Академический Документы

Профессиональный Документы

Культура Документы

Qualification of Autoclaves

Загружено:

jermac17Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Qualification of Autoclaves

Загружено:

jermac17Авторское право:

Доступные форматы

Autoclaves Qualification & Validation

By Holger Fabritz

Autoclaves: Qualification & Validation

Contents

Types of autoclaves Regulatory Aspects GMP Risk Analysis URS / FDS Design Qualification Installation Qualification / Operational Qualification Performance Qualification / Process Validation Responsibilities Summary

Holger Fabritz

Expertentreff 14. September 2007 in Baden

2 of 39

Autoclaves: Qualification & Validation

- Types of Autoclaves -

Steam Autoclaves Sterilisation with Steam / Air Mixture Saturated Steam with possible initial vacuum sequence(s) Cooling with Air cooled down by heat exchanger Hot Water Spray Autoclaves Sterilisation with Spraying of Water (Flooding with water) Cooling with Water cooled down by heat exchanger Hot Air Sterilisers

Expertentreff 14. September 2007 in Baden 3 of 39

Holger Fabritz

Autoclaves: Qualification & Validation

- Types of Autoclaves -

Large Steam Autoclave

Revolving Steam Autoclave xxx chambers,

Holger Fabritz

Expertentreff 14. September 2007 in Baden

4 of 39

Autoclaves: Qualification & Validation

- Regulatory Aspects -

Ph. Eur. 6 5.1.1, Methods of Preparation of Sterile Products 5.1.2, Biological Indicators of Sterilisation 5.1.5, Application of the F0 Concept to Steam Sterilisation of Aqueous Preparations USP 29 <55> Biological Indicators - Resistance Performance Tests <1035> Biological Indicators for Sterilisation <1211> Sterilization and Sterility Assurance of Compendial Articles

Holger Fabritz

Expertentreff 14. September 2007 in Baden

5 of 39

Autoclaves: Qualification & Validation

- Regulatory Aspects GMP-Regulations EU-GMP-Guideline Part 1, Annexes 1, 15 & 17 Code of Federal Regulations (CFR) 21, Part 210: Current Good Manufacturing Practice in Manufacturing, Processing, Packing of Holding of Drugs; General 21 CFR Part 211: Current Good Manufacturing Practice for finished Pharmaceuticals 21 CFR Part 11: Electronic Records; Electronic Signatures FDA Guidance for Industry Sterile Drug Products Produced by Aseptic Processing Documentation for Sterilisation Process Validation European Medicines Agency (EMEA) CPMP/QWP/054/98 Corr., Decision Trees for the Selection of Sterilisation Methods CPMP/QWP/3015/99, Note for Guidance on Parametric Release

Holger Fabritz Expertentreff 14. September 2007 in Baden 6 of 39

Autoclaves: Qualification & Validation

- Regulatory Aspects -

GAMP The Good Automated Manufacturing Practice (GAMP) Guide for Validation of Automated Systems in Pharmaceutical Manufacture, Vol. 4 PDA Technical Reports PDA Technical Report No. 1, Validation of Steam Sterilisation Cycles HTM (Health Technical Memorandum) 2010; Sterilisation; Part 3: Validation and verification; NHS Estates; Department of Health; UK International, European and National Standards (ISO / EN / DIN) / Others EN 285, Sterilisation, Steam Sterilisation, Large Sterilisers DIN 58950, Sterilisation , Steam Sterilisers for Pharmaceutical Products EN 554, Sterilisation of Medical Devices ...

Expertentreff 14. September 2007 in Baden 7 of 39

Holger Fabritz

Autoclaves: Qualification & Validation

- GMP Risk Analysis GMP Risk Analysis at the beginning of the qualification activities: Definition of GMP-relevant issues to be considered in the design and further qualification steps: GMP relevance of single components (e.g. heat exchanger, sterilisation chamber, valves) Control System computer validation, definition of the GMP-relevant instrumentation including requirements for accuracy and recording, GMPrelevant sensors (double measurement of critical parameters) Utilities: quality of media piping quality Material specification incl. necessary certificates Additional test devices (e.g. WIT-test possibility for aeration filter, incl. sensors) Documentation including welding documentation, wiring check, software documentation etc. Possibility to have a traceability to the subsequent qualification steps Influence of Risk Analysis on Engineering activities (URS) & basis for DQ / IQ / OQ / .

Holger Fabritz

Expertentreff 14. September 2007 in Baden

8 of 39

Autoclaves: Qualification & Validation

- GMP Risk Analysis 1 2 Process step / 3 Possible failure 4 GMP Risk 5 Explanation 6 Tests / Measures 7 Traceability

Equipment

[ Y/N ]

[ A/B/C ]

I Q

O P Q Q

N C / Q V A

Components with product contact

Inadequate material of steel surfaces Inadequate plastics or gaskets Wrong surface finishes

Corrosion could deteriorate the product.

Steel: 316L min. certified by EN10204 2.2

Material might not be inert against product. Rough surface might lead to adherence of product or bad cleanability.

Plastics/gaskets: Food graded materials certified acc. to CFR Title 21 177.2600. Surface finishing or surface roughness is defined and proven. Certificate of manufacturer is available.

Bad quality of weld seams (pipework)

Weld seams of product or clean media pipes have another material and surface roughness than the tubes. Risk of porosities or material impurities.

Weld seams of stainless steel pipes should be welded under inert gas conditions and with appropriate welding material (TIG technique).

s. a.

As far as technically possible orbital welding should be applied. Weld seams of pipework for product or clean media transfer should be visually checked by endoscope.

Quality of weld seams is not traceable.

When pipework is completed, the weld seams cannot be checked visibly any more.

Required by ISPE publications

100% of handmade weld seams and an appropriate percentage of orbital weld seams have to be checked accordingly.

Requirement of good documentation practice.

Test report contains every weld seam with a single test.

Holger Fabritz

Expertentreff 14. September 2007 in Baden

9 of 39

Autoclaves: Qualification & Validation

- User Requirement Specification (URS) -

To be issued by the User (Pharmaceutical Enterprise) Basis for GMP Risk Analysis and influenced by the results (e.g. documentation requirements, number of critical sensors) Reference to Pharmacopoeias, guidelines and standards to be used ( EMEA CPMP/QWP/054/98 Decision trees for the selection of sterilisation methods) Description of the sterilisation process (e.g. standard sterilisation, F0-sterilisation) on basis of the product properties Definition of all (as possible) relevant GMP-critical points (e.g. sterility of cooling media, coldest spots) Definition of the user needs for documentation and operation (e.g. batch documentation, operating instructions etc.)

Holger Fabritz

Expertentreff 14. September 2007 in Baden

10 of 39

Autoclaves: Qualification & Validation

- User Requirement Specification (URS) -

Completed by detailed technical specifications: Volume of sterilisation chamber Standards for electrical standards, wiring, valves, Standards for materials to be used (stainless steel)including surface roughness (< 0,8 m or higher values?) Interfaces to existing systems Drying / Air Filters (e.g. for stoppers for dry powder filling, clean room clothes) Definition of requirements for FAT / SAT

Holger Fabritz

Expertentreff 14. September 2007 in Baden

11 of 39

Autoclaves: Qualification & Validation

- User Requirement Specification (URS) -

Detail description of requirements for Computer Validation Audit Trail User Access Backup / Recovery Disaster Recovery Definition of requirements for qualification (in case that supplier should support qualification)

Combined with commercial requirements as request for an offer to be submitted to different potential suppliers

Holger Fabritz

Expertentreff 14. September 2007 in Baden

12 of 39

Autoclaves: Qualification & Validation

- Functional Design Specification (FDS) -

To be issued by the potential suppliers FDS should comprise detailed proposals for technical solutions for the URS requirements All requirements of the URS must be commented by the supplier (can be met or cant be met) In case of deviation from a requirement of the URS, an explanation and alternative proposals for technical solutions are necessary

Holger Fabritz

Expertentreff 14. September 2007 in Baden

13 of 39

Autoclaves: Qualification & Validation

- Project Implementation -

RA

Engineering

Manufacturing

Delivery/ Installation

Commissioning

Test Runs/ Start-up

Process Optimisation

Production

URS

DQ/FDS

FAT

IQ/SAT

OQ

PQ

PV / CV

Re-Val.

Change Control / Requalification

Holger Fabritz

Expertentreff 14. September 2007 in Baden

14 of 39

Autoclaves: Qualification & Validation

- Design Qualification (DQ) -

is performed by documented comparison of URS and FDS, focussed on GMP- relevant topics all requirements set up be the URS (resulting from the risk analysis) should be met, traceability to risk analysis and URS should be given deviations from the requirements of the URS must be evaluated whether acceptable or not ( GMP-requirements) Supplier Audits (quality system, software development) should be implemented in this phase Note: Implementation of supplier audit in Computer Validation strategy necessary Approval of DQ protocol and report respective approval of URS/FDS comparison by defined persons (VMP) Start of project change control

15 of 39

Holger Fabritz

Expertentreff 14. September 2007 in Baden

Autoclaves: Qualification & Validation

- Summary of RA/URS/FDS/DQ -

Some practical experiences:

Results of GMP Risk Analysis are often not considered in URS GMP Risk Analysis too detailed (discussion about construction of valves) Important company standards are not added to URS (Welding standards for pipes) FDS does not answer URS (standard documents by suppliers) Design Qualification finalised too late / after FAT Changes are performed but without change control ...... Mistakes in early project stages lead to irritations/discussions/deviations during IQ/OQ/PQ

Holger Fabritz

Expertentreff 14. September 2007 in Baden

16 of 39

Autoclaves: Qualification & Validation

- Factory Acceptance Test (FAT) / Site Acceptance Test (SAT) -

FAT

SAT

Qualification staff should join FAT Preliminary documentation should be available and should be checked during FAT (incl. IQ and OQ - protocols) First formal check of P&I-Diagram by qualification staff Definition of test program on basis of suppliers possibilities Structured FAT can substitute some IQ(OQ)-testing

Basis for SAT should be mechanical completion of autoclave SAT should be performed as Pre-IQ / Pre-OQ / can substitute some IQ / OQ testing.

Holger Fabritz

Expertentreff 14. September 2007 in Baden

17 of 39

Autoclaves: Qualification & Validation

- Installation Qualification (IQ) -

Holger Fabritz

Expertentreff 14. September 2007 in Baden

18 of 39

Autoclaves: Qualification & Validation

- Installation Qualification (IQ) IQ - Checked P&I-Diagram

Holger Fabritz

Expertentreff 14. September 2007 in Baden

19 of 39

Autoclaves: Qualification & Validation

- Installation Qualification (IQ) -

Further points to be checked Calibration of the different sensors Three points for temperature/pressure One point for timer or paper speed of the recorder Availability of relevant SOPs (operation, maintenance), at least as draft version Check of the supplier documentation Completeness Formal correctness Correctness of content Finalisation of IQ Deviations must be evaluated In case of GMP-critical deviations (e.g. wrong type of sensors), IQ not successful remedy of deviation and repetition of IQ (Change Control) In case of non GMP-critical deviations, a pre-approval of the IQ is possible in order to start next qualification step

Holger Fabritz Expertentreff 14. September 2007 in Baden

SOP SOP 1.... 1.... 2.... 2.... 3.... Calibration 3.... Calibration Certificate Certificate

20 of 39

Autoclaves: Qualification & Validation

- Operational Qualification (IQ) Pre-requisites (Pre-)Approval of IQ Used measuring devices (e.g. Kaye system, data loggers) should be calibrated before performing measurement (and afterwards) Function testing of all procedures & sequences Tightness and stability of piping after performing a sterilisation cycle (Visual checks!) Loading and unloading tests Interlocks of doors Check of programs Fractionated pre-vacuum Heating phase Equilibration time Sterilisation time Drying and Cooling Correct re-start after power failure

Holger Fabritz Expertentreff 14. September 2007 in Baden 21 of 39

Autoclaves: Qualification & Validation

- Operational Qualification (OQ) -

Points to be checked Check of alarms Temperature too high or too low Pressure too high or too low (pressure variations) Time limits of process steps Utility supply Cable break of sensors ... Computer Validation related points User access and audit trail Data storage / Print Out Electromagnetic failure, radio frequency test ...

Holger Fabritz

Expertentreff 14. September 2007 in Baden

22 of 39

Autoclaves: Qualification & Validation

- Operational Qualification (OQ) Points to be checked

Check of steam quality (should be covered by qualification of clean steam system)

Check of chamber tightness Possible acceptance criteria: pressure drop 1,3 mbar / min Procedure: Evacuation of the chamber on a predefined pressure and closing of all valves. Measurement for 10 min Bowie-Dick-Test for sterilisation cycles with saturated steam Use of test kids Colour change of indicator complete Integrity of aeration filter Water Intrusion Test for hydrophobic filters

Holger Fabritz

Expertentreff 14. September 2007 in Baden

23 of 39

Autoclaves: Qualification & Validation

- Operational Qualification (OQ) -

Measurement of Measurement of Empty Chamber Empty Chamber

Data Data Logger Logger

Data Logger Data Logger on Autoclave on Autoclave Tray Tray

All operation parameters in specification

Holger Fabritz Expertentreff 14. September 2007 in Baden

24 of 39

Autoclaves: Qualification & Validation

- Operational Qualification (OQ) -

Points to be checked: Heat distribution check of the empty chamber (Identification of cold spots)

Acceptance Criteria Correct process incl. recording without alarms Pre-defined maximum standard deviation not exceeded for validation sensors Pre-defined maximum allowed deviation from the mean value for single validation sensors not exceeded for validation sensors Pre-defined maximum allowed deviation from the mean value of the validation sensors for control and documentation sensors not exceeded

Holger Fabritz

Expertentreff 14. September 2007 in Baden

25 of 39

Autoclaves: Qualification & Validation

- Operational Qualification (OQ) -

Points to be checked: Heat distribution check of the empty chamber (Identification of cold spots) Method Repeated measurement of the empty chamber (e.g. 3 times) Use of in minimum 10 to 12 sensors / m3 of chamber volume One sensor should be near to the control sensor respect. near to the condensate drain Documentation of the exact localisation of the used sensors Finalisation of OQ Deviations must be evaluated In case of GMP-critical deviations (e.g. bugs in sterilisation cycles), OQ not successful remedy of deviation and repetition of IQ (Change Control) In case of non GMP-critical deviations, a pre-approval of the OQ is possible in order to start next qualification step

Holger Fabritz Expertentreff 14. September 2007 in Baden

Autoclave Chamber Autoclave Chamber with location of with location of validation sensors validation sensors

26 of 39

Autoclaves: Qualification & Validation

- Summary IQ / OQ -

Some Experiences

Surface roughness out of specified limits Valves incorrect mounted Documentation incomplete or wrong, e.g. material certificates not available Heat distribution out of specified range Failures during procedures (bugs in programming) ....

Holger Fabritz

Expertentreff 14. September 2007 in Baden

27 of 39

Autoclaves: Qualification & Validation

- Performance Qualification (PQ)- Process Validation (PV) Definition as Performance Qualification or as Process Validation possible (in reality combination of both aspects)

Focus of PQ on autoclave (heat penetration,

reduction of viable germs on bio-indicators)

Focus of PV on product quality (e.d. decomposition

of active ingredient, increase of particulate contamination) Test with product / material to be sterilised or with adequate placebo Combination of heat penetration test controlled by external temperature sensors and bio-indicators Detailed test plan including a risk based approach for planned procedure to be defined

Holger Fabritz Expertentreff 14. September 2007 in Baden 28 of 39

Autoclaves: Qualification & Validation

- PQ / PV -

Bio-indicators:

Bio-indicators to be used defined in Pharmacopoeias

Ph.Eur.6, 5.1.2 USP 29 <1035>

Determination of population in independent laboratory of each batch

viable spores > 105 - 107 D-Value (> 1,5 min at +121 C)

Independent determined number viable population should be taken for calculation of Sterility Assurance Level (SAL)

Holger Fabritz

Expertentreff 14. September 2007 in Baden

29 of 39

Autoclaves: Qualification & Validation

- PQ / PV -

Bio-indicators

Incubation for 14 days between +55 and +60 C

(first results after 1 day possible)

Parallel growth promotion test for each single sterilisation run Possible contamination of equipment should be considered and

must be avoided by adequate measures (e.g. additional prolonged sterilisation run of empty autoclave after runs with bio-indicators)

Holger Fabritz

Expertentreff 14. September 2007 in Baden

30 of 39

Autoclaves: Qualification & Validation

- PQ / PV -

Procedure

Pre-requisites and principle procedure of temperature mapping

equivalent to temperature mapping of empty chamber

Definition of the loading scheme(s) (SOP) to be validated Adequate and reasoned bracketing possible; validation of worst

case loads

Location of temperature sensor as near as possible to bio-indicators Location of temperature sensors inside product, if possible

Holger Fabritz

Expertentreff 14. September 2007 in Baden

31 of 39

Autoclaves: Qualification & Validation

- PQ / PV -

Placing of Validation Sensors in Autoclave Load Kaye Validator Sensor Holder for Kaye Validator

Holger Fabritz Expertentreff 14. September 2007 in Baden 32 of 39

Autoclaves: Qualification & Validation

- PQ / PV Procedure: Selection of cold spots on basic of experience and scientific approach (to be described in detail in the PQ/PV protocol):

Small tubes Between primary and secondary packaging Contact areas of different materials

Consider maximum temperature and cycle time to determine maximum degradation Repeat validation run 3 times Re-Validation of sterilisation process (e.g. every 6 / 12 months)

Holger Fabritz

Expertentreff 14. September 2007 in Baden

33 of 39

Autoclaves: Qualification & Validation

- PQ / PV -

Acceptance Criteria: Heat distribution

Correct process incl. recording without alarms Predefined maximum standard deviation not exceeded for

validation sensors

Pre-defined maximum allowed deviation from the mean value for

each single validation sensor is not exceeded Microbiological evaluation

Sterility Assurance Level (SAL) of 10-6 to be reached Growth of control bio-indicator (positive control)

Holger Fabritz

Expertentreff 14. September 2007 in Baden

34 of 39

Autoclaves: Qualification & Validation

- PQ / PV -

Acceptance Criteria: Drying effectiveness, if applicable

Evaluation of remaining humidity by adequate methods for critical

material (e.g. rubber stoppers for powder filling lines) by

gravimetric methods (e.g. clothes, rubber stoppers) analytical method (Karl-Fischer-titration) Optical control for metallic or plastic parts

Holger Fabritz

Expertentreff 14. September 2007 in Baden

35 of 39

Autoclaves: Qualification & Validation

- PQ / PV -

Validation of sterilisation process for parametric release, points to consider: Guidelines EU-GMP-Guide Part 1, Annex 17 CPMP/QWP/3015/99: Note for guidance on parametric release

Follow the requirements of the relevant guidelines Clear justification for the chosen approach Define the relevant physical parameters on basis of an risk analysis Definition of an overkill procedure under consideration of the bioburden

Expertentreff 14. September 2007 in Baden 36 of 39

Holger Fabritz

Autoclaves: Qualification & Validation

- Responsibilities -

The pharmaceutical manufacturer is responsible for the whole qualification on basis of VMP GMP Risk Analysis should evaluate risks & define test measurements by team work betw. Autoclave manufacturer, engineering/qualification and pharmaceutical producer Qualification work is usually performed by autoclave supplier / engineering. The approval of test protocols and test reports should be in the responsibility of pharmaceutical producer.

Holger Fabritz

Expertentreff 14. September 2007 in Baden

37 of 39

Autoclaves: Qualification & Validation

- Summary -

Define relevant requirements to be compliant with current GMPrequirements on basis of a GMP Risk Analysis during initial specification phase and verify them during Design Qualification Perform adequate IQ- and OQ-procedure incl. an adequate approach for Computer Validation. The traceability to GMP Risk Analysis should be considered. Define the strategy for PQ/PV with detailed justification and under consideration of the product properties (separate GMP risk assessment) Consider the relevant guidelines and recommendations especially for parametric release The final responsibility of qualification / validation is held by the pharmaceutical producer.

Holger Fabritz

Expertentreff 14. September 2007 in Baden

38 of 39

Autoclaves: Qualification & Validation

- Summary -

Sterilisation is a well known process with a lot of autoclave manufacturer experience. Adequate qualification and validation shouldnt be a point of concern during inspections. Rational approaches to reduce validation work is possible.

Holger Fabritz

Expertentreff 14. September 2007 in Baden

39 of 39

Вам также может понравиться

- The Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderОт EverandThe Manufacture of Sterile Pharmaceuticals and Liquid Medical Devices Using Blow-Fill-Seal Technology: Points to ConsiderОценок пока нет

- Equipment Qualification in the Pharmaceutical IndustryОт EverandEquipment Qualification in the Pharmaceutical IndustryРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Pda Technical Report 48 Moist Heat Sterilizer SystemsДокумент70 страницPda Technical Report 48 Moist Heat Sterilizer Systemsmkmncs457475% (4)

- Autoclave Validation MSPDAДокумент35 страницAutoclave Validation MSPDAYessine Mrabet100% (1)

- PQ of AutoclaveДокумент23 страницыPQ of Autoclavedinesh000786100% (7)

- M 171 Validation MasterplanДокумент41 страницаM 171 Validation MasterplanMohamed KamalОценок пока нет

- Autoclave Validation MalibaДокумент74 страницыAutoclave Validation Malibaph_homa3040Оценок пока нет

- PDA TR 80 《制药实验室数据完整性管理体系》中英文对照版Документ98 страницPDA TR 80 《制药实验室数据完整性管理体系》中英文对照版于天一100% (1)

- Media Fills - PDAДокумент22 страницыMedia Fills - PDAdmtalbhoge100% (6)

- Autoclave Validation ProtocolДокумент4 страницыAutoclave Validation Protocolsalluraj100% (2)

- PQ Sterile TunnelДокумент10 страницPQ Sterile TunnelReza JafariОценок пока нет

- PQ - Autoclave (HPHV Steam Sterilizer)Документ26 страницPQ - Autoclave (HPHV Steam Sterilizer)hbhatt88100% (5)

- How To Validate An AutoclaveДокумент3 страницыHow To Validate An AutoclaveqhpuongОценок пока нет

- Media FillДокумент27 страницMedia FillKuruva ShivaОценок пока нет

- 2.10 Risk-Based Qualification For The 21st CenturyДокумент7 страниц2.10 Risk-Based Qualification For The 21st CenturyJorge Humberto HerreraОценок пока нет

- 15702, Maintenance and Facilities OutsourДокумент6 страниц15702, Maintenance and Facilities OutsournabilbyОценок пока нет

- Validation Protocol CG TAДокумент30 страницValidation Protocol CG TACarlo Duran100% (1)

- Validation of Sterile ProductДокумент30 страницValidation of Sterile Productneetisaharia92% (24)

- Investigating SterilityTest FailuresДокумент16 страницInvestigating SterilityTest FailuresMahesh_ChokshiОценок пока нет

- Tech Report #2 Validation of Aseptci Filling For Solution Drug ProductsДокумент32 страницыTech Report #2 Validation of Aseptci Filling For Solution Drug ProductsEnrique Pomales0% (1)

- Validation and Facility Design PDFДокумент16 страницValidation and Facility Design PDFjpabloqfОценок пока нет

- Autoclave Validation PresentationДокумент17 страницAutoclave Validation PresentationAnkur Bhatia100% (1)

- Site VMPДокумент34 страницыSite VMPJonatan Dominguez PerezОценок пока нет

- ISPE ArticleДокумент12 страницISPE Articledrs_mdu48Оценок пока нет

- FDA CGMP Checklists: ValidationДокумент2 страницыFDA CGMP Checklists: ValidationFDACGMPОценок пока нет

- Risk Management in Sterile EnvironmentsДокумент30 страницRisk Management in Sterile EnvironmentsTim Sandle100% (4)

- Cleaning Validation ProtocolДокумент6 страницCleaning Validation ProtocolVega life sciences100% (1)

- Utilities QualificationДокумент162 страницыUtilities QualificationDoan Chi ThienОценок пока нет

- TR 35 A Proposed Training Model For The Microbiological Function in The Pharmaceutical Industry 2001Документ32 страницыTR 35 A Proposed Training Model For The Microbiological Function in The Pharmaceutical Industry 2001Sheetal Agree100% (2)

- Validation of Water SystemДокумент25 страницValidation of Water Systemsukanya100% (2)

- 30 ML Moulded Vial Filling OQДокумент15 страниц30 ML Moulded Vial Filling OQSubhash NaiduОценок пока нет

- ISPE CTU Evaluation PresentationДокумент25 страницISPE CTU Evaluation PresentationOscar HoyosОценок пока нет

- 21 CFR Part 11 Complete Guide To International Computer Validation Compliance PDFДокумент287 страниц21 CFR Part 11 Complete Guide To International Computer Validation Compliance PDFZigma Delta100% (2)

- Annual Product Review Developing An SOPДокумент26 страницAnnual Product Review Developing An SOPanants2567% (3)

- Cleaning ValidationДокумент21 страницаCleaning ValidationBrian WilliamsОценок пока нет

- Batch DispositionДокумент21 страницаBatch DispositionNUPharma Consular100% (1)

- Autoclave Validation ProtocolДокумент23 страницыAutoclave Validation ProtocolErum Manzoor100% (2)

- Validation of Sterile Water For Injection in PharmДокумент12 страницValidation of Sterile Water For Injection in PharmSehrish KanwalОценок пока нет

- PQ WfiДокумент9 страницPQ Wfisami2210Оценок пока нет

- PDA TR Nº40 Sterilizing Filtration of Gases PDFДокумент45 страницPDA TR Nº40 Sterilizing Filtration of Gases PDFehsan050628Оценок пока нет

- Management of Out of Specification (OOS) For Finished ProductДокумент12 страницManagement of Out of Specification (OOS) For Finished Productpires35100% (1)

- TocДокумент7 страницTocIlayaraja Boopathy0% (1)

- Qualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesДокумент1 страницаQualification Procedure For Vial Washing Machine - Pharmaceutical GuidelinesAli Goutas50% (2)

- PLC ValidationДокумент26 страницPLC ValidationdesignselvaОценок пока нет

- Cleaning Validation Report Dec2018 PDFДокумент21 страницаCleaning Validation Report Dec2018 PDFPrashansa ShresthaОценок пока нет

- 04 ISPEs Guides and How They Apply To Cleaning and Cleaning Validation by Stephanie WilkinsДокумент33 страницы04 ISPEs Guides and How They Apply To Cleaning and Cleaning Validation by Stephanie Wilkinsmjamil0995100% (1)

- Iq Oq PQ ChamberДокумент17 страницIq Oq PQ Chamberelias_7760% (5)

- Performance Qualification of Vial Washer 7363Документ25 страницPerformance Qualification of Vial Washer 7363Juan DanielОценок пока нет

- Facility ValidationДокумент12 страницFacility ValidationGhanta Ranjith Kumar100% (1)

- 2015 VMP TemplateДокумент10 страниц2015 VMP Templatekulbhushan singh100% (2)

- Process Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2Документ12 страницProcess Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2MykolaОценок пока нет

- Testing Computers Systems For FDA Mhra Compliance Computer Systems Val - ebooKOIDДокумент136 страницTesting Computers Systems For FDA Mhra Compliance Computer Systems Val - ebooKOIDquangterumo100% (10)

- 10072-02 RQ Protocol Line-1 Tunnel-001Документ34 страницы10072-02 RQ Protocol Line-1 Tunnel-001deepanmb00750% (2)

- Equipment Qualification ToolkitДокумент26 страницEquipment Qualification ToolkitMuqeet7683% (6)

- Validation VialWasher OQ NIHДокумент30 страницValidation VialWasher OQ NIHcongacon3aОценок пока нет

- Cleanroom Technology: Fundamentals of Design, Testing and OperationОт EverandCleanroom Technology: Fundamentals of Design, Testing and OperationОценок пока нет

- Good Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsОт EverandGood Manufacturing Practices (GMP) Modules for Pharmaceutical ProductsОценок пока нет

- Dalal & MishraДокумент491 страницаDalal & MishraKarthika M TharakanОценок пока нет

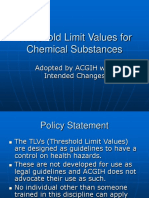

- Threshold Limit Values For Chemical Substances: Adopted by ACGIH With Intended ChangesДокумент18 страницThreshold Limit Values For Chemical Substances: Adopted by ACGIH With Intended ChangesrosaОценок пока нет

- Dengue Fever Health TeachingДокумент3 страницыDengue Fever Health TeachingDante Sales100% (3)

- Characterization of Glaucoma Medication Adherence in Kaiser Permanente Southern CaliforniaДокумент5 страницCharacterization of Glaucoma Medication Adherence in Kaiser Permanente Southern CaliforniaAu ZouОценок пока нет

- Garden Trust Launches A CompetitionДокумент3 страницыGarden Trust Launches A CompetitionCami GrossiОценок пока нет

- Explanatory ModelДокумент6 страницExplanatory Modeljagdish_vankarОценок пока нет

- Jurnal AsiДокумент6 страницJurnal AsiAmeliarОценок пока нет

- SPA vs. GPAДокумент24 страницыSPA vs. GPAYabb TabianОценок пока нет

- Zero B Product PresentationДокумент27 страницZero B Product PresentationKalyan DeshpandeОценок пока нет

- 08 Permit To Work ProcedureДокумент24 страницы08 Permit To Work Procedureniteshsh31100% (1)

- Parag Milk FoodsДокумент2 страницыParag Milk Foodskiran crОценок пока нет

- Dr-Nursing Care PlanДокумент2 страницыDr-Nursing Care PlanKhrisha Anne Davillo100% (1)

- Sorted Feedback TopicwiseДокумент55 страницSorted Feedback TopicwiseLokesh BakshiОценок пока нет

- Pharma IndiaДокумент58 страницPharma IndiaSaravana Kumar50% (4)

- PCO Accreditation Application Form 2017Документ3 страницыPCO Accreditation Application Form 2017Miguel Pillas100% (4)

- Application For Employment Form - THPAL (2014-05) PDFДокумент7 страницApplication For Employment Form - THPAL (2014-05) PDFRome CamingueОценок пока нет

- 2017 Coca Cola Foundation GrantsДокумент51 страница2017 Coca Cola Foundation GrantsPrincess PatagocОценок пока нет

- Mad - men.S01E01.720p.bluray.2CH.x264 PSAДокумент62 страницыMad - men.S01E01.720p.bluray.2CH.x264 PSARakshan SharmaОценок пока нет

- Industrial Ergonomics SSRДокумент35 страницIndustrial Ergonomics SSRShkar GalalyОценок пока нет

- Government of Canada Report On Emend (Aprepitant)Документ6 страницGovernment of Canada Report On Emend (Aprepitant)jennabushОценок пока нет

- Adherence - An Analysis of Concept - Gardner, 2015 PDFДокумент6 страницAdherence - An Analysis of Concept - Gardner, 2015 PDFRicardo Costa da SilvaОценок пока нет

- Suture Removal: - Check Room ForДокумент4 страницыSuture Removal: - Check Room ForNiña Dianne Rubin RustiaОценок пока нет

- Formulasi Fast Desintegrating Tablet (FDT) Sari Buah Jambu Biji Merah Dengan Perbedaan Konsentrasi Ac-DisolДокумент8 страницFormulasi Fast Desintegrating Tablet (FDT) Sari Buah Jambu Biji Merah Dengan Perbedaan Konsentrasi Ac-Disolfauzul husnaОценок пока нет

- Case Analysis PaperДокумент2 страницыCase Analysis PaperKukugirl DavisОценок пока нет

- 2020-04-08 A New World Through My Window - Olga TokarczukДокумент4 страницы2020-04-08 A New World Through My Window - Olga TokarczukNatalia CimoОценок пока нет

- Self-Esteem Moderates The Associations Between Body-Related Self-Conscious Emotions and Depressive SymptomsДокумент11 страницSelf-Esteem Moderates The Associations Between Body-Related Self-Conscious Emotions and Depressive SymptomsAlliyah Roma CadaОценок пока нет

- Cambios Tranvversales, Verticales Anclaje Oseo VS DentosoportadoДокумент12 страницCambios Tranvversales, Verticales Anclaje Oseo VS DentosoportadoLAURA MARCELA BARRENECHE CALLEОценок пока нет

- Employee Safety and HealthДокумент4 страницыEmployee Safety and HealthHEZEL FELCY CASTELINOОценок пока нет

- Checklist With RationalesДокумент174 страницыChecklist With RationalesZoey Francisco100% (1)

- Adhd Powerpoint-1Документ21 страницаAdhd Powerpoint-1api-516280936Оценок пока нет