Академический Документы

Профессиональный Документы

Культура Документы

Magnetic Bearing Actuator

Загружено:

ryakirИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Magnetic Bearing Actuator

Загружено:

ryakirАвторское право:

Доступные форматы

Magnetic Bearing Actuator

Group 6

1. List of symbols:

B H Rc Rext R E I lav N Acond Acoil j r OT o ROT

Flux Density Field Intensity Magneto-motive Force (MMF) Resistance of the coil Resistance of the external circuit Total resistance Electro-motive force (EMF) Current Average length of the wire Number of turns Cross-Sectional Area of the conductor Cross-Sectional Area of the coil Current Density Radius to the centre of the coil Resistivity Resistivity at operating temperature Permeability of air Resistance at operating temperature

Magnetic Bearing Actuator

Group 6

2. Introduction:

This report is to explain the necessary steps that were taken to achieve the task of theoretically building a Magnetic Bearing Actuator. This specific report entails the design details of a radial 8-pole, heteropolar magnetic bearing actuator. The design had to be within certain specifications had to adhere to. The bearing had to be optimized in accordance to certain design criteria (such as coil area, resultant force on the journal, minimum core volume etc). There are two parts to the design a magneto-statics component which was used to obtain the load capacity and a thermal component that determines the temperature operating range of the bearing depending on the insulation class given. The main aim of the design was to make sure that: The bearing develops the required load capacity (slightly higher) result must be confirmed by FE model and relevant calculations. The winding temperature was within the acceptable range for the required insulator class.

Magnetic Bearing Actuator

Group 6

3. Theory:

Magnetic Bearings:

Magnetic bearings are used to in lieu of rolling element or fluid film journal bearings in some high performance turbo machinery applications. Specific applications include pumps for hazardous/caustic fluids, precision machining spindles, energy storage flywheels, and high reliability pumps and compressors. Magnetic bearings yield several advantages. Since there is no mechanical contact in magnetic bearings, mechanical friction losses are eliminated. In addition, reliability can be increased because there is no mechanical wear. Besides the obvious benefits of eliminating friction, magnetic bearings also allow some perhaps less obvious improvements in performance. Magnetic bearings are generally open loop unstable, which means that active electronic feedback is required for the bearings to operate stably. However, the requirement of feedback control actually brings great flexibility into the dynamic response of the bearings. By changing controller gains or strategies, the bearings can be made to have virtually any desired closed-loop characteristics. For example, flywheel bearings are extremely compliant, so that the flywheel can spin about its inertial axis--the bearings serve only to correct large, low frequency displacements.

Typical Bearing Geometry

Conceptually, the typical magnetic bearing is composed of eight of horseshoe-shaped electromagnets. This configuration is shown in Figure 1. The eight magnets are arranged evenly around a circular piece of iron mounted on the shaft that is to be levitated. Each of the electromagnets can only produce a force that attracts the rotor iron to it, so all eight electromagnets must act in concert to produce a force of arbitrary magnitude and direction on the rotor.

Fig.1: Eight Pole Magnetic Bearing with 4 poles active at any time

Magnetic Bearing Actuator

Group 6

4. Design Process Electromagnetic (parts a-k) 4.1 Initial implementation of the design:

The design procedure involved several steps: Bearing dimension calculations Coil calculations Thermal calculations

Bearing Dimension Calculations:

a) Selection of a reasonable flux density: The example given from the lecture notes was of 1.6 1.7T. For the design of the model took the average of the example value hence =1.65T. This then required steel that will provide the necessary flux density. Through trial and error it was discovered that Steel M-14 would provide the best results for our design. b) Estimate the flux density in the air gap . Assuming 10% leakage:

c) From the known load capacity (LC or F) calculate force per/pole F1: For the design the decision was taken to make three active poles: Pole Pitch: Hence

d) Using the approximate expression for force/pole,

Calculate the required cross-sectional are of the stator pole formula:

, to do this make

the subject of the

Magnetic Bearing Actuator

( )

Group 6

Hence

e, f) Calculation of the width of the pole (

, journal thickness ) (

and journal outside diameter : )

( Therefore the width of pole: Hence to obtain the journal OD: ( g) Calculate the axial length of the bearing ) : ( )

h) Estimate the pole (radial) length

Used 1.25 as it was the average between the 1 and 1.5. ( i) ) ( )

Calculate back iron (radial) width:

( j) Calculate the stator outside diameter OD: ( (

) )

k) Calculate the required MMF/pole; assuming (20-25) % leakage and infinite permeability of the steel: ( ( ) ( ) ) 5

Magnetic Bearing Actuator

Group 6

l) The area of the coil was assumed to be quite small for the initial calculations and had to be optimized in the process of achieving the specified load capacity.

m) Calculate number of turns and wire diameter: To obtain this value required the calculation of to be a trapezium. ,this was done by assuming the shape of the coil

The value of the line DC. For this model

is taken as the distance between the centroid (point were the diagonals intersect) and

, taken from the FE model. ( ( ) ( ) ( )

=

Standard copper wire is to be used: resistivity at 20C is 20 coefficient = 0.0039 1/C.

0.17241*10-7 m and temperature

Due to the class H insulation maximum operation temperature was 1800C. Assuming an acceptable temperature range means winding temperature between 65% and 80%. Therefore class H would be (0.65 to 0.8)*180 = 1170C to 1440C To obtain resistivity at maximum operating temperature is as follows: [ Assuming J= A/m2 ( ) ]

Magnetic Bearing Actuator

Group 6

)( (

) )

Therefore actual Coil filling co-efficient results.

taken from the standard metric wire sizes = was not assumed but was calculated and then adjust to produce the best ( )

(Max) = =0.78 The coil filling factor is too high and this was unacceptable ( n) Calculate resistance and current At the actual area of conductor = 0.02270mm2 the corresponding nominal resistance at 200C is 0.7596/m. Therefore at 1440C the nominal resistance is:

The resistance at 1440C is:

o) Calculation of Actual MMF and MMF density

Magnetic Bearing Actuator

Group 6

Figure 1: Schematic of the initial design implementation

Magnetic Bearing Actuator

Group 6

4.2 Final Optimization of Design:

a) Selection of a reasonable flux density: The example given from the lecture notes was of 1.6 1.7T. For the design of the model took the average of the example value hence =1.65T. This then required steel that will provide the necessary flux density. Through trial and error we discovered that Steel M-14 would provide the best results for our design. b) Estimate the flux density in the air gap . Assuming 10% leakage:

c) From the known load capacity (LC or F) calculate force per/pole F1: For the design the decision was taken to make four active poles: Pole Pitch: Hence

d) Using the approximate expression for force/pole,

Calculate the required cross-sectional are of the stator pole formula: Hence

( )

, to do this make

the subject of the

e, f) Calculation of the width of the pole (

, journal thickness ) (

and journal outside diameter : )

Magnetic Bearing Actuator

Group 6

( Therefore the width of pole: Hence to obtain the journal OD: ( g) Calculate the axial length of the bearing ) : ( )

h) Estimate the pole (radial) length

Used 1.25 as it was the average between the 1 and 1.5. ( ii) ) ( )

Calculate back iron (radial) width:

( j) Calculate the stator outside diameter OD: ( (

) )

k) Calculate the required MMF/pole; assuming (20-25) % leakage and infinite permeability of the steel: ( ( Coil design Calculations l) Calculate the cross-sectional area of the coil : ) ( ) )

This value was not calculated but was done using trial and error until the maximum or optimal load capacity was achieved. , this is obtained from the FE model. 10

Magnetic Bearing Actuator m) Calculate number of turns and wire diameter: To obtain this value required the calculation of to be a trapezium.

Group 6

, this was done by assuming the shape of the coil

The value of the line DC. For this model

is taken as the distance between the centroid (point were the diagonals intersect) and

, taken from the FE model. ( ( ) ( ) ( )

=

Standard copper wire is to be used: resistivity at 20C is 20 coefficient = 0.0039 1/C.

0.17241*10-7 m and temperature

Due to the class H insulation maximum operation temperature was 1800C. Assuming an acceptable temperature range means winding temperature between 65% and 80%. Therefore class H would be (0.65 to 0.8)*180 = 1170C to 1440C To obtain resistivity at maximum operating temperature is as follows: [ Assuming J= A/m2 ( ) ]

)(

) 11

Magnetic Bearing Actuator

Group 6

( Therefore actual Coil filling co-efficient results.

taken from the standard metric wire sizes = was not assumed but was calculated and then adjust to produce the best ( )

It can be seen that the coil filling factor was low n) Calculate resistance and current At the actual area of conductor = 0.02270mm2 the corresponding nominal resistance at 200C is 0.7596/m. Therefore at 1440C the nominal resistance is:

The resistance at 1440C is:

o) Calculation of Actual MMF and MMF density

The value of mmf density that was used in Quick-Field did not produce the required force and required further optimization. This was done by recalculating with a thicker wire diameter but keeping the same number of turns. Chosen and the nominal resistance was

12

Magnetic Bearing Actuator m) The new is: ( )

Group 6

This value of n)

is higher than the original but is still lower than the expected value

The resistance at 1440C is:

o) Calculation of Actual MMF and MMF density

The actual MMF is higher than the initial MMF but at this value we were able to obtain the correct MMF density to be used in the simulation.

Figure 2: Schematic of the Final design implementation

13

Magnetic Bearing Actuator

Group 6

4.3 Thermal design:

Using the maximum allowable temperature for class H insulation of 1800C, ambient temperature of the shaft is 400C and of the air is 200C The temperature operating range for class H insulation assuming (65 to 80)%of the winding temperature from the maximum 180oC. RANGE 0.65*180OC 0.8*180OC DEGREES 117OC 144OC KELVIN(+273) 390K 417K

Copper loss in the winding (coil):

)(

Hence

Volume of the coil: ( )( )

Volume of Coil = 65836.867mm3, taken from the FE Model Power density in the coil (in W/m3):

14

Magnetic Bearing Actuator

Group 6

5. Simulation Results:

5.1 Initial design implementation:

Figure 3: Showing the initial implementation, where we obtained a less than required flux density in the core (1.45T as compared to 1.6T)

This was the initial simulation of the magnetic bearing actuator design. Please note that the actual load capacity for this model was 767.92N. This was unacceptable as the specified load capacity was given to be 1000N. Further optimization was necessary.

15

Magnetic Bearing Actuator

Group 6

5.2 Final design implementation:

Figure 6: Showing the final implementation of the design, with the correct flux flowing through the journal

Selecting the x-component and utilizing the equations to follow

Figure 4: Showing the Force calculation interface 16

Magnetic Bearing Actuator

Group 6

When setting the problem properties of the model on Quick-Field, we set the model class Plane-Parallel value . By doing this the force obtained in Quick-field already accounted for the

length of the bearing. Thus the resultant force becomes:

But ( )

This result is slightly higher then the required load capacity. The error obtained can be found below: % Error =( )

The load capacity obtained is acceptable as the requirement was to produce the load capacity given or produce slightly higher.

5.3 Thermal design results:

Figure 5: Showing the thermal response of the model

17

Magnetic Bearing Actuator

Group 6

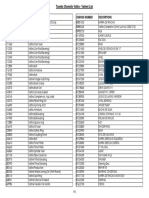

6. Summary of Final Design Parameters:

Parameter Winding No of turns Wire diameter (std) Average length of turn Operating temp. resistance Developed MMF Coil volume Power loss density Force per pole (based on FE model) Number of poles switched on Axial length of the bearing Winding max. temperature (FE model) Unit mm mm A-t mm3 W/m3 N mm 0 C Value 4334.18 0.05515 120.64 242.49 1070.5 65836.867 225558 383.14 4 15.5 119

18

Magnetic Bearing Actuator

Group 6

7. Discussion of results:

The simulation design of the magnetic bearing was to achieve the maximum load capacity that was initially given and for the thermal properties of the bearing to in the range of the maximum temperature. Initial Approach: Initially it was decided to design the bearing using 3-pole activation. By activating three active poles it produced a high force per pole (414.214N) as a result of the high force, the cross-sectional area of the stator pole was large. Reason being the cross-sectional area of the stator pole is directly proportional to the force per pole obtained. Since the cross-sectional are of the stator pole is high it resulted in the axial length of the bearing to be high. The actual value of MMF (475.562A-t) calculated, using the number of turns and current which was calculated using the area of conductor and coil. Resulted in a higher value of MMF, although this value was acceptable it produced an error of: Initial value of MMF = 434.284A-t %Error = ( )

The MMF density that was produced using the actual MMF and the area of coil was relatively high. However when used in the simulation of the model the MMF density did not produce the expected results such as the force and flux density. The force produced using this design was 767.92 a value well below the expected load capacity of 1000N, an error of: %Error = ( )

This was unacceptable, as the requirement for the design was to produce the given load capacity or slightly higher. The flux density was assumed to 1.65T but in the simulation at some points the flux density was 1.45T. The coil filling co-efficient was 0.83, above the maximum of 0.78. As a result of the results not meeting expectations, we decided to change the approach used. Final Approach: In this approach we decided to use 4-pole activation, although by doing this the value of the force per pole would decrease, directly influencing both the cross-sectional area of the stator pole and the axial length of the bearing (a decrease in both).

19

Magnetic Bearing Actuator

Group 6

This design produced an actual MMF closer to the initial calculations being 442.086A-t; the decrease was a result of using a larger coil that dropped the average length. This decrease the number of turns used. The error between the actual and initial is: %Error = ( )

The model produced a smaller MMF density as the area of coil was much larger and the MMF itself was lower. When used in the FE model once again the load capacity was lower and so was the coil filling coefficient. On optimizing this model by increasing the area of conductor; the result was a large coil filling coefficient. This changed caused a decrease in the resistance, producing a higher current. The number of turns stayed the same. A result of the above change produced an actual MMF considerably larger then the initial calculation, an error of: Actual MMF= 1070.5A-t %Error = ( )

This is large error; however the MMF density that was calculated using this MMF produced a high value. When used in the simulation the MMF density generated through the journal produced the required load capacity although higher, the value is acceptable. Load capacity achieved = 1013.985N %Error = ( ) a minimal error.

The thermal design used the design that was just discussed. The result of the simulation of thermal design produced a temperature of 392K. The expected range of the winding temperature was 390K to 417K. The model produced a temperature in range of the insulation class H (1800C max).

20

Magnetic Bearing Actuator

Group 6

8. Conclusion:

The aim of the design was to simulate a magnetic bearing actuator using Quick-Field. The design had to adhere to certain constraints whilst some could be optimized. The results of our design had met the specifications asked such as the achievement of the load capacity and the thermal properties. With respect to the load capacity it required it to have a minimum volume to maximum force ratio. Although we had not met this requirement to exact levels, we still produce a high load capacity. Another aspect was the high MMF we achieved on the design, this value produced the required results. The thermal design had utilized the same model used for magneto-statics, this allowed for maximum expected results as the design had already been optimized. The difficulty was achieving the optimal power density that would be used in the simulation. Once we obtained the correct power density and boundary conditions we were able to produce the required temperature of the winding. In all we had met most of the requirements, errors can be expected. We had worked through most difficulties and produce required expectations.

21

Magnetic Bearing Actuator

Group 6

9. References:

1. Lecture notes distributed by Professor M. Hippner , based on magneto-statics and magnetic circuit analysis using Quick Field.

2.

Electro-mechanics and Electric Machines , by S.A. Nasar and L.E. Unnewehr.

22

Magnetic Bearing Actuator

Group 6

10. Appendix:

10.1 Optimization 1:

The value of the line DC. For this model

is taken as the distance between the centroid (point were the diagonals intersect) and

, taken from the FE model. ( ) ( )

Standard copper wire is to be used: resistivity at 20C is 20 coefficient = 0.0039 1/C.

0.17241*10-7 m and temperature

Due to the class H insulation maximum operation temperature was 1800C. Assuming an acceptable temperature range means winding temperature between 65% and 80%. Therefore class H would be (0.65 to 0.8)*180 = 1170C to 1440C To obtain resistivity at maximum operating temperature is as follows: [ Assuming J= A/m2 ( ) ]

23

Magnetic Bearing Actuator

Group 6

)( (

) )

Therefore actual Coil filling co-efficient results.

taken from the standard metric wire sizes = was not assumed but was calculated and then adjusted to produce the best ( )

(Max) = =0.78 The coil filling factor was too low and unacceptable n) Calculate resistance and current At the actual area of conductor = 0.01767mm2 the corresponding nominal resistance at 200C is 0.9757/m. Therefore at 1440C the nominal resistance is:

The resistance at 1440C is:

o) Calculation of Actual MMF and MMF density

24

Magnetic Bearing Actuator

Group 6

Figure 6: Showing the Flux line distribution and hence flux density

Figure 7: Showing the schematic where we used a greater concentration of nodes on the core, rather than the air gap in order to increase the accuracy of the force calculated on the journal

25

Magnetic Bearing Actuator

Group 6

Figure 8: Showing the actual flux density distribution, it can be noted that were not achieving approx. 1.6T in the air gap

Selecting the x-component, the required load capacity was not achieved

. The load capacity obtained was

unacceptable as the requirement was to produce the given load capacity of 1000N.

26

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Genset Dkaf Parts Manual - 0981-0254 - I3 - 201405Документ140 страницGenset Dkaf Parts Manual - 0981-0254 - I3 - 201405theunauthorised100% (1)

- 2001 Toyota Maintenance ScheduleДокумент58 страниц2001 Toyota Maintenance ScheduleFelix Gabriel Varela50% (2)

- 2 6 PDFДокумент19 страниц2 6 PDFhernando ramosОценок пока нет

- Hybrid Ceramic Bearing Fatigue Testing For The Future Advanced Rotorcraft Drive System ProgramДокумент10 страницHybrid Ceramic Bearing Fatigue Testing For The Future Advanced Rotorcraft Drive System ProgramAnonymous lEX5U51wOAОценок пока нет

- Report On Industrial Training On NBCДокумент29 страницReport On Industrial Training On NBCKhooshal agarwalОценок пока нет

- Models HRSB & HRSD: Model FeaturesДокумент9 страницModels HRSB & HRSD: Model FeaturesAlejandro DuranОценок пока нет

- SKF Cylindircal Roller BearingsДокумент36 страницSKF Cylindircal Roller Bearingskvramanan_1100% (1)

- MH PDFДокумент7 страницMH PDFSaubatul IslamiyahОценок пока нет

- Bearing Capacity of Ring FootingДокумент9 страницBearing Capacity of Ring FootingilmarebluОценок пока нет

- Manual SFKДокумент24 страницыManual SFKJesusSalvadorMontielSotoОценок пока нет

- Actuadores Neumáticos e HidraulicosДокумент8 страницActuadores Neumáticos e HidraulicosdavidnpsОценок пока нет

- Manual GearbokДокумент66 страницManual GearbokJong JavaОценок пока нет

- Conveyor Motion MonitorДокумент4 страницыConveyor Motion Monitoratorresh090675100% (3)

- Service Station Manual: RX SX 125Документ219 страницService Station Manual: RX SX 125redmotosОценок пока нет

- Nook Jack CatalogДокумент212 страницNook Jack Catalogswoo323Оценок пока нет

- Indonesia-Japan Business Matching Meeting - 121116Документ48 страницIndonesia-Japan Business Matching Meeting - 121116raisetozerotechОценок пока нет

- All Bema Operators ManualДокумент20 страницAll Bema Operators ManualDaniel PricopОценок пока нет

- Magnetic Force Gravitational ForceДокумент4 страницыMagnetic Force Gravitational ForceLaven LeiОценок пока нет

- No Thread SetДокумент2 страницыNo Thread SetpimpdaddywilkinsОценок пока нет

- Module 2 (Answered)Документ33 страницыModule 2 (Answered)Roland Paul PrincipeОценок пока нет

- MAS Training Courses 2020Документ11 страницMAS Training Courses 2020Mohamed ElnahОценок пока нет

- ESP Failure Analysis of Forties Experience ApacheДокумент14 страницESP Failure Analysis of Forties Experience ApacheMohamed AshrafОценок пока нет

- Bearing Embedded Thermocouples Type 6 Pt100 Sensors Type 66Документ6 страницBearing Embedded Thermocouples Type 6 Pt100 Sensors Type 66rahuliitianluvОценок пока нет

- IOM Horizontal Bandlock 2 Closure - ManualДокумент22 страницыIOM Horizontal Bandlock 2 Closure - Manualcderin2000Оценок пока нет

- SKF - Ybearings Cat Eng 6001EДокумент227 страницSKF - Ybearings Cat Eng 6001Eshafique-ahmadОценок пока нет

- Taneks Valmet-Valtra ListДокумент6 страницTaneks Valmet-Valtra ListeCommerce SAJID AutoОценок пока нет

- Global Institute of Technology, Jaipur Blown Up 6ME4-04:: Iii Year B.Tech. Vi Semester Design of Machine Elements-IIДокумент3 страницыGlobal Institute of Technology, Jaipur Blown Up 6ME4-04:: Iii Year B.Tech. Vi Semester Design of Machine Elements-IIGautam GunjanОценок пока нет

- Mast Repair (S/N A698 AND A699) : MaintenanceДокумент64 страницыMast Repair (S/N A698 AND A699) : MaintenanceZoltán RozinkaОценок пока нет

- ZORO 6 in - TSBДокумент36 страницZORO 6 in - TSBRashida MajeedОценок пока нет