Академический Документы

Профессиональный Документы

Культура Документы

Making Hollow Ring

Загружено:

ezequielmzИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Making Hollow Ring

Загружено:

ezequielmzАвторское право:

Доступные форматы

Making a hollow ring - Fretz Design, Goldsmiths, Jewelry, Smithing Tools and Met...

Pgina 1 de 7

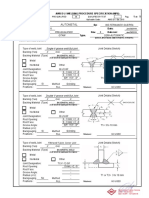

MAKING A HOLLOW RING

These four stakes (R-1,R-2,R-3 and F-8) are designed to make hollow rings. They are also useful for general forming and large bezel work. By choosing different stakes, a single blank as it is formed, will take on many different shapes. The metal conforms to the curve of the stake as the hammer compresses the metal against it.

The first step in designing a hollow ring is to make a paper pattern. It is a good idea to make the metal inner rim first as this determines the ring size. Then make the pattern fit over this band. The paper pattern allows the craftsperson see the

http://www.fretzdesign.com/tools/making-hollow-ring.html

28/09/2011

Making a hollow ring - Fretz Design, Goldsmiths, Jewelry, Smithing Tools and Met... Pgina 2 de 7

shape in 3-D if the ends are taped together. This pattern can be fixed to the sheet metal with rubber cement or two way tape before cutting with a jewelers saw and a 2/0 blade. Make a metal template if the design is to be repeated often.

The ring blank is bent into a U shape with round pliers and one set of tabs bent to meet. It is much easier to do one side at a time. Doing both together makes it a balancing act.

File the ends to be soldered true so the seam will be tight. Flattening and getting a perfect fit is easy if the ends are very lightly hammered over a Rolled Edge Domed Bezel Stake (B-6 Stake) . Two bench mounted holders save changing time on projects requiring multiple stakes.

http://www.fretzdesign.com/tools/making-hollow-ring.html

28/09/2011

Making a hollow ring - Fretz Design, Goldsmiths, Jewelry, Smithing Tools and Met... Pgina 3 de 7

Use a hard solder for the first seams. It is important to use enough solder so this seam does not have to be resoldered. Hard solder works best if done once. Flip over and repeat the forming and soldering of the other side. Hammer either side of the solder joint on the same stake again so the seam domes up slightly. It is important not to hit the solder. Use a plastic or rawhide hammer to be safe. The slightly domed solder seam is easier to clean up. File with a #2 cut flat file. Follow up with 320 emery cloth or paper to leave a relatively smooth surface.

Begin hammering the top section of the ring over a Tapered Rounded Raising Stake (R-2) or if the ring is big, a Rounded Raising Stake (R-3). The ring will become round if the ring is rotated around the stake while hammering. Plannish the low spots to bring them up. This seems backwards, but because the metal has nowhere to go after striking the stake, the stretched metal pops up. The smoothing of the metal against a stake with repetitious hammer blows is called plannishing.

http://www.fretzdesign.com/tools/making-hollow-ring.html

28/09/2011

Making a hollow ring - Fretz Design, Goldsmiths, Jewelry, Smithing Tools and Met... Pgina 4 de 7

The ring shank or any part of the ring can be domed on a Horn Stake (F-8). This is done by leaving a space between the metal and the stake and using the rounded side of the plannishing hammer to move the metal down to the stake without stretching it. This is raising and does not thin the metal like plannishing. The doming of the shank reduces the ring size and this can be helpful getting the correct size. After the desired form is roughed out, the hammer is flipped over and the flat side is used to plannish the piece smooth.

Stamp the hallmarks on the inner band at this stage as stamping later becomes impossible. Slide the inner band inside the ring shell.

http://www.fretzdesign.com/tools/making-hollow-ring.html

28/09/2011

Making a hollow ring - Fretz Design, Goldsmiths, Jewelry, Smithing Tools and Met... Pgina 5 de 7

The first step in designing a hollow ring is to make a paper pattern. It is a good idea to make the metal inner rim first as this determines the ring size. Then make the pattern fit over this band. The paper pattern allows the

Tap both ends of the inner band with a slightly larger dapping punch to get a very tight fit. This will make the solder seams virtually invisible.

http://www.fretzdesign.com/tools/making-hollow-ring.html

28/09/2011

Making a hollow ring - Fretz Design, Goldsmiths, Jewelry, Smithing Tools and Met... Pgina 6 de 7

A top unit or bezel is made with a slight taper. The taper is useful because the top unit will get tighter as it moves into position. If the side walls of the top bezel are parallel, you only have one chance at a good fit.

A vent hole should be drilled before soldering the inner ring and top to the ring blank. It is important to do this as part of a seam will not close, or worse, you could have the piece explode.

http://www.fretzdesign.com/tools/making-hollow-ring.html

28/09/2011

Making a hollow ring - Fretz Design, Goldsmiths, Jewelry, Smithing Tools and Met... Pgina 7 de 7

Chrysoprase rough was then cut to fit with a slight bevel. Set by chasing and then ground and polished flush with the rings top. The inner band is trimmed off with a 2/0 jewelers saw blade and the whole ring filed flush. First 320, then 600 emery cloths were used to smooth the surface. The first buffing compound was bobbing on a wool sewn buff and this was followed by white diamond on a cotton buff. PRICE LIST - BEZEL INSTRUCTIONS - TRICKS FOR HOLLOW RINGS HOME PAGE - TOOLS PAGE - H-1 STAKE HOLDER INSTALLATION gold@fretzgoldsmiths.com FRETZ DESIGN, LLC 20 Elm Street P.O. Box 1010 Bucksport, Maine 04416 207-469-2700

2006 Fretz Design

http://www.fretzdesign.com/tools/making-hollow-ring.html

28/09/2011

Вам также может понравиться

- Jewelry Making for Beginners: 32 Projects with MetalsОт EverandJewelry Making for Beginners: 32 Projects with MetalsРейтинг: 4 из 5 звезд4/5 (2)

- Chainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyОт EverandChainmail Made Easy: Learn to Chainmail in 24 Hours or Less!: Chainmail Made EasyРейтинг: 5 из 5 звезд5/5 (4)

- Making Your Own Jewelry Like A ProДокумент40 страницMaking Your Own Jewelry Like A ProNadia Oliphant-Momplè100% (1)

- Gemstone Settings BLAD WebДокумент8 страницGemstone Settings BLAD WebInterweave75% (16)

- Copper Work: A Text Book for Teachers and Students in the Manual ArtsОт EverandCopper Work: A Text Book for Teachers and Students in the Manual ArtsОценок пока нет

- Metal Jewelry Workshop: Essential Tools, Easy-to-Learn Techniques, and 12 Projects for the Beginning Jewelry ArtistОт EverandMetal Jewelry Workshop: Essential Tools, Easy-to-Learn Techniques, and 12 Projects for the Beginning Jewelry ArtistРейтинг: 4 из 5 звезд4/5 (2)

- Handcrafted Jewelry Step by Step: Crafts Series, #1От EverandHandcrafted Jewelry Step by Step: Crafts Series, #1Рейтинг: 4 из 5 звезд4/5 (1)

- Wire Jewelry Photo Gallery: Crafts Series, #3От EverandWire Jewelry Photo Gallery: Crafts Series, #3Рейтинг: 4.5 из 5 звезд4.5/5 (3)

- So You Want To Be A Jewelry Designer: Merging Your Voice With FormОт EverandSo You Want To Be A Jewelry Designer: Merging Your Voice With FormОценок пока нет

- The Cutting, Setting and Engraving of Precious Stones - A Historical Article on Working GemstonesОт EverandThe Cutting, Setting and Engraving of Precious Stones - A Historical Article on Working GemstonesОценок пока нет

- Simple Beginnings: Soldering Jewelry: A Step-by-Step Guide to Creating Your Own Necklaces, Bracelets, Rings & MoreОт EverandSimple Beginnings: Soldering Jewelry: A Step-by-Step Guide to Creating Your Own Necklaces, Bracelets, Rings & MoreОценок пока нет

- Chain Maille Wire Weaving: How to Make Chain Maille With Affordable Metals and Minimal ToolsОт EverandChain Maille Wire Weaving: How to Make Chain Maille With Affordable Metals and Minimal ToolsОценок пока нет

- The Jeweler's Studio Handbook: Traditional and Contemporary Techniques for Working with Metal and Mixed Media MaterialsОт EverandThe Jeweler's Studio Handbook: Traditional and Contemporary Techniques for Working with Metal and Mixed Media MaterialsРейтинг: 5 из 5 звезд5/5 (2)

- Silverwork and JewelryДокумент542 страницыSilverwork and JewelryIoana Balint-Rădulescu86% (7)

- Silver Jewelry Making: An Easy & Complete Step by Step GuideОт EverandSilver Jewelry Making: An Easy & Complete Step by Step GuideРейтинг: 3 из 5 звезд3/5 (7)

- Twisted Earrings Wire & Jewelry Making Tutorial Series T163От EverandTwisted Earrings Wire & Jewelry Making Tutorial Series T163Рейтинг: 2 из 5 звезд2/5 (1)

- The Craft of Jewellery Making - A Collection of Historical Articles on Tools, Gemstone Cutting, Mounting and Other Aspects of Jewellery MakingОт EverandThe Craft of Jewellery Making - A Collection of Historical Articles on Tools, Gemstone Cutting, Mounting and Other Aspects of Jewellery MakingОценок пока нет

- Metal Jewelry in Bloom PDFДокумент113 страницMetal Jewelry in Bloom PDFbgvt100% (3)

- Jewelry Making Tools 1Документ29 страницJewelry Making Tools 1orquideasanchez100% (8)

- Glass Beads: Tips, Tools, & Techniques for Learning the CraftОт EverandGlass Beads: Tips, Tools, & Techniques for Learning the CraftРейтинг: 3 из 5 звезд3/5 (2)

- Handcrafted Jewelry Photo Gallery: Crafts Series, #2От EverandHandcrafted Jewelry Photo Gallery: Crafts Series, #2Рейтинг: 4 из 5 звезд4/5 (1)

- The Pearl Book (4th Edition): The Definitive Buying GuideОт EverandThe Pearl Book (4th Edition): The Definitive Buying GuideОценок пока нет

- Wire Jewelry Make It Funky! - Release Your Funky Wire Jewelry StyleОт EverandWire Jewelry Make It Funky! - Release Your Funky Wire Jewelry StyleРейтинг: 4 из 5 звезд4/5 (4)

- Guide To Jewelry TechniquesДокумент22 страницыGuide To Jewelry TechniquesJill Krahling80% (5)

- Intermediate Wire Weaving: How to Create Wire Jewelry Without Splurging on Expensive MetalsОт EverandIntermediate Wire Weaving: How to Create Wire Jewelry Without Splurging on Expensive MetalsРейтинг: 2.5 из 5 звезд2.5/5 (3)

- Engraving Metals: With Numerous Engravings and DiagramsОт EverandEngraving Metals: With Numerous Engravings and DiagramsРейтинг: 5 из 5 звезд5/5 (1)

- Wired Chinese Knot, Wire Jewelry Tutorial: Layer Coiled Crystal Pearls EarringsОт EverandWired Chinese Knot, Wire Jewelry Tutorial: Layer Coiled Crystal Pearls EarringsРейтинг: 1 из 5 звезд1/5 (1)

- Kumihimo Wire Weaving: How to Make Wire Kumihimo Braids With Affordable Metals and Minimal ToolsОт EverandKumihimo Wire Weaving: How to Make Wire Kumihimo Braids With Affordable Metals and Minimal ToolsРейтинг: 2.5 из 5 звезд2.5/5 (3)

- Metalwork Jewelry: 35 step-by-step projects inspired by steampunkОт EverandMetalwork Jewelry: 35 step-by-step projects inspired by steampunkРейтинг: 0.5 из 5 звезд0.5/5 (1)

- Enameling Jewelry Free EbookДокумент22 страницыEnameling Jewelry Free EbookAwo Òkànràn DuuruОценок пока нет

- Gemstone Facet Cutting - A Collection of Historical Articles on Methods and Equipment Used for Working GemsОт EverandGemstone Facet Cutting - A Collection of Historical Articles on Methods and Equipment Used for Working GemsОценок пока нет

- Wire Weaving: Beginner + Intermediate Guide to Wire Weaving: 2-in-1 Wire Weaving Compendium for Beginner and Intermediate Wire WorkersОт EverandWire Weaving: Beginner + Intermediate Guide to Wire Weaving: 2-in-1 Wire Weaving Compendium for Beginner and Intermediate Wire WorkersРейтинг: 3 из 5 звезд3/5 (5)

- DIY Stamped Metal Jewelry: From Monogrammed Pendants to Embossed Bracelets--30 Easy Jewelry Pieces from HappyHourProjects.com!От EverandDIY Stamped Metal Jewelry: From Monogrammed Pendants to Embossed Bracelets--30 Easy Jewelry Pieces from HappyHourProjects.com!Рейтинг: 5 из 5 звезд5/5 (1)

- Jewelry Making: Step by step Guide To Creating Your Own Original And Unique JewelryОт EverandJewelry Making: Step by step Guide To Creating Your Own Original And Unique JewelryОценок пока нет

- Wire Weaving: Beginner + Intermediate Guide + Chain Maille + Kumihimo Wire Weaving: 4-in-1 Wire Weaving Compendium for Beginner Wire WorkersОт EverandWire Weaving: Beginner + Intermediate Guide + Chain Maille + Kumihimo Wire Weaving: 4-in-1 Wire Weaving Compendium for Beginner Wire WorkersРейтинг: 3 из 5 звезд3/5 (5)

- The Art of Gem Cutting - Including Cabochons, Faceting, Spheres, Tumbling and Special TechniquesОт EverandThe Art of Gem Cutting - Including Cabochons, Faceting, Spheres, Tumbling and Special TechniquesОценок пока нет

- Soldering How To Solder Jewelry JMD PDFДокумент16 страницSoldering How To Solder Jewelry JMD PDFPaul Blythe Sr.75% (4)

- Creating Wooden Jewelry: 20 Skill-Building Projects and TechniquesОт EverandCreating Wooden Jewelry: 20 Skill-Building Projects and TechniquesОценок пока нет

- Magical Metal Clay: Amazingly Simple No-Kiln Techniques For Making Beautiful AccessoriesОт EverandMagical Metal Clay: Amazingly Simple No-Kiln Techniques For Making Beautiful AccessoriesРейтинг: 4 из 5 звезд4/5 (4)

- BS 115 - Rev 1 (STUD) Guidelines For Composite GirdersДокумент25 страницBS 115 - Rev 1 (STUD) Guidelines For Composite Girderserharsingh83% (6)

- Technology Multi Choice Exam Package 4 QДокумент5 страницTechnology Multi Choice Exam Package 4 QraofrhanОценок пока нет

- PDIL Cable Tray RackДокумент6 страницPDIL Cable Tray Rack9044nksОценок пока нет

- Handcraft in Wood and MetalДокумент288 страницHandcraft in Wood and MetalArtisan Ideas100% (3)

- Flange Loading CheckДокумент48 страницFlange Loading CheckrefuzerОценок пока нет

- BMT WeldingGuide 1017 2Документ8 страницBMT WeldingGuide 1017 2kcarmachОценок пока нет

- Pages From Asme Viii Div 1-2007Документ2 страницыPages From Asme Viii Div 1-2007kaustubh_dec17Оценок пока нет

- Steel Strip SpecificationsДокумент2 страницыSteel Strip SpecificationsAndre SodaОценок пока нет

- FSX 414 Weld Wire PDFДокумент1 страницаFSX 414 Weld Wire PDFJ. BangjakОценок пока нет

- Grundfosliterature 1654 PDFДокумент64 страницыGrundfosliterature 1654 PDFkiranОценок пока нет

- Creep & SpheroidizationДокумент10 страницCreep & Spheroidizationabet_singkong8930Оценок пока нет

- Energimac PHOENIXДокумент4 страницыEnergimac PHOENIXdlight0Оценок пока нет

- Passage 3Документ1 страницаPassage 3retno pideksoОценок пока нет

- Torsionally Stressed CylinderДокумент9 страницTorsionally Stressed CylinderCharyОценок пока нет

- Astm17 0104Документ4 страницыAstm17 0104JMFPОценок пока нет

- Lightolier ProSpec Track Lighting Brochure 1996Документ36 страницLightolier ProSpec Track Lighting Brochure 1996Alan MastersОценок пока нет

- Thornhill Craver Chokes and Couplings PDFДокумент32 страницыThornhill Craver Chokes and Couplings PDFhaidinu100% (3)

- Module 2 Lecture 1 FinalДокумент16 страницModule 2 Lecture 1 Finalvenkateshyadav2116Оценок пока нет

- Useful Grinding InformationДокумент40 страницUseful Grinding InformationmrjkopelОценок пока нет

- 76 - 200Документ11 страниц76 - 200rajaОценок пока нет

- Theoretical Steel Weight Calculation Formula (2018 Updated)Документ12 страницTheoretical Steel Weight Calculation Formula (2018 Updated)Chaitanya Sai T100% (1)

- Catalogo CONNEX 2010-11 PDFДокумент538 страницCatalogo CONNEX 2010-11 PDFschioppoОценок пока нет

- 4340 Wire For Low Alloy SteelsДокумент1 страница4340 Wire For Low Alloy SteelsPankaj KumbhareОценок пока нет

- SIE SA PanelboardsP1-P5Документ84 страницыSIE SA PanelboardsP1-P5asim saeedОценок пока нет

- A Study On The Diffusion Kinetics of Borides On Boronized Cr-Based SteelsДокумент7 страницA Study On The Diffusion Kinetics of Borides On Boronized Cr-Based SteelsSuellen FerreiraОценок пока нет

- Section 2 (Understanding Warren Rupp) KLMДокумент67 страницSection 2 (Understanding Warren Rupp) KLMMaulia SabrinaОценок пока нет

- Brocas WDX Técnica!Документ9 страницBrocas WDX Técnica!Wilson DantasОценок пока нет

- Types of Household Cleaning ProductsДокумент13 страницTypes of Household Cleaning ProductsSheraz Khan100% (2)

- Role of Vanadium in Microalloyed Steels - Lagneborg PDFДокумент86 страницRole of Vanadium in Microalloyed Steels - Lagneborg PDFYogi173Оценок пока нет

- AUT-GMAW-2 Rev.0 PDFДокумент5 страницAUT-GMAW-2 Rev.0 PDFDarioОценок пока нет