Академический Документы

Профессиональный Документы

Культура Документы

Fibres N Yarn

Загружено:

Karishma S. YadavИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fibres N Yarn

Загружено:

Karishma S. YadavАвторское право:

Доступные форматы

Fibres and Yarns

Fabric Knowledge under the guidance of Mr.Dibyendu Bikash Dutta

SUBMITED BY: KARISHMA YADAV MFM-2011-13 ROLL NO.35

Fibres and Yarns 2

TABLE OF CONTENT

S.No. 1. TOPICS Fibres.2 Classification of fibres3-6 2. Silk.7-11 Manufacturing process Properties End uses of silk Cotton..12-15 Jute.16-20 Rayon..21-27 Spandex28-32 Yarns..33-35 Simple and decorative yarns.36-38

3. 4. 5. 6. 7.

Fibres and Yarns 3

Fibres

A fibre is a hair like strand from which all fabrics are made. Fiber or fibre is classes of materials that are continuous filaments or are in discrete elongated pieces, similar to lengths of thread.They are very important in the biology of both plants and animals, for holding tissues together. Human uses for fibers are diverse. They can be spun into filaments, string or rope, used as a component of composite materials or matted into sheets to make products such as paper or felt.

Fibres and Yarns 4

CLASSIFICATION OF FIBRES

Short fibres: staple fibres Long fibres: filament fibres Fibres can also be classified on basis of origin Natural Fibres silk cotton wool jute Man-Made Fibres Nylon Polyester Rayon Spanex

Natural Fibres :

these are the fibres obtained from naural sources such as plants and animals These fibres are obtained from different plants. Some are well known and useful to man. Cotton can you think of any such fibre? That is right, cotton, jute and coir. Cotton is obtained from seed of the plant, jute is obtained from the stem of a plant and coir is the outer covering of coconut. Animal Fibres These fibres are obtained from different animal sources. Can you name the fibre we get from sheep and goat? Thats right, we get wool from their hair. Wool can also be obtained from the hair of rabbits and camels. Another animal fibre you all are familiar with is silk. It is the secretion of an insect called the silk worm. Example : cotton , slik, jute, wool

Man-Made Fibres :

these are the fibres obtained from chemical substances When you go to the market to buy fabrics, you must have heard from the shopkeeper that it is a synthetic material. Dont get disturbed. Synthetic is another name for manmade fabrics. The first man-made fibre is known as rayon and was produced in the latter part of 19th century. Example : Rayon , Polyester, Nylon, Spamdex

Fibres and Yarns 5

Fibres

on basis of Length

on basis of Origin

Staple

Filament

Natural

ManMade

vegetable

Animals

Fibres and Yarns 6

SILK

Silk fibers are smooth, translucent, rod-like filaments with occasional swellings along their length. The raw silk fiber actually consists of two filaments called fibroin bound by a soluble silk gum called sericin. Fibroin and sericin are made up of carbon, hydrogen, nitrogen, and oxygen. Silk has several important qualities: (1) It is lower in density than wool, cotton, or rayon. (2) It is a poor conductor of heat and electricity. (3) It is capable of soaking up to 30% of its weight in moisture. (4) It is extremely strong, with a breaking strength as high as 65,000 psi. (5) It will stretch to as much as 20% of its length without breaking. (6) It is thermally stable; it is able to withstand temperatures as high as 284F (140C). (7) It becomes smooth, lustrous, and luxurious when processed. (8) It is remarkably resilient, and shows excellent wrinkle recovery.

Fibres and Yarns 7

MANUFACTURING PROCESS The natural habitat for a silk worm is the mulberry tree, which is cultivated in large amount for the breeding of the silk worm. The traditional silk production process is also known as sericulture. Following steps are involved in silk fiber production process:

1- Hatching of Eggs First of all, silk moth lays eggs and when the eggs get hatched, caterpillars feed mulberry leaves. Further, when the silkworms are about 35 days old they are much heavier, than when they hatched. Finally, now they are now ready to spin a silk cocoon.

2- Silk production by worm The silk is actually produced in two glands, in the silkworms head, and the liquid is also formed, in the openings called spinnerets. The silk gets solidify when it comes in contact with the natural air. Further, silkworm spins approximately one mile of filament and completely encloses itself in a cocoon for about 2 or three days.

3- Transition of the worm The silkworm then passes through various other stages and changes into a moth. But, the silkworm is usually killed using heat before it reaches this particular stage. The silkworms are killed for the reason that, if once they reach the moth stage, moth secretes a fluid to dissolve the silk so it can emerge from the cocoon. This is because cocoon gets damaged and in turn lowers the quality of silk.

4- Raw Fiber Obtained Then further, silk is extracted from the undamaged cocoons by brushing the cocoon to find the outside ends of the filament. The silk filaments are then wound on a reel. One cocoon contains roughly 1,000 yards of silk filament. The silk prepared at this stage is known as raw silk. A yarn can now be produced by combining several other filaments of silk. Production of silk is considered one of the time consuming and labour intensive practice.

Fibres and Yarns 8

Fibres and Yarns 9

PROPERTIES

PHYSICAL

CHEMICAL

*Silk is one of the strongest natural fibers but loses up to 20% of its strength when wet.

Silk fibers from the Bombyx mori silkworm have a triangular cross section with rounded corners, 5-10 m wide . Silk has a smooth, soft texture that is not slippery, unlike many synthetic fibers.

Silk emitted by the silkworm consists of two main proteins, sericin and fibroin, fibroin being the structural center of the silk, and serecin being the sticky material surrounding i The high proportion (50%) of glycine, which is a small amino acid, allows tight packing and the fibers are strong and resistant to breaking. The tensile strength is due to the many interseeded hydrogen bonds, and when stretched the force is applied to these numerous bonds and they do not break. Silk is resistant to most mineral acids, except for sulfuric acid, which dissolves it

Silk is one of the strongest natural fibers but loses up to 20% of its strength when wet.

It has a good moisture regain of 11%. Silk is a poor conductor of electricity and thus susceptible to static cling.

It is yellowed by perspiration.

Fibres and Yarns 10

END USES OF SILK

The ready-to-wear sector is also a large user of silk, especially in the luxe category. silk shirts, silk pyjamas, dressing gowns. Silk laces and tulles: Are unbeatable for their lightness and are frequently used for bridal veils and dresses. Knitting: Silk-knitting is a very important activity which produces a very wide range of clothing articles. Knitting gives hosiery items that ideal elasticity and that plastic character which no other article can rival. Scarves and squares: Permanent components of womens and mens wear, they are also highly appreciated as gifts Ties : For the man who is anxious to look welldressed, the silk tie is must. It also makes a very welcome present. Passementerie: Is the name given to all the techniques connected with the production of decorative articles such as ribbons, braids, pompoms, tassels, etc. used both in clothing and in furnishing. Furnishing and upholstery: As far as art is concerned, furnishing and upholstery have been one of the chief outlets for silk for centuries. Sewing-thread: Essential for sewing quality garments. Ribbons: Ribbons for typewriters, computers, cashregisters, etc. are often made of silk. Insulation: Silk is often used as an insulator in sophisticated devices such as space vessels.

Fibres and Yarns 11

COTTON

Cotton, as a natural cellulosic fiber, has a lot of characteristics, such as; Comfortable Soft hand Good absorbency Color retention Prints well Machine-washable Dry-cleanable Good strength Drapes well Easy to handle and sew

Fibres and Yarns 12

MANUFACTURING PROCESS Opening and Cleaning Conversion of fibers into a bat, weighing 10-30 ounces/sq. yard, by Needle punching or Air-lay technique. Scouring Bleaching Finishing Washing Drying Fiber opening

Fibres and Yarns 13

PROPERTIES

PHYSICAL Fibre Length Fiber length is described [7] as "the average length of the longer one-half of the fibers (upper half mean length)" This measure is taken by scanning a "beard " of parallel fibers through a sensing region. The beard is formed from the fibers taken from the sample, clasped in a holding clamp and combed to align the fibers. Typical lengths of Upland cottons might range from 0.79 to 1.36in. CHEMICAL

Cotton swells in a high humidity environment, in water and in concentrated solutions of certain acids, salts and bases.

The moisture regain for cotton is about 7.1~8.5% and the moisture absorption is 7~8%. [20]

Cotton is attacked by hot dilute or cold concentrated acid solutions. Acid hydrolysis of cellulose produces hydrocelluloses. Cold weak acids do not affect it. The fibers show excellent resistance to alkalis. There are a few other solvents that will dissolve cotton completely.

Cotton degradation is usually attributed to oxidation, hydrolysis or both.

Fibres and Yarns 14

END USES

The major end uses for cotton fibre include wearing apparel, home furnishings, and other industrial uses (such as medical supplies). The cotton fibre is made primarily into yearns and threads for use in the textile and apparel sectors (wearing apparel would account for approximately 60% of cotton consumption). Cotton is also used to make home furnishings, such as draperies (eventually the third major end use) or professional garments (about 5% of cotton fibre deman Apparel - Wide range of wearing apparel: blouses, shirts, dresses, childrenswear, active wear, separates, swimwear, suits, jackets, skirts, pants, sweaters, hosiery, neckwear. Home Fashion - curtains, draperies, bedspreads, comforters, throws, sheets, towels, table cloths, table mats, napkins Cotton fabrics with specialty applications include, for example, fire-proof (flame resistant) apparel, which is suitable for professional uses and provides effective protection against potential risks associated with high temperature and particularly flashover. Flame resistant cotton fabrics are treated with chemicals.

Fibres and Yarns 15

JUTE

Jute fibre is 100% bio-degradable and recyclable and thus environmentally friendly. It is a natural fibre with golden and silky shine and hence called The Golden Fibre. It is the cheapest vegetable fibre procured from the bast or skin of the plant's stem. It is the second most important vegetable fibre after cotton, in terms of usage, global consumption, production, and availability. It has high tensile strength, low extensibility, and ensures better breathability of fabrics. Therefore, jute is very suitable in agricultural commodity bulk packaging. It helps to make best quality industrial yarn, fabric, net, and sacks. It is one of the most versatile natural fibres that has been used in raw materials for packaging, textiles, non-textile, construction, and agricultural sectors. Bulking of yarn results in a reduced breaking tenacity and an increased breaking extensibility when blended as a ternary blend. The best source of jute in the world is the Bengal Delta Plain in theGanges Delta, most of which is occupied by Bangladesh. Advantages of jute include good insulating and antistatic properties, as well as having low thermal conductivity and a moderate moisture regain. Other advantages of jute include acoustic insulating properties and manufacture with no skin irritations.

Fibres and Yarns 16

MANUFACTURING PROCESS

Land Preparation The first step of Jute cultivation is land preparation. The land preparation is completed at between January to March of a year. Land preparation for the jute also depend on the types of Land, Weather and the kind of water. Seeds Sown The time of jute seeds sowing is February to March. Basically 10 to 12 pound per acore seeds is sowed. Plants Grow After sowing the seeds the jute plants take time to grow and eventually it is seen that, jute is growing rapidly. Weeding & Thinning When it is seen that, the plants are being surrounded by the weeds, then an attempt is taken to wiped out all of the weeds to thinning the lands. Harvesting When the jute plants got bigger and the jute fruits seem like ripen than jute plant is to be harvested. Generally the harvesting time continues from June to September. Retting

Fibres and Yarns 17

In this stage the Jute plants is to be submerged into the water for 3 to 4 weeks. Stripping After retting when the jute fiber seems to be detached from the body of jute plant, then the jute fiber is stripped. Washing After stripping it is recommended to wash the fiber in fresh water. It is necessary to make the jute fiber more brighter and clean. Drying After washing, drying process is started. Generally the Sun is used to dry the jute fibers. After drying which fiber we will get it is called Jute Fiber and it is ready to use then.

Fibres and Yarns 18

PROPERTIES

PHYSICAL PROPERTIES Ultimate Jute Length: 1.5 to 4 mm. Ultimate Diameter of Jute: 0.015 to 0.002 mm CHEMICAL PROPERTIES Cellulose > 65%

Hemi-cellulose > 22.5%

Jute Color: Jute fiber can be White, Yellow, Brown or Grey. Strength of Jute: 3.5 to 5 G/Den. Specific Gravity: 1.48 Elasticity: Breaking Extension 1.8% and Elastic Recovery very low. Moisture Regain of Jute: 13.75 % (Standard). Dimensional Stability of Jute: Good on average.

Lignin > 11%

Fat and Wax > 0.3%

Water Soluble Materials > 1.2%

Fibres and Yarns 19

END USES OF JUTE

It is used to make cloth for wrapping bales of raw cotton & to make

sacks for packaging goods. used to make cloth for wrapping bales of raw cotton & to make sacks for packaging goods. Jute Geotextile is used for preventing soil erosion, while natural vegetation becomes established, seed protection, weed control etc. Food Grade Jute bags are used for packaging of Cocoa, Coffee & shelled nuts, as per international specification, IJO standard 98/01. Jute composites are used for automobile interior production. Flame proof & mild deed proof fabric using jute yarn as core & high performance fibre as core sheath are used in Protech application, eg Personal & property protection. Canvas cloth & Tarpaulin are used in Agrotech & Oekotech application.

Home Textile: Pep up the Living room or office rooms with bright jute

cushion covers and an amazing range of jute furnishing for the sofas & curtains. Add a dash of colour to table settings with vibrant jute mats & other accessories. Dress up the walls with delicately embroidered jute wall hanging. Floor Dcor : Jute & jute blended floor coverings with ruffed textures, earthly tones or bright exotic designs makes home & workplace a true delight . The machine made or hand knotted carpets, rugs & dhurries are environment friendly, light weight and easy to lay and use. Hand Bags & Shopping Bags : While one enjoy the novelty and different ranges of Jute Hand bags, one can also feel 2000 about using an environment-friendly product, for corporate image. The range also includes luggage, wallets and fashion bags.

Novelties & Gifts : Jute novelties are as varied as it can be from tea

coaster, string bags, purses, water bottle/wine bags, hanging chairs etc. Jute Gift item include jute doll are free from hazards, jute ornaments, jute pencil stand for your esteemed client with a jute calendar. Gift items of jute are not just different, they are distinct - they make a better world.

Fibres and Yarns 20

RAYON

There are two main categories of man-made fibers: those that are made from natural products (cellulosic fibers) and those that are synthesized solely from chemical compounds (noncellulosic polymer fibers). Rayon is a natural-based material that is made from the cellulose of wood pulp or cotton. This natural base gives it many of the characteristicslow cost, diversity, and comfort that have led to its popularity and success. Today, rayon is considered to be one of the most versatile and economic fibre.

Fibres and Yarns 21

PROPERTIES

PHYSICAL

CHEMICAL

Hot dilute acids attack rayon, whereas Microscopic appearance bases do not seem to significantly attack Striations seen in viscose and high rayon. strength rayon If delustered , scattered specks of pigment can beseen Fibers with thickness of 1.7 to 5.0dtex, particularly those between 1.7 and 3.3 dtex, dominate large scale production.

Rayon is attacked by bleaches at very high Tenacity ranges between 2.0 to 2.6 g/den concentrations and by mildew under severe hot and moist conditions. when dry and 1.0 to 1.5 g/den when wet.

Wet strength of the fiber is of importance Prolonged exposure to sunlight causes loss during its manufacturing and also in of strength because of subsequent usage. Modifications in the production process have led to the problem of low wet strength being overcome.

Fibres and Yarns 22 Dry and wet tenacies extend over a range depending on the degree of polymerization and crystallinity. The higher the crystallinity and orientation of rayon, the lower is the drop in tenacity upon wetting.

Percentage elongation-at-break seems to vary from 10 to 30 % dry and 15 to 40 % wet. Elongation-at-break is seen to decrease with an increase in the degree of crystallinity and orientation of rayon Abrasion resistance is fair and rayon resists pill formation. Rayon has both poor crease recovery and crease retention.

The Manufacturing Process

While there are many variations in the manufacturing process that exploit the versatility of the fiber, the following is a description of the procedure that is used in making regular or viscose rayon.

Regardless of whether wood pulp or cotton linters are used, the basic raw material for making rayon must be processed in order to extract and purify the cellulose. The resulting sheets of white, purified cellulose are then treated to form regenerated cellulose filaments. In turn, these filaments are spun into yarns and eventually made into the desired fabric.

Fibres and Yarns 23

Processing purified cellulose

1 Sheets of purified cellulose are steeped in sodium hydroxide (caustic soda), which produces sheets of alkali cellulose. These sheets are dried, shredded into crumbs, and then aged in metal containers for 2 to 3 days. The temperature and humidity in the metal containers are carefully controlled. 2 After ageing, the crumbs are combined and churned with liquid carbon disulfide, which turns the mix into orange-colored crumbs known as sodium cellulose xanthate. The cellulose xanthate is bathed in caustic soda, resulting in a viscose solution that looks and feels much like honey. Any dyes or delusterants in the design are then added. The syrupy solution is filtered for impurities and stored in vats to age, this time between 4 and 5 days. Producing filaments

Fibres and Yarns 24

3 The viscose solution is next turned into strings of fibers. This is done by forcing the liquid through a spinneret, which works like a shower-head, into an acid bath. If staple fiber is to be produced, a large spinneret with large holes is used. If filament fiber is being produced, then a spinneret with smaller holes is used. In the acid bath, the acid coagulates and solidifies the filaments, now known as regenerated cellulose filaments. Spinning

4 After being bathed in acid, the filaments are ready to be spun into yarn. Depending on the type of yarn desired, several spinning methods can be used, including Pot Spinning, Spool Spinning, and Continuous Spinning. In Pot Spinning, the filaments are first stretched under controlled tension onto a series of offsetting rollers called godet wheels. This stretching reduces the diameter of the filaments and makes them more uniform in size, and it also gives the filaments more strength. The filaments are then put into a rapidly spinning cylinder called a Topham Box, resulting in a cake-like strings that stick to the sides of the Topham Box. The strings are then washed, bleached, rinsed, dried, and wound on cones or spools. Spool Spinning is very similar to Pot Spinning. The filaments are passed through rollers and wound on spools, where they are washed, bleached, rinsed, dried, and wound again on spools or cones. In Continuous Spinning, the filaments are washed, bleached, dried, twisted, and wound at the same time that they are stretched over godet wheels. 5 Once the fibers are sufficiently cured, they are ready for post-treatment chemicals and the various weaving processes necessary to produce the fabric. The resulting fabric can then be given any of a number of finishing treatments.

Fibres and Yarns 25

These include calendaring, to control smoothness; fire resistance; preshrinking; water resistance; and wrinkle resistance. High-Wet-Modulus Rayon Manufacture

The process for manufacturing high-wet-modulus rayon is similar to that used for making regular rayon, with a few exceptions. First, in step #1 above, when the purified cellulose sheets are bathed in a caustic soda solution,

After the syrupy viscose solution is prepared, it is forced through a spinneret into an acid bath. The resulting strings or filaments are then stretched on godet wheels to strengthen them and put into a spinning Topham box. This method produces cakelike strings of rayon, which are washed, rinsed, and dried before being wound on spools or cones. a weaker caustic soda is used when making HWM rayon. Second, neither the alkali crumbs (#1 above) nor the viscose solution (step #2) is aged in the HWM process. Third, when making HWM rayon, the filaments are stretched to a greater degree than when making regular rayon.

Fibres and Yarns 26

END USES

Rayon's versatility and color range long have made it a popular fiber in apparel and home furnishings. Ultra-fine rayon gives blouses and dresses a silkier look and feel. High-wet modulus rayon, used alone or in blends, produces apparel fabrics that are wrinkle and shrink-resistant. They hold color well and can be washed rather than dry-cleaned. Rayon filament is used in tire cord, fiber deniers, suit linings, and jewel boxes. Flame-resistant rayon/wool blends are used in commercial airline seats.

Fibres and Yarns 27

SPANDEX

Spandex is a lightweight, synthetic fiber that is used to make stretchable clothing such as sportswear. It is made up of a long chain polymer called polyurethane, which is produced by reacting a polyester with a diisocyanate. The polymer is converted into a fiber using a dry spinning technique. Although the market for spandex remains relatively small compared to other fibers such as cotton or nylon, new applications for spandex are continually being discovered.

These fibers are superior to rubber because they are stronger, lighter, and more versatile. In fact, spandex fibers can be stretched to almost 500% of their length.

The Manufacturing Process

Spandex fibers are produced in four different ways including melt extrusion, reaction spinning, solution dry spinning, and solution wet spinning. Each of these methods involve the initial step of reacting monomers to produce a prepolymer. Then the prepolymer is reacted further, in various ways, and

Fibres and Yarns 28

drawn out to produce a long fiber. Since solution dry spinning is used to produce over 90% of the world's spandex fibers, it is described. Polymer reactions

1 The first step in the production of spandex is the production of the prepolymer. This is done by mixing a macroglycol with a diisocyanate monomer. The compounds are mixed in a reaction vessel and under the right conditions they react to form a prepolymer. Since the ratio of the component materials produces fibers with varying characteristics, it is strictly controlled. A typical ratio of glycol to diisocyanate may be 1:2. 2 In dry spinning fiber production, the prepolymer is further reacted with an equal amount of diamine. This is known as a chain extension reaction. The resulting solution is diluted with a solvent to produce the spinning solution. The solvent helps make the solution thinner and more easily handled. It can then be pumped into the fiber production cell. Producing the fibers

3 The spinning solution is pumped into a cylindrical spinning cell where it is cured and converted into fibers. In this cell, the polymer solution is forced through a metal plate, called a spinneret, which has small holes throughout. This causes the solution to be aligned in strands of liquid polymer. As the strands pass through the cell, they are heated in the presence of a nitrogen and solvent gas. These conditions cause the liquid polymer to chemically react and form solid strands. 4 As the fibers exit the cell, a specific amount of the solid strands are

Fibres and Yarns 29

bundled together to produce the desired thickness. This is done with a compressed air device that twists the fibers together. In reality, each fiber of spandex is made up of many smaller individual fibers that adhere to one another due to the natural stickiness of their surface. Final processing

5 The fibers are then treated with a finishing agent. This may be magnesium stearate or another polymer such as poly(dimethyl-siloxane). These finishing materials prevent the fibers from sticking together and aid in textile manufacture. After this treatment, the fibers are transferred through a series of rollers onto a spool. The windup speed of the entire process can be anywhere from 300-500 mi (482.7-804.5 km) per minute depending on the thickness of the fibers. 6 When the spools are filled with fiber, they are put into final packaging and shipped to textile manufacturers and other customers. Here, the fibers may be woven with other fibers such as cotton or nylon to produce the fabric that is used in clothing manufacture. This fabric can also be dyed to produce a desired color.

Fibres and Yarns 30

PROPERTIES

PHYSICAL

CHEMICAL

Density: The density of spandex filaments ranges from 1.15 to 1.32 g/cc, the fibres lower density being based on polyesters.

Acid: Good resistance to most of acids unless exposure is over 24 hours.

Moisture regain: The moisture of fibres from which the surface finish has been removed lies between 0.8 & 1.2% Length: It can be of any length. May be used as filament or staple fibre

Alkalies: Good resistance to most of the alkalies, but some types of alkalies may damage the fibre Organic solvents: offer resistance to dry cleaning solvents

Colour: It has white or nearly white colour.

Bleaches: can be degreaded by sodium hypochloride. chlorine

bleach should not be used. Luster :-It has usually dull luster. Dyeing: A full range of coloures is available. Some types are more difficult to dye than others.

Strength: Low strength compared to most other synthetic fiber. .Elasticity: Elastic properties are excellent. This is the outstanding characteristic of the fibre.

Fibres and Yarns 31

END USERS

The primary use for spandex fibers is in fabric. They are useful for a number of reasons. First, they can be stretched repeatedly, and will return almost exactly back to original size and shape. Second, they are lightweight, soft, and smooth. Additionally, they are easily dyed. They are also resilient since they are resistant to abrasion and the deleterious effects of body oils, perspiration, and detergents. They are compatible with other materials, and can be spun with other types of fibers to produce unique fabrics, which have characteristics of both fibers. Spandex is used in a variety of different clothing types. Since it is lightweight and does not restrict movement, it is most often used in athletic wear. This includes such garments as swimsuits, bicycle pants, and exercise wear. The form-fitting properties of spandex makes it a good for use in undergarments. Hence, it is used in waist bands, support hose, bras, and briefs.

Fibres and Yarns 32

YARNS

Yarn is a long continuous length of interlocked fibers, suitable for use in the

production of textiles, sewing, crocheting, knitting, weaving, embroidery and ropemaking. Thread is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for hand or machine embroidery.

Spun yarn is made by twisting or otherwise bonding staple fibres together to make a cohesive thread. Twisting fibres into yarn in the process called spinning can be dated back to the Upper Paleolithic, and yarn spinning was one of the very first processes to be industrialized. Spun yarns may contain a single type of fibre, or be a blend of various types. Combining synthetic fibres (which can have high strength, lustre, and fire retardant qualities) with natural fibres (which have good water absorbency and skin comforting qualities) is very common. The most widely used blends are cotton-polyester and wool-acrylic fibre blends. Blends of different natural fibres are common too, especially with more expensive fibres such as alpaca, angora and cashmere. Bamboo yarn is a less expensive type that is a recent innovation. Yarns are selected for different textiles based on the characteristics of the yarn fibres, such as warmth (wool), light weight (cotton or bamboo), durability (nylon is added to sock yarn, for example), or softness (cashmere, alpaca). Acrylic and cotton yarns are the least expensive. Yarns are made up of a number of plies, each ply being a single spun yarn. These single plies of yarn are twisted together (plied) in the opposite direction to make a thicker yarn. Depending on the direction of this final twist, the yarn will be known as s-twist or ztwist. For a single ply, the direction of the final twist is the same

o

Fibres and Yarns 33

as its original twist.

Filament yarn consists of filament fibres (very long continuous fibres) either twisted together or only grouped together. Thicker monofilaments are typically used for industrial purposes rather than fabric production or decoration. Silk is a natural filament, and synthetic filament yarns are used to produce silk-like effects.

Texturized yarns are made by a process of air texturizing (sometimes referred to as taslanizing), which combines multiple filament yarns into a yarn with some of the characteristics of spun yarns.

Yarn Twist: Yarn Twist is the measure of the spiral given to a yarn in order to hold the constituent fibres or threads together. According to textile institute Twist is the spiral disposition of the components of a thread which is usually the result of the relative rotation of the two ends.

Fibres and Yarns 34

Types of Yarn Twist: According to direction of twist, it is of two types: - 1. S- Twist 2. Z- Twist. S- Twist: A single yarn has S twist if, when it is held in the vertical position. The fibres inclined to the axis of the yarn conform in the direction by slope to the central portion of the letter S. Z-Twist: A single yarn Z Twist if, when it is held in the vertical position, the fibres inclined to the axis of the yarn conform in the direction of slope to the central portion of the letter Z.

YARNS

Simple Yarn

Decorative Yarn

Chenille

Boucle

Nub

Flake

Slub

Spiral

Fibres and Yarns 35

SIMPLE YARNS

Simple yarns are those yarns with uniform size and regular surface. They have varying degrees of twist, ranging frim loose to moderate, tight or hard twist. Single, ply, and cord yarns can all be simple yarns if their components are uniform in size and have a regular surface. When one strand of fibers is twisted together evenly, it is classified as simple single yarn. Two simple, single yarns twisted together can create a simple ply yarn.

DECORATIVE YARNS

Yarns made to create interesting decorative effects in the fabrics into which they are woven are known as novelty or decorative yarns. The spinning process can produce decorative effects by varying the amount of twist or by twisting together yarns of different amounts of twist in them. Such yarns can give fabrics limitless textural effects of various color combinations. Decorative yarns can be of the following types: BOUCLE YARN These yarns are ply yarns. An effect yarn forms irregular loops around the base yarn or yarns. Another yarn binds or ties the effect yarn to the base. The boucle effect is created by allowing one of the plies to remain slack during the twist operation, causing it to twist n itself and form a loop. Ratine Yarns are similar to boucle in construction. the loops in this type of yarn are spaced evenly alongthe base yarn. Snarl Yarn are another type of loop yarn in which two or more single yarns under different tension are twisted together.

Fibres and Yarns 36

FLAKE YARN This yarn is made of loosely twisted yarns that are held in place either by a base yarn as it twists or by a third ir binder yarn. These yarns are relatively weak and are used in the filling to achieve decorataive surface effects. This yarn is limited to fancy uses.

NUB YARN Nub yarns are made by twisting the effect ply around the core ply many times within a very short space, causing bumps or nubs that may be spaced at intervals along the yarns. Variations can be made when two effect plies each of different color, may be used, and the nubs arranged so that the colors are alternated along the length of the yarn.

SLUB YARN Slub yarns may be either ply or single yarns of staple fibers. The slub effect is created by varying twist in the yarn, allowing areas of looser twist to be created. This produces a long, soft area in the fabric called a SLUB. Slub yarns are irregular in diameter. Yarns made in this way have areas of varying twist, causing weaker areas in the yarn. Filament yarns

Fibres and Yarns 37

can be spun with varying degrees of twist. These yarns also created a stubbed appearance. In fabrics. Such filament yarns are known as thick-and-thin yarns.

SPIRAL YARN: Yarns are made of two plies, one soft and heavy, the other fine. The heavy yarn winds around the fine yarn. Spiral yarn is also known as the corkscrew yarn.

CHENILLE YARN The term chenille is derived from the French word for caterpillar as the yarn resembles a caterpillar. This type of yarn is made by a completely different process. First, leno-weave fabric is woven, this fabric is cut into strips, and these strips, which have a soft pile on all sides, are used as yarns. These are not yarns in the traditional sense of twisted fiber but have been taken through a series of preliminary stages before being readied for use.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- All in One - 10th Class em - Fa-2Документ35 страницAll in One - 10th Class em - Fa-2sai ramxeroxОценок пока нет

- Box 1.5m 1.5mДокумент22 страницыBox 1.5m 1.5mveevimalОценок пока нет

- Qualcast Trucks Catalog2015Документ188 страницQualcast Trucks Catalog2015Edwin Javier Garavito100% (2)

- Exjobb1 MBRДокумент86 страницExjobb1 MBRNermeen ElmelegaeОценок пока нет

- Repairment Methods of PipelinesДокумент8 страницRepairment Methods of PipelinescanakyuzОценок пока нет

- Design For RC Flat SlabsДокумент70 страницDesign For RC Flat SlabsAil AafaaqОценок пока нет

- Advances in Materials Technology For Fossil Power PlantsДокумент1 121 страницаAdvances in Materials Technology For Fossil Power Plantsadadamovicines100% (5)

- Why Is Carbon So VersatileДокумент8 страницWhy Is Carbon So VersatileDiana YucosingОценок пока нет

- Equivalencia AceroДокумент30 страницEquivalencia AceroJose VelosaОценок пока нет

- Notes of CH 2 Is Matter Around Us Pure - Class 9th ScienceДокумент9 страницNotes of CH 2 Is Matter Around Us Pure - Class 9th SciencepjatinОценок пока нет

- Sampling and Testing Modified Bituminous Sheet Material: Standard Test Methods ForДокумент8 страницSampling and Testing Modified Bituminous Sheet Material: Standard Test Methods ForProvocateur SamaraОценок пока нет

- Click' Chemistry in Polymer and Materials Science: ReviewДокумент40 страницClick' Chemistry in Polymer and Materials Science: ReviewDilip Kumar TiwariОценок пока нет

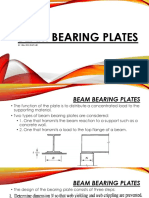

- 7-B. Beam Bearing PlatesДокумент14 страниц7-B. Beam Bearing PlatesMelchizedek EllОценок пока нет

- Methods and Techiniques in PathologyДокумент15 страницMethods and Techiniques in PathologyKiran100% (1)

- Welding PDFДокумент22 страницыWelding PDFKhawaja Abdul Basit SohailОценок пока нет

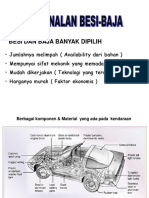

- 011 Besi BajaДокумент34 страницы011 Besi BajaMFA nounОценок пока нет

- Tutorial 3 - Questions Only - PVT Behavior - Ideal Gas - Virial EOSДокумент5 страницTutorial 3 - Questions Only - PVT Behavior - Ideal Gas - Virial EOSMihir Kumar Mech100% (1)

- 1 s2.0 S0950061820318560 MainДокумент7 страниц1 s2.0 S0950061820318560 MainElias SoaresОценок пока нет

- Pages From Certificate of Conformance For Lot-2 ASTM A490M Bolts, Nuts &washers (Key's and Clamp)Документ1 страницаPages From Certificate of Conformance For Lot-2 ASTM A490M Bolts, Nuts &washers (Key's and Clamp)Krishna VachaОценок пока нет

- Softening & Aniline PointsДокумент10 страницSoftening & Aniline Pointsكرار الكعبيОценок пока нет

- Note On Mac 1 Casting Process 1. Draw Block Diagram of Foundry Layout. Discuss Objectives of Good Plant LayoutДокумент28 страницNote On Mac 1 Casting Process 1. Draw Block Diagram of Foundry Layout. Discuss Objectives of Good Plant LayoutBVoc AutomobileОценок пока нет

- S001Документ1 страницаS001Yong Hui OngОценок пока нет

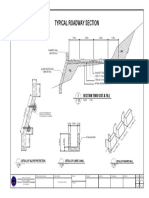

- Typical Roadway SectionДокумент1 страницаTypical Roadway SectionCarmela Ayessa PiguerraОценок пока нет

- Lecture 1Документ22 страницыLecture 1Sameer HussainОценок пока нет

- LAKBAY A Proposed PNR StationДокумент5 страницLAKBAY A Proposed PNR StationJohn Paul RamosОценок пока нет

- Solution To Problem 111 Normal Stress - Strength of Materials ReviewДокумент6 страницSolution To Problem 111 Normal Stress - Strength of Materials ReviewNagaraj MuniyandiОценок пока нет

- C Mastic: Main ApplicationДокумент1 страницаC Mastic: Main ApplicationHung Mai Van100% (2)

- Normal ResistivityДокумент1 страницаNormal ResistivityShahzad KhanОценок пока нет

- Thermometry PDFДокумент49 страницThermometry PDFYe YeoОценок пока нет