Академический Документы

Профессиональный Документы

Культура Документы

Win-Win-Win Partnership Between Farmers, Local Government and Nestlé

Загружено:

Kunal PatilИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Win-Win-Win Partnership Between Farmers, Local Government and Nestlé

Загружено:

Kunal PatilАвторское право:

Доступные форматы

Win-Win-Win Partnership between Farmers, Local Government and Nestl Nestls high quality dairy production always begins

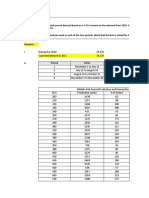

at the source with milk farmers. To build long-term, direct relationships, Nestl has established a unique milk collection model called 'factory and farmers' through solid efforts over the past 20 years. Based on a Win-Win-Win partnership between farmers, the local government and Nestl, this model ensures each party takes its responsibility and works together to achieve highest quality and safety. Government supports have been instrumental in the successful implementation of this model, which also effectively eliminates the 'middleman' and ensures the traceability and accountability of the overall supply chain. Most importantly, through this model Nestl dairy farmers are provided with continuous training, technology and skill development from cow selection, quality feed, breeding practices, disease prevention, milking, storage and transportation to bring world-class standards and processes to local communities, which in turn produces high quality milk and promotes positive development of the local industry. Every year, for the last 20 years, Nestl conducts more than 300 free training sessions for farmers. Milk Collection Model The unique milk collection model employed by Nestl and its farmers includes a computerized system where information on each farmer, cow and batch of raw fresh milk is tracked from pickup to delivery and production. In this model, every batch of milk received needs to pass a series of strict quality checks before it is 'lead sealed' prior to being transported to the factory. In order to ensure freshness of the source milk, every Nestl farmer is approximately one-hour from the milk stations, which are managed by Nestle-trained staff. World-class Production and Processing Over the past 20 years, the Shuangcheng factory has undergone rapid growth and consistent enhancement to become one of the most technologically advanced and largest Nestl factories in the world. Its highly efficient quality and safety management and stringent regulation over its milk supply chain has ensured the consistent supply of high-quality products made from fresh milk that comply with world standards. In fact, this process includes over 70 international quality and safety tests developed through Nestls worldwide network of dairy scientists and engineers. As a result, the Shuangcheng milk district has been rated as the number one county in China for milk cow production by the China Dairy Association. Advanced Research and Development As the worlds foremost dairy and nutrition expert for over 140 years, Nestl is committed to investing in advanced research and development to ensure the quality and safety of products in China. This commitment includes leveraging its 23 global R&D centers, with one in Shanghai and another with the opening of a new state-of-the-art Beijing Research and Development Centre. With an initial set-up investment of RMB 70million, the new Beijing R&D Center provides high-tech quality testing, safety technical and scientific support. The Beijing R&D Center also strengthens Nestls ability to further adapt its products to local taste preferences, and address the nutritional and health needs of future generations of Chinese consumers. For more than 140 years, families have trusted Nestl for the best milk and infant nutrition products, said Mr. Bula. At Nestle, consumer safety is an uncompromising priority. Thats why we have been employing these best practices that set the standard for the industry. Mr. Bula also noted that during the current milk

crisis in China, Nestl undertook immediate, decisive actions to ensure continuous and uncompromised quality and safety of its products.

Since Sept 14th, no milk products are released to the market before passing internal tests and government lab certifications. To deliver our commitment to our consumers about product safety and quality, immediate voluntary testing is being conducted on all Nestl milk products produced before Sept 2008. As of today, Nestl has passed all tests and received more than 16,000 government certifications. This allowed Nestl to respond speedily ahead of our competitors in making sure that our products remain available on store shelves after the Chinese authorities issued recently its 'Green sticker' policy to satisfy consumer needs. Nestl massively invested in the quality control of its fresh milk supply in order to achieve best-inclass standard of fresh milk quality. Nestl has made immediate investment to equip its factories with 20 state-of-the-art analytical machines, including some of the most sophisticated equipment used during the Beijing Olympics. The Nestl headquarters in Switzerland has sent more than 20 of its leading scientists from Europe who are working on the ground with the local team as well as relevant authorities to ensure the highest product quality and safety. These actions, plus the already existing world class operations in Shuangcheng factory, enabled Nestl to comply with all government standards and requirements, and ensure that Chinese consumers continued to enjoy our high

Вам также может понравиться

- Modernizing Sanitary and Phytosanitary Measures to Expand Trade and Ensure Food Safety: 2nd CAREC Trade Facilitation Learning Opportunity: Sharing the Baltic ExperienceОт EverandModernizing Sanitary and Phytosanitary Measures to Expand Trade and Ensure Food Safety: 2nd CAREC Trade Facilitation Learning Opportunity: Sharing the Baltic ExperienceОценок пока нет

- Nestle Quality PracticesДокумент7 страницNestle Quality PracticesAditya KumarОценок пока нет

- Nestle Operations Management ProjectДокумент8 страницNestle Operations Management ProjectDaily vidbd100% (1)

- Nestlé S.A. Is A Swiss Multinational Food and Drink Processing Conglomerate CorporationДокумент15 страницNestlé S.A. Is A Swiss Multinational Food and Drink Processing Conglomerate CorporationHalle TeferiОценок пока нет

- Global Case StudyДокумент8 страницGlobal Case Studyharsh7mm100% (1)

- Nestle Operation Management Analysis 12010119190124 Andika Daffa EliantoДокумент15 страницNestle Operation Management Analysis 12010119190124 Andika Daffa EliantoAndika Daffa Elianto100% (1)

- The Business Environment of PakistanДокумент31 страницаThe Business Environment of PakistanMoon Kazmi67% (6)

- Dream Company Research BankДокумент5 страницDream Company Research BankRebal ZahoorОценок пока нет

- Mother Dairy: Operations Management-1Документ31 страницаMother Dairy: Operations Management-1champ1909Оценок пока нет

- Improving Food Safety and Food Quality: The Case of NestleДокумент11 страницImproving Food Safety and Food Quality: The Case of NestledaliyaОценок пока нет

- Outsourcing at NestleДокумент10 страницOutsourcing at NestleAyeshaRasheedОценок пока нет

- Quality Awareness in DairyДокумент6 страницQuality Awareness in Dairybalbir kumarОценок пока нет

- TQM Report Nestle Waters Final ZohaibДокумент32 страницыTQM Report Nestle Waters Final ZohaibFahad AlianiОценок пока нет

- An Analysis Distribution Network in Supply Chain Management at Vijaykant Dairy and Food ProductsДокумент13 страницAn Analysis Distribution Network in Supply Chain Management at Vijaykant Dairy and Food ProductsCupid CuteОценок пока нет

- NESTLEДокумент4 страницыNESTLEMhaiel EscalОценок пока нет

- Total Quality M-Wps Officegroup2Документ16 страницTotal Quality M-Wps Officegroup2Rolando ArquellosОценок пока нет

- Amity University: Amity College of Commerce and FinanceДокумент19 страницAmity University: Amity College of Commerce and FinanceSahadev TyagiОценок пока нет

- Mother DairyДокумент5 страницMother Dairysid3286Оценок пока нет

- ANALYZING THE COMPANY RESOURCES (MR THINH)Документ3 страницыANALYZING THE COMPANY RESOURCES (MR THINH)Nhật NinhОценок пока нет

- Chapter 1 FinalДокумент4 страницыChapter 1 Finalkwagala joshuaОценок пока нет

- Strategic ManagementДокумент20 страницStrategic ManagementHà Mai AnhОценок пока нет

- A Business Orientation Project Report On Mother DairyДокумент46 страницA Business Orientation Project Report On Mother DairyLakshay ChhibbarОценок пока нет

- Projects: Dairy Farms From Vision To SuccessДокумент8 страницProjects: Dairy Farms From Vision To SuccessAditya Kumar DwivediОценок пока нет

- NestléДокумент2 страницыNestléMariana DíazОценок пока нет

- Nestle Doubles Down On Food Safety, Quality: Monica WatrousДокумент2 страницыNestle Doubles Down On Food Safety, Quality: Monica WatrousMikko RamiraОценок пока нет

- NutriMoo Official 2016Документ14 страницNutriMoo Official 2016Priyank ToliaОценок пока нет

- Benchmarking MengNiuДокумент2 страницыBenchmarking MengNiuScarlett LiuОценок пока нет

- Quality ControlДокумент9 страницQuality Controlsunnykumar.m2325Оценок пока нет

- SCMДокумент11 страницSCMHardik GangarОценок пока нет

- Operations Management Sept 2019 LastestДокумент16 страницOperations Management Sept 2019 LastestAnas TawfiqОценок пока нет

- Project Report Mother DairyДокумент54 страницыProject Report Mother DairyRavinder Kasana67% (9)

- 4812 12142 Mother Dairy Training ReportДокумент55 страниц4812 12142 Mother Dairy Training ReportPari SavlaОценок пока нет

- Nestle Operation Management FinalДокумент21 страницаNestle Operation Management FinalMuhammadArsalanОценок пока нет

- Ost On Visakha DairyДокумент25 страницOst On Visakha DairyrahulchagantiОценок пока нет

- GMP Dairy KosovoДокумент39 страницGMP Dairy KosovoAzmee UmamОценок пока нет

- NestleДокумент5 страницNestlePPmanОценок пока нет

- NESTLE AssignmentДокумент9 страницNESTLE AssignmentHuzaifaОценок пока нет

- Quality Process ProcurementДокумент5 страницQuality Process Procurementsid3286Оценок пока нет

- Project On Marketing MixДокумент25 страницProject On Marketing Mixtejpratap_gupta2100% (1)

- Dairy Industry AnalysisДокумент48 страницDairy Industry AnalysisNeha SrivastavaОценок пока нет

- Nestlé - The World Food CompanyДокумент22 страницыNestlé - The World Food Companydoktor99Оценок пока нет

- Mohammad Ali Jinnah University: Supply Chain Management Supply Chain Model of NestleДокумент6 страницMohammad Ali Jinnah University: Supply Chain Management Supply Chain Model of Nestleatif hussainОценок пока нет

- Nestle Inventry SystemДокумент13 страницNestle Inventry SystemDaeem shanazzerОценок пока нет

- AccountingДокумент5 страницAccountingMmОценок пока нет

- Marketing Assignment No 1Документ8 страницMarketing Assignment No 1Mishal ArshadОценок пока нет

- Prsentación Proyecto Profinat S.A.SДокумент13 страницPrsentación Proyecto Profinat S.A.SOSCARОценок пока нет

- Nestle PakistanДокумент18 страницNestle PakistanPawan DhimanОценок пока нет

- Assignment 1 PDFДокумент14 страницAssignment 1 PDFfaranimohamedОценок пока нет

- NESTLE TQM (Syndicate 5 & 6)Документ16 страницNESTLE TQM (Syndicate 5 & 6)Edlyn Valmai Devina SОценок пока нет

- Nestle StrategyДокумент3 страницыNestle Strategysara bazziОценок пока нет

- NestléДокумент13 страницNestléObaid Khurshid MughalОценок пока нет

- Micro or Small Goat Entrepreneurship Development in IndiaОт EverandMicro or Small Goat Entrepreneurship Development in IndiaОценок пока нет

- Augmentation of Productivity of Micro or Small Goat Entrepreneurship through Adaptation of Sustainable Practices and Advanced Marketing Management Strategies to Double the Farmer’s IncomeОт EverandAugmentation of Productivity of Micro or Small Goat Entrepreneurship through Adaptation of Sustainable Practices and Advanced Marketing Management Strategies to Double the Farmer’s IncomeОценок пока нет

- FSMA and Food Safety Systems: Understanding and Implementing the RulesОт EverandFSMA and Food Safety Systems: Understanding and Implementing the RulesОценок пока нет

- Lean Startup: The Ultimate Guide to Business Innovation. Adopt the Lean Startup Method and Learn Profitable Entrepreneurial Management Strategies to Build Successful Companies.От EverandLean Startup: The Ultimate Guide to Business Innovation. Adopt the Lean Startup Method and Learn Profitable Entrepreneurial Management Strategies to Build Successful Companies.Оценок пока нет

- Project Management Pro: Powerpoint SlidesДокумент350 страницProject Management Pro: Powerpoint SlidesJosephОценок пока нет

- What Is Degrowth - Demaria Schneider Sekulova Martinez Alier Env ValuesДокумент27 страницWhat Is Degrowth - Demaria Schneider Sekulova Martinez Alier Env ValuesNayara SantosОценок пока нет

- Chapter 1Документ4 страницыChapter 1Steffany RoqueОценок пока нет

- Class 8 PPT - Abhijeet Singh GureniyaДокумент16 страницClass 8 PPT - Abhijeet Singh Gureniyasimran simmyОценок пока нет

- U.S. Individual Income Tax Return: Miller 362-94-3108 DeaneДокумент2 страницыU.S. Individual Income Tax Return: Miller 362-94-3108 DeaneKeith MillerОценок пока нет

- Douglas Boyz Release Bridging The Gap Via Extraordinary Collective Music GroupДокумент2 страницыDouglas Boyz Release Bridging The Gap Via Extraordinary Collective Music GroupPR.comОценок пока нет

- The Best John Green QuotesДокумент10 страницThe Best John Green Quotesapi-586467925Оценок пока нет

- Athletic KnitДокумент31 страницаAthletic KnitNish A0% (1)

- GE Money and BankingДокумент110 страницGE Money and BankingBabita DeviОценок пока нет

- 9 Electrical Jack HammerДокумент3 страницы9 Electrical Jack HammersizweОценок пока нет

- Astm A709-04Документ8 страницAstm A709-04Артем ТитовОценок пока нет

- W1 MusicДокумент5 страницW1 MusicHERSHEY SAMSONОценок пока нет

- Journal of Exceptional Experiences and PДокумент62 страницыJournal of Exceptional Experiences and Pbinzegger100% (1)

- The Old Rugged Cross - George Bennard: RefrainДокумент5 страницThe Old Rugged Cross - George Bennard: RefrainwilsonОценок пока нет

- Teaching English in The Elementary Grades (Language Arts)Документ21 страницаTeaching English in The Elementary Grades (Language Arts)RENIEL PABONITAОценок пока нет

- Amit Singh RF EngineerДокумент3 страницыAmit Singh RF EngineerAS KatochОценок пока нет

- Past Paper1Документ8 страницPast Paper1Ne''ma Khalid Said Al HinaiОценок пока нет

- Botswana Ref Ranges PaperДокумент7 страницBotswana Ref Ranges PaperMunyaradzi MangwendezaОценок пока нет

- Created by EDGAR Online, Inc. Dow Chemical Co /de/ Table - of - Contents Form Type: 10-K Period End: Dec 31, 2020 Date Filed: Feb 05, 2021Документ286 страницCreated by EDGAR Online, Inc. Dow Chemical Co /de/ Table - of - Contents Form Type: 10-K Period End: Dec 31, 2020 Date Filed: Feb 05, 2021Udit GuptaОценок пока нет

- Vol. III (B) - FANSДокумент8 страницVol. III (B) - FANSKhaled ELSaftawyОценок пока нет

- CTY1 Assessments Unit 6 Review Test 1Документ5 страницCTY1 Assessments Unit 6 Review Test 1'Shanned Gonzalez Manzu'Оценок пока нет

- Hop Movie WorksheetДокумент3 страницыHop Movie WorksheetMARIA RIERA PRATSОценок пока нет

- 2007.01 What Does Jesus Think of Science?Документ2 страницы2007.01 What Does Jesus Think of Science?William T. PelletierОценок пока нет

- Martin Vs MalcolmДокумент17 страницMartin Vs Malcolmronnda100% (2)

- World Price List 2014: Adventys Induction Counter TopsДокумент4 страницыWorld Price List 2014: Adventys Induction Counter TopsdiogocorollaОценок пока нет

- News Item GamesДокумент35 страницNews Item GamesUmi KuswariОценок пока нет

- SMM Live Project MICA (1) (1)Документ8 страницSMM Live Project MICA (1) (1)Raj SinghОценок пока нет

- Excavations OSHA 2226Документ44 страницыExcavations OSHA 2226Al DubОценок пока нет

- Part - 1 LAW - 27088005 PDFДокумент3 страницыPart - 1 LAW - 27088005 PDFMaharajan GomuОценок пока нет

- July 2006 Bar Exam Louisiana Code of Civil ProcedureДокумент11 страницJuly 2006 Bar Exam Louisiana Code of Civil ProcedureDinkle KingОценок пока нет