Академический Документы

Профессиональный Документы

Культура Документы

A Redditor's Dilemma

Загружено:

kurelumИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A Redditor's Dilemma

Загружено:

kurelumАвторское право:

Доступные форматы

A Redditors Dilemma

How many Legos, stacked on top of the other, would it take to destroy the bottom brick?

Shortbushero Science_man_29

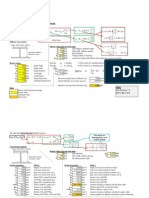

Experimental Setup

15 2x4 yellow Legos were bought from bricklink.com and weighed on an analytical balance and their dimensions measured with calipers without any modification. Three of the Legos were chosen at random and their nubs were removed via a metal file. Compression tests were performed on an Instron 5567 with a 50kN test cell. Acoustic emission tests measured with a Physical Acoustics PCI 2 sensor, with the sensor attached to the front side of the top compression platen.

Experimental Data Dimensions and Mass

Dimensions Length: 31.79 mm Width: 15.77 mm Height (with nubs): 11.41 mm Height (w/o nubs): 9.54 mm Tolerance: 0.01 mm

Mass Highest: 2.2715 g Lowest: 2.2492 g Range: 0.0223 g

Average : 2.2576 g St. Dev : 0.0077 g

Experimental Results - Compression

Compressive Test - 0.1 mm/min

18 16 14 12 10 8 6 4 2 0 0

Stress (MPa)

E2

Plastic deformation region

E1 0.05 0.1 0.15 0.2 Strain (mm/mm) 0.25 0.3 0.35

E1 = 192.997 MPa E2 = 245.973 MPa

y = 15.841 MPa Max. Load = 7942 N

Experimental Results - Compression

Compressive Test - 1.5 mm/min

20 18 16 14 12 10 8 6 4 2 0 0 0.1 0.2 0.3 Strain (mm/mm) 0.4 0.5

Stress (MPa)

E1 = 280.34 MPa E2 = 400.69 MPa

y = 18.363 MPa Max. Load = 9206 N

Experimental Results - Compression

Compressive Test - 2 mm/min

20 18 16 14 12 10 8 6 4 2 0 0 0.1 0.2 0.3 0.4 Strain (mm/mm) 0.5 0.6

Stress (MPa)

E1 = 279.75 MPa E2 = 387.95 MPa

y = 18.45 MPa Max. Load = 9248 N

Experimental Results - Compression

Compressive Test - 3 mm/min

20 18 16 14 12 10 8 6 4 2 0 0 0.1 0.2 Strain (mm/mm) 0.3 0.4

Axis Title

E1 = 257.42 MPa E2 = 348.30 MPa

y = 18.19 MPa Max. Load = 9120 N

Experimental Results - Compression

Compressive Test - 5 mm/min

20 18 16 14 12 10 8 6 4 2 0 0 0.1 0.2 0.3 Strain (mm/mm) 0.4 0.5

Stress (MPa)

E1 = 238.78 MPa E2 = 338.68 MPa

y = 18.92 MPa Max. Load = 9489 N

Experimental Results - Compression

Compressive Test (nubless) - 1 mm/min

20 18 16 14 12 10 8 6 4 2 0 0 0.1 0.2 0.3 0.4 Strain (mm/mm) 0.5 0.6

Stress (MPa)

E1 = 394.14 MPa

y = 18.77 MPa Max. Load = 9410 N

Experimental Results - Compression

Compressive Test (nubless) - 3 mm/min

20 18 16 14 12 10 8 6 4 2 0 0 0.1 0.2 Strain (mm/mm) 0.3 0.4

Stress (MPa)

E1 = 417.44 MPa

y = 19.31 MPa Max. Load = 9679 N

Experimental Results - Compression

Compressive Test (nubless) - 5 mm/min

20 Stress (MPa) 15 10 5 0 0 0.05 0.1 0.15 0.2 Strain (mm/mm) 0.25 0.3 0.35

E1 = 445.01 MPa

y = 20.06 MPa Max. Load = 10058.2 N

Experimental Results Compression with Acoustic Emission

Acoustic Emission - 1 mm/min

70 60 Amplitude of Emission (dB) 20 18 16 14 12 10 8 6 4 2 0 0 80

Stress (MPa)

50 40

30

Elastic to plastic transition.

20 10 0 0.3 0.4

0.1

0.2 Strain (mm/mm)

y = 17.844 MPa Max. Load = 8941 N

Experimental Results Compression with Acoustic Emission

Acoustic Emission - 2 mm/min

20 18 16 14 12 10 8 6 4 2 0 0 0.1 0.2 0.3 Strain (mm/mm) 0.4 0.5 90 80 70 60 50 40 30 20 10 0 Amplitude of Emission (dB)

Stress (MPa)

y = 17.835 MPa Max. Load = 8941 N

Experimental Results A Comparison

Compression Rate vs. Max. Load

10500 10000 Max Load (N) 9500 9000 8500 y = 400.92ln(x) + 8886.2 R = 0.9451

~13% increase!

8000

7500 0 1 2 3 Compression Rate (mm/min) 4

Normal Legos Nubless Legos 5

Experimental Results Qualitative Analysis

Conclusions How many Legos?

Compression Rate 0.1 mm/min 1.0 mm/min 1.5 mm/min 2.0 mm/min Legos 358,602 (1,227) 407,163 (1,393) 415,674 (1,422) 417,582 (1,429) Height (mi) 2.148 (.007) 2.421 (.008) 2.472 (.008) 2.483 (.008)

3.0 mm/min

5.0 mm/min 1.0 mm/min* 3.0 mm/min* 5.0 mm/min*

411,803 (1,409)

428,467 (1,466) 424,903 (1,454) 437,039 (1,495) 454,159 (1,554)

2.449 (.008)

2.547 (.009) 2.527 (.009) 2.599 (.009) 2.701 (.009)**

* - Denotes nubless legos ** - Mt. Everest is 5.49 miles at its tallest height

Conclusions Notable Points

Structural Integrity One can determine the relative density of a Lego given its volume and mass. When done so, Legos have 41.33% the density of acrylonitrile butadiene styrene (ABS), yet they have

17.81% of ABS Youngs modulus 45.95% of ABS yield strength

Conclusions Failure Analysis

Under high load, the weakest points on a Lego are the sidewalls, which bulge outwards. Center, cylindrical supports are not affected

and remain (relatively) unchanged in

comparison to sidewalls. To reinforce Legos, add support beams from center cylinder to outside walls. (See right)

Summary

One can stack upwards of 454,000 Legos on top of one

another until the bottom one breaks.

This result is highly dependant on compression rate, and follows a log scale. Nubless Lego can support ~13% more weight than their normal counterparts. This provides a more realistic answer, as Legos stack platen-on-platen rather than nub-on-nub. Although its high toughness and hardness make it attractive

as use for housing materials, its high thermal conductivity

and high flammability ultimately makes it unsafe.

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Gujarat Technological UniversityДокумент2 страницыGujarat Technological UniversityKing BossОценок пока нет

- Me 2202Документ2 страницыMe 2202pandikalaiОценок пока нет

- BEAM SampleДокумент70 страницBEAM SampleAira Joyce Salazar100% (1)

- Sheet No.2 (Simple Stress)Документ3 страницыSheet No.2 (Simple Stress)elhalawanyh46Оценок пока нет

- PHYS 102 - General Physics II Midterm Exam 1: Duration: 90 Minutes Saturday, 03 March 2018, 10:00Документ3 страницыPHYS 102 - General Physics II Midterm Exam 1: Duration: 90 Minutes Saturday, 03 March 2018, 10:00Nano SuyatnoОценок пока нет

- Electric Charges & Fields: Chapter-1 class-XIIДокумент20 страницElectric Charges & Fields: Chapter-1 class-XIIMohit SahuОценок пока нет

- 9D12102 Theoretical Soil MechanicsДокумент1 страница9D12102 Theoretical Soil MechanicssubbuОценок пока нет

- Experimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoДокумент10 страницExperimental Thermal and Fluid Science: A.L. Neckel, M. GodinhoPett PeeveОценок пока нет

- Effects of Variable-Volume Helmholtz Resonator On Air Mass Flow Rate of Intake Manifold - SpringerLinkДокумент7 страницEffects of Variable-Volume Helmholtz Resonator On Air Mass Flow Rate of Intake Manifold - SpringerLinksunziv19Оценок пока нет

- Wind Tunnel Notes PDFДокумент173 страницыWind Tunnel Notes PDFaeronautical rajasОценок пока нет

- The Origins of Rheology: A Short Histórica! Excursión: Deepak Doráis WantyДокумент1 страницаThe Origins of Rheology: A Short Histórica! Excursión: Deepak Doráis WantyLaura AquinoОценок пока нет

- Creep Behavior of CMC - NASAДокумент20 страницCreep Behavior of CMC - NASAVaradhaYamunan KKОценок пока нет

- B. Equivalent Axial (N) and Lateral (Q) Loads: SD SDДокумент2 страницыB. Equivalent Axial (N) and Lateral (Q) Loads: SD SDRahul Malani100% (1)

- In-situ stress assessment of concrete structures using different techniquesДокумент25 страницIn-situ stress assessment of concrete structures using different techniquesTony VrtonyОценок пока нет

- Solution To Problem 110 Normal Stress - Strength of Materials ReviewДокумент5 страницSolution To Problem 110 Normal Stress - Strength of Materials ReviewNagaraj Muniyandi100% (1)

- Report 16Документ5 страницReport 16M AbdullahОценок пока нет

- MOVERS ACADEMY FIRST QUARTER EXAMДокумент3 страницыMOVERS ACADEMY FIRST QUARTER EXAMRain Vicente100% (1)

- Torsional Response of Assymetric Multy Story Building - ThesisДокумент89 страницTorsional Response of Assymetric Multy Story Building - Thesis폴로 쥰 차Оценок пока нет

- Column New EC2 LastДокумент81 страницаColumn New EC2 LastsuniljayaОценок пока нет

- FEM MidShip Project ReportДокумент21 страницаFEM MidShip Project Reportchiliesweet100% (2)

- GovernorStability, Pressure Rise& Speed RiseДокумент5 страницGovernorStability, Pressure Rise& Speed Risejhaamit4Оценок пока нет

- Hui-Hui Dai and Jibin Li - Solitary Shock Waves and Periodic Shock Waves in A Compressible Mooney-Rivlin Elastic RodДокумент1 страницаHui-Hui Dai and Jibin Li - Solitary Shock Waves and Periodic Shock Waves in A Compressible Mooney-Rivlin Elastic RodArchmcaОценок пока нет

- Open Channel Flow AnalysisДокумент29 страницOpen Channel Flow AnalysisMD. TANVIR ANJUM JIMОценок пока нет

- Sustainability 14 11189 v2 PDFДокумент25 страницSustainability 14 11189 v2 PDFZhiger KurmangalievОценок пока нет

- Elasticity and FlextureДокумент37 страницElasticity and FlextureArif SetiawanОценок пока нет

- Formulacion de Capacidad PortanteДокумент11 страницFormulacion de Capacidad PortanteJhon KenyiОценок пока нет

- Flexural Strength and Deflection Characteristics of High-Strength Concrete Beams With Hybrid FRP and Steel Bar ReinforcementДокумент23 страницыFlexural Strength and Deflection Characteristics of High-Strength Concrete Beams With Hybrid FRP and Steel Bar ReinforcementCu ToànОценок пока нет

- ENGR1003 Finals Week 1Документ40 страницENGR1003 Finals Week 1celinewinchester7Оценок пока нет

- Heat Exchanger DesignДокумент19 страницHeat Exchanger DesignMohawk Chavanant Roongchao100% (2)

- IndexДокумент158 страницIndexAlly TОценок пока нет