Академический Документы

Профессиональный Документы

Культура Документы

VW Passat B5 21 (38) Charge Air System

Загружено:

José Luis OrmeñoИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

VW Passat B5 21 (38) Charge Air System

Загружено:

José Luis OrmeñoАвторское право:

Доступные форматы

21-1

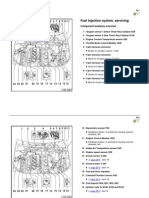

Charge air system

Turbocharger & components, removing and installing

Observe rules for cleanliness Note: All hose connections are secured with clips. Charge air system must be free of leaks. Replace self-locking nuts. Page 21-16 .

21-2

1 - Exhaust manifold 2 - Gasket Note installation position 3 - Seal Always replace 4 - Connection, 30 Nm 5 - From oil filter bracket 6 - Oil supply line Tighten to 25 Nm 7 - From coolant pipe on intake manifold Tighten to 30 Nm 8 - Connection, 35 Nm 9 - Washer 10 - 25 Nm Coat threads with G 052 112 A3

21-3

11 - Hose To Wastegate Bypass Regulator valve N75- Page 21-10 , item 13 12 - Banjo bolt, 25 Nm 13 - To cylinder block 14 - Coolant supply pipe 15 - 10 Nm 16 - Hose To Wastegate Bypass Regulator valve N75- Page 21-10 , item 13 17 - Banjo bolt, 15 Nm 18 - Retainer Between turbocharger and cylinder block 19 - 40 Nm

21-4

20 - From air cleaner 21 - To charge air cooler 22 - 10 Nm 23 - Plug, 15 Nm 24 - Oil return line To oil pan 25 - 10 Nm 26 - Turbocharger Checking charge air pressure regulation Page 21-18 Charge pressure regulator valve and pressure unit are components of the turbocharger and cannot be replaced individually 27 - 25 Nm Coat threads with G 052 112 A3

21-5

28 - Three-Way Catalytic Converter 29 - 35 Nm Always replace Coat threads and bolt head seating surface with G 052 112 A3

21-6

Charge air system cooling components, removing and installing

Note: All hose connections secured by clips. Charge air system must be free of leaks. When installing, note the assembly markings on the hoses and components. 1 - Intake hose 2 - From air cleaner 3 - From EVAP canister 4 - From crankcase breather 5 - To turbocharger 6 - Pressure regulator valve For Positive Crankcase Ventilation valve 7 - Connecting line/hose Note assembly markings

21-7

8 - To throttle valve control module 9 - Connecting pipe/hose Charge air cooler/throttle valve control module Note assembly markings 10 - 10 Nm 11 - Charge air pressure sensor -G31-* Only for engine code ATW Replace O-ring if damaged Checking Page 21-33

12 - Charge air cooler 13 - Air duct 14 - Connecting pipe/hose Cross tube/charge air cooler Note assembly markings

21-8

15 - From turbocharger 16 - Cross tube 17 - Connecting pipe/hose Turbocharger/cross tube Note assembly markings 18 - Vacuum hose/line 19 - Recirculating valve for turbocharger N249Checking 20 - Angle piece Page 21-31

21-9

Charge air system diagram

Engine code AEB 1 - EVAP canister 2 - Vent pipe From gravity valve on fuel tank 2 , Item 5 3 - Check valve For EVAP canister 4 - Turbocharger Charge pressure regulator valve and pressure unit are components of the turbocharger and cannot be replaced individually 5 - Fuel pressure regulator 6 - Intake manifold 7 - Crankcase ventilation Page 20-

21-10

8 - Check valve For EVAP canister 9 - Throttle valve control module 10 - Charge air cooler 11 - Pressure unit For wastegate Integral part of turbocharger; cannot be replaced 12 - Recirculating valve for turbocharger N24913 - Wastegate Bypass Regulator valve -N75The valve will be activated from the Engine Control Module (pulsed) Closed with no current, charge pressure limited Checking activation: Repair Manual, 1.8 Liter 4-Cyl. 5V Turbo Fuel Injection & Ignition, Repair Group 01

21-11

14 - Pressure regulator valve For Positive Crankcase Ventilation 15 - EVAP Canister Purge Regulator valve N80Checking: Repair Manual, 1.8 Liter 4-Cyl. 5V Turbo Fuel Injection & Ignition, Repair Group 01

21-12

Engine code ATW 1 - EVAP canister 2 - Vent pipe From gravity valve on fuel tank 2 , Item 5 3 - Check valve For EVAP canister 4 - Turbocharger Charge pressure regulator valve and pressure unit are components of the turbocharger and cannot be replaced individually 5 - Combination valve For secondary air system Checking Page Page 26-17 Page 20-

6 - Fuel pressure regulator 7 - To brake servo

21-13

8 - Vacuum booster 9 - Vacuum reservoir Secured in wheel housing, front left 10 - Check valve 11 - Check valve 12 - Crankcase ventilation 13 - Secondary Air Injection (AIR) solenoid valve -N112Checking 14 - Check valve For EVAP canister 15 - Recirculating valve for turbocharger N249Checking Page 21-38 Page 26-21

16 - Charge air pressure sensor -G31-* Checking Page 21-33

17 - Charge air cooler

21-14

18 - Throttle valve control module 19 - Intake manifold 20 - Pressure unit For wastegate Integral part of turbocharger; cannot be replaced 21 - Recirculating valve for turbocharger N24922 - Wastegate Bypass Regulator valve -N75) The valve will be activated from the engine control module (pulsed) Closed with no current, charge pressure limited Checking activation: Repair Manual, 1.8 Liter 4-Cyl. 5V Turbo Fuel Injection & Ignition, Repair Group 01 23 - Secondary Air Injection (AIR) pump motor -V101-* Checking function Page 26-19

21-15

24 - Pressure regulator valve For Positive Crankcase Ventilation 25 - EVAP Canister Purge Regulator valve N80Checking: Repair Manual, 1.8 Liter 4-Cyl. 5V Turbo Fuel Injection & Ignition, Repair Group 01

21-16

Rules for cleanliness

When working on the exhaust gas turbocharger, pay careful attention to the following 5 rules: Thoroughly clean all unions and the adjacent areas before disconnecting. Place parts that have been removed on a clean surface and cover. Do not use fluffy cloths! Carefully cover opened components or seal, if the repair cannot be carried out immediately. Only install clean components: Only unpack replacement parts immediately prior to installation. Do not use parts that have been stored loose (e.g. in tool boxes etc.). When the system is open: Do not work with compressed air if this can be avoided. Do not move the vehicle unless absolutely necessary.

21-17

Safety precautions

Observe the following if test and measuring instruments are required during a test drive: Test and measuring instruments must be secured to the rear seat and operated by a 2nd person from this location. CAUTION! If test and measuring instruments are operated from the front passenger's seat and the vehicle is involved in an accident, there is a possibility that the person sitting in this seat may receive serious injuries when the airbag is triggered.

21-18

Charge air pressure regulation, checking

Vehicles with E-Gas system Special tools and equipment V.A.G 1551 Scan Tool or vehicle system tester V.A.G 1552 with cable V.A.G 1551/3 Engine code AEB V.A.G 1397 A Turbocharger tester Checking conditions No leaks on intake and exhaust systems. Engine oil temperature min. 80 Test sequence - Connect V.A.G 1551 (V.A.G 1552). Start engine and select engine electronics control module with "Address word" 01. Repair Manual, 1.8 Liter 4-Cyl. 5V Turbo Fuel Injection & Ignition, Repair Group 01

Rapid data transfer HELP

Page 21-24

Indicated on display

Select function XX

- Press -0- and -8- buttons to select "Read measured value block" and confirm entry with -Q- button.

HELP

Read measured value block Input display group number XXX

Indicated on display

21-19

- Press -1-, -1- and -4- buttons for "Display group number 114" and confirm entry with -Q- button.

Read Measured value block 114 1 2 3 4

Indicated on Display - Check on/off ratio of Wastegate Bypass Regulator valve -N75- during a test drive or on a rolling test stand (at Wide Open Throttle 1800 to 2300 rpm) in display field 4. Specification: 5 to 95 % If the specification is obtained: Page 21-21 (Engine code ATW) Engine code AEB The charge pressure is measured under full load while driving or on a rolling test stand. Test period per measurement = max. 10 seconds. - Disconnect hose between intake manifold and charge pressure bypass valve at intake manifold and connect turbocharger tester V.A.G 1397 A using T piece. - Select measuring range l.

21-20

Note: To operate turbocharger tester see operating instructions. The hoses must be connected so that there is no possibility of leaks. If charge pressure is measured while driving, for safety reasons a second person must operate the turbocharger tester. Ensure that the pressure hose is not trapped between the hood and the body. - Measure charge pressure at Wide Open Throttle. On a rolling test stand Test in 3rd gear (manual transmission), 2nd gear (automatic transmission). During test drive Vehicles with manual transmission

- Accelerate vehicle in 2nd gear at Wide Open Throttle. Vehicles with automatic transmission - Manually select 4th gear range and begin accelerating from low speed at Wide Open Throttle (avoid kickdown; transmission must not shift into a lower gear). - At engine speed of 1800 to 2300 rpm press memory button "M" on turbocharger tester (V.A.G. 1397 A) and read display. Specification: (absolute pressure) 1.350 to 1.750 bar

21-21

Note: If the full charge pressure was not attained, repeat the test. If the charge pressure is exceeded: - Test Wastegate Bypass Regulator valve -N75. Hose from turbocharger via valve to pressure unit not blocked when connector is pulled off - Check that pressure unit for charge pressure regulator valve is securely mounted on turbocharger. - Check pressure unit, Page Page 21-29

- Check charge pressure regulator valve shaft mounting in turbocharger for ease of movement. If corroded together: - Replace turbocharger. If the charge pressure is not attained:

- Replace turbocharger assembly. Engine code ATW - Press -C- button. - Press -0-, -7- and -7- buttons to select "Display group number 77" and confirm entry with -Qbutton.

21-22

Read Measured value block 115 1 2 3 4

Indicated on Display - Check actual charge pressure value at Wide Open Throttle in display group 4. On a rolling test stand Test in 3rd gear (manual transmission), 2nd gear (automatic transmission). During test drive Vehicles with manual transmission - Accelerate vehicle at Wide Open Throttle in 2nd gear. Vehicles with automatic transmission - Manually select 4th gear range and begin accelerating from low speed at Wide Open Throttle (avoid kickdown; transmission must not shift into a lower gear). - Press memory button "M" on turbocharger tester and read display. Specification: (Relative pressure) 1.350 to 1.650 bar - Compare actual charge pressure value with value shown in display field 3. Difference: max. 100 mbar

21-23

Note: Repeat the test if the full charge pressure was not attained or if the difference between the actual value and the displayed value is exceeded. If the charge pressure is exceeded: - Check Charge air pressure sensor -G31Page 21-33 . - Test Wastegate Bypass Regulator valve -N75. Hose from turbocharger via valve to pressure unit not blocked when connector is pulled off - Check pressure unit for charge pressure regulator valve is securely mounted on turbocharger. - Check wastegate bypass regulator valve pressure unit, Page Page 21-29 - Check charge pressure regulator valve shaft mounting in turbocharger for ease of movement.

If corroded together: - Replace turbocharger. If the charge pressure is not attained: - Replace turbocharger.

21-24

Charge pressure regulation, checking (vehicles with E-Gas system)

Special tools and equipment VAG1551 Scan Tool (ST) or VAG1552 mobile scan tool with VAG1551/3 adapter cable. Test requirements No leaks on intake and exhaust side. Engine oil temperature at least 80 C.

21-25

Test sequence - Connect VAG1551 (VAG1552) scan tool. Start engine and select Engine Control Module (ECM) via "address word" 01.

Repair Manual, 1.8 Liter 4-Cyl. 5V Turbo Fuel Injection & Ignition, Engine Code(s) AEB, Repair Group 01; Connecting VAG1551 Scan Tool (ST) and selecting Engine Control Module (ECM).

Rapid data transfer Select function XX HELP

Indicated on display: - Press buttons -0- and -8- to select function "Read measuring value block" and press -Q- button to confirm input.

Read measuring value block Enter display group number XXX

HELP

Indicated on display: - Press buttons -1-, -1- and -4- to select "display group number 114" and press -Q- button to confirm input.

Read measuring value block 114 1234

Indicated on display - During a road test or on a dynamometer (at Wide Open Throttle between 1800 and 2300 RPM), check the duty cycle of Wastegate Bypass Regulator valve in display field 4 Specified value: 5 to 95%

If specified value is obtained: - Press -C- button

21-26

- Press buttons -1-, -1- and -5- to select "display group number 115" and press -Q- button to confirm.

Read measuring value block 115 1234

Indicated on display - Check actual charge pressure value in display field 4 at Wide Open Throttle (WOT): On dynamometer In 3rd gear or in 2nd drive mode While driving Vehicles with manual transmission - Accelerate vehicle in 2nd gear at Wide Open Throttle (WOT). Vehicles with automatic transmission - Manually select (Tiptronic) 4th gear and accelerate vehicle from low speed at Wide Open Throttle (WOT) (without kick down, transmission will not downshift). - Press print button between 1800 and 2300 RPM and read actual charge pressure value in display field 4. Specified value: 1350 to 1750 mbar

- Compare actual charge pressure value to specified value in display field 3. Deviation: max. 100 mbar

21-27

Note: Repeat measurement if the full charge pressure has not yet built up or if the deviation between specified and actual value is too large. If charge pressure is exceeded: - Check Charge air pressure sensor -G31Page 21-33 - Check Wastegate bypass regulator valve -N75-. (throughput in hose from turbocharger via valve to vacuum diaphragm with connector disconnected) - Check vacuum diaphragm for for proper seating at turbocharger. - Check Recirculating valve for turbocharger N249- Page 21-31 . - Check bearing for shaft of charge pressure regulator valve in turbocharger for ease of movement. If rusted solid, replace turbocharger. If lower limit for charge pressure is not met:

- Check Charge air pressure sensor -G31Page 21-33 - Check Wastegate bypass regulator valve N75-. - Check bearing for shaft of charge pressure regulator valve in turbocharger for ease of movement. If rusted solid, replace turbocharger.

21-28

Wastegate Bypass Regulator valve -N75, checking

Special tools and equipment Multimeter V.A.G 1526, V.A.G 1715 or Fluke 83 Adapter set V.A.G 1594 Checking conditions Output Diagnostic Test Mode (DTM) must be performed.

Repair Manual, 1.8 Liter 4-Cyl. 5V Turbo Fuel Injection & Ignition, Repair Group 01 Checking sequence - Switch ignition off. - Disconnector connector from wastegate bypass regulator valve. - Measure resistance between valve contacts.

Specification: 25 to 35 If the specification is not obtained: - Replace Wastegate Bypass Regulator valve -N75-.

21-29

Pressure unit for charge pressure regulator valve, checking

Special tools and equipment V.A.G 1551 Scan Tool or vehicle system tester V.A.G 1552 with cable V.A.G 1551/3 Checking conditions Engine oil temperature min. 80 C Checking sequence - Disconnect connector -2- from Wastegate Bypass Regulator valve N75- -1-.

21-30

- Start engine and raise to maximum rpm briefly using throttle. Operating rod -2- must move. If the operating rod does not move: - Check valve lever -1- for ease of movement. If corroded together: - Replace turbocharger. If the operating rod does not move, even though the lever is free to move: - Test Wastegate Bypass Regulator valve -N75-. Hose from turbocharger via valve to pressure unit not blocked when connector is pulled off If the valve -N75- is OK: - Replace turbocharger Page 21-4 , item 26 .

21-31

Charge pressure bypass valve, checking

Engine code AEB Charge pressure bypass valve, Engine code ATW, Page 21-38 Special tools and equipment V.A.G 1390 Hand vacuum pump Checking conditions Noticeable reduced performance or load change judders Checking sequence Note: The charge pressure bypass valve is located in front of the turbocharger. It is opened by vacuum pressure during the overrun phase and at idling speed. - Connect hand vacuum pump V.A.G 1390 to vacuum connection on valve.

21-32

- Operate hand vacuum pump. Valve must open (arrow). - Operate vent valve on hand vacuum pump. Valve must close (arrow). If valve does not open or close: - Replace charge pressure bypass valve. Note: The charge pressure bypass valve connections are secured with screw-type clips.

21-33

Charge air pressure sensor -G31-, checking

Only for engine code ATW Checking conditions A code has been recognized by the On Board Diagnostic and stored in the Diagnostic Trouble Code (DTC) memory

21-34

Special tools and equipment V.A.G 1526 or Fluke 83 multimeter V.A.G 1594 A Adapter set V.A.G 1598/31 Test box Wiring diagram

21-35

Checking voltage supply and wiring to control module - Switch ignition off. - Disconnect 4-pin connector -2- from Charge air pressure sensor -G31-, -1-.

- Connect multimeter to measure voltage using auxiliary cables from V.A.G 1594 to connector contacts 1 + 3. - Switch ignition on. Specification: min. 4.5 V - Switch ignition off. If the specification is not obtained:

21-36

- Connect test box V.A.G 1598/31 to control module wiring harness (Engine control module remains disconnected).

- Check wiring between test box and connector for open circuit according to wiring diagram. Contact 1 + socket 108 Contact 2 + socket 98 Contact 3 + socket 101 Wire resistance: Max. 1.5 - Additionally check wires for short to one another. If no faulty wiring is detected and voltage was present between contacts 1 + 3: - Check function, Page 21-37 .

21-37

If no faulty wiring is detected and no voltage was present between contacts 1 + 3: - Replace engine control module.

Repair Manual, 1.8 Liter 4-Cyl. 5V Turbo Fuel Injection & Ignition, Repair Group 24 Checking function - Connect test box V.A.G 1598/31 to engine control module wiring harness and to engine control module. - Reconnect connector to Charge air pressure sensor -G31-. - Connect multimeter to sockets 101 and 108. - Start engine and measure basic voltage. Specification: 1.80 to 2.00 V - Raise engine revs by pressing accelerator to: Specification: 2.00 to 3.00 V If the specifications are not attained: - Replace Charge air pressure sensor -G31-.

21-38

Recirculating valve for turbocharger N249-, checking

Only for engine code ATW The valve in the hose between the intake manifold and the recirculating valve is open if it is without current. The hose to the vacuum reservoir is closed. Checking conditions Output Diagnostic Test Mode (DTM) must be performed.

Repair Manual, 1.8 Liter 4-Cyl. 5V Turbo Fuel Injection & Ignition, Repair Group 01 Checking sequence - Switch off ignition. - Disconnect connector from Recirculating valve for turbocharger -N249-. - Measure resistance between valve contacts.

Specification: 25 to 35 If the specification is not obtained: - Replace Recirculating valve for turbocharger -N249-.

Вам также может понравиться

- Service Manual FORD Everest 2001-2007Документ1 118 страницService Manual FORD Everest 2001-2007โจ้ สแปร์แร็ค100% (15)

- Repair ABS Unit PassatДокумент13 страницRepair ABS Unit Passatbars_winner100% (3)

- 01 - Om200 - Operation & Maintenance Manual BX50Документ147 страниц01 - Om200 - Operation & Maintenance Manual BX50Alejandro Maya50% (4)

- Ford Fault CodesДокумент272 страницыFord Fault CodesAriez Zacky Hermawan67% (3)

- Passat Fuse and Relay LocationsДокумент10 страницPassat Fuse and Relay Locationsgosa46100% (3)

- b5 Vacuum Hose Diagram - PassatДокумент3 страницыb5 Vacuum Hose Diagram - Passatjackass_tОценок пока нет

- Spare Parts CaterpillarДокумент122 страницыSpare Parts CaterpillarAyuat Fathy100% (5)

- 2013 Catalog # FLSC240P-SO Updated Date: August 15, 2013 Expiry Date: December 30, 2013Документ7 страниц2013 Catalog # FLSC240P-SO Updated Date: August 15, 2013 Expiry Date: December 30, 2013Ashraf MostafaОценок пока нет

- Honda HR194 Owners ManualДокумент45 страницHonda HR194 Owners ManualBradford Mc MullinОценок пока нет

- Volkswagen Passat B5 VCDS InfoДокумент3 страницыVolkswagen Passat B5 VCDS InfoAnthony Yao Hama100% (2)

- Mercedes Catalog SparepartДокумент94 страницыMercedes Catalog SparepartAndryana SusiloОценок пока нет

- Volkswagen Passat B5 Work ProceduresДокумент182 страницыVolkswagen Passat B5 Work ProceduresJurek Ogórek100% (1)

- Manual Climatronic b5Документ61 страницаManual Climatronic b5Muraru Dan91% (11)

- b5 Rear Drive ShaftДокумент11 страницb5 Rear Drive ShaftTanee BoonmalertОценок пока нет

- 3TNV88F-EPHB ZX35U-5A 0CD11-M16303 - enДокумент26 страниц3TNV88F-EPHB ZX35U-5A 0CD11-M16303 - enjavier muñozОценок пока нет

- VW Passat B5 ATF Fluid & Filter ChangeДокумент6 страницVW Passat B5 ATF Fluid & Filter ChangeJosé Luis Ormeño100% (3)

- VW Passat B5 ATF Fluid & Filter ChangeДокумент6 страницVW Passat B5 ATF Fluid & Filter ChangeJosé Luis Ormeño100% (3)

- VW Passat B5 1998 System Wiring Diagrams, Schematy by - Chytry - KlechaДокумент74 страницыVW Passat B5 1998 System Wiring Diagrams, Schematy by - Chytry - KlechaJosé Luis Ormeño100% (1)

- VW Passat B6 parking brake components overview under 40 charsДокумент7 страницVW Passat B6 parking brake components overview under 40 charsPopa MihaiОценок пока нет

- Schema Electrica VW PassatДокумент160 страницSchema Electrica VW Passatonuta780% (5)

- Climatronic Self DiagnosticsДокумент7 страницClimatronic Self Diagnosticsmuath007100% (2)

- 1 Mitsubishi Lancer Evo IX.Документ1 000 страниц1 Mitsubishi Lancer Evo IX.seregap84100% (2)

- VW Passat B5 24 Fuel Injection Sys, ServicingДокумент126 страницVW Passat B5 24 Fuel Injection Sys, ServicingJosé Luis Ormeño100% (5)

- VW Passat B5 57-32 Central LockingДокумент10 страницVW Passat B5 57-32 Central LockingJosé Luis Ormeño100% (2)

- VW Passat B5 57-32 Central LockingДокумент10 страницVW Passat B5 57-32 Central LockingJosé Luis Ormeño100% (2)

- VW Passat B5 Ignition Servicing (SERVICE)Документ28 страницVW Passat B5 Ignition Servicing (SERVICE)José Luis Ormeño100% (2)

- VW Passat B5 Ignition Servicing (SERVICE)Документ28 страницVW Passat B5 Ignition Servicing (SERVICE)José Luis Ormeño100% (2)

- b6 42 EngДокумент159 страницb6 42 EngepicenterrulezОценок пока нет

- Tricks & TipsДокумент68 страницTricks & TipsEngine Tuning UpОценок пока нет

- Subaru Ea81 GL 1983Документ14 страницSubaru Ea81 GL 1983David Emmanuel Turcios CarrilloОценок пока нет

- VW Passat B5 87-132 AC Refrigerant SysДокумент9 страницVW Passat B5 87-132 AC Refrigerant SysJosé Luis Ormeño100% (1)

- VW Passat B5.5 Service Light Reset ProceedureДокумент1 страницаVW Passat B5.5 Service Light Reset ProceedureJosé Luis Ormeño100% (1)

- VW Passat B5.5 Service Light Reset ProceedureДокумент1 страницаVW Passat B5.5 Service Light Reset ProceedureJosé Luis Ormeño100% (1)

- Secondary Air System ComponentsДокумент24 страницыSecondary Air System ComponentsNPОценок пока нет

- VW Passat b5 70-1 Instrument PanelДокумент13 страницVW Passat b5 70-1 Instrument PanelJosé Luis Ormeño75% (4)

- VW Passat b5 70-1 Instrument PanelДокумент13 страницVW Passat b5 70-1 Instrument PanelJosé Luis Ormeño75% (4)

- b5 45-06Документ15 страницb5 45-06Tanee BoonmalertОценок пока нет

- VW Passat b5 Door Lock Mechanism RepairДокумент8 страницVW Passat b5 Door Lock Mechanism RepairJosé Luis Ormeño67% (3)

- VW Passat b5 Door Lock Mechanism RepairДокумент8 страницVW Passat b5 Door Lock Mechanism RepairJosé Luis Ormeño67% (3)

- C - ECU Pinout - Toyota - Land Crusier 5vz-Fe (6 Cylinder - 1 Coil Control 2 Ignition Point) - 5vz-3rz-Right Manual For Lahore Landcruiser 5vz-1998Документ4 страницыC - ECU Pinout - Toyota - Land Crusier 5vz-Fe (6 Cylinder - 1 Coil Control 2 Ignition Point) - 5vz-3rz-Right Manual For Lahore Landcruiser 5vz-1998Boomer Boomer100% (1)

- BMW USB Retrofit 1Документ20 страницBMW USB Retrofit 1Andre SoetadjiОценок пока нет

- SSP 191 - VW Passat B5 '97 - Construction & OperationДокумент47 страницSSP 191 - VW Passat B5 '97 - Construction & OperationaleuzevaxОценок пока нет

- Maintaining Micro Pilot InjectorsДокумент40 страницMaintaining Micro Pilot InjectorsPeteОценок пока нет

- Audi AC Control UnitДокумент19 страницAudi AC Control Unitredmouse10Оценок пока нет

- VW Passat B5 42-1 Rear Axle, FFДокумент19 страницVW Passat B5 42-1 Rear Axle, FFJosé Luis Ormeño100% (1)

- BMW CD Changer E60Документ14 страницBMW CD Changer E60MOHSINОценок пока нет

- A4 B8 Stereo RemovalДокумент7 страницA4 B8 Stereo RemovalMickyman123Оценок пока нет

- 17 Engine and Emission ControlДокумент38 страниц17 Engine and Emission ControlJoaoBorgesОценок пока нет

- 182 - Audi A3Документ57 страниц182 - Audi A3Kaloyan Marinov100% (4)

- VW Climatronic Codes Service EngДокумент24 страницыVW Climatronic Codes Service Engmegatron_vf50% (2)

- D65ex-16 SN81402 UpДокумент1 498 страницD65ex-16 SN81402 UpVictor Villarroel Vargas Micky100% (1)

- VW Golf 4 Secondary Air Injection System - Engines: Aeg Avh AzgДокумент22 страницыVW Golf 4 Secondary Air Injection System - Engines: Aeg Avh AzgNPОценок пока нет

- VW Passat B5 58-1 Rear DoorДокумент26 страницVW Passat B5 58-1 Rear DoorJosé Luis Ormeño100% (2)

- Manual Skoda Octavia 1,9 81 KWДокумент18 страницManual Skoda Octavia 1,9 81 KWCornea Horatiu SebastianОценок пока нет

- Lister Petter LT-LV Parts ManualДокумент126 страницLister Petter LT-LV Parts ManualLicínio Dâmaso100% (1)

- VW Passat B5 69-28 AirbagДокумент40 страницVW Passat B5 69-28 AirbagJosé Luis Ormeño67% (3)

- DIY Heated Seats RetrofitДокумент27 страницDIY Heated Seats RetrofitvalymadОценок пока нет

- SBT Electrical Distribution Centre - E87, E90, E91, E92Документ2 страницыSBT Electrical Distribution Centre - E87, E90, E91, E92Engsolution LdaОценок пока нет

- Running Gear SystemДокумент35 страницRunning Gear SystemMohammed Bin Jafarullah100% (2)

- Omegas Plus: Software ManualДокумент40 страницOmegas Plus: Software ManualВіктор ЛялькаОценок пока нет

- BMW OBC ManualДокумент13 страницBMW OBC ManualblutinkerОценок пока нет

- VW Passat B5 48-15 Steering ColumnДокумент23 страницыVW Passat B5 48-15 Steering ColumnAleksandar Kovačević100% (1)

- Removing and Installing Mechatronic Unit For Dual Clutch Gearbox - J743Документ93 страницыRemoving and Installing Mechatronic Unit For Dual Clutch Gearbox - J743Sandro CozaciucОценок пока нет

- Cutie LUPO 3L GrundjusteringДокумент5 страницCutie LUPO 3L GrundjusteringCoso GarajОценок пока нет

- BMW E23 24 28 OdogearДокумент9 страницBMW E23 24 28 OdogearporkfaceОценок пока нет

- Mercedes COMAND DiagnosticДокумент16 страницMercedes COMAND DiagnosticDongwoo KwakОценок пока нет

- VW Passat B5 Secondary Air Injection, Engine Aug AwmДокумент14 страницVW Passat B5 Secondary Air Injection, Engine Aug AwmNPОценок пока нет

- Checking Turbocharger Charge PressureДокумент17 страницChecking Turbocharger Charge Pressurejromero_rpgОценок пока нет

- Aaz 1z Ahu Turbocharger SystДокумент39 страницAaz 1z Ahu Turbocharger Systboschit100% (1)

- Fuel Supply System Components: Screw, Spring or Clamp-Type ClipsДокумент39 страницFuel Supply System Components: Screw, Spring or Clamp-Type Clipsifu62319Оценок пока нет

- g3 Air System AbaДокумент15 страницg3 Air System Aba08088338Оценок пока нет

- VW Golf 3 Secondary Air Injection (AIR) System Engine AaaДокумент18 страницVW Golf 3 Secondary Air Injection (AIR) System Engine AaaNPОценок пока нет

- Diesel Turbo Direct Injection (TDI) system servicing overviewДокумент149 страницDiesel Turbo Direct Injection (TDI) system servicing overviewuriiiОценок пока нет

- Toyota - Paseo - Workshop Manual - 1990 - 1991Документ3 179 страницToyota - Paseo - Workshop Manual - 1990 - 1991cginternet.ofcОценок пока нет

- Manual Pajero 4x4 Intake and ExhaustДокумент20 страницManual Pajero 4x4 Intake and ExhaustGIAN CARLO MAMANI GILES.Оценок пока нет

- 1z Ahu Diesel Tdi ServicingДокумент149 страниц1z Ahu Diesel Tdi ServicingAleksandar VeberovicОценок пока нет

- 14sPACE WAGONДокумент20 страниц14sPACE WAGONrafaelcruzgjaОценок пока нет

- PG Si 0039 en WebДокумент2 страницыPG Si 0039 en Webb82monicaОценок пока нет

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- VW Passat B5 Aeb - Timing - BeltДокумент3 страницыVW Passat B5 Aeb - Timing - BeltJosé Luis Ormeño100% (1)

- VW Passat B5 70-14 Door TrimДокумент13 страницVW Passat B5 70-14 Door TrimJosé Luis Ormeño100% (1)

- VW Passat B5 69-28 AirbagДокумент40 страницVW Passat B5 69-28 AirbagJosé Luis Ormeño67% (3)

- VW Passat B5 48-15 Steering ColumnДокумент23 страницыVW Passat B5 48-15 Steering ColumnAleksandar Kovačević100% (1)

- Piston Ring TypesДокумент4 страницыPiston Ring TypesramanaОценок пока нет

- Valvoline Premium Blue Classic (Spanish)Документ2 страницыValvoline Premium Blue Classic (Spanish)Juan Carlos Gaytan LopezОценок пока нет

- Yamaha Mio Checking The Engine Oil LevelДокумент1 страницаYamaha Mio Checking The Engine Oil Levelmotley crewzОценок пока нет

- U1. Internal Combustion Engine Valves and Valve TrainДокумент9 страницU1. Internal Combustion Engine Valves and Valve Trainnicu oprisanОценок пока нет

- Parts Manual: C4.4 Industrial EngineДокумент296 страницParts Manual: C4.4 Industrial Enginenerit0loco83100% (1)

- Important Information: Operator's Manual DC9 EMS With S6/PDE Industrial EngineДокумент60 страницImportant Information: Operator's Manual DC9 EMS With S6/PDE Industrial Enginemmmm100% (1)

- Hydraulic Pump - Wikipedia, The Free EncyclopediaДокумент5 страницHydraulic Pump - Wikipedia, The Free EncyclopediaAakash ChatakeОценок пока нет

- Mio Amore - Engine Oil and Oil StrainerДокумент1 страницаMio Amore - Engine Oil and Oil Strainermotley crewzОценок пока нет

- Remi Obd CodesДокумент8 страницRemi Obd CodesSonny RaymundoОценок пока нет

- Mechanic Dictionary WordsДокумент44 страницыMechanic Dictionary WordsErfan.TОценок пока нет

- SI Engine Combustion StagesДокумент4 страницыSI Engine Combustion Stagesmailsk123Оценок пока нет

- BHEL PresentationДокумент16 страницBHEL Presentationsushant47Оценок пока нет

- Manual Partes BAIFAДокумент178 страницManual Partes BAIFAadenyrОценок пока нет

- Engine Maintenance and Diagnosis Tune-Up: 1.1 Objective of The TrainingДокумент5 страницEngine Maintenance and Diagnosis Tune-Up: 1.1 Objective of The TrainingGetachew TikueОценок пока нет

- Daihatsu - 5DK-20 - Instruction Manual Aux. Engine DK-20 (Operation)Документ114 страницDaihatsu - 5DK-20 - Instruction Manual Aux. Engine DK-20 (Operation)andriy.b1979Оценок пока нет

- Yz250f 2014Документ61 страницаYz250f 2014Adrian DiezОценок пока нет