Академический Документы

Профессиональный Документы

Культура Документы

08-Vessel Min Thickness Evaluation

Загружено:

avazcИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

08-Vessel Min Thickness Evaluation

Загружено:

avazcАвторское право:

Доступные форматы

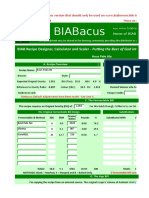

Diversified Technology Services

2045 Preisker Ln. Suite-A - Santa Maria, CA 93454 - (805) 928-6392 Equipment ID Number: Client: FWKO-111 DTS Client Date: Location: 25-Oct-03 Somewhere USA

Pressure Vessel Calculation U-1A Form Information

MFG Info: Manufactured By: Type Horiz Ser.#: Unkown NB. #: Vessel Builder USA 2114 Year Built: 1971

Operating Conditions: MAWP: Shell: Matl.: SA-516-70 143.25 Stress at Temp: Eff.(%): 1 17500 Nom.: 0.375 C/A: 0.0625 60 psi at max temp. 650

o

Diameter ID Heads: (A) Matl: (B) Matl:

ID

Est. M/T: 0.0%

SA-516-70 SA-516-70

Corrosion Allow 0.0625 0.0625

Stress at Temp: Stress at Temp:

17500 17500

Elliptical Ratio

Eff.(%): Eff.(%):

Connical Apex Angle

1 1

Hemi Radius

Est. M/T: Est. M/T:

0.0% 0.0%

Nominal Thickness 0.500 0.500

Crown Radius Knuckle Radius 122 122 10.5 10.5

Flat Diam.

A B Nozzles:

ID

Size 2.0 16.0 24.0

Nominal Thickness 0.154 0.375 0.375

Material A-53-B A-53-B A-53-B

Matl Stress @ temp. 18000 18000 18000

Eff (%) 1.00 1.00 1.00

Est. Mill Tolerance 12.5% 12.5% 12.5%

A B C D E F G

The Values used in these calculations were defined by U-1A forms supplied by the Owner. There was a U-1A form provided for this particular Vessel.

API-510 Inspector:

API Certified Inspector

Certification Number:

16

File Name: 08 - Vessel Min Thickness Evaluation Section: U-1A Info

DTS Calculation Database (Vessel "t-min")

Page 1 of 6

Diversified Technology Services

2045 Preisker Ln. Suite-A - Santa Maria, CA 93454 - (805) 928-6392 Equipment ID Number: Client: FWKO-111 DTS Client Date: Location: 25-Oct-03 Somewhere USA

Pressure Vessel Calculation Form for Cylindrical Shells

Formula: Pr t = SE-0.6P Statistics:

Pressure (MAWP) : Joint Efficiency (E):

Nominal Thickness of Material (Nom) : 60 1

Material Allowable Stress (S): Vessel ID in inches (D) :

0.375 17500 143.25

Variables: Fluid Level in feet (FL): Specific Gravity (SG):

4.00 0.885

Vessel total height in feet (VH):

Distance from top of Vessel to bottom of Shell Course (DFT):

8.00 8.00

Corrosion Allow. (CA): Mill Tolerance Percentage (MT):

0.0625 0.0%

Calculations for Variables: Static Head: SH = FL - ( VH - DFT ) X SG SH SH SH SH = = = = 4.00 4.00 4.00 3.540 Calculation for Structural t-min. ts ts 63.5 17500.000 X 1.000 X 71.625 0.600 X 63.5 ts ts = Nom MT 0.0% 0.063 ) CA 0.063 X ( 8.00 0.00 0.885 X 8.00 0.89 ) X 0.89 Static Head Compensation for "P" P = MAWP + SH P P = = 60.0 + 3.540

63.540

Calculation for Pressure t-min. Pr t = SE-0.6P

= ( 0.375 = = 0.375 0.313

= 17500.000 4551.053 17461.876

4551.053 38.124

Structural t-min based on M/T and C/A only.

ts

0.313

Inches

Pressure t-min Requirements: t = 0.261 Inches

0.261

Actual Nominal Min Required with C/A

tn API-510 Inspector: API Certified Inspector

0.323 16

Inches

Certification Number:

File Name: 08 - Vessel Min Thickness Evaluation Section: Shell Course

DTS Calculation Database (Vessel "t-min")

Page 2 of 6

Diversified Technology Services

2045 Preisker Ln. Suite-A - Santa Maria, CA 93454 - (805) 928-6392 Equipment ID Number: Client: FWKO-111 DTS Client Date: Location: 25-Oct-03 Somewhere USA

Pressure Vessel Calculation Form for Torispherical Head (A)

Formula: t = 2SE-0.2P ASME Sect. VIII Div-1 (1-4(d)) Statistics: PLM

Pressure (MAWP) : Joint Efficiency (E) :

Nominal Thickness of Material (Nom) : 60 1

Material Allowable Stress (S) : Inside Crown Radius (L) :

0.500 17500 122 1.6 0.0625 0.0%

Variables: Fluid Level in feet (FL): Specific Gravity (SG):

4.00 0.885

Vessel total height in feet (VH):

Distance from top of Vessel to bottom of Shell Course (DFT):

8.00 8.00

Torispherical Head Proportion Factor: (M) Corrosion Allow. (CA): Mill Tolerance Percentage (MT):

Calculations for Variables: Static Head: SH = FL - ( VH - DFT ) X SG SH SH SH SH = = = = 4.00 4.00 4.00 3.54 X ( 8.00 0.00 0.89 X 8.00 0.89 ) X 0.89 Static Head Compensation for "P" P = MAWP + SH P P = = 60.0 63.5 + 3.54

Calculation for L/r to provide factor "M" 122 / 10.5 = 11.62

Calculation for Pressure t-min. PLM t = 2SE-0.2P

Calculation for Structural t-min. ts ts X X 122 1.000 X 0.200 1.60 X 63.5 ts ts = Nom MT 0.0% 0.063 ) CA 0.063

= ( 0.500 = = 0.5 0.438

63.5 35000.000

= 35000.000 12403.008 34987.292

12403.008 12.708

Structural t-min based on M/T and C/A only.

ts

0.438

Inches

Pressure t-min Requirements: t = 0.355 Inches

0.355

Actual Nominal Min Required with C/A

tn API-510 Inspector: API Certified Inspector

0.417 16

Inches

Certification Number:

File Name: 08 - Vessel Min Thickness Evaluation Section: Torispherical Head-A (1-4(d))

DTS Calculation Database (Vessel "t-min")

Page 3 of 6

Diversified Technology Services

2045 Preisker Ln. Suite-A - Santa Maria, CA 93454 - (805) 928-6392 Equipment ID Number: Client: FWKO-111 DTS Client Date: Location: 25-Oct-03 Somewhere USA

Pressure Vessel Calculation Form for Cylindrical Nozzles (A)

Formula: Pr t = SE-0.6P Statistics:

Pressure (MAWP) : Joint Efficiency (E):

Nominal Thickness of Material (Nom) : 60 1.00

Material Allowable Stress (S): Nozzle ID in inches (D) :

0.154 18000 2

Variables: Fluid Level in feet (FL): Specific Gravity (SG):

0.00 0.000

Vessel total height in feet (VH):

Distance from top of Vessel to bottom of Shell Course (DFT):

0.00 0

Corrosion Allow. (CA): Mill Tolerance Percentage (MT):

0.0625 12.5%

Calculations for Variables: Static Head: SH = FL - ( VH - DFT ) X SG SH SH SH SH = = = = 0.00 0.00 0.00 0.000 Calculation for Structural t-min. ts ts 60.0 18000 X 1.000 X 1.000 0.600 X 60.0 ts ts = Nom MT 12.5% 0.063 ) CA 0.063 X ( 0.00 0.00 0.000 X 0.00 0.00 ) X 0.00 Static Head Compensation for "P" P = MAWP + SH P P = = 60.0 + 0.000

60.000

Calculation for Pressure t-min. Pr t = SE-0.6P

= ( 0.154 = = 0.135 0.072

= 18000.000 60.000 17964.000

60.000 36.000

Structural t-min based on M/T and C/A only.

ts

0.072

Inches

Pressure t-min Requirements: t = 0.003 Inches

0.003

Actual Nominal Min Required with C/A

tn API-510 Inspector: API Certified Inspector

0.066 16

Inches

Certification Number:

File Name: 08 - Vessel Min Thickness Evaluation Section: Nozzle-A

DTS Calculation Database (Vessel "t-min")

Page 4 of 6

Diversified Technology Services

2045 Preisker Ln. Suite-A - Santa Maria, CA 93454 - (805) 928-6392 Equipment ID Number: Client: FWKO-111 DTS Client Date: Location: 25-Oct-03 Somewhere USA

Pressure Vessel Calculation Form for Cylindrical Nozzles (B)

Formula: Pr t = SE-0.6P Statistics:

Pressure (MAWP) : Joint Efficiency (E):

Nominal Thickness of Material (Nom) : 60 1.00

Material Allowable Stress (S): Nozzle ID in inches (D) :

0.375 18000 16

Variables: Fluid Level in feet (FL): Specific Gravity (SG):

0.00 0.000

Vessel total height in feet (VH):

Distance from top of Vessel to bottom of Shell Course (DFT):

0.00 0

Corrosion Allow. (CA): Mill Tolerance Percentage (MT):

0.0625 12.5%

Calculations for Variables: Static Head: SH = FL - ( VH - DFT ) X SG SH SH SH SH = = = = 0.00 0.00 0.00 0.000 Calculation for Structural t-min. ts ts 60.0 18000 X 1.000 X 8.000 0.600 X 60.0 ts ts = Nom MT 12.5% 0.063 ) CA 0.063 X ( 0.00 0.00 0.000 X 0.00 0.00 ) X 0.00 Static Head Compensation for "P" P = MAWP + SH P P = = 60.0 + 0.000

60.000

Calculation for Pressure t-min. Pr t = SE-0.6P

= ( 0.375 = = 0.328 0.266

= 18000.000 480.000 17964.000

480.000 36.000

Structural t-min based on M/T and C/A only.

ts

0.266

Inches

Pressure t-min Requirements: t = 0.027 Inches

0.027

Actual Nominal Min Required with C/A

tn API-510 Inspector: API Certified Inspector

0.089 16

Inches

Certification Number:

File Name: 08 - Vessel Min Thickness Evaluation Section: Nozzle-B

DTS Calculation Database (Vessel "t-min")

Page 5 of 6

Diversified Technology Services

2045 Preisker Ln. Suite-A - Santa Maria, CA 93454 - (805) 928-6392 Equipment ID Number: Client: FWKO-111 DTS Client Date: Location: 25-Oct-03 Somewhere USA

Pressure Vessel Calculation Form for Cylindrical Nozzles (C)

Formula: Pr t = SE-0.6P Statistics:

Pressure (MAWP) : Joint Efficiency (E):

Nominal Thickness of Material (Nom) : 60 1.00

Material Allowable Stress (S): Nozzle ID in inches (D) :

0.375 18000 24

Variables: Fluid Level in feet (FL): Specific Gravity (SG):

0.00 0.000

Vessel total height in feet (VH):

Distance from top of Vessel to bottom of Shell Course (DFT):

0.00 0

Corrosion Allow. (CA): Mill Tolerance Percentage (MT):

0.0625 12.5%

Calculations for Variables: Static Head: SH = FL - ( VH - DFT ) X SG SH SH SH SH = = = = 0.00 0.00 0.00 0.000 Calculation for Structural t-min. ts ts 60.0 18000 X 1.000 X 12.000 0.600 X 60.0 ts ts = Nom MT 12.5% 0.063 ) CA 0.063 X ( 0.00 0.00 0.000 X 0.00 0.00 ) X 0.00 Static Head Compensation for "P" P = MAWP + SH P P = = 60.0 + 0.000

60.000

Calculation for Pressure t-min. Pr t = SE-0.6P

= ( 0.375 = = 0.328 0.266

= 18000.000 720.000 17964.000

720.000 36.000

Structural t-min based on M/T and C/A only.

ts

0.266

Inches

Pressure t-min Requirements: t = 0.040 Inches

0.040

Actual Nominal Min Required with C/A

tn API-510 Inspector: API Certified Inspector

0.103 16

Inches

Certification Number:

File Name: 08 - Vessel Min Thickness Evaluation Section: Nozzle-C

DTS Calculation Database (Vessel "t-min")

Page 6 of 6

Вам также может понравиться

- pg0 Us PDFДокумент19 страницpg0 Us PDFMOHAMMAD ASIFОценок пока нет

- Carpenter & Patterson Pipe HangersДокумент164 страницыCarpenter & Patterson Pipe HangersRobert JaszekОценок пока нет

- Pocket UT Brochure 107-07Документ3 страницыPocket UT Brochure 107-07Hanafi BasriОценок пока нет

- Clamp Connectors - Galperti PDFДокумент24 страницыClamp Connectors - Galperti PDFavazcОценок пока нет

- Hydrogen Plant Steam-Hydrocarbon Reformer Glob AleДокумент26 страницHydrogen Plant Steam-Hydrocarbon Reformer Glob AleSalim YilmazОценок пока нет

- Catalogo ISO PDFДокумент129 страницCatalogo ISO PDFavazcОценок пока нет

- Hydrogen Plant Steam-Hydrocarbon Reformer Glob AleДокумент26 страницHydrogen Plant Steam-Hydrocarbon Reformer Glob AleSalim YilmazОценок пока нет

- Scan UT DatasheetДокумент2 страницыScan UT DatasheetavazcОценок пока нет

- Pocket UT Brochure 107-07Документ3 страницыPocket UT Brochure 107-07Hanafi BasriОценок пока нет

- Carbon Steel Pipe and Fittings GuideДокумент10 страницCarbon Steel Pipe and Fittings GuideavazcОценок пока нет

- SMX Clamp BrochureДокумент36 страницSMX Clamp BrochureCjvele81Оценок пока нет

- Condition Monitoring of Pumps With Acoustic Diagnostics PDFДокумент8 страницCondition Monitoring of Pumps With Acoustic Diagnostics PDFavazcОценок пока нет

- Basco Engineered ProductsДокумент12 страницBasco Engineered ProductsavazcОценок пока нет

- SSINA - Designer's Handbook - Stainless Steel FastenersДокумент23 страницыSSINA - Designer's Handbook - Stainless Steel FastenersSerguei DobrinОценок пока нет

- Carbon Steel Pipe and Fittings GuideДокумент10 страницCarbon Steel Pipe and Fittings GuideavazcОценок пока нет

- Santella ManuscriptДокумент7 страницSantella ManuscriptavazcОценок пока нет

- Jfe - Japanese Steel ClassificationДокумент24 страницыJfe - Japanese Steel ClassificationEsteban TraveltoUsa100% (1)

- Iaea Tecdoc 1445Документ114 страницIaea Tecdoc 1445avazcОценок пока нет

- Materials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding FittingsДокумент1 страницаMaterials Comparison DIN / EN / ASTM: Pipes / Tubes Flanges Buttwelding Fittingsnaseema1Оценок пока нет

- Corrosion-resistant clad steel plate sizes and usesДокумент23 страницыCorrosion-resistant clad steel plate sizes and usesavazcОценок пока нет

- Api682 Iso21049 John Crane General CommentsДокумент62 страницыApi682 Iso21049 John Crane General CommentsMixtli Garcia100% (4)

- CADWorx Plant User GuideДокумент655 страницCADWorx Plant User GuideHisbullah Kalanther Lebbe100% (4)

- Head Info 2Документ5 страницHead Info 2avazcОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 50 ML Oil and Water Retort PDFДокумент31 страница50 ML Oil and Water Retort PDFmamanОценок пока нет

- Evaluation of Asphalt Absorption by Mineral AggregatesДокумент21 страницаEvaluation of Asphalt Absorption by Mineral AggregatesProf. Prithvi Singh KandhalОценок пока нет

- Tank Shell DesignДокумент4 страницыTank Shell Designgon972001Оценок пока нет

- Hempel Book MarineДокумент336 страницHempel Book Marineminhnn100% (1)

- Procedures of TestingsДокумент54 страницыProcedures of TestingsSK Emran AliОценок пока нет

- CMATS Exp3Документ6 страницCMATS Exp3Vanessa ValdezОценок пока нет

- BIABacus PR1.3T - Haus Pale Ale (Casc - Mosaic) - Batch 1aДокумент22 страницыBIABacus PR1.3T - Haus Pale Ale (Casc - Mosaic) - Batch 1anghtlghtОценок пока нет

- Transmisores de Nivel FisherДокумент16 страницTransmisores de Nivel Fishercolh_10052789Оценок пока нет

- Process Datasheet for On-Off ValvesДокумент1 страницаProcess Datasheet for On-Off ValvesChakravarthy BharathОценок пока нет

- Solution Manual For Fluid Mechanics For Engineers - David ChinДокумент41 страницаSolution Manual For Fluid Mechanics For Engineers - David ChinAfshar Arabi50% (2)

- Determination of Moisture ContentДокумент21 страницаDetermination of Moisture ContentasadaltafgillОценок пока нет

- D2627 - 08 (2012) Standard Specification For Diacetone Alcohol PDFДокумент2 страницыD2627 - 08 (2012) Standard Specification For Diacetone Alcohol PDFJacques BlueqОценок пока нет

- Methods of Analysis - Oils and FatsДокумент114 страницMethods of Analysis - Oils and Fats09058275% (4)

- Marshall Mix DesignДокумент8 страницMarshall Mix DesignSwapan Deb RayОценок пока нет

- Poettmann Carpenter BHPДокумент5 страницPoettmann Carpenter BHPPablo GnzgaОценок пока нет

- Marshall Mix Design ProcedureДокумент31 страницаMarshall Mix Design Procedurebraackw100% (2)

- D6111Документ5 страницD6111Christina FerreiraОценок пока нет

- C127-15 Standard Test Method For Relative Density (Specific Gravity) and Absorption of Coarse AggregateДокумент5 страницC127-15 Standard Test Method For Relative Density (Specific Gravity) and Absorption of Coarse AggregateAndrea Ley100% (1)

- Specific Gravity Density Ratio GuideДокумент3 страницыSpecific Gravity Density Ratio Guidesushantkadam75Оценок пока нет

- Ammonia Properties and HandlingДокумент25 страницAmmonia Properties and HandlingJohn Harken100% (2)

- Marshall Mix DesignДокумент27 страницMarshall Mix Designzuzu_ismail83% (6)

- Pipesize Documentation Chemeng SoftДокумент34 страницыPipesize Documentation Chemeng SoftvuongОценок пока нет

- Guide Estimates Flaring and Venting Volumes from Oil and Gas FacilitiesДокумент59 страницGuide Estimates Flaring and Venting Volumes from Oil and Gas FacilitiesSakhibОценок пока нет

- Geotech Chapter 3 QuestionДокумент3 страницыGeotech Chapter 3 Questiongautam100% (1)

- GMM PDFДокумент2 страницыGMM PDFWayne ChuОценок пока нет

- Gas Line Sizing GuideДокумент3 страницыGas Line Sizing Guideputrude100% (1)

- DETERMINING SPECIFIC GRAVITY USING U-TUBE MANOMETERДокумент4 страницыDETERMINING SPECIFIC GRAVITY USING U-TUBE MANOMETERrenz espino100% (1)

- TestДокумент104 страницыTestkasvikrajОценок пока нет

- Astm D2726 PDFДокумент4 страницыAstm D2726 PDFEnio Barros (Freemind)Оценок пока нет

- Quality Evaluation of Banana WineДокумент6 страницQuality Evaluation of Banana WineSatish KuchiОценок пока нет