Академический Документы

Профессиональный Документы

Культура Документы

PVC Pipe (SCH.40, SCH.80, and SCH.120) Condensed

Загружено:

Ahmed ZakiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PVC Pipe (SCH.40, SCH.80, and SCH.120) Condensed

Загружено:

Ahmed ZakiАвторское право:

Доступные форматы

CONDENSED CATALOG

CLE AR

PVC Pipe

PVC SCHEDULE 40

Nominal Pipe Size (in.) 1/8 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4 5 6 8 10 12 14 16 18 20 24 O.D. .405 .540 .675 .840 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500 5.563 6.625 8.625 10.750 12.750 14.000 16.000 18.000 20.000 24.000 Average I.D. .261 .354 .483 .608 .810 1.033 1.364 1.592 2.049 2.445 3.042 3.520 3.998 5.017 6.031 7.943 9.976 11.890 13.072 14.940 16.809 18.743 22.544 Min. Wall .068 .088 .091 .109 .113 .133 .140 .145 .154 .203 .216 .226 .237 .258 .280 .322 .365 .406 .437 .500 .562 .593 .687 Nominal Wt./ft. .045 .081 .109 .161 .214 .315 .426 .509 .682 1.076 1.409 1.697 2.006 2.726 3.535 5.305 7.532 9.949 11.810 15.416 20.112 23.624 32.873

HPB-103-A Effective 9/1/97 Revised 6/1/99

PVC SCHEDULE 40

O.D. .540 .675 .840 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500 6.625 6.625 8.625 Average I.D. .354 .483 .608 .810 1.033 1.364 1.592 2.049 2.445 3.042 3.520 3.998 6.031 6.355 7.943 Min. Wall .088 .091 .109 .113 .133 .140 .145 .154 .203 .216 .226 .237 .280 .125 .322 Nominal Wt./ft. .081 .109 .161 .214 .315 .426 .509 .682 1.076 1.409 1.697 2.006 3.535 1.647 5.305

Nominal Pipe Size (in.) 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4 6 6x1/8 8

Max. W.P. PSI 390 310 300 240 220 180 170 140 150 130 120 110 90 45 80

Max. W.P. PSI

810 780 620 600 480 450 370 330 280 300 260 240 220 190 180 160 140 130 130 130 130 120 120

CLE

AR

PVC SCHEDULE 80

O.D. .540 .675 .840 1.050 1.315 1.660 1.900 2.375 3.500 4.500 Average I.D. .288 .407 .528 .724 .935 1.256 1.476 1.913 2.864 3.786 Min. Wall .119 .126 .147 .154 .179 .191 .200 .218 .300 .337 Nominal Wt./ft. .100 .138 .202 .273 .402 .554 .673 .932 1.903 2.782

Nominal Pipe Size (in.) 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 3 4

Max. W.P. PSI 570 460 420 340 320 260 240 200 190 160

PVC SCHEDULE 80

Nominal Pipe Size (in.) 1/8 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4 5 6 8 10 12 14 16 18 20 24 O.D. .405 .540 .675 .840 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500 5.563 6.625 8.625 10.750 12.750 14.000 16.000 18.000 20.000 24.000 Average I.D. .203 .288 .407 .528 .724 .935 1.256 1.476 1.913 2.289 2.864 3.326 3.786 4.767 5.709 7.565 9.492 11.294 12.410 14.214 16.014 17.814 21.418 Min. Wall .095 .119 .126 .147 .154 .179 .191 .200 .218 .276 .300 .318 .337 .375 .432 .500 .593 .687 .750 .843 .937 1.031 1.218 Nominal Wt./ft. .058 .100 .138 .202 .273 .402 .554 .673 .932 1.419 1.903 2.322 2.782 3.867 5.313 8.058 11.956 16.437 19.790 25.430 31.830 40.091 56.882

PVC SDR 13.5

Nominal Pipe Size (in.) 1/2 O.D. .840

W.P. 315 PSI (Water @ 73.4F.)

Min. Wall .062 Nominal Wt./ft. .104

Average I.D. .696

PVC SDR 21

Nominal Pipe Size (in.) 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4 5 6 8 O.D. 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500 5.563 6.625 8.625

W.P. 200 PSI (Water @ 73.4F)

Average I.D. .910 1.169 1.482 1.700 2.129 2.581 3.146 3.596 4.046 5.001 5.955 7.755 Min. Wall .060 .063 .079 .090 .113 .137 .167 .190 .214 .265 .316 .410 Nominal Wt./ft. .129 .170 .263 .339 .521 .754 1.106 1.443 1.825 2.792 3.964 6.679

Max. W.P. PSI 1230 1130 920 850 690 630 520 470 400 420 370 350 320 290 280 250 230 230 220 220 220 220 210

For water at 73.4F with solvent-cemented joints. Threading recommended for Schedules 80 and 120 only. Threaded pipe requires a 50% pressure de-rating. NOTES: Complete range of PVC fittings in Schedules 40 and 80 as well as valves are stocked. Standard color is gray unless otherwise noted. Bell, Gasket, and Roll Grooved Pipe is available in Schedules 40, 80, 120 and SDR's 21, 26, and 41. All PVC pipe is produced from compounds which conform to and are specified in ASTM D1784. Schedules 40, 80, and 120 PVC Pipe are manufactured in strict compliance with ASTM Standard D-1785. Pressure-Rated (SDR Series) PVC Pipe is manufactured in strict compliance with ASTM D2241. All PVC piping is manufactured from NSF-Approved compounds and are NSF-Listed for potable water use. ASTM D1784 Material Classification Equivalents: PVC Normal Impact = Type I Grade I = PVC 1120 = Cell Classification 12454-B Custom sizes, lengths and colors are available; contact factory for details.

PVC SCHEDULE 120

Nominal Pipe Size (in.) 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4 6 O.D. .840 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.500 6.625 Average I.D. .480 .690 .891 1.204 1.423 1.845 2.239 2.758 3.572 5.434 Min. Wall .170 .170 .200 .215 .225 .250 .300 .350 .437 .562 Nominal Wt./ft. .223 .295 .440 .614 .744 1.052 1.529 2.184 3.516 6.759

PVC SDR 26

Nominal Pipe Size (in.) 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4 5 6 8 10 12 14 16 18 20 24 O.D. 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500 5.563 6.625 8.625 10.750 12.750 14.000 16.000 18.000 20.000 24.000

W.P. 160 PSI (Water @ 73.4F)

Average I.D. 1.175 1.512 1.734 2.173 2.635 3.210 3.672 4.134 5.109 6.085 7.921 9.874 11.710 12.860 14.696 16.534 18.370 22.043 Min. Wall .060 .064 .073 .091 .110 .135 .154 .173 .214 .255 .332 .413 .490 .538 .615 .692 .769 .923 Nominal Wt./ft. .164 .221 .284 .432 .622 .915 1.183 1.494 2.288 3.228 5.468 8.492 11.956 14.430 18.810 23.860 29.470 42.520

Max. W.P. PSI

1010 770 720 600 540 470 470 440 430 370

PVC SDR 41

Nominal Pipe Size (in.) 18 20 24 O.D. 18.000 20.000 24.000

W.P. 100 PSI (Water @ 73.4F)

Average I.D. 17.070 18.970 22.748 Min. Wall .439 .488 .585 Nominal Wt./ft. 15.370 18.920 27.320

Product Specifications PVC Industrial Pipe: Schedule 40

Application:

Corrosion resistant pressure pipe, IPS sizes 1/8" through 24", for use at temperatures up to and including 140F. Pressure rating (120 psi to 810 psi) varies with schedule, pipe size, and temperature as stated in Harvel Plastics, Inc. engineering bulletin (Product Bulletin 112/401). Pipe is also suitable for PVC plastic drain, waste, and vent (DWV) applications. Generally resistant to most acids, bases, salts, aliphatic solutions, oxidants, and halogens. Chemical resistance data is available and should be referenced for proper material selection. Pipe exhibits excellent physical properties and flammability characteristics (independently tested flame and smoke characteristics-ULC). Typical applications include: chemical processing, plating, high purity applications, potable water systems, water and wastewater treatment, drainage, irrigation, agricultural, and other applications involving corrosive fluid transfer.

PVC Schedule 40 Pipe Product Specifications

Scope:

This specification outlines minimum manufacturing requirements for Polyvinyl Chloride (PVC) Schedule 40 iron pipe size (IPS) pressure pipe. This pipe is intended for use in applications where the fluid conveyed does not exceed 140F. This pipe meets and or exceeds the industry standards and requirements as set forth by the American Society for Testing and Materials (ASTM D1785 & D2665) and the National Sanitation Foundation (NSF International STD 61 & Std 14).

PVC Materials:

The material used in the manufacture of the pipe shall be domestically produced rigid polyvinyl chloride (PVC) compound, Type I Grade I, with a Cell Classification of 12454 as defined in ASTM D1784, trade name designation H707 PVC. This compound shall be white or gray in color as specified, and shall be approved by NSF International for use with potable water (NSF Std 61).

Dimensions:

All sizes of PVC Schedule 40 pipe shall be manufactured in strict accordance to the requirements of ASTM D1785 for physical dimensions and tolerances. PVC Sch 40 pipe sizes 11/4" through 24" diameters shall also meet the requirements of ASTM D2665 Standard Specification for PVC plastic drain, waste and vent (DWV) pipe and shall be dual marked as such. Each production run of pipe manufactured in compliance to the standard, shall also meet or exceed the test requirements for materials, workmanship, burst pressure, flattening, and extrusion quality defined in ASTM D1785 and ASTM D2665 as applicable. All belled-end pipe shall have tapered sockets to create an interference-type fit, which meet or exceed the dimensional requirements and the minimum socket length for pressure-type sockets as defined in ASTM D2672. All PVC Schedule 40 pipe must also meet the requirements of NSF Standard 14 and CSA Standard B137.3 rigid PVC pipe for pressure applications, and shall bear the mark of these Listing agencies. This pipe shall have a flame spread rating of 0-25 when tested for surface burning characteristics in accordance with CAN/ULC-S102-2-M88 or equivalent.

Marking:

Product marking shall meet the requirements of ASTM D1785 and ASTM D2665 as applicable and shall include: the manufacturers name (or the manufacturers trademark when privately labeled); the nominal pipe size; the material designation code; the pipe schedule and pressure rating in psi for water @ 73F; the ASTM designation D1785; the ASTM designation D2665 (when dual marked); the independent laboratorys seal of approval for potable water usage; and the date and time of manufacture.

Sample Specification:

All PVC Schedule 40 pipe shall be manufactured from a Type I, Grade I Polyvinyl Chloride (PVC) compound with a Cell Classification of 12454 per ASTM D1784. The pipe shall be manufactured in strict compliance to ASTM D1785 and D2665 (where applicable), consistently meeting and/or exceeding the Quality Assurance test requirements of these standards with regard to material, workmanship, burst pressure, flattening, and extrusion quality. The pipe shall be manufactured in the USA, using domestic materials, by an ISO 9001 certified manufacturer. Standard lengths of pipe sizes 6" and larger shall be beveled each end by the pipe manufacturer. All pipe shall be stored indoors after production at the manufacturing site until shipped from factory. This pipe shall carry the National Sanitation Foundation (NSF) seal of approval for potable water applications. All pipe shall be manufactured by HARVEL PLASTICS, INC.

Product Specifications PVC Industrial Pipe: Schedule 40

Schedule 40 Dimensions

Nom. Pipe Size (in.) 1/8 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4 5 6 8 10 12 14 16 18 20 24 O.D. 0.405 0.540 0.675 0.840 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500 5.563 6.625 8.625 10.750 12.750 14.000 16.000 18.000 20.000 24.000 Average I.D. 0.249 0.344 0.473 0.602 0.804 1.029 1.360 1.590 2.047 2.445 3.042 3.521 3.998 5.016 6.031 7.942 9.976 11.889 13.073 14.940 16.809 18.743 22.544 Min. Wall 0.068 0.088 0.091 0.109 0.113 0.133 0.140 0.145 0.154 0.203 0.216 0.226 0.237 0.258 0.280 0.322 0.365 0.406 0.437 0.500 0.562 0.593 0.687 Nom. Wt./Ft. 0.051 0.086 0.115 0.170 0.226 0.333 0.450 0.537 0.720 1.136 1.488 1.789 2.118 2.874 3.733 5.619 7.966 10.534 12.462 16.286 20.587 24.183 33.652 Max. W.P. 810 780 620 600 480 450 370 330 280 300 260 240 220 190 180 160 140 130 130 130 130 120 120

The pressure ratings given are for water, non-shock, @ 73F. The following temperature de-rating factors are to be applied to the working pressure ratings (WP) listed when operating at elevated temperatures. Multiply the working pressure rating of the selected pipe at 73F, by the appropriate de-rating factor to determine the maximum working pressure rating of the pipe at the elevated temperature chosen. EX: 10" PVC SCH 40 @ 120F = ? 140 psi x 0.40 = 56 psi max. @ 120F

De-Rating Factor

Operating Temp (F) 73 80 90 100 110 120 130 140 De-Rating Factor 1.00 0.88 0.75 0.62 0.51 0.40 0.31 0.22

* * * * * * * * * * * * * *

PVC Schedule 40 Pipe

THE MAXIMUM SERVICE TEMPERATURE FOR PVC IS 140F. Solvent-cemented joints should be utilized when working at or near maximum temperatures. Harvel Plastics does not recommend the use of PVC for threaded connections at temperatures above 110F; use flanged joints, unions, or roll grooved couplings where disassembly is necessary at elevated temperatures. Threading of Schedule 40 PVC pipe is not a recommended practice due to insufficient wall thickness. Thread only Schedule 80 or heavier walls. Threading requires a 50% reduction in pressure rating stated for plain end pipe @ 73F. Chemical resistance data should be referenced for proper material selection and possible de-rating when working with fluids other than water. Refer to Harvel Plastics 112/401 Product Bulletin for chemical resistance, installation data, and additional information. ASTM STANDARD D1784 MATERIAL EQUIVALENTS: Cell Classification 12454 = PVC Type I Grade I = PVC1120 Pipe sizes shown are manufactured in strict compliance with ASTM D1785 and ASTM D2665 where applicable.

Product Specifications

* Denotes these sizes are dual marked as being in compliance with both ASTM D1785 (pressure pipe) and ASTM D2665 (drain, waste & vent pipe- DWV).

Product Specifications PVC Industrial Pipe: Schedule 80

Application:

Corrosion resistant pressure pipe, IPS sizes 1/8" through 24", for use at temperatures up to and including 140F. Pressure rating (210 psi to 1230 psi) varies with schedule, pipe size, and temperature as stated in Harvel Plastics, Inc. engineering bulletin (Product Bulletin 112/401). Generally resistant to most acids, bases, salts, aliphatic solutions, oxidants, and halogens. Chemical resistance data is available and should be referenced for proper material selection. Pipe exhibits excellent physical properties and flammability characteristics (independently tested flame and smoke characteristics-ULC). Typical applications include: chemical processing, plating, high purity applications, potable water systems, water and wastewater treatment, irrigation, agricultural, and other industrial applications involving corrosive fluid transfer.

PVC Schedule 80 Pipe Product Specifications

Scope:

This specification outlines minimum manufacturing requirements for Polyvinyl Chloride (PVC) Schedule 80 iron pipe size (IPS) pressure pipe. This pipe is intended for use in applications where the fluid conveyed does not exceed 140F. This pipe meets and or exceeds the industry standards and requirements as set forth by the American Society for Testing and Materials (ASTM) and the National Sanitation Foundation (NSF International).

PVC Materials:

The material used in the manufacture of the pipe shall be domestically produced rigid polyvinyl chloride (PVC) compound, Type I Grade I, with a Cell Classification of 12454 as defined in ASTM D1784, trade name designation H707 PVC. This compound shall be gray in color as specified, and shall be approved by NSF International for use with potable water (NSF Std 61).

Dimensions:

PVC Schedule 80 pipe shall be manufactured in strict accordance to the requirements of ASTM D1785 for physical dimensions and tolerances. Each production run of pipe manufactured in compliance to this standard, shall also meet or exceed the test requirements for materials, workmanship, burst pressure, flattening, and extrusion quality defined in ASTM D1785. All belled-end pipe shall have tapered sockets to create an interference-type fit, which meet or exceed the dimensional requirements and the minimum socket length for pressure-type sockets as defined in ASTM D2672. All PVC Schedule 80 pipe must also meet the requirements of NSF Standard 14 and CSA Standard B137.3 rigid PVC pipe for pressure applications, and shall bear the mark of these Listing agencies. This pipe shall have a flame spread rating of 0-25 when tested for surface burning characteristics in accordance with CAN/ULC-S102-2-M88 or equivalent.

Marking:

Product marking shall meet the requirements of ASTM D1785 and shall include: the manufacturers name (or the manufacturers trademark when privately labeled); the nominal pipe size; the material designation code; the pipe schedule and pressure rating in psi for water @ 73F; the ASTM designation D1785; the independent laboratorys seal of approval for potable water usage; and the date and time of manufacture.

Sample Specification:

All PVC Schedule 80 pipe shall be manufactured from a Type I, Grade I Polyvinyl Chloride (PVC) compound with a Cell Classification of 12454 per ASTM D1784. The pipe shall be manufactured in strict compliance to ASTM D1785, consistently meeting and/or exceeding the Quality Assurance test requirements of this standard with regard to material, workmanship, burst pressure, flattening, and extrusion quality. The pipe shall be manufactured in the USA, using domestic materials, by an ISO 9001 certified manufacturer. Standard lengths of pipe sizes 6" and larger shall be beveled each end by the pipe manufacturer. All pipe shall be stored indoors after production at the manufacturing site until shipped from factory. This pipe shall carry the National Sanitation Foundation (NSF) seal of approval for potable water applications. All pipe shall be manufactured by HARVEL PLASTICS, INC.

Product Specifications PVC Industrial Pipe: Schedule 80

Schedule 80 Dimensions

Nom. Pipe Size (in.) 1/8 1/4 3/8 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 3-1/2 4 5 6 8 10 12 14 16 18 20 24 O.D. 0.405 0.540 0.675 0.840 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.000 4.500 5.563 6.625 8.625 10.750 12.750 14.000 16.000 18.000 20.000 24.000 Average I.D. 0.195 0.282 0.403 0.526 0.722 0.936 1.255 1.476 1.913 2.290 2.864 3.326 3.786 4.768 5.709 7.565 9.493 11.294 12.410 14.213 16.014 17.814 21.418 Min. Wall 0.095 0.119 0.126 0.147 0.154 0.179 0.191 0.200 0.218 0.276 0.300 0.318 0.337 0.375 0.432 0.500 0.593 0.687 0.750 0.843 0.937 1.031 1.218 Nom. Wt./Ft. 0.063 0.105 0.146 0.213 0.289 0.424 0.586 0.711 0.984 1.500 2.010 2.452 2.938 4.078 5.610 8.522 12.635 17.384 20.852 26.810 33.544 41.047 58.233 Max. W.P. 1230 1130 920 850 690 630 520 470 400 420 370 350 320 290 280 250 230 230 220 220 220 220 210

The pressure ratings given are for water, non-shock, @ 73F. The following temperature de-rating factors are to be applied to the working pressure ratings (WP) listed when operating at elevated temperatures. Multiply the working pressure rating of the selected pipe at 73F, by the appropriate de-rating factor to determine the maximum working pressure rating of the pipe at the elevated temperature chosen. EX: 10" PVC SCH 80 @ 120F = ? 230 psi x 0.40 = 92 psi max. @ 120F

De-Rating Factor

Operating Temp (F) 73 80 90 100 110 120 130 140 De-Rating Factor 1.00 0.88 0.75 0.62 0.51 0.40 0.31 0.22

PVC Schedule 80 Pipe Product Specifications

THE MAXIMUM SERVICE TEMPERATURE FOR PVC IS 140F. Solvent-cemented joints should be utilized when working at or near maximum temperatures. Harvel Plastics does not recommend the use of PVC for threaded connections at temperatures above 110F; use flanged joints, unions, or roll grooved couplings where disassembly is necessary at elevated temperatures. Thread only Schedule 80 or heavier walls. Threading requires a 50% reduction in pressure rating stated for plain end pipe @73F. Threading of Schedule 40 PVC pipe is not a recommended practice due to insufficient wall thickness. Chemical resistance data should be referenced for proper material selection and possible de-rating when working with fluids other than water. Refer to Harvel Plastics 112/401 Product Bulletin for chemical resistance, installation data, and additional information. ASTM STANDARD D1784 MATERIAL EQUIVALENTS: Cell Classification 12454 = PVC Type I Grade I = PVC1120 Pipe sizes shown are manufactured in strict compliance with ASTM D1785.

Product Specifications PVC Industrial Pipe: Schedule 120

Application:

High pressure corrosion resistant, IPS sizes 1/2" through 8", for use at temperatures up to and including 140F. Pressure rating (380 psi to 1010 psi) varies with pipe size and temperature as stated in Harvel Plastics, Inc. engineering bulletin (Product Bulletin 112/401). Generally resistant to most acids, bases, salts, aliphatic solutions, oxidants, and halogens. Chemical resistance data is available and should be referenced for proper material selection. Pipe exhibits excellent physical properties and flammability characteristics (independently tested flame and smoke characteristics-ULC). Typical applications include: chemical processing, plating, high purity applications, potable water systems, water and wastewater treatment, and other industrial applications involving corrosive fluid transfer where high pressures are encountered. Schedule 120 heavy wall dimensions provide sufficient wall thickness suitable for many drilling, tapping, and other custom machining/fabrication operations.

PVC Schedule 120 Pipe Product Specifications

Scope:

This specification outlines minimum manufacturing requirements for Polyvinyl Chloride (PVC) schedule 120 iron pipe size (IPS) pressure pipe. This pipe is intended for use in industrial systems where the fluid conveyed does not exceed 140F. This pipe meets and or exceeds the industry standards and requirements as set forth by the American Society for Testing and Materials (ASTM) and NSF International (NSF Std. 61 and NSF Std 14).

PVC Materials:

The material used in the manufacture of the pipe shall be domestically produced rigid polyvinyl chloride (PVC) compound, Type I Grade I, with a Cell Classification of 12454 as defined in ASTM D1784. This compound shall be gray in color, and shall be approved by the NSF International (NSF) for use with potable water.

Dimensions:

PVC Schedule 120 pipe shall be manufactured in strict accordance to the requirements of ASTM D1785 for physical dimensions and tolerances. Each production run of pipe manufactured in compliance to this standard, shall also meet or exceed the test requirements for materials, workmanship, burst pressure, flattening, and extrusion quality defined in ASTM D1785. All belled-end pipe shall have tapered sockets to create an interference-type fit, which meet or exceed the dimensional requirements and the minimum socket length for pressure-type sockets as defined in ASTM D2672.

Marking:

Product marking shall meet the requirements of ASTM D1785 and shall include: the manufacturers name (or the manufacturers trademark when privately labeled); the nominal pipe size; the PVC 1120 material designation code; the pipe schedule and pressure rating in psi for water @ 73F; the ASTM designation D1785; the independent laboratorys seal of approval for potable water usage (NSF-pw), and the date of manufacture.

Sample Specification:

All PVC Schedule 120 pipe shall be manufactured from a Type I, Grade I Polyvinyl Chloride (PVC) compound with a Cell Classification of 12454 per ASTM D1784, trade name H707 PVC. The pipe shall be manufactured in strict compliance to ASTM D1785, consistently meeting and/or exceeding the Quality Assurance test requirements of this standard with regard to material, workmanship, burst pressure, flattening, and extrusion quality. The pipe shall be manufactured in the USA, using domestic materials, by an ISO 9002 certified manufacturer. All pipe shall be stored indoors after production at the manufacturing site until shipped from factory. This pipe shall carry the National Sanitation Foundation (NSF) seal of approval for potable water applications. All pipe shall be manufactured by HARVEL PLASTICS, INC.

Product Specifications PVC Industrial Pipe: Schedule 120

Schedule 120 Dimensions

Nom. Pipe Size (in.) 1/2 3/4 1 1-1/4 1-1/2 2 2-1/2 3 4 6 8 O.D. 0.840 1.050 1.315 1.660 1.900 2.375 2.875 3.500 4.500 6.625 8.625 Average I.D. 0.480 0.690 0.891 1.204 1.423 1.845 2.239 2.758 3.574 5.434 7.189 Min. Wall 0.170 0.170 0.200 0.215 0.225 0.250 0.300 0.350 0.437 0.562 0.718 Nom. Wt./Ft. 0.236 0.311 0.464 0.649 0.787 1.111 1.615 2.306 3.713 7.132 11.277 Max. W.P. 1010 770 720 600 540 470 470 440 430 370 380

Multiply the working pressure rating of the selected pipe at 73F by the appropriate de-rating factor to determine the maximum working pressure rating of the pipe at the elevated temperature chosen. EX: 6" PVC SCHEDULE 120 @ 130F = ? 370 psi x 0.31 = 115 psi max. @ 130F THE MAXIMUM SERVICE TEMPERATURE FOR PVC IS 140F.

De-Rating Factor

Operating Temp (F) 73 80 90 100 110 120 130 140 De-Rating Factor 1.00 0.88 0.75 0.62 0.51 0.40 0.31 0.22

PVC Schedule 120 Pipe

ASTM STANDARD D1784 MATERIAL EQUIVALENTS: Cell Classification 12454 = PVC Type I Grade I = PVC1120 PIPE SIZES SHOWN ARE MANUFACTURED IN STRICT COMPLIANCE WITH ASTM D1785 The working pressure ratings (W.P.) given are for water, non-shock, @ 73F. The following temperature de-rating factors are to be applied to the working pressure ratings (W.P.) listed when operating at elevated temperatures.

Solvent cemented joints should be utilized when working at or near maximum temperatures. Harvel Plastics does not recommend the use of PVC for threaded connections at temperatures above 110F; use flanged joints, unions, or roll grooved couplings where disassembly is necessary at elevated temperatures.

Threading requires a 50% reduction in pressure rating stated for plain end pipe @73F.

Product Specifications

Chemical resistance data should be referenced for proper material selection and possible de-rating when working with fluids other than water. Refer to Harvel Plastics 112/401 Product Bulletin for chemical resistance and installation data. Reference Harvel Plastics, Inc Product Bulletin 112/401 for information pertaining to chemical resistance, physical properties, joining methods, hangers and supports, collapse pressure ratings, system components and other system design and installation related data.

Вам также может понравиться

- Wreck It Ralph ScreenplayДокумент114 страницWreck It Ralph ScreenplayRebekah Sommerville100% (4)

- Quick Reference CardДокумент3 страницыQuick Reference Cardaslam.ambОценок пока нет

- Differences of Classical and Modern Views On GravityДокумент4 страницыDifferences of Classical and Modern Views On GravityJose Miguel Lopez83% (6)

- Watson McDaniel EngineeringDataДокумент61 страницаWatson McDaniel EngineeringDataViswanathan DamodaranОценок пока нет

- Copper PPR Pipe SizesДокумент1 страницаCopper PPR Pipe Sizespsn_kylmОценок пока нет

- BNC Lesson 1-4Документ34 страницыBNC Lesson 1-4Alyssa LoisОценок пока нет

- Strainer Type 305Документ5 страницStrainer Type 305alexiel1806Оценок пока нет

- Tech PDFДокумент3 страницыTech PDFAwais JalaliОценок пока нет

- Nissan Skyline RB Engine Oil Control ModsДокумент1 страницаNissan Skyline RB Engine Oil Control Modsbyrnesvictim100% (1)

- Flexible ConnectionsДокумент118 страницFlexible ConnectionsMuzaffarОценок пока нет

- Pipe SizingДокумент16 страницPipe SizingnagarajhebbarОценок пока нет

- Geberit Piping Systems Catalogue 2010/2011Документ95 страницGeberit Piping Systems Catalogue 2010/2011Catalin Frincu0% (1)

- Backpressure 250Документ2 страницыBackpressure 250epicenterrulezОценок пока нет

- Introduction To Piping EngineerДокумент46 страницIntroduction To Piping EngineerFebrianto Edy PratamaОценок пока нет

- TRALEG KYABGON - The-Influence-of-Yogacara-on-Mahamudra PDFДокумент145 страницTRALEG KYABGON - The-Influence-of-Yogacara-on-Mahamudra PDFFilippo Lunardo100% (1)

- Major Practice in Swine ProductionДокумент29 страницMajor Practice in Swine ProductionMark GarciaОценок пока нет

- NBC vs. NFPAДокумент12 страницNBC vs. NFPAMGHIRBI HAYKELОценок пока нет

- Kaharamaa Water Network Design GuidelinesДокумент66 страницKaharamaa Water Network Design GuidelinesHaytham Tantawy69% (13)

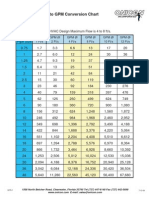

- Flow Velocity (FT/S) To GPM Conversion ChartДокумент1 страницаFlow Velocity (FT/S) To GPM Conversion Chartmonaco59Оценок пока нет

- Water Treatment Plant Performance Evaluations and OperationsОт EverandWater Treatment Plant Performance Evaluations and OperationsОценок пока нет

- Water Distribution ManualДокумент20 страницWater Distribution ManualOxfamОценок пока нет

- Abu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003Документ8 страницAbu Orf M.M. Centrate Viscosity For Continuous Monitoring of Polymer Feed in Dew Ate Ring Applications 2003fermortaraОценок пока нет

- Questions STPДокумент22 страницыQuestions STPRabindra SinghОценок пока нет

- 02 Design Guide Warehouses LoresДокумент21 страница02 Design Guide Warehouses LoresReinaldo SouzaОценок пока нет

- Design, Operation & Maintenance Manual: Industrial Fixed Aerosol Fire Suppression SystemДокумент70 страницDesign, Operation & Maintenance Manual: Industrial Fixed Aerosol Fire Suppression SystemAhmad Saleem AlawwadОценок пока нет

- Project Standard Specification: Jacuzzi 15491 - Page 1/5Документ5 страницProject Standard Specification: Jacuzzi 15491 - Page 1/5adel rihanaОценок пока нет

- Plastics as a Building Material GuideДокумент24 страницыPlastics as a Building Material GuideVinod Nair100% (1)

- Instructional Design HypertensionДокумент8 страницInstructional Design HypertensionGeoffrey OnyanchaОценок пока нет

- Installation Manual flexES 798980.GB0Документ64 страницыInstallation Manual flexES 798980.GB0gius uddinОценок пока нет

- Sizing Drain and Condensate Lines To TrapsДокумент18 страницSizing Drain and Condensate Lines To TrapsMubarik Ali100% (1)

- Carnauba WaxДокумент5 страницCarnauba WaxsimilcemalcemilОценок пока нет

- Basic Aeration Design CalculationsДокумент4 страницыBasic Aeration Design Calculationssandun nissankaОценок пока нет

- How To Use PathlossДокумент32 страницыHow To Use Pathlosspathlossanwar100% (9)

- COMMUNITY HEALTH NURSING: PREVENTION, FAMILIES, PRIMARY CAREДокумент4 страницыCOMMUNITY HEALTH NURSING: PREVENTION, FAMILIES, PRIMARY CAREJohn Vincent VasquezОценок пока нет

- Eurocode 5 Design of Timber StructuresДокумент54 страницыEurocode 5 Design of Timber StructuresAhmed Zaki0% (1)

- Flex Head para RociadoresДокумент2 страницыFlex Head para RociadoresjoravicaОценок пока нет

- Woods Silencer Catalogue and Technical DataДокумент12 страницWoods Silencer Catalogue and Technical DataJagatjeet MaanОценок пока нет

- Water Treatment Catalogue GuideДокумент12 страницWater Treatment Catalogue GuideJim TsikasОценок пока нет

- Kaiflex MasterSpecificationДокумент8 страницKaiflex MasterSpecificationnaseema1Оценок пока нет

- Pipe Pressure Drope ASEREHДокумент3 страницыPipe Pressure Drope ASEREHSenghou MeasОценок пока нет

- Green PPR Pipe FittingДокумент12 страницGreen PPR Pipe FittinggeorgeОценок пока нет

- Calculation of The Built Up Back Pressure - LESERДокумент4 страницыCalculation of The Built Up Back Pressure - LESERArjed Ali ShaikhОценок пока нет

- Terrain Rainwater BrochureДокумент56 страницTerrain Rainwater BrochureterinthomasОценок пока нет

- Sand Oil Interceptor Sizing Calculations 90 SubmittalДокумент4 страницыSand Oil Interceptor Sizing Calculations 90 SubmittalBRANDONОценок пока нет

- Forbes Marshall Consultancy specifications for compressed air accessoriesДокумент2 страницыForbes Marshall Consultancy specifications for compressed air accessoriessppatilОценок пока нет

- TrapДокумент4 страницыTrapdcsamaraweeraОценок пока нет

- Phuong Phap Tinh Tai Theo Phan Mem MistralДокумент8 страницPhuong Phap Tinh Tai Theo Phan Mem Mistralntt_121987Оценок пока нет

- Wavin PE Pressure Pipes Data SheetДокумент2 страницыWavin PE Pressure Pipes Data SheetConspiracy_PTОценок пока нет

- Non Circular Pipe FrictionДокумент3 страницыNon Circular Pipe Frictionravi_radanОценок пока нет

- TrueUnion - True Union Ball ValveДокумент4 страницыTrueUnion - True Union Ball ValveKarthick VenkateshОценок пока нет

- Ozone Treatment For Cooling Towers PDFДокумент28 страницOzone Treatment For Cooling Towers PDFlhphong021191Оценок пока нет

- FUSION BONDED EPOXY COATED LYE DUCTILE IRON PIPE FITTINGSДокумент16 страницFUSION BONDED EPOXY COATED LYE DUCTILE IRON PIPE FITTINGSkhai rule100% (1)

- PalDuct Phenolic Datasheet MEДокумент2 страницыPalDuct Phenolic Datasheet MERamadan RashadОценок пока нет

- Tuttle and Bailey CircularДокумент2 страницыTuttle and Bailey CircularTalha BaigОценок пока нет

- PREFCO Fire and Smoke Damper Product Catalog 2007Документ16 страницPREFCO Fire and Smoke Damper Product Catalog 2007iask52750% (1)

- Chilled Water TreatmentДокумент10 страницChilled Water TreatmentacmvorgОценок пока нет

- HDPE Manual: LamasatДокумент51 страницаHDPE Manual: LamasatMalay Kar0% (1)

- N2 Generator CalculationДокумент9 страницN2 Generator CalculationBagus PrambudiОценок пока нет

- Volume Control DampersДокумент4 страницыVolume Control Dampersdignified34Оценок пока нет

- AlMunifPipes UPVC CPVC FittingsДокумент24 страницыAlMunifPipes UPVC CPVC FittingsDanZel DanОценок пока нет

- Booster Pump-TechPart - 2of2 BДокумент71 страницаBooster Pump-TechPart - 2of2 BKatie RamirezОценок пока нет

- DIffuser Selection PDFДокумент24 страницыDIffuser Selection PDFpanyamnrОценок пока нет

- HVWS SystemДокумент1 страницаHVWS Systemabhinay02meОценок пока нет

- Liquid Process Piping - Part 1 General Piping Design PDFДокумент33 страницыLiquid Process Piping - Part 1 General Piping Design PDFnitin guptaОценок пока нет

- Compressor Inlet Piping - Compressed Air Best PracticesДокумент10 страницCompressor Inlet Piping - Compressed Air Best PracticesBehroozRaadОценок пока нет

- BOQ From (HVAC)Документ26 страницBOQ From (HVAC)Neeta Samir Munj ParkarОценок пока нет

- Bomba FanДокумент88 страницBomba FanJA_RRY100% (1)

- ASLI 02 Supply Air Grilles Set - AIR ConditioningДокумент21 страницаASLI 02 Supply Air Grilles Set - AIR ConditioningAminul Hassan50% (2)

- 6206 Guide For Selection Installation andДокумент32 страницы6206 Guide For Selection Installation andakbavra80% (5)

- Yazd-System Description For Clean Drain System PDFДокумент7 страницYazd-System Description For Clean Drain System PDFace-winnieОценок пока нет

- Air Calculations and Conversions Guide for Particulate, SO2, and NO2 EmissionsДокумент4 страницыAir Calculations and Conversions Guide for Particulate, SO2, and NO2 EmissionsveschaferОценок пока нет

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationДокумент3 страницыGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarОценок пока нет

- A Guide To Ventilation Exhaust FansДокумент4 страницыA Guide To Ventilation Exhaust FansLoter BelautОценок пока нет

- Is 655 & SmacnaДокумент4 страницыIs 655 & SmacnaWasim AkhtarОценок пока нет

- Polyethylene Gas Pipe 2007Документ10 страницPolyethylene Gas Pipe 2007asgharkhanОценок пока нет

- Hanging and Supports PDFДокумент3 страницыHanging and Supports PDFmartin.rubenОценок пока нет

- City of Phoenix Water Services Department: Wastewater Lift Station Design Guidance ManualДокумент66 страницCity of Phoenix Water Services Department: Wastewater Lift Station Design Guidance ManualJuan CarlosОценок пока нет

- Stormwater Ceu Training Course $100.00: Registration FormДокумент18 страницStormwater Ceu Training Course $100.00: Registration FormAhmed ZakiОценок пока нет

- Updated Manual On Treatment For Small Supplies PDFДокумент95 страницUpdated Manual On Treatment For Small Supplies PDFkunОценок пока нет

- Best Practices For Small Drinking Water Systems-ManualДокумент51 страницаBest Practices For Small Drinking Water Systems-ManualSlobodan JankovicОценок пока нет

- Engineering Journal Reviews Water Hammer AlternativesДокумент15 страницEngineering Journal Reviews Water Hammer AlternativesAhmed ZakiОценок пока нет

- Pipe Outside Diameter GuideДокумент1 страницаPipe Outside Diameter GuideRonaldo Daniel Martín Pasapera MontalbánОценок пока нет

- Coursera DUZ958KA5G4W PDFДокумент1 страницаCoursera DUZ958KA5G4W PDFAhmed ZakiОценок пока нет

- SEISMIC LOAD ANALYSISДокумент9 страницSEISMIC LOAD ANALYSISAditya RoyОценок пока нет

- Presentation by Harshal Sethiya N Mitul UpadhyayДокумент26 страницPresentation by Harshal Sethiya N Mitul Upadhyaysanket jain100% (1)

- Um Centuris Pro Li900b1 - enДокумент70 страницUm Centuris Pro Li900b1 - enOsires Ferreira100% (1)

- LPVDДокумент12 страницLPVDPardha SaradhiОценок пока нет

- 842e In001 - en PДокумент4 страницы842e In001 - en PNilson Eduardo TorresОценок пока нет

- Work Permit SystemДокумент50 страницWork Permit SystemBin khammash and sons Co.Оценок пока нет

- The Enchanted ForestДокумент3 страницыThe Enchanted ForestRichealle Vaniel Delicano SeverinoОценок пока нет

- 2019-Ag-8750 Poultry Farm Visit ReportДокумент7 страниц2019-Ag-8750 Poultry Farm Visit ReportYOUSAF0% (1)

- Solving Motion ProblemsДокумент5 страницSolving Motion ProblemsAkshat Kumar AgarwalОценок пока нет

- Outrider Character SheetДокумент6 страницOutrider Character SheetColin ZachauОценок пока нет

- Automated Home Rainwater Harvesting Earns MoneyДокумент4 страницыAutomated Home Rainwater Harvesting Earns MoneysaravananОценок пока нет

- SSCM Roads and Bridges - Annex III Technical Specifications 105 C1 PDFДокумент254 страницыSSCM Roads and Bridges - Annex III Technical Specifications 105 C1 PDFSite Engineer.2p2100% (1)

- CT AC 72A<INV=<90A 70A<REC=<135A Part SpecДокумент7 страницCT AC 72A<INV=<90A 70A<REC=<135A Part SpecEdwin Mosos RamosОценок пока нет

- Specification SG 15CДокумент3 страницыSpecification SG 15CJohan AlvarezОценок пока нет

- Stentorian December 2009Документ8 страницStentorian December 2009amplourde3106Оценок пока нет

- Report on internship at JDS TransformersДокумент50 страницReport on internship at JDS TransformersSachinОценок пока нет

- BGMEA University of Fashion & Technology (BUFT)Документ9 страницBGMEA University of Fashion & Technology (BUFT)RIFAT HASANОценок пока нет