Library Of: Superior Sewing Machine & Supply LLCДокумент16 страницSinger: From The Library Of: Superior Sewing Machine & Supply LLCAndrew OrmeОценок пока нет

- Dom InpДокумент4 страницыDom InpcrackenhОценок пока нет

- Piston GrptsДокумент46 страницPiston GrptsPramono AdiОценок пока нет

- Design FMEAДокумент10 страницDesign FMEAAbu AzkhaОценок пока нет

- Bizhub Pro 1050-PmДокумент194 страницыBizhub Pro 1050-PmRoxana AndreeaОценок пока нет

- Ashok ParetoДокумент3 страницыAshok ParetoShailesh MishraОценок пока нет

- Steps in Facility DesignДокумент20 страницSteps in Facility DesignVarun MehrotraОценок пока нет

- Apache Belt CatalogДокумент50 страницApache Belt CatalogdaucОценок пока нет

- MI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3Документ29 страницMI Plan For NDC Expected Order Date 05-06-2018 Rev 1 With VF50 - String 3EduardОценок пока нет

- Eng-Lifting Lug 01Документ1 страницаEng-Lifting Lug 01AbderraoufAffesОценок пока нет

- Cert Yugo ElectromagneticoДокумент4 страницыCert Yugo ElectromagneticoMANUELОценок пока нет

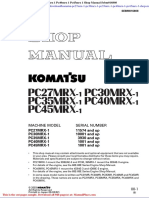

- Komatsu pc27mrx 1 pc30mrx 1 pc35mrx 1 pc40mrx 1 pc45mrx 1 Shop Manual Sebm016808Документ20 страницKomatsu pc27mrx 1 pc30mrx 1 pc35mrx 1 pc40mrx 1 pc45mrx 1 Shop Manual Sebm016808Jose100% (42)

- Parts List: Published in Feb.'03 3HK70770Документ11 страницParts List: Published in Feb.'03 3HK70770Luiz DiasОценок пока нет

- 212 86 92 - RepairedДокумент11 страниц212 86 92 - Repairedsebastian cruzОценок пока нет

- Ray P. Prasad (Auth.) - Surface Mount Technology - Principles and Practice-Springer Netherlands (1989)Документ616 страницRay P. Prasad (Auth.) - Surface Mount Technology - Principles and Practice-Springer Netherlands (1989)Muhammad Fatiyan RizkilahОценок пока нет

- Webster Engine Works 4 Cycle Gas Engine: Displacement: .75 Ci Bore: .875" Stroke 1.25"Документ21 страницаWebster Engine Works 4 Cycle Gas Engine: Displacement: .75 Ci Bore: .875" Stroke 1.25"Julio Raizer100% (1)

- EN 1092 1 FlangesДокумент29 страницEN 1092 1 FlangesTungОценок пока нет

- Fixed Side BRW20 0662Документ1 страницаFixed Side BRW20 0662Thành NguyễnОценок пока нет

- G12 - Weld DefectsДокумент2 страницыG12 - Weld DefectsKram Anonuevo Yatigal100% (1)

- Sem 1 Brazing With Oxyacetylene WeldingДокумент3 страницыSem 1 Brazing With Oxyacetylene WeldingKamarul Nizam100% (1)

- Powertools Inventory (Sillon)Документ3 страницыPowertools Inventory (Sillon)Jube Kathreen ObidoОценок пока нет

- How It Works - PDF RotaBoltДокумент5 страницHow It Works - PDF RotaBoltaop10468Оценок пока нет

- Module - IntroductioninMetalWorkДокумент19 страницModule - IntroductioninMetalWorkDaniel Daryl CalingОценок пока нет

- 423 - Fresa DiscoДокумент28 страниц423 - Fresa DiscoVinicius Sabrina PedroОценок пока нет

- Abrasive Machining ProcessДокумент13 страницAbrasive Machining ProcessAbdulRehman Ahmed SoomroОценок пока нет

- Manual Torno JetДокумент72 страницыManual Torno JetPREVISTOОценок пока нет

- Sand Casting of A 9mm PistolДокумент16 страницSand Casting of A 9mm PistolZarian HanifОценок пока нет

- 34-12 Boring ExerciseДокумент1 страница34-12 Boring ExerciseDavid BumbaloughОценок пока нет

- Daily Eng Ref TablesДокумент26 страницDaily Eng Ref TablesPalaОценок пока нет

- Acid PicklingДокумент7 страницAcid PicklingPhan Văn ThạnhОценок пока нет

- NavojiДокумент193 страницыNavojianon_419810527Оценок пока нет

- Level Mount TV Wallmount Instruction Fixed Tilt2Документ12 страницLevel Mount TV Wallmount Instruction Fixed Tilt2candidate49Оценок пока нет

- Bi006008-00 2B PDFДокумент5 страницBi006008-00 2B PDFRamon HidalgoОценок пока нет

- Productsheet Nfs WebДокумент3 страницыProductsheet Nfs WebCkaal74Оценок пока нет

- Sa 213Документ11 страницSa 213gst ajahОценок пока нет

- Metric Socket Head Cap ScrewsДокумент2 страницыMetric Socket Head Cap ScrewsImam MulyonoОценок пока нет

- Components of Flexible Manufacturing SystemsДокумент11 страницComponents of Flexible Manufacturing SystemsjackОценок пока нет

- A Simple Small Metalworking ShaperДокумент7 страницA Simple Small Metalworking ShaperĐặng Ngọc Hùng100% (2)

- Study of Plain Plug Gauge: Mini ProjectДокумент19 страницStudy of Plain Plug Gauge: Mini ProjectdomiОценок пока нет

- Gas Welding, Brazing and SolderingДокумент7 страницGas Welding, Brazing and SolderingAkashОценок пока нет

- Tungsten Carbide PropertiesДокумент2 страницыTungsten Carbide Propertiessudhan56psgОценок пока нет

- Ray Osborne Rotary Bending Presentation For ISTMA Technical SessionsДокумент25 страницRay Osborne Rotary Bending Presentation For ISTMA Technical SessionsElaine JohnsonОценок пока нет

- Abrasive Jet Machine - AbstractДокумент6 страницAbrasive Jet Machine - AbstractManju KbОценок пока нет

- Forming ProcessesДокумент8 страницForming ProcessesKishor PatilОценок пока нет

- Lab 7 Workshop Teacher VersionДокумент4 страницыLab 7 Workshop Teacher Versionumar272Оценок пока нет

- CAD CAM LAB MANUAL - MT8711-REG-2017-MCT-7th SemДокумент87 страницCAD CAM LAB MANUAL - MT8711-REG-2017-MCT-7th SemKathirvelan DОценок пока нет

- Heat Treatment ProcessДокумент46 страницHeat Treatment ProcessMallappa KomarОценок пока нет