Академический Документы

Профессиональный Документы

Культура Документы

Friction Torque

Загружено:

Faber SaldanhaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Friction Torque

Загружено:

Faber SaldanhaАвторское право:

Доступные форматы

Friction Torque

Friction torque in rolling bearings will vary with the bearing load and the condition of the lubricant. Where the bearing load is light-to-normal (P0.12C) and the lubricant provides good separation between the rolling contact surfaces, bearing friction torque may be calculated using the following formula:

where: M = friction torque (N mm) = coefficient of friction F = bearing load (N) d = shaft diameter (mm)

Temperature Rise

Temperature rise in bearings is caused by the conversion of friction energy into heat. Bearing temperature will generally rise quite abruptly during the initial stage of operation and then gradually climb until a steady state is reached. The steady state condition will exist if temperature rise from frictional energy is removed by the cooling "heat-sink" effect from the shaft and housing, and from heat conductance via the shaft, housing and lubricant.

The time until equilibrium is attained depends on the difference between heating volume generated by the bearing and the heating volume removed by the cooling effect. If the equilibrium temperature is excessively high, then review of the bearing application should be done. The bearing internal clearance or preload, fits, bearing support structure, seal contact area surface finish, rotating speed, load, and lubrication type, amount, and delivery system are subjects for investigation where excessive temperature occurs. An abnormal temperature rise can cause a spiraling condition where no equilibrium will occur, thus leading to a break-down in the lubricant and lubricant film, with catastrophic results.

Mounting and Dismounting

Rolling bearings have higher accuracy than other parts in most equipment and are often considered to be the most important rotating component. Improper handling of bearings reduces machine accuracy and can cause early bearing failures. To attain predicted bearing performance, utmost care should be taken in handling bearings from the pointof-receipt through the mounting operation.

Storage and Handling

The major problems encountered during the bearing storage and retrieval operations are in rusting and impact damage to the parts. To protect bearings against rusting during storage, parts should be placed in a dry, clean, cool area. Bearings should not be subjected to extremes of humidity during storage. Impacts to bearings can create damage to the raceways, rolling elements, and cages. Do not drop bearings. Bearings which are dropped should not be used for service.

Mounting

Proper bearing mounting governs the life, accuracy, and performance of a bearing. Before mounting the bearing, carefully check the following points. Check to see if: the job standards are established and the necessary jigs are prepared. the shaft and housing size, tolerance, and finish are defined and met. lubricant type and amount specified is at hand. inspection standards are established.

the method of cleaning the bearing and relevant parts is clear. (1) Mounting Precautions Select a clean, dry place to handle the bearing, and keep necessary tools and workbench clean. Do not unpack the bearing until it is to be mounted. If the bearing is unpacked before mounting for acceptance inspection or for any other reason, follow these directions: a) If the bearing is to be mounted within a short time period, coat it with rust preventive oil and place it in a clean container. b) If the bearing will not be mounted in a short time, coat it with rust preventative oil and repack it in the original container.

Вам также может понравиться

- 4HK1 & 6HK1 ManualДокумент352 страницы4HK1 & 6HK1 Manuallionkinghd94% (104)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreОт EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreРейтинг: 4.5 из 5 звезд4.5/5 (11)

- Isuzu Diesel Engine (4HK1, 6HK1) PDFДокумент11 страницIsuzu Diesel Engine (4HK1, 6HK1) PDFtin tunlin100% (2)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideОт EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingОт EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Layout Plan - Pilot Solar Power Plant - Kabulasoke PDFДокумент24 страницыLayout Plan - Pilot Solar Power Plant - Kabulasoke PDFMardi RahardjoОценок пока нет

- Dec Pump Assembly Cross Sectional Drawing e Agitator d7868Документ11 страницDec Pump Assembly Cross Sectional Drawing e Agitator d7868GabrielОценок пока нет

- Jamalpur Earthing Calculation Final PDFДокумент10 страницJamalpur Earthing Calculation Final PDFarafinОценок пока нет

- BearingДокумент39 страницBearingZaiDillah SayaОценок пока нет

- Selection of Bearing: Assignment No. 1Документ18 страницSelection of Bearing: Assignment No. 1Aakash VirdheОценок пока нет

- Topic 4 - BearingДокумент37 страницTopic 4 - BearingNazuan NazriОценок пока нет

- Dme Unit - 5 Produce by Assistant Professor G.Ganapathy (9629027354)Документ13 страницDme Unit - 5 Produce by Assistant Professor G.Ganapathy (9629027354)Anonymous tZfJJPRKsОценок пока нет

- To The World Of: BearingsДокумент42 страницыTo The World Of: BearingsNaag RajОценок пока нет

- BearingsДокумент48 страницBearingsgaurav tiwariОценок пока нет

- Spindle Bearing and LubricationДокумент17 страницSpindle Bearing and LubricationmutthudarurОценок пока нет

- JR Fibreglass - Failure ReportДокумент4 страницыJR Fibreglass - Failure ReportTahir MansuriОценок пока нет

- 1 - Module 2Документ15 страниц1 - Module 2Kelvin karaniОценок пока нет

- Third Engineer To Second Engineer Mentoring Program: Name:Abhijith Sreevalsan PillaiДокумент42 страницыThird Engineer To Second Engineer Mentoring Program: Name:Abhijith Sreevalsan PillaiAbhijith Sreevalsan PillaiОценок пока нет

- Third Engineer To Second Engineer Mentoring Program: Name:Abhijith Sreevalsan PillaiДокумент42 страницыThird Engineer To Second Engineer Mentoring Program: Name:Abhijith Sreevalsan PillaiAbhijith Sreevalsan PillaiОценок пока нет

- Chapter 7 Rolling Contact Bearing-3Документ26 страницChapter 7 Rolling Contact Bearing-3Abaziz Mousa OutlawZzОценок пока нет

- Basic Knowledge For Using Bearings SafelyДокумент40 страницBasic Knowledge For Using Bearings SafelypibearingОценок пока нет

- Q & A: When To Clean and Repack BearingsДокумент4 страницыQ & A: When To Clean and Repack BearingsMachineryengОценок пока нет

- Chapter 27 BennetДокумент56 страницChapter 27 BennetpapipapiiОценок пока нет

- TOPIC 4 BearingДокумент44 страницыTOPIC 4 BearingHafiy Qursyeini100% (1)

- SLIDING CONTACT BEARINGS W ProblemsДокумент28 страницSLIDING CONTACT BEARINGS W ProblemsRex OabelОценок пока нет

- LO 4 Handout SLO1,2,3, and 4 All Suboutcome CompleteДокумент38 страницLO 4 Handout SLO1,2,3, and 4 All Suboutcome Completesushil.vgiОценок пока нет

- Plant MaintenanceДокумент37 страницPlant MaintenanceAli khanОценок пока нет

- Boiler Ash Handling Operation & Maintenance PDFДокумент64 страницыBoiler Ash Handling Operation & Maintenance PDFdreamboy87Оценок пока нет

- Heavy-Duty Truck Axle Service and RepairДокумент66 страницHeavy-Duty Truck Axle Service and RepairbidyadharОценок пока нет

- SOP Bearing ReplacementДокумент10 страницSOP Bearing ReplacementzaidmuzammilОценок пока нет

- BearingДокумент12 страницBearingDahlan DahlanОценок пока нет

- Design of Machine Elements: MEPC24Документ18 страницDesign of Machine Elements: MEPC24Joe AllanОценок пока нет

- 5556 Setting Techniques For Timken Tapered Roller BearingsДокумент20 страниц5556 Setting Techniques For Timken Tapered Roller BearingsAnonymous Clyy9NОценок пока нет

- Bearing Installation ProcedureДокумент6 страницBearing Installation ProcedureHamad KhaledОценок пока нет

- Cylinder Liner NotesДокумент15 страницCylinder Liner NotesHrishikesh MoreОценок пока нет

- Bearing Mounting Basics PDFДокумент4 страницыBearing Mounting Basics PDFssoares1989Оценок пока нет

- Turbine Engine MaintenanceДокумент36 страницTurbine Engine MaintenancesushantreshmaОценок пока нет

- Angular Contact Bearing InstallationДокумент3 страницыAngular Contact Bearing Installationdk4monjureОценок пока нет

- SKF Mount - 22232 CCK-W33 - Hydraulic Nut - Adapter SleeveДокумент11 страницSKF Mount - 22232 CCK-W33 - Hydraulic Nut - Adapter SleeveMohamed Abo elkhairОценок пока нет

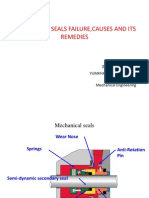

- Mechanical Seals Failure, Causes and Its RemediesДокумент26 страницMechanical Seals Failure, Causes and Its RemediesFaruque Khan Yumkhaibam100% (6)

- Tyre Curing: Curing Recipes and SettingsДокумент6 страницTyre Curing: Curing Recipes and SettingsMALAY GUPTAОценок пока нет

- NSK Bearing Doctor2Документ36 страницNSK Bearing Doctor2ssamonasОценок пока нет

- Lubrication GuideДокумент22 страницыLubrication GuideRizalОценок пока нет

- L&S Electric EASA AR100 AccreditationДокумент66 страницL&S Electric EASA AR100 AccreditationAlbert Daniel Torres100% (1)

- 2 - Three Phase Induction Motors Maintenance ManualДокумент26 страниц2 - Three Phase Induction Motors Maintenance ManualMiguel Angel67% (3)

- SKF Mount - 22318 EJA - VA405 - Hot Mounting - ShaftДокумент4 страницыSKF Mount - 22318 EJA - VA405 - Hot Mounting - ShaftcumtjerryОценок пока нет

- Vasim 2Документ17 страницVasim 2Vasim shaikhОценок пока нет

- 1st Class Motor Examination QuestionsДокумент3 страницы1st Class Motor Examination QuestionsSethu RajОценок пока нет

- 3 Lobe BearingДокумент5 страниц3 Lobe BearingRaman KumarОценок пока нет

- Bearing AdvancedДокумент81 страницаBearing Advancedibrahim samy100% (1)

- Maintenance and Troubleshooting of Electric MotorsДокумент27 страницMaintenance and Troubleshooting of Electric MotorsNguyễn Thanh Sơn100% (1)

- 6000 en 00 08 Mounting and DismountingДокумент18 страниц6000 en 00 08 Mounting and Dismountingmzarei_1982Оценок пока нет

- Boilers: 9-1. Minimum Maintenance Activities For BoilersДокумент12 страницBoilers: 9-1. Minimum Maintenance Activities For BoilersLacshay ShekharОценок пока нет

- Clutches: by Abanega WДокумент20 страницClutches: by Abanega WAbanega WoltejiОценок пока нет

- CCK - W33 - Mounting - Withdrawal Sleeve - Mechanical MountingДокумент14 страницCCK - W33 - Mounting - Withdrawal Sleeve - Mechanical Mountingpmf engineering limitedОценок пока нет

- OTR DatabookДокумент91 страницаOTR DatabookSamuel Hendra Sinaga100% (2)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesОт EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesРейтинг: 5 из 5 звезд5/5 (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsОт EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsРейтинг: 4 из 5 звезд4/5 (1)

- Naval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyОт EverandNaval Diesel Engineering: The Fundamentals of Operation, Performance and EfficiencyОценок пока нет

- Steps For Filling Up The Online Application Form: Step 1Документ5 страницSteps For Filling Up The Online Application Form: Step 1Faber SaldanhaОценок пока нет

- Analysis of Bearing FailureДокумент22 страницыAnalysis of Bearing FailureFaber SaldanhaОценок пока нет

- Advanced Mechanical Vibrations (MME-623) RCSДокумент2 страницыAdvanced Mechanical Vibrations (MME-623) RCSFaber SaldanhaОценок пока нет

- Ana 2008Документ2 страницыAna 2008Faber SaldanhaОценок пока нет

- Feyzin Oil Refinery DisasterДокумент8 страницFeyzin Oil Refinery DisasterDavid Alonso Cedano EchevarriaОценок пока нет

- Shell Pakistan Stock in Trade: Horizontal AnalysisДокумент12 страницShell Pakistan Stock in Trade: Horizontal Analysisfahad pansotaОценок пока нет

- RBK-1 Details For Relay SettingДокумент3 страницыRBK-1 Details For Relay SettingWinny MathewОценок пока нет

- Varianta Test Competenta Mai 2009Документ5 страницVarianta Test Competenta Mai 2009Florina LepadatuОценок пока нет

- Recovery PDFДокумент164 страницыRecovery PDFAzizi AbdullahОценок пока нет

- Retigo Vision CatalogueДокумент32 страницыRetigo Vision Cataloguesuonodimusica0% (1)

- Plant Floor Safety Fall 2020 PDFДокумент54 страницыPlant Floor Safety Fall 2020 PDFPravivVivpraОценок пока нет

- Semiconductor TimesДокумент24 страницыSemiconductor Timessaj4uuОценок пока нет

- Fabrication Tecniques of Quantum Well, Quantum Dot and Quantum WireДокумент4 страницыFabrication Tecniques of Quantum Well, Quantum Dot and Quantum WireRia Rushin Joseph100% (1)

- Attenuation ProjectДокумент12 страницAttenuation Projectapi-352698073Оценок пока нет

- THC 301D Operation ManualRev3Документ12 страницTHC 301D Operation ManualRev3RC13Оценок пока нет

- Sir. Abdul-Kareem: Stereoisomerism - Geometric IsomerismДокумент8 страницSir. Abdul-Kareem: Stereoisomerism - Geometric IsomerismsaudОценок пока нет

- ProductBrochure A35F A40F EN 21A1006561 2010-12Документ24 страницыProductBrochure A35F A40F EN 21A1006561 2010-12Muhammad Ridha FatriantaОценок пока нет

- Current Transformer: Engineering DepartmentДокумент8 страницCurrent Transformer: Engineering DepartmentbinodeОценок пока нет

- Green Building - Thesis Report (Administrative Block of NIT Raipur, New Campus)Документ86 страницGreen Building - Thesis Report (Administrative Block of NIT Raipur, New Campus)Pranav Mishra89% (47)

- KP-00+++-MQ758-V0010-Rev 0-MS For CB Installation Works PDFДокумент27 страницKP-00+++-MQ758-V0010-Rev 0-MS For CB Installation Works PDFUtku Can Kılıç100% (1)

- CementДокумент11 страницCementHerdian NafiОценок пока нет

- Termotehnica Part2Документ95 страницTermotehnica Part2Cirstea AlexandruОценок пока нет

- 6.1 Mastering IELTS Writing Task 1 (PDFeBook) PDFДокумент228 страниц6.1 Mastering IELTS Writing Task 1 (PDFeBook) PDFHarsh Patel100% (6)

- Siemons - Cello Bowing TechniqueДокумент15 страницSiemons - Cello Bowing TechniqueMassa Awaj100% (2)

- Reports & Indices: Atish Mathur: MATHUR10Документ11 страницReports & Indices: Atish Mathur: MATHUR10Manasa VarshiniОценок пока нет

- Energy, Work and Power: PHY111: Mechanics and Thermo Properties of MatterДокумент71 страницаEnergy, Work and Power: PHY111: Mechanics and Thermo Properties of MatterStudent 365Оценок пока нет

- 1 - Firewater Piping Spec - DIДокумент2 страницы1 - Firewater Piping Spec - DISuezie Iella100% (1)

- Ultra Series Boom LiftsДокумент16 страницUltra Series Boom Liftsmcuentas1984Оценок пока нет

- Title - Study and Analysis of The Effects of Waves and Wind On Offshore Structures and Marine VesselsДокумент5 страницTitle - Study and Analysis of The Effects of Waves and Wind On Offshore Structures and Marine VesselsIszysax MediaОценок пока нет

- Honeywell Mag Meter 4000Документ28 страницHoneywell Mag Meter 4000cgasior1Оценок пока нет