Академический Документы

Профессиональный Документы

Культура Документы

05770211

Загружено:

Mayank ShandilyaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

05770211

Загружено:

Mayank ShandilyaАвторское право:

Доступные форматы

1786

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 47, NO. 4, JULY/AUGUST 2011

Pulsewidth Modulation Technique for BLDCM Drives to Reduce Commutation Torque Ripple Without Calculation of Commutation Time

Yong-Kai Lin and Yen-Shin Lai

AbstractThis paper presents a three-phase pulsewidth modulation (PWM) technique for brushless dc motor (BLDCM) drives to reduce the commutation torque ripple. As compared to previous approaches, the presented technique does not require any torque observer and calculation of commutation time which may be sensitive to motor parameters and may require more calculation time. The commutation time for the presented technique is determined by a detection circuit which consists of simple comparator circuit. The experimental results derived from a eld programmable gate array based controlled BLDCM drive show that the commutation current ripple can be signicantly reduced by the presented PWM technique. Index TermsBrushless dc motor (BLDCM), commutation torque ripple, current ripple reduction.

NOMENCLATURE CP dc1 dc2 chopdn chopdc chop j + chop j Djp Djn deg dn E ej Commutation period. Used duty ratio in commutation period while Sector = 2, 4, 6. Used duty ratio in commutation period while Sector = 1, 3, 5. Chop signal with respect to dn . Chop signal with respect to dc1 or dc2 . Chop signal for high side switch, j = a, b, c. Chop signal for low side switch, j = a, b, c. Output signal of the comparator; the reference voltage is kVP N and j = a, b, c, y. Output signal of the comparator; the reference voltage is 0 V and j = a, b, c, y. Rotor position of brushless dc motor (BLDCM). Used duty ratio in the noncommutation period. Peak value of back EMF. Per-phase back EMF of BLDCM, j = a, b, c.

ex ey ez I Irated IP N IP N ij ix iy iz i j+ j Ke k L N P Prated R Ts tc1 tc2 tn Vd VP N vy vyN vsN vj y+ y r

Manuscript received December 15, 2010; revised February 20, 2011; accepted March 22, 2011. Date of publication May 19, 2011; date of current version July 20, 2011. Paper 2010-EPC-441.R2, presented at the 2010 Industry Applications Society Annual Meeting, Houston, TX, October 37, and approved for publication in the IEEE T RANSACTIONS ON I NDUSTRY A PPLICATIONS by the Electrostatic Processes Committee of the IEEE Industry Applications Society. Y.-K. Lin was with the Center for Power Electronics Technology, National Taipei University of Technology, Taipei 10608, Taiwan. He is currently with the Industrial Technology Research Institute, Hsinchu 326, Taiwan (e-mail: yklin@itri.org.tw). Y.-S. Lai is with the Center for Power Electronics Technology, National Taipei University of Technology, Taipei 10608, Taiwan (e-mail: yslai@ntut.edu.tw). Color versions of one or more of the gures in this paper are available online at http://ieeexplore.ieee.org. Digital Object Identier 10.1109/TIA.2011.2155612

Back EMF of the noncommutation phase. Back EMF of the outgoing phase. Back EMF of the incoming phase. Peak value of the phase current. Rated current of BLDCM. Feedback signal of the dc-link current. Regular value for current control. Per-phase current of BLDCM, j = a, b, c. Current of the noncommutation phase. Current of the outgoing phase. Current of the incoming phase. Current ripple of the phase current. High side switch for each phase, j = a, b, c. Low side switch for each phase, j = a, b, c. Back EMF constant. Portion ratio of the voltage divider. Inductance of each phase. Negative terminal of dc-link. Positive terminal of dc-link. Rated power of BLDCM. Resistance of each phase. Switching period of the chop signal. Turn-on time with respect to dc1 . Turn-on time with respect to dc2 . Turn-on time with respect to dn . Forward voltage of parallel diode. DC-link voltage. Terminal voltage of the outgoing phase. Terminal voltage of the outgoing phase with respect to the negative dc-link. Central-tap voltage of three-phase winding with respect to the negative dc-link. Per-phase terminal voltage of BLDCM, j = a, b, c. High side switch of the outgoing phase. Low side switch of the outgoing phase. Rotor speed of BLDCM. I. I NTRODUCTION

LDCMs have been widely applied to industry and home appliances recently for energy-saving concerns. For some applications, torque ripple is one of the performance evaluation indexes. Fig. 1(a) shows the ideal waveforms of the back EMF and phase current of BLDCM. As shown in Fig. 1(a), the current is with a at waveform which is in phase with the back EMF, thereby giving a smooth torque. However, due to the

0093-9994/$26.00 2011 IEEE

LIN AND LAI: PWM TECHNIQUE FOR BLDCM DRIVES TO REDUCE COMMUTATION TORQUE RIPPLE

1787

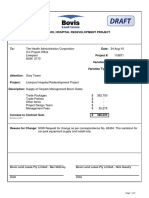

Fig. 2. BLDCM drives.

calculation. However, inductance of motor winding is required for commutation time calculation (see [9, eq. (27)]). Several PWM techniques [10][12] have been proposed to eliminate reversal dc-link current or circulating current of BLDCM drives. These research results have not yet discussed the reduction of commutation current ripple for BLDCM drives. In this paper, a PWM technique for current ripple reduction is proposed. Moreover, a detection circuit for determining the commutation period is presented. Finally, the experimental results derived from a eld programmable gate array (FPGA) based BLDCM drive show that the commutation current ripple can be signicantly reduced by the presented PWM technique. II. P ROPOSED C OMMUTATION T ORQUE R EDUCTION PWM T ECHNIQUES

Fig. 1. Ideal and practical waveforms of BLDCM. (a) Ideal back EMF and phase current. (b) Practical terminal voltage (Ch1) and phase current (Ch2).

limitation of current slew rate and commutation of inverter, the current waveform is not at, as shown in Fig. 1(b). Moreover, this fact gives a signicant torque ripple which can be up to 50% of the average torque, as addressed in [1]. Some papers which reduce torque ripple by controlling the commutation current have been presented to deal with this issue. A current control method has been presented in [2] to reduce current ripple. However, current ripple caused by commutation is not fully considered in [2]. In [3], the commutation current is reduced by changing the dc-link voltage, which requires additional dc-link voltage control circuit and capacitors, thereby increasing the cost. A predictive current method which requires motor parameters is shown in [4] to reduce commutation current ripple. As shown in [4, Fig. 13], the results fail to meet the ideal ones. The commutation current ripple can be reduced by changing duty during commutation, as shown in [5] and [6]. However, two-phase pulsewidth modulation (PWM) is retained in [5] and [6], which limits the contribution to current ripple reduction, as discussed in [7] and [8]. Three-phase PWM techniques are presented to reduce the commutation current ripple in [7][9]. Either three-phase current sensors or torque observer is required in [7] and [8], respectively, in changing the PWM method to a three-phase one. Therefore, these result in either cost increase or computation and parameter sensitivity. In [9], the commutation time for commutation control of three-phase PWM is determined by

A new three-phase PWM technique for BLDCM drives that is used to reduce the commutation torque is proposed. As compared to previous approaches, the presented technique does not require any torque observer and calculation of commutation time which may be sensitive to motor parameters and may require more calculation time. The commutation time for the presented technique is determined by a detection circuit which consists of simple comparator circuit. A. Basic Idea Fig. 2 shows the block diagram of BLDCM drives. Moreover, Fig. 3 shows the basic idea in reducing the commutation current ripple. As shown in Fig. 3, using phase a as the noncommutation phase, phase b as the outgoing phase, and phase c as the incoming phase, as an example, the basic idea is to retain the same magnitude of current slew rate while with opposite sign for the incoming and outgoing phases. This basic idea can be achieved by controlling the duty during commutation. Fig. 4 shows the proposed commutation control patent. During noncommutation period (CP = Low"), the required turnon time tn is applied to PWM control, and two-phase PWM control is retained during this period. tn can be derived from a control loop such as speed control loop, torque control loop, etc. In contrast, turn-on times tc1 and tc2 are used during the commutation period (CP = High"), and three-phase PWM control is applied, as shown in Fig. 4. tc1 and tc2 will be derived in the next section.

1788

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 47, NO. 4, JULY/AUGUST 2011

Fig. 3. Basic idea of the proposed technique (|dib /dt| = |dic /dt|).

B. Derivation of tc1 and tc2 During the Commutation Period As shown in Fig. 3, the three-phase windings of BLDCM can be divided into noncommutation, incoming, and outgoing phases during the commutation period. The current of the noncommutation phase is maintained during the commutation period. The current of the incoming phase increases with a controlled slew rate. In contrast, the current of the outgoing phase decreases during the commutation period. In order to derive the general forms of tc1 and tc2 , this paper uses phases x, y, and z to represent the noncommutation, outgoing, and incoming phases, respectively. Moreover, Table I shows the relationship of x, y, and z between the threephase winding of BLDCM in different sectors. During the commutation period of Sector 2, the circuit of BLDCM is shown in Fig. 5(a) while the chop signal is on. According to Table I, the equivalent model of BLDCM can be derived as shown in Fig. 6(a) if the winding resistor is neglected. As shown in Fig. 6(a), (1)(3) can be derived by Kirchhoffs voltage law vsN = VP N L vsN = L vsN = L dix ex dt (1) (2) (3)

Fig. 4. Proposed three-phase PWM control for commutation current reduction. TABLE I R ELATIONSHIP OF x, y, AND z TO T HREE -P HASE W INDING

diy ey dt diz ez . dt

By (1)(3), the central tap voltage can be derived as 3vsN = VP N L vsN dix diy diz + + dt dt dt (ex + ey + ez )

Fig. 5. Circuit of BLDCM during the commutation period at Sector 2. (a) Chop on. (b) chop off.

(ex + ey + ez ) VP N . = 3 3

(4) When the chop signal becomes off, the circuit of BLDCM is shown in Fig. 5(b). Moreover, the equivalent circuit of Fig. 5(b) is shown in Fig. 6(b). As shown in Fig. 6(b), (8)(10) can be derived by Kirchhoffs voltage law vsN = L vsN vsN dix ex dt diy ey = VP N L dt diz ez . = L dt (8) (9) (10)

Substituting (4) into (1)(3), the current slew rate of each phase can be written as dix 1 2VP N (ey +ez 2ex ) = (VP N vsN ex ) = + (5) dt L 3L 3L diy 1 VP N (ex +ez 2ey ) = (vsN ey ) = + dt L 3L 3L diz 1 VP N (ex +ey 2ez ) = (vsN ez ) = + . dt L 3L 3L (6) (7)

LIN AND LAI: PWM TECHNIQUE FOR BLDCM DRIVES TO REDUCE COMMUTATION TORQUE RIPPLE

1789

where dc1 is the duty ratio during the commutation period of Sector 2, and it can be dened as (18). In the succeeding equation, Ts represents the switching period dc1 = tc1 . Ts (18)

In order to retain the same magnitude of current slew rate while with opposite sign for the incoming and outgoing phases, the following equation can be derived: diy dt =

Ts

diz dt

Ts

VP N (2 3dc1 ) (ex + ez 2ey ) + 3L 3L VP N (ex + ey 2ez ) = 3L 3L 2ex ey ez 1 dc1 = + . 3VP N 3

(19)

Moreover, the on-time tc1 during the commutation period can be derived as

Fig. 6. Equivalent circuit of Fig. 5. (a) Chop on. (b) Chop off.

tc1 =

2ex ey ez 1 + 3VP N 3

Ts .

(20)

By (8)(10), the central tap voltage can be derived as 3vsN = VP N L vsN = dix diy diz + + dt dt dt (ex + ey + ez ) (11)

Assuming ey = eb E, (20) can be rewritten as = tc1 = 4E 1 + 3VP N 3 Ts (21)

(ex + ey + ez ) VP N . 3 3

Substituting (11) into (8)(10), the current slew rate of each phase can be written as dix 1 VP N (ey +ez 2ex ) = (vsN ex ) = + (12) dt L 3L 3L diy 1 2VP N (ex +ez 2ey ) = (VP N vsN ey ) = + (13) dt L 3L 3L diz 1 VP N (ex +ey 2ez ) = (vsN ez ) = + . (14) dt L 3L 3L The average current slew rate of each phase can be written as dix dt = (5) dc1 + (12) (1 dc1 )

Ts

where E back EMF = Ke r ; VP N dc-link voltage. Similarly, the on-time tc2 during the commutation period of Sector 3 can be written as tc2 = ey + ez 2ex 1 + 3VP N 3 Ts . (22)

Assuming ey = ea E, (22) can be rewritten as = tc2 = 4E 1 + 3VP N 3 Ts . (23)

C. Proposed Commutation Period Detection Circuit Fig. 7 shows the block diagram of the commutation period detection circuit. In Sectors 2, 4, and 6, the outgoing phase with chop off control is used as an example, as shown in Fig. 7(b) and (c). Fig. 7(b) and (c) shows the detection results under the conditions of zero current and nonzero current, respectively. In Fig. 7(b), the output of comparator Dyp is H if the current of the outgoing phase is not zero during chop off. In contrast, Dyp is L as the current of the outgoing phase becomes zero, as shown in Fig. 7(c). Therefore, when the commutation period comes to the end, the status of Dyp becomes low, thereby indicating the commutation period. As the commutation period, indicated by CP in Fig. 4, comes to its end, the duty is changed to the required turn-on time tn , as shown in Fig. 4,

VP N (3dc1 1) (ey + ez 2ex ) = + 3L 3L diy dt = (6) dc1 + (13) (1 dc1 )

Ts

(15)

= diz dt

VP N (2 3dc1 ) (ex + ez 2ey ) + 3L 3L

(16)

= (7) dc1 + (14) (1 dc1 )

Ts

(ex + ey 2ez ) VP N + 3L 3L

(17)

1790

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 47, NO. 4, JULY/AUGUST 2011

Fig. 9. Measured waveforms for the case of y = b (phase b). Ch1 = iy , Ch2 = Dyp , Ch3 = sampling signal, and Ch4 = CP .

Fig. 7. Proposed commutation period detection circuit. (a) Circuit. (b) Nonzero current @ chop off, (vyN = VP N + Vd ) > VP N , and Sector = 2, 4, and 6. (c) Zero current @ chop off, (vyN = f loating) < VP N , and Sector = 2, 4, and 6.

Fig. 10.

FPGA-based experimental system.

Fig. 8. Experimental result of the commutation period detection circuit. Ch1 = iy , Ch2 = chop y , Ch3 = Dyp , and Ch4 = CP .

For the readers understanding, the waveforms of the comparison circuit action with the phase current are shown in Fig. 8. As shown in Fig. 8, for the current shown in Ch1 during the chop off period of y (see Ch2), as the signal of Dyp becomes L (see Ch3), it indicates that the related commutation period Ch4 comes to its end. For the presented commutation period detection circuit, the fault detection issue caused by noise can be avoided by sampling technique. For the case shown in Fig. 5(b), the measurement results of the current of phase b in Sector 2 (see Fig. 4) using this sampling technique are shown in Fig. 9. As shown in Fig. 9, the output of Dyp is not sampled around the switching points (see Ch2 in Fig. 9). III. E XPERIMENTAL R ESULTS Fig. 10 shows the FPGA-based experimental system. As shown in Fig. 10, the dc-link current is fed back for current

and two-phase PWM control is resumed. A voltage divider consisting of resistors R1 and R2 with division ratio of k is used to attenuate the terminal voltage.

LIN AND LAI: PWM TECHNIQUE FOR BLDCM DRIVES TO REDUCE COMMUTATION TORQUE RIPPLE

1791

Fig. 11. Block diagram in FPGA.

Fig. 13. Experimental results. IP N = 0.5Irated , Ch1 = vaN , Ch2 = ia , and Ch3 = CP . (a) Without the proposed method. (b) With the proposed method.

Fig. 12. Experimental results. IP N = 0.8Irated , Ch1 = vaN , Ch2 = ia , and Ch3 = CP. (a) Without the proposed method. (b) With the proposed method.

control. The dc-link voltage and switching frequency of the inverter are 24 V and 20 kHz, respectively. The division ratio of the voltage divider is 0.25 (R1 = 6.04 k and R2 = 2 k). Fig. 11 shows the block diagram of the proposed method which is implemented using FPGA. As shown in Fig. 11, the rotating speed of BLDCM is calculated by sensing Hall signals. The chop signal chopdn is used in generating PWM signals when CP = Low. As CP becomes high, the chop signal chopdc is used in generating PWM signals according to Fig. 4. The specications of BLDCM are shown in the Appendix. Figs. 12 and 13 show the measured results of the terminal

voltage, phase current, and detected commutation period for methods with and without the proposed current ripple reduction technique. Comparing the current ripple in Fig. 12(a) without the proposed technique with that in Fig. 12(b) with the proposed technique, it is obvious that the presented technique significantly reduces the current ripple and almost square current waveform. Similar results can be derived for other current command, as shown in Figs. 13 and 14 for current command = 0.5Irated and 0.2Irated , respectively. These experimental results fully support the effectiveness of the proposed technique. Fig. 15 shows the measurement system with load cell Kistler 4503A for the measurement of torque ripple. As shown in Fig. 16(a), for the measured torque of 0.5 p.u. of the rated current with coupling inertia, the torque ripple (peak to peak) can be improved signicantly. Fig. 17 shows the measured speed for the same rated current while with/without torque ripple compensation. As shown in Fig. 17, the speed can be increased as compared to the case without torque compensation. This is contributed by torque ripple reduction, conrming the effectiveness of the method. IV. C ONCLUSION This paper has presented a three-phase PWM technique for BLDCM drives to reduce the commutation torque. The presented technique does not require any torque observer and calculation of commutation time which may be sensitive to

1792

IEEE TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL. 47, NO. 4, JULY/AUGUST 2011

Fig. 14. Experimental results. IP N = 0.2Irated , Ch1 = vaN , Ch2 = ia , and Ch3 = CP . (a) Without the proposed method. (b) With the proposed method.

Fig. 16. Measured torque ripple (IP N = 0.5 p.u.). (a) Without the torque ripple reduction method. (b) With the torque ripple reduction method.

Fig. 15. Measurement system.

motor parameters and may require more calculation time. The commutation time for the presented technique is determined by a detection circuit. The experimental results derived from FPGA-based controlled BLDCM drives show that the commutation current ripple can be signicantly reduced by the presented PWM technique. A PPENDIX I M OTOR PARAMETERS 3 BLDCM, L = 0.6 mH, R = 0.33 , Prated = 70 W, and Irated = 3 A.

Fig. 17. Measured results (Y -axis; in revolutions per minute) and speed versus IP N (X-axis; in amperes).

A PPENDIX II M OTOR PARAMETERS Inuence of back EMF error on torque ripple. Fig. 18 shows the torque ripple contributed by the back EMF error , as shown in (A1), which shows the turn-on time. The torque ripple in per unit is derived by (A2). As shown in (A2), Tmin , Tmax , and

LIN AND LAI: PWM TECHNIQUE FOR BLDCM DRIVES TO REDUCE COMMUTATION TORQUE RIPPLE

1793

[7] H. Lu, L. Zhang, and W. Qu, A new torque control method for torque ripple minimization of BLDC motors with un-ideal back EMF, IEEE Trans. Power Electron., vol. 23, no. 2, pp. 950958, Mar. 2008. [8] Y. Liu, Z. Q. Zhu, and D. Howe, Commutation-torque-ripple minimization in direct-torque-controlled PM brushless dc drives, IEEE Trans. Ind. Appl., vol. 43, no. 4, pp. 10121021, Jul./Aug. 2007. [9] S. S. Bharatkar, R. Yanamshetti, D. Chatterjee, and A. K. Ganguli, Reduction of commutation torque ripple in a brushless dc motor drive, in Proc. IEEE PECon, 2008, pp. 289294. [10] Y. S. Lai and Y. K. Lin, Quicken the pulse, IEEE Ind. Appl. Mag., vol. 14, no. 5, pp. 3444, Sep./Oct. 2008. [11] Y. S. Lai, F. S. Shyu, and Y. K. Lin, Novel PWM technique without causing reversal dc-link current for brushless dc motor drives with bootstrap driver, in Conf. Rec. IEEE IAS Annu. Meeting, 2005, vol. 3, pp. 21822188. [12] Y. S. Lai and Y. K. Lin, Assessment of pulse-width modulation techniques for brushless dc motor drives, in Conf. Rec. IEEE IAS Annu. Meeting, 2006, vol. 4, pp. 16291636.

Fig. 18. Simulation result of the torque ripple with back EMF error.

Tavg indicate the minimum, maximum, and average values of the torque waveform, respectively tc = Tripple = where Tmin Tmax Tavg 4E(1 + ) 1 + Ts 3VP N 3 Tmax Tmin Tavg (A1) (A2)

Yong-Kai Lin received the B.S., M.S., and Ph.D. degrees in electrical engineering from the National Taipei University of Technology, Taipei, Taiwan. He is currently an Engineer with the Industrial Technology Research Institute, Hsinchu, Taiwan. His research interests include eld programmable gate array design and inverter control.

minimum value of the torque waveform; maximum value of the torque waveform; average of the torque waveform. R EFERENCES

[1] R. Carlson, M. Lajoie-Mazenc, and J. C. D. S. Fagundes, Analysis of torque ripple due to phase commutation in brushless dc machines, IEEE Trans. Ind. Appl., vol. 28, no. 3, pp. 632638, May/Jun. 1992. [2] C. T. Pan and E. Fang, A phase-locked-loop-assisted internal model adjustable-speed controller for BLDC motors, IEEE Trans. Ind. Electron., vol. 55, no. 9, pp. 34153425, Sep. 2008. [3] K. Y. Nam, W. T. Lee, C. M. Lee, and J. P. Hong, Reducing torque ripple of brushless dc motor by varying input voltage, IEEE Trans. Magn., vol. 42, no. 4, pp. 13071310, Apr. 2006. [4] J. Cao, B. Cao, P. Xu, S. Zhou, G. Guo, and X. Wu, Torque ripple control of position-sensorless brushless dc motor based on neural network identication, in Proc. IEEE ICIEA, 2008, pp. 752757. [5] X. Xiao, Y. Li, M. Zhang, and M. Li, A novel control strategy for brushless dc motor drive with low torque ripples, in Proc. IEEE IECON, 2005, pp. 16601664. [6] D. K. Kim, K. W. Lee, and B. I. Kwon, Commutation torque ripple reduction in a position sensorless brushless dc motor drive, IEEE Trans. Power Electron., vol. 21, no. 6, pp. 17621768, Nov. 2006.

Yen-Shin Lai received the M.S. degree in electronic engineering from the National Taiwan University of Science and Technology, Taipei, Taiwan, and the Ph.D. degree in electronic engineering from the University of Bristol, Bristol, U.K. In 1987, he joined the Electrical Engineering Department, National Taipei University of Technology, Taipei, as a Lecturer, where he has been a Full Professor since 1999 and where he served as the Chairperson in 20032006. He has been a Distinguished Professor since 2006. His research interests include the design of control IC, circuit design of dc/dc converter, and inverter control. Dr. Lai served as the Secretary of the IEEE IAS Industrial Drives Committee in 20082009, the Chapter Chair of the IEEE IAS Taipei Chapter in 20092010, and the Editor-in-Chief of the Journal of Power Electronics, Taiwan Power Association, in 20082011. He is currently the Vice Chair (20102013) of the IEEE IAS Industrial Drives Committee and an Associate Editor of the IEEE T RANSACTIONS ON I NDUSTRIAL E LECTRONICS and IEEE T RANSACTIONS ON I NDUSTRY A PPLICATIONS . He is an AdCom member (20112013) of the IEEE Industrial Electronics Society and board member of the Taiwan Power Electronics Association. He received several national and international awards, including the John Hopkinson Premium for the session 19951996 from the Institute of Electrical Engineers, the Technical Committee Prize Paper Award from the IEEE IAS Industrial Drives Committee for 2002, the Best Presentation Award from IEEE IECON in 2004, and the Best Paper Award from Taiwan Power Electronics Conference in 2009 and 2010.

Вам также может понравиться

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Impressionism and Its CanonsДокумент303 страницыImpressionism and Its CanonsAni Thomas100% (4)

- Privatisation: A Formula For Provision or Perversion of Municipal Solid Waste Management?Документ56 страницPrivatisation: A Formula For Provision or Perversion of Municipal Solid Waste Management?SoniaSegerMercedesОценок пока нет

- Remote Viewing, Anytime, From Anywhere: Product DetailsДокумент15 страницRemote Viewing, Anytime, From Anywhere: Product DetailsShrijendra ShakyaОценок пока нет

- Electronics Primer: RC Filters and Op-Amp BasicsДокумент11 страницElectronics Primer: RC Filters and Op-Amp BasicsAlexandre RamosОценок пока нет

- This Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsДокумент298 страницThis Manual Includes: Repair Procedures Fault Codes Electrical and Hydraulic SchematicsJugaro OscarОценок пока нет

- SF - Domestic Water PipingДокумент16 страницSF - Domestic Water PipingJahat AtencioОценок пока нет

- Marcet BoilerДокумент7 страницMarcet BoilerSt Oong100% (1)

- Tone Totke Aur Upay Pitradosh UpayДокумент156 страницTone Totke Aur Upay Pitradosh Upayajay bhatnagarОценок пока нет

- Seeing Sounds Worksheet: Tuning Fork StationДокумент2 страницыSeeing Sounds Worksheet: Tuning Fork StationEji AlcorezaОценок пока нет

- Rickmeier - Gear Pump R25-16 PDFДокумент48 страницRickmeier - Gear Pump R25-16 PDFAdam Kowalski60% (5)

- Japanese Construction Firms enДокумент4 страницыJapanese Construction Firms enLanang Ardi ParinggaОценок пока нет

- VA CarparkManagementSysДокумент22 страницыVA CarparkManagementSysmerkermanОценок пока нет

- Panduit Electrical CatalogДокумент1 040 страницPanduit Electrical CatalognumnummoОценок пока нет

- Regulador Voltage 3.3v Xbox360Документ18 страницRegulador Voltage 3.3v Xbox360ignorameОценок пока нет

- Closed Source DocumentationДокумент12 страницClosed Source Documentation이즈르엘Оценок пока нет

- Configure Dynamic NAT and PATДокумент20 страницConfigure Dynamic NAT and PATMary Amirtha Sagayee. GОценок пока нет

- Performance Adjustment On Me Engine 20130415Документ24 страницыPerformance Adjustment On Me Engine 20130415NAGENDRA KUMAR DONTULAОценок пока нет

- Catalog Zumex Multifruit 2021Документ7 страницCatalog Zumex Multifruit 2021Valentin ValentinОценок пока нет

- BSC Agri Engineering Course OutlineДокумент117 страницBSC Agri Engineering Course OutlineFarhanAwaisiОценок пока нет

- Electric Loco Moti 00 NewtДокумент232 страницыElectric Loco Moti 00 NewtNanu KaruniaОценок пока нет

- (X) Selection Guide - PowerFlex Low Voltage Drives - PFLEX-SG002K-En-P - February 2017Документ178 страниц(X) Selection Guide - PowerFlex Low Voltage Drives - PFLEX-SG002K-En-P - February 2017Nicolás A. SelvaggioОценок пока нет

- Java Important Questions SetДокумент64 страницыJava Important Questions SetChairil Aditya NurfadlilahОценок пока нет

- SMPS Application NotesДокумент4 страницыSMPS Application Notesalguien1972Оценок пока нет

- How To Upgrade IOS Image On Cisco Catalyst Switch or RouterДокумент4 страницыHow To Upgrade IOS Image On Cisco Catalyst Switch or RouterBarbara ChamberlainОценок пока нет

- Userspace Drivers in LinuxДокумент4 страницыUserspace Drivers in LinuxJeffi Edward100% (1)

- Midterm Exam Summary For Data Communications PDFДокумент9 страницMidterm Exam Summary For Data Communications PDFKit Jason MonjeОценок пока нет

- Flight 60T Turbine Operating ManualДокумент128 страницFlight 60T Turbine Operating Manualtravieso112Оценок пока нет

- Ultima Forte Required Data Inputs For Nokia InfrastructureДокумент61 страницаUltima Forte Required Data Inputs For Nokia InfrastructureAlexDon81Оценок пока нет

- BP Solar Bp275Документ2 страницыBP Solar Bp275NandoMoralesОценок пока нет