Академический Документы

Профессиональный Документы

Культура Документы

Bda20303 Chapter 1-Gear System

Загружено:

Wan SamiraИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bda20303 Chapter 1-Gear System

Загружено:

Wan SamiraАвторское право:

Доступные форматы

CHAPTER 1 POWER TRANSMISSION SYSTEM - GEAR SYSTEM

1.1 Introduction to Gear System 1

1.2 Types oI Gear system 1

1.3 Relationship between pitch diameter and pitch circle 7

1.4 Gear Ratio 9

1.5 Gear Train 11

1.6 Gear EIIiciency 12

1.7 Power Transmission in a Gear Train System 12

1.8 Equivalent Moment oI Inertia 14

1.9 Gear Train Applications 15

1.10 Vehicle Dynamics 22

CHAPTER 1

POWER TRANSMISSION SYSTEM: GEAR SYSTEM

1.1 Gear System

Gears are used Ior two basic purposes; increase or decrease oI rotation speed and increase

or decrease oI power or torque. Torque is a measure oI a Iorce to produce torsion and rotation

about an axis. To increase speed and reduce torque a large drive gear is coupled to a smaller

driven gear. To reduce speed and increase torque a small Lego gear turning a larger gear is used.

They are also used Ior enhancement Ior positioning systems.

In gear system, gear that Iunctions as mover mentioned as driver gear, while gear moved

name as driven gear.

1.2 Types of Gear System

Gears are categorized into several types. They are used in a wide era oI industries

including automotive, milling, paper industry etc. According to diIIerent applications in

industries and diIIerent materials used they are categorized separately. DiIIerent types oI gears

are also custom design and are Iabricated by gear manuIacturing services as par the

speciIications.

Gears Types

- Angular Bevel Gears

- Bevel Gears

- rown Wheel

- rown Wheel and Pinion

- DiIIerential Gears

- ine Pitch Gears

- Girth Gears

- ardened and Ground Gears

- elical Bevel Gears

- elical Gears

- erringbone Gears

- Master Gear

- Mill eaders

- Miter Gears

- on-Involute Gears

- Pinion Gears

- Rack Gears

- Ring Gear and Pinion

- Spiral Bevel Gears

- Spur Gears

- Straight Bevel Gears

- Support Rollers

- Tacho Drives

- Thrust Rollers

- Idler Gear

- Gear Trains

- Planetary Gear

- Ground Gear

- ace Gear

- Internal Gears

- ycloidal Gears

- External Gear

- Winch Gears

- Sprockets

- Worm Gears

- Involute Gears

1able 1

Gear can also be classiIied according to the relative position oI the axes oI mating gears.

Parallel Axes

Intersecting

Axes

Non-Intersecting

(Non-parallel) Axes

Rotary to

Translation

Spur Gears Bevel gears ypoid gears Rack and Pinion

elical Gears Straight bevel rossed helical gears -

erring bone or

double helical

gears

Zerol bevel Worm gears -

- Spiral bevel - -

1able 2

a) !arallel Axes Shaft

The shaIt axes between driver and driven gear is parallel to each other. Example oI this

type oI gear is Spur Gear.

:re 1: Sp:r Cear

Spur gears connect parallel shaIts, have involute teeth that are parallel to the shaIt and

can have internal or external teeth. They cause no external thrust between gears. They are

inexpensive to manuIacture. They give lower but satisIactory perIormance. They are used when

shaIt rotates in the same plane.

The main Ieatures oI spur gears are dedendum, addendum, Ilank, and Iillet. Dedendum

cylinder is a root Irom where teeth extend, it extends to the tip called the addendum circle. lank

or the Iace contacts the meshing gear, the most useIul Ieature iI the spur gears. The Iillet in the

root region is kinetically irrelevant.

The speed and change oI the Iorce depends on the gear ratio, the ratio oI number oI teeth

on the gears that are to be meshed. One gear among the two is on the input axle; the axle oI the

motor and the other gear oI the pair is on the output axle, the axle oI the wheel.

They have higher contact ratio that makes them smooth and quiet in operation. They are

available Ior corrosion resistant operation. They are among the most cost-eIIective type oI

gearing. They are also used to create large gear reductions.

They are available in plastic, non-metallic, brass, steel and cast iron and are manuIactured

in a variety oI styles. They are made with many diIIerent properties. actors like design liIe,

power transmission requirements, noise and heat generation, and presence oI corrosive elements

contribute to the optimization oI the gear material.

Generally used in simple machines like washing machines, clothes dryer or power

winches. They are not used in automobiles because they produce sound when the teeth oI both

the gears collide with each other. It also increases stress on the gear teeth. They are also used in

construction equipment, machine tools, indexing equipment, multi spindle drives, roller Ieeds,

and conveyors.

b) 3tersect3 Axes Shaft

The shaIt axes between driver and driven gear is perpendicular to each other. Example oI

gear is bevel gears.

:re 2: bevel ear

:re 2: Bevel Cear

They connect intersecting axes and come in several types. The pitch surIace oI bevel

gears is a cone. They are useIul when the direction oI a shaIt's rotation needs to be changed.

Using gears oI diIIering numbers oI teeth can change the speed oI rotation. They are usually

mounted on shaIts that are 90 degrees apart, but can be designed to work at other angles as well.

These gears permit minor adjustment during assembly and allow Ior some displacement

due to deIlection under operating loads without concentrating the load on the end oI the tooth.

or reliable perIormance, Gears must be pinned to shaIt with a dowel or taper pin. Bevel gear

sets consist oI two gears oI diIIerent pitch diameter that yield ratios greater than 1:1.

The teeth on bevel gears can be straight, spiral or bevel. In straight bevel gears teeth have

no helix angles. They either have equal size gears with 90 degrees shaIt angle or a shaIt angle

other than 90 degrees. Straight bevel angle can also be with one gear Ilat with a pitch angle oI 90

degrees. In straight when each tooth engages it impacts the corresponding tooth and simply

curving the gear teeth can solve the problem. Spiral bevel gears have spiral angles, which gives

perIormance improvements. The contact between the teeth starts at one end oI the gear and then

spreads across the whole tooth. In both the bevel types oI gears the shaIt must be perpendicular

to each other and must be in the same plane. The hypoid bevel gears can engage with the axes in

diIIerent planes. This is used in many car diIIerentials. The ring gear oI the diIIerential and the

input pinion gear are both hypoid. This allows input pinion to be mounted lower than the axis oI

the ring gear. ypoid gears are stronger, operate more quietly and can be used Ior higher

reduction ratios. They also have sliding action along the teeth, potentially reducing eIIiciency.

A good example oI bevel gears is seen as the main mechanism Ior a hand drill. As the

handle oI the drill is turned in a vertical direction, the bevel gears change the rotation oI the

chuck to a horizontal rotation. The bevel gears in a hand drill have the added advantage oI

increasing the speed oI rotation oI the chuck and this makes it possible to drill a range oI

materials.

The bevel gears Iind its application in locomotives, marine applications, automobiles,

printing presses, cooling towers, power plants, steel plants, deIenses and also in railway track

inspection machine. They are important components on all current rotorcraIt drive system.

Spiral bevel gears are important components on all current rotorcraIt drive systems.

These components are required to operate at high speeds, high loads, and Ior an extremely large

number oI load cycles. In this application, spiral bevel gears are used to redirect the shaIt Irom

the horizontal gas turbine engine to the vertical rotor.

c) 433tersect3 (43parallel) Axes Shaft

The shaIt axes between the driver and driven gears are not intersecting but not parallel at

the same time. A very good example oI a non-intersecting-non-parallel gear system is a worm

gear as in igure 3.

:re 3: W4rm Cear

A worm gear is an inclined plane wrapped around a central axle. It is a gear with one or

more teeth in the Iorm oI screwed threads. Worm gears are made oI two parts: the pinion and the

worm gear. The pinion has small number oI teeth and they wrap around the pitch cylinder. The

worm gear has concave Iaces to Iit the curvature oI the worm in order to provide line oI contact

instead oI point oI contact. They are cut helically Ior better mating Worm gears can provide a

high angular velocity between non-intersecting shaIts at right angles.

They are capable oI transmitting high tooth loads, the only disadvantage is the high

sliding velocities across the teeth. They provide ultimate power ratio. The eIIiciency oI worm

gear depends on the lead angle, sliding speed, and lubricant, surIace quality and installation

conditions. They oIIer smoothest, quietest Iorm oI gearing. They provide high-ratio speed

reduction in minimal spaces.

Worm gears are used when large gear reductions are required. Worm gear has a unique

property oI easily turning the gear. The gear cannot turn the worm because the angle on the

worm is shallow and when the gear tries to spin the worm, the Iriction between the two holds the

worm in place.

Worm gears work under diIIicult conditions, presenting unique lubrication demands. The

types oI oils most commonly used to lubricate worm gears are compounded mineral oils, EP

mineral gear oils and synthetics. Worm gear is always used as the input gear. or the operation

oI worm gear, torque is applied to the input end oI the worm shaIt by a driven sprocket or

electric motor. The worm and the worm shaIt are supported by anti-Iriction roller bearings.

Because oI high Iriction worm gears are very ineIIicient. There is lot oI Iriction between a worm

gear and the gear being driven by the worm gear. When used in high torque applications, the

Iriction causes the wear on the gear teeth and erosion oI restraining surIace.

There are three types oI worm gears. on throated- a helical gear with a straight worm.

Tooth contact is a single moving point on the worm drive. Single throated- has concave helical

teeth wrap around the worm. This leads to line contact. Double throated- called a cone or

hourglass. It has concave teeth both on the worm and helical gear. Worm gears are widely used

in packaging machinery, material handling, machine tools, indexing and Iood processing. They

are used widely in conveyor systems. They are also used in torsen diIIerential, used on some

high-perIormance cars and trucks. They serve as speed reducers in many diIIerent industries.

/) !erpe3/c:lar Axes Shaft / R4tary t4 1ra3slat43

The shaIt axes between driver and driven gear are perpendicular to each other and do not

intersect to each other. Example oI gear is Rack and Pinion Gear.

:re 4: Rack a3/ !343 Cear

Rack and pinion gears are used to convert rotation into linear motion. The speed with

which the rack moves as the pinion turns is determined by the diameter oI the gear. The Ilat,

toothed part is the rack and the gear is the pinion. A piston coaxial to the rack provides hydraulic

assistance Iorce, and an open centered rotary valve controls the assist level. A rack and pinion

gears system is composed oI two gears. The normal round gear is the pinion gear and the straight

or Ilat gear is the rack. The rack has teeth cut into it and they mesh with the teeth oI the pinion

gear. Rack and pinion gears provide a less mechanical advantage than other mechanisms, but

greater Ieedback and steering sensation.

Rack and pinion gears are available in three variations: straight teeth metric pitch, straight

teeth modular pitch, and helical teeth modular pitch. Rack and pinion gears variations are

available in diIIerent qualities: 9/10 milled teeth or milled and hardened quality, 7/8 precision cut

or precision cut and hardened quality, and 5/6 teeth hardened and ground quality. A rack and

pinion gear gives a positive motion especially compared to the Iriction drive oI a wheel in

tarmac. In a rack and pinion railway, a central rack between the two rails engages with a pinion

on the engine allowing a train to be pulled up very steep slopes. A ring and pinion gear is the

diIIerential's critical point oI power transIer. A ring and pinion gear set is one oI the simplest

perIormance modiIications that can be perIormed on a vehicle. The most common reason to

change ring and pinion ratios Irom the original equipment is to retain power when bigger tires

are put on a vehicle. The torque can be increased by a ratio change when there is enhanced

pulling or higher take oII power Irom a dead start. A well designed mechanism such as the rack

and pinion gears save eIIort and time.

Rack and pinions gears are commonly used in the steering system oI cars to convert the

rotary motion oI the steering wheel to the side to side motion in the wheels. The steering wheel

rotates a gear which engages the rack. As the gear turns, it slides the rack either to the right or

leIt, depending on which way the wheel is turned. Rack and pinion gears are also used in some

scales to turn the dial that displays a weight.

1.3 Relationship between Pitch Diameter and Pitch Circle

:re 5: Cear term34l4y

Some oI the terminology oI gear system includes;

- Pitch surface : The surIace oI the imaginary rolling cylinder (cone, etc.) that the toothed

gear may be considered to replace.

- Pitch circle: A right section oI the pitch surIace.

- Addendum circle: A circle bounding the ends oI the teeth, in a right section oI the gear.

- Root (or dedendum) circle: The circle bounding the spaces between the teeth, in a right

section oI the gear.

- Addendum: The radial distance between the pitch circle and the addendum circle.

- Dedendum: The radial distance between the pitch circle and the root circle.

- Clearance: The diIIerence between the dedendum oI one gear and the addendum oI the

mating gear.

- lank of a tooth: The part oI the tooth surIace lying inside the pitch surIace.

- Circular thickness (also called the tooth thickness): The thickness oI the tooth

measured on the pitch circle. It is the length oI an arc and not the length oI a straight line.

- Tooth space: The distance between adjacent teeth measured on the pitch circle.

- acklash: The diIIerence between the circle thickness oI one gear and the tooth space oI

the mating gear.

- Circular pitch p: The width oI a tooth and a space, measured on the pitch circle.

- Diametral pitch P: The number oI teeth oI a gear per inch oI its pitch diameter. A

toothed gear must have an integral number oI teeth. The circular pitch, thereIore, equals

the pitch circumIerence divided by the number oI teeth. The diametral pitch is, by

deIinition, the number oI teeth divided by the pitch diameter. That is,

N

D

p

x

= and

D

N

P = ence x = pP

Where;

p circular pitch N number oI teeth

P diametral pitch D pitch diameter

That is, the product oI the diametral pitch and the circular pitch equals .

- Module m: Pitch diameter divided by number oI teeth. The pitch diameter is usually

speciIied in inches or millimeters; in the Iormer case the module is the inverse oI

diametral pitch.

- Pinion: The smaller oI any pair oI mating gears. The larger oI the pair is called simply

the gear.

- 'elocity ratio: The ratio oI the number oI revolutions oI the driving (or input) gear to the

number oI revolutions oI the driven (or output) gear, in a unit oI time.

- Pitch point: The point oI tangency oI the pitch circles oI a pair oI mating gears.

- Pressure angle : The angle between the common normal at the point oI tooth contact

and the common tangent to the pitch circles. It is also the angle between the line oI action

and the common tangent.

1.4 Gear Ratio

Gear ratio 3 is deIined as ratio oI speed oI driven gear with the speed oI driver gear.

onsider a gear set below;

:re : Cear set

When two gear mate eIIiciently at point A, the vel4cty, ; 4f b4th ear are the same.

Thus;

2 1

; ; ; = =

with

2

D

; =

Then Irom

2 2

2 2 1 1

D D

= will produce

1

2

2

1

D

D

=

Where

1

speed oI driver gear

2

speed oI driven gear

D

1

pitch diameter oI driver gear

D

2

pitch diameter oI driven gear

ence, gear ratio, n;

1

2

2

1

2

1

1

2

= = = =

N

N

D

D

3

Where N

1

number teeth oI driver gear

N

2

number teeth oI driven gear

1

angular acceleration oI driver gear

2

angular acceleration oI driven gear

Driver gear

Driven gear

1.5 Gear Train

Gear trains consist oI two or more gears Ior the purpose oI transmitting motion Irom one

axis to another.

Simple Gear Train is the most common oI the gear train is the gear pair connecting

parallel shaIts. The teeth oI this type can be spur, helical or herringbone. The angular velocity is

simply the reverse oI the tooth ratio. The main limitation oI a simple gear train is that the

maximum speed change ratio is 10:1. or larger ratio, large sizes oI gear trains are required; this

may result in an imbalance oI strength and wear capacities oI the end gears.

The sprockets and chain in the bicycle is an example oI simple gear train. When the

paddle is pushed, the Iront gear is turned and that meshes with the links in the chain. The chain

moves and meshes with the links in the rear gear that is attached to the rear wheel. This enables

the bicycle to move.

Compound Gear Train is used Ior large velocities, compound arrangement is preIerred.

Two keys are keyed to a single shaIt. A double reduction train can be arranged to have its input

and output shaIts in a line, by choosing equal center distance Ior gears and pinions.

Gear trains are used in representing the phases oI moon on a watch or clock dial. It is also

used Ior driving a conventional two-disk lunar phase display oII the day-oI-the-week shaIt oI the

calendar.

:re 7 (a) Smple ear tra3 (b) C4mp4:3/ ear tra3

When a gear train is complex (consist oI many gear sets), it is important Ior the designer

to identiIy the rotation oI the driver and the Iinal driven gear respectively. owever, there is a

simple Iormula to determine the rotation oI each successive gear in a gear train.

:re 8: etw4rk ear sh4rt

A ear trai3 may have several drivers and several driven gears. When gear A turns once

clockwise, gear B turns 4 times counter-clockwise and gear turns once clockwise. ence gear

B does not change the speed oI Irom what it would have been iI geared directly to gear A, but

it changes its direction Irom counterclockwise to clockwise.

:re 9: O// 3:mber 4f mat3 ear

'or an ODD number oI mating gears, the rotation oI Driven gear is the SAME as Driver Gear.

:re 1: Eve3 3:mber 4f mat3 ear

'or an EJE number oI mating gears, the rotation oI Driven gear is REJERSE oI Driver

Gear.

Another classiIication oI gear train is called Reverted Gear Train and Epicyclic Gear Train.

1.6 Gear Efficiency

Gear eIIiciency is deIined as the ratio oI Output Power Irom Driven Gear to the Input

Power Irom Driver Gear. Gear eIIiciency measures how eIIicient a gear system is to transmit

power. igh value oI gear eIIiciency reIlects a more eIIicient gear system. Power loss in a gear

system may come Irom sources like Iriction, slip, backlash and so on.

rom Power, % P = , then

Gear EIIiciency, 3

%

%

%

%

P

P

G

1

2

1 1

2 2

1

2

2 1 ,

= = =

g

Where

1

P Input power Irom driver gear

2

P Output power Irom driven gear

3 Gear ratio

II the 0 . 1 =

G

g , thus the torque at driver gear

1

% is;

2 1

3% % =

II the 0 . 1 =

G

g , thus the torque at driver gear

1

% is;

2 1 ,

2

1

=

G

3%

%

g

1.7 Power Transmission in a Gear Train System

In a gear train system, power loss normally happen in the bearing and gear due to Iriction

and loading imposed on it and also power loss in overcoming shaIt inertia. onsider a gear train

consists oI two sets oI gear reducing arrangement. A motor is attached to the system with

m

I is

the moment oI inertia oI motor shaIt,

%

I is moment oI inertia oI middle shaIt and

G

I is the

moment oI inertia oI hoist which acts as the load oI the system. Gear ratio and gear eIIiciency oI

gear set 1-2 is

2 / 1

3 and

2 / 1 G

g , between gear set 3-4 is

4 / 3

3 and

4 / 3 G

g respectively. Let;

m

% Torque oI motor

G

% Torque oI hoist

% riction torque at bearing X

Draw the Iree body diagram and using ewton Second Law,

= I %

:re 11: ree b4/y /aram

Assume clockwise direction as positive value.

4r (A)

m m m

I % % =

1

........................ (1)

4r (B)

% %

I % % =

3 2

......................... (2)

Since there is gear mating between gear 1 and 2, thus, must include in the analysis its own gear

ratio and gear eIIiciency, and relate it to the inertia oI middle shaIt,

%

I .

Previously,

2 / 1

1

2

2 / 1

3

%

%

G

= g , thus it Iollows that

2 / 1

1 2 / 1

2

3

%

%

G

g

= ............................... (3)

4r (C)

G G G

I % % % =

4

............................. (4)

also

4 / 3

4 / 3 3

4

3

%

%

G

g

= ..............................(5)

Hoist

Using power, , % P = power transIer to each gear component is;

a) !4wer tra3sfer by the m4t4r

m m m

% P =

b) !4wer at ear 1

m m m m m

I % % P = =

1 1

c) !4wer at ear 2

2 / 1 1 2 G

P P g =

/) !4wer at ear 3

% % % %

I % % P = =

2 3 3

e) !4wer at ear 4

4 / 3 3 4 G

P P g =

f) !4wer at h4st

G G G G G G

I % % % P = =

4

) Overall p4wer tra3sfer effce3cy,

g

m

G

P

P

= g

Thus iI Iriction torque,

% eIIect is neglected,

This concludes that

4 / 3 2 / 1 G G

%

G

m

%

m

G

P

P

P

P

P

P

g g g - =

'

+

'

'

+

'

= =

Also;

4 / 3 2 / 1

3 3

%

%

m

G

= g

1.8 Equivalent Moment of Inertia,

equi;

I

onsider a simple gear system as igure below. In order Ior the driver gear A to start

rotate, it must have enough torque to overcome its own inertia,

I Iirst, and then another

additional torque to start accelerate the driver gear B. owever, to relate torque with the gear

parameter, inertia term will be taken into account. or a simple gear system, the solution is

straightIorward, but when it comes to complex gear train design, it is useIul to simpliIy / group

together all inertia term in the system into a single compact inertia expression. The inertia term

oI each moving gear parts will be reIerred to a single part in the system, normally at motor side.

:re 12: Eq:vale3t m4me3t 4f 3erta

1. Torque at B to overcome

I

I % =

ReIer

to gear A side. Use gear ratio,

= =

Thus,

3 I % =

2. Gear eIIiciency is related to power and thus torque oI the mating gears, thus

G

%

3 %

P

P

= = g

3. ThereIore, torque at A, to accelerate

I

G

G

G

G

3 I 3 3 I

3

I 3 %

%

g

g

2

= = = =

4. ThereIore total torque at A to accelerate

I and

I is

%%

% I % =

%%

3 I

I %

g

|

=

2

, Or in general Iorm,

equi; %%

I % = (reIerred to motor side)

Thus

'

+

'

=

G

equi;

3 I

I I

g

2

The derivation oI

equi;

I oI this simple gear system can be extended to a double set oI gear

reducing problem as in section 1.7. By neglecting the Iriction torque eIIect,

% , thus,

) )( (

) ( ) ( ) (

4 / 3 , 2 / 1 ,

2

4 / 3

2

2 / 1

2 / 1 ,

2

2 / 1

G G

G

G

%

m equi;

3 3 I 3 I

I I

g g g

=

Driven gear Driver gear

A

1.9 Gear Train Applications (Solved Problem)

Example 1(1ake3 fr4m R4sla3, Che' Abas, Y:3:s (21), U1M)

A motor is accelerating a 250 kg load with acceleration oI 1.2 m/s

2

through a gear system as

shown below. The rope that carries the load are encircled on a hoist with diameter 1.2m.Gear Ior

the hoist`s shaIt has 200 teeth, gear Ior motor shaIt has 20 teeth. Gear eIIiciency is 90. Mass

and radius oI gyration oI each shaIt is as below;

Mass (kg) Radius oI gyration (mm)

Motor shaIt 250 100

oist shaIt 1100 500

alculate the torque oI the motor needed to bring up the load with acceleration 1.2 m/s

2

. eglect

Iriction eIIect.

:re 13: Cear system attache/ t4 h4st

S4l:t43

Total torque at motor to bring up load

2 1 total

% % % =

Where

1

% Torque to overcome equivalent inertia (reIer to motor side).

2

% Torque to accelerate the load through gear system

a) C43s/er f4r

1

%

rom

G

G

equi;

3 I

I I

g

2

=

Thus

I Motor shaIt inertia

5 . 2 1 . 0 250

2 2

= = = mr I

kgm

2

G

I oist shaIt inertia

275 5 . 0 1100

2

= =

G

I kgm

2

Dia 1.2 m

Hoist

Gear ratio, 1 . 0

200

20

2

1

= = =

N

N

3

Put into

55 . 5

9 . 0

1 . 0 275

5 . 2

2

=

=

equi;

I kgm

2

Acceleration oI hoist,

G G G

r a =

Thus 2

6 . 0

2 . 1

= =

G

rad/s

rom the gear ratio, angular acceleration oI motor, 20

1 . 0

2

= = =

3

G

m

rad/s

ow torque due to equivalent inertia,

m equi;

I % =

1

1 . 111 ) 20 ( 55 . 5

1

= =

% m.

b) C43s/er f4r

2

%

rom ewton 2

nd

Law,

= ma F

N F

a F

a F

5 . 2752

2 . 1 81 . 9 250 250

250 250

=

= =

=

Then, torque at hoist

5 . 1651 6 . 0 5 . 2752 = = = Fr %

G

m

But due to gear eIIiciency (since the hoist shaIt is connected to the gear system), torque to

accelerate the load,

5 . 183

9 . 0

1 . 0 5 . 1651

2 / 1 ,

2 / 1

2

= = =

G

G

3 %

%

g

m

Then total torque reIerred to motor side is;

5 . 183 1 . 111

2 1

=

=

total

total

%

% % %

6 . 294 =

total

% Nm

:re 14: ree b4/y /aram 4f h4st a3/ l4a/

250g

a

T

G

250 kg

r

oist

Example 2(1ake3 fr4m R4sla3, Che' Abas, Y:3:s, (21), U1M)

igure 12 below shows a motor used to accelerate a hoist through two sets oI gear reducing

system. Moment oI inertia Ior the motor shaIt is 5 kgm

2

, middle shaIt is 40 kgm

2

and hoist shaIt

is 500 kgm

2.

Gear ratio Ior gear set 1 and 2 is 1/3.5 while Ior gear set 3 and 4 is 1/ 4.5. Gear

eIIiciency Ior both gear set is 90. By neglecting the Iriction eIIect, Iind the total torque

required by the motor to accelerate the load oI 6 tones at acceleration oI 0.4 m/s

2

.

:re 15: L4a/3 system 43 ear

S4l:t43

Given that

I 5 kgm

2

, 40 =

%

I kgm

2

,

G

I 500 kgm

2

,

5 . 3

1

2 / 1

= 3 ,

5 . 4

1

4 / 3

= 3 , 9 . 0 =

G

g

eglect Iriction eIIect.

Total torque required Ior the motor is

2 1 total

% % % =

Where

1

% Torque to overcome equivalent inertia (reIer to motor side).

2

% Torque to accelerate the load through gear system

a) C43s/er f4r

1

%

Recall that

m equi;

I % =

1

, but Ior two set oI gear system with Iriction eIIect is neglected,

) )( (

) ( ) ( ) (

4 / 3 , 2 / 1 ,

2

4 / 3

2

2 / 1

2 / 1 ,

2

2 / 1

G G

G

G

%

m equi;

3 3 I 3 I

I I

g g g

=

Nm I

equi;

116 . 11

) 9 . 0 )( 9 . 0 (

)

5 . 4

1

( )

5 . 3

1

( 500

9 . 0

)

5 . 3

1

( 40

5

2 2 2

= =

Diameter 1.2 m

Hoist

rom question, given that, 4 . 0 =

G

a m/s

2

, thus;

6 . 0

4 . 0

= =

G

G

G

r

a

6667 . 0 =

G

rad/s

2

rom gear ratio,

75 . 15

1

5 . 3

1

5 . 4

1

= - = - =

m

%

%

G

m

G

Thus,

G m

75 . 15 =

5 . 10 6667 . 0 75 . 15 = =

m

rad/s

2

Thus, 5 . 10 116 . 11

1

= =

m equi; m

I %

72 . 116

1

=

% m.

It is known that

G

% reIerred to motor side will be denoted as

2

% and is related by

4 / 3 , 2 / 1 ,

4 / 3 2 / 1

2

G G

G

3 3 %

%

g g

=

6 . 889

9 . 0 9 . 0

5 . 4

1

5 . 3

1

349 . 11

2

= =

% m

Thus total torque at motor required is

2 1 total

% % % =

6 . 889 72 . 116 =

total

%

32 . 1006 =

total

% Nm.

4500g

1

a

4500 kg

oist

6000g

6000 kg

2

a

:re 1: L4a/3 BD

b) C43s/er f4r

2

% 3 :re 13;

rom ewton 2

nd

Law, ma F =

a F 4500 4500

1

=

42345 41 . 9 4500 4500

1

= = = a F

a F 6000 6000

2

=

61260 6000

2

= = a F

Resultant torque at hoist

915 . 18

1 2

= = F F F

R

k

Thus torque at hoist

349 . 11 6 . 0 915 . 18 = = =

G R G

r F % k

Example 3(1ake3 fr4m R4sla3, Che' Abas, Y:3:s, (21), U1M)

:re 17: Cear wth 3cl3e/ l4a/3

igure 14 above shows a motor accelerating a hoist with diameter 0.9m, through two sets

oI gear reducing system. Gear ratio Ior gear 1 and 2 is 1/3.5 while Ior gear 3 and 4 is 1/ 4.5.

Moment oI inertia Ior the motor shaIt is 5 kgm

2

, middle shaIt is 20 kgm

2

and hoist shaIt is 100

kgm

2

. The rope that is encircled on the hoist must be capable to liIt up a load oI 5 tones that is

sliding on a 1 in 50 slope. riction on the slope is 1000 and the total torque at motor required to

raise the load is 1500. Use gear eIIiciency oI 90 Ior both gear set. II there is Iriction torque

eIIect on the middle shaIt, 150 =

% m and at hoist shaIt is 800 =

% m. alculate the

acceleration oI the load at the above condition.

S4l:t43

or the overall gear ratio,

75 . 15

1

5 . 4

1

5 . 3

1

4 / 3 2 / 1 0

= - = = 3 3 3

Total torque required by motor to raise load

3 2 1 total

% % % % =

Where

1

% Torque to overcome equivalent inertia (reIer to motor side).

2

% Torque to accelerate the load through gear system

=

3

% Total torque to overcome Iriction eIIect.

a) C43s/er f4r

1

%

Previously,

m equi;

I % =

1

or double set oI gear reducing system,

) )( (

) ( ) ( ) (

4 / 3 , 2 / 1 ,

2

4 / 3

2

2 / 1

2 / 1 ,

2

2 / 1

G G

G

G

%

m equi;

3 3 I 3 I

I I

g g g

=

312 . 7

) 9 . 0 )( 9 . 0 (

)

5 . 4

1

( )

5 . 3

1

( 100

9 . 0

)

5 . 3

1

( 20

5

2 2 2

= =

equi;

I kgm

2

Dia 0.9 m

Hoist

rom r a = , thus,

45 . 0

a

r

a

G

G

= =

Also Irom gear ratio,

75 . 15

1

=

m

G

, thus, a

a

G m

35

45 . 0

75 . 15 75 . 15 =

'

+

'

= =

Thus a %

35 312 . 7

1

= a 92 . 255 = m

b) C43s/er f4r

2

% as 3 :re 15;

c) C43s/er f4r

3

%

riction eIIect can be grouped together to Iorm

3

% where;

4 / 3 , 2 / 1 ,

4 / 3 2 / 1

2 / 1 ,

2 / 1

3

G G

Y

G

3 3 % 3 %

%

g g g

=

33 . 110

9 . 0

5 . 4

1

5 . 3

1

800

9 . 0

5 . 3

1

150

2

3

=

'

+

'

'

+

'

'

+

'

% m

rom

3 2 1 total

% % % % =

33 . 110 876 . 69 4 . 176 92 . 255 1500 = a a

Thus 1 . 3 = a m/s

2

R

F

5000g

1

F

0

Mg sin0

r

1

hoist

:re 18: 3cl3e/ l4a/3

rom

= , ma F

ma m F F

R

= sin

1

50

1

81 . 9 5000 1000 5000

1

= a F

81 . 9 5000

1

= a F

Thus, torque to accelerate hoist

45 . 0 81 . 9 5000

1

= = a r F %

G

45 . 891 2250 = a %

G

m

Use gear eIIiciency to relate

G

% with

2

%

4 / 3 , 2 / 1 ,

4 / 3 2 / 1

2

G G

G

3 3 %

%

g g

=

876 . 69 4 . 176

2

= a %

m

1.10 'ehicle Dynamics

:re 19: Jehcle /y3amcs

or a moving vehicle as in igure 16, some oI the Iorces acting on it are;

- riction due to the vehicle`s body (aerodynamic Iriction), R

- orces due to Iriction Irom the engine to the wheel such as Iriction in bearing, shaIt,

clutch and gears,

IN%

R .

- orces due the acceleration oI the vehicle, which is called tractive Iorce,

%

F considering

no slip between the wheel and the road surIace.

We can estimate the speed oI the moving vehicle by considering the speed oI the wheel itselI.

Vehicle speed,

'

+

'

=

2

D

;

r

Example 1 (S4lve/ !r4blem)

Total mass Ior a two wheeled motorcycle including passenger is 190 kg. The engine produce

torque oI 25 m at speed oI 1800 RPM. Moment oI inertia Ior each wheel is 1.4 kgm

2

while Ior

other rotating parts in the engine is considered as 0.15 kgm

2

. The wheel`s eIIective diameter is

610 mm. II the motorcycle is moving on a road with a speed 23 km/hr at second gear, Iind

(i) Gear ratio Ior the second gear

(ii) Acceleration at speed 23 km/hr

Assume wind Iriction is 200 and gear eIIiciency is 90.

S4l:t43

Given that;

m190 kg,

total

% 25 m at N 1800 PM,

R

I 1.4 kgm

2

,

int

I 0.15 kgm

2

, D610 mm,

II ; 23 km/hr at 2

nd

gear, with R 200 ,

G

g 90.

D/2

r

F

%

R

;

Wheel

S:rface

1

st

Step - Draw ree B4/y Daram

:re 2: ree b4/y /aram

2

3/

Step

Total torque at engine,

total

%

2 1 total

% % % =

Where

1

% Torque due to equivalent inertia oI rotating parts in the engine.(reIerred to engine

side).

2

% Torque to accelerate the wheel.

3

r/

Step

onvert all measurement to SI standard.

Engine speed,

5 . 188

60

1800 2

60

2

int

= = =

x xN

rad/s

Wheel speed,

3889 . 6

3600

1000 23

/ 23 = = = hr km ; m/s

4

th

Step- Determ3e

1

%

In order to Iind gear ratio Ior second gear,

9

1

5 . 188

305 . 0

3889 . 6

int

= = =

3

R

(Where

2 D

;

R

= )

1h:s ear rat4 f4r sec43/ ear s

9

1

= 3

Equivalent moment oI inertia is

G

R

equi;

3 I

I I

g

2

int

=

1884 . 0

9 . 0

9

1

4 . 1 2

15 . 0

2

=

-

=

equi;

I kgm

2

In order to Iind

int

, use

R

and gear ratio

Engine

Gear system

Wheel

I

int

I

R

2 D

a

R

=

a

a

3

R

508 . 29

9

1

305 . 0

int

= = =

rad/s

2

Thus, a I %

equi;

508 . 29 1884 . 0

int 1

= =

a %

559 . 5

1

= m.

5

th

Step - Determ3e

2

% as 3 :re 18;

:re 21: /y3amc f4rce 43 the m4t4rcycle

rom

= , ma F

ma R F

%

=

a F

%

190 200 =

Total torque at wheel,

305 . 0 190 200 a r F %

% R

= =

a %

R

95 . 57 61 =

ReIer

R

% to motor side using gear eIIiciency

9 . 0

9

1

95 . 57 61

2

a

3 %

%

G

R

= =

g

) 154 . 7 35 . 7 (

2

a %

= m

Thus, total torque at engine

a a %

total

154 . 7 35 . 7 559 . 5 =

The acceleration at that speed is;

By solving the equation Ior the total torque above, thus

374 . 1 = a m/s

2

m190 kg

T

R

a

PROEMS-GEAR SYSTEM

1. The axes oI two parallel shaIts are to be 600mm apart approximately, and have to be

connected by spur gear, having a circular pitch oI 30 mm. II gear A rotate at 200 rpm and

gear B rotate at 600 rpm, Iind the number oI teeth on each gear.

2. igure below showed a motor used to accelerate a hoist through a set oI gear system.

Gear Ior the hoist`s shaIt has 200 teeth and gear Ior motor shaIt has 20 teeth. Gear

eIIiciency is 90 . Moment oI inertia Ior the motor shaIt is 2.5 kgm and hoist shaIt is

275 kgm. The rope that carries a 250 kg load are encircle on hoist with diameter 1.2 m.

By neglecting the Iriction, Iind

a) gear ratio,

b) equivalent moment inertia Ior a gear system,

c) the total torque required by the motor to accelerate the load at acceleration oI 1.0

m/s.

Motor

Rope

Set oI gear

Load

oist

22

3 The diagram above shows a gear train composed oI three gears. Gear A revolves at 60

revs/min in a clockwise direction.

GEAR A GEAR B GEAR

20 TEET 60 TEET 10 TEET

a) What is the output in revolutions per minute at Gear

b) In what direction does Gear revolve

| 120 rpm, clockwise |

Вам также может понравиться

- Gear Types, Spur, Helical, Bevel, Rack and Pinion, Worm - Engineers EdgeДокумент3 страницыGear Types, Spur, Helical, Bevel, Rack and Pinion, Worm - Engineers EdgeMohd Sabaruddin Mohd SallehОценок пока нет

- Gear Terminology and Its Types: Pitch CircleДокумент6 страницGear Terminology and Its Types: Pitch CircleMuhammad UmerОценок пока нет

- Pulleys 1 Rotary Cams 1 Gears 2: Pulleys Are Used To Transfer Rotating Motion, Via A BeltДокумент17 страницPulleys 1 Rotary Cams 1 Gears 2: Pulleys Are Used To Transfer Rotating Motion, Via A BeltRentu PhiliposeОценок пока нет

- Mechanisms Notes 2012Документ12 страницMechanisms Notes 2012kookwfОценок пока нет

- Axes and Motion StructureДокумент30 страницAxes and Motion StructureBhuban LimbuОценок пока нет

- Gearabc A1 PDFДокумент19 страницGearabc A1 PDFjinriОценок пока нет

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesДокумент18 страницDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaОценок пока нет

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesДокумент20 страницDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaОценок пока нет

- Everything You Need to Know About Drill BitsДокумент23 страницыEverything You Need to Know About Drill BitsIndah CharismasariОценок пока нет

- Cams and Camfollowers LessonДокумент38 страницCams and Camfollowers LessonleannaОценок пока нет

- Lathe Alignment Tests (MetrologyДокумент63 страницыLathe Alignment Tests (MetrologySudhanwa KulkarniОценок пока нет

- Design of Jigs Fixtures and Press Tools PDFДокумент4 страницыDesign of Jigs Fixtures and Press Tools PDFniharika kadiriОценок пока нет

- Tool Makers MicroscopeДокумент11 страницTool Makers Microscopeirfanajai100% (1)

- Chapter2 Locating Principles and DevicesДокумент57 страницChapter2 Locating Principles and DevicesAbhishek KulhariОценок пока нет

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureДокумент12 страницDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaОценок пока нет

- Simple Machine Component of Rube GoldbergДокумент7 страницSimple Machine Component of Rube GoldbergThomas Adam Johnson100% (1)

- W1 Introduction To Mechanisms and Kinematics 20140724Документ38 страницW1 Introduction To Mechanisms and Kinematics 20140724Izzat MalikОценок пока нет

- Mechanical SickelДокумент42 страницыMechanical SickelPaul AntoОценок пока нет

- 5.1 Chordal Tooth Thickness MeasurementДокумент20 страниц5.1 Chordal Tooth Thickness Measurementsharma RISHIОценок пока нет

- Simplemechanism 180302020307Документ58 страницSimplemechanism 180302020307Kunal GadgilОценок пока нет

- Cam and FollowersДокумент18 страницCam and Followersnandkishore_singh100% (1)

- Machine Tools Guide: Lathes, Milling, Cutting ToolsДокумент85 страницMachine Tools Guide: Lathes, Milling, Cutting ToolsVipul Mahajan100% (1)

- Gear Teeth: Clocks and ShipsДокумент16 страницGear Teeth: Clocks and ShipsČika BrkoОценок пока нет

- 3 MechanismsДокумент35 страниц3 Mechanismsesham2100% (1)

- Surface PlateДокумент5 страницSurface Platetevqwe1Оценок пока нет

- CamДокумент95 страницCamMurugesan KandaОценок пока нет

- Gear IntroductionДокумент17 страницGear Introductionpatel ketan100% (1)

- Involute Spur GearДокумент7 страницInvolute Spur GeardhimanrayatОценок пока нет

- The Indexing or Dividing Head For Milling MachineДокумент4 страницыThe Indexing or Dividing Head For Milling MachineDion Adi PutraОценок пока нет

- Gear Cutting AttachmentДокумент40 страницGear Cutting AttachmentGoutham Reddy100% (1)

- Reaming, Boring and Broaching Processes ExplainedДокумент58 страницReaming, Boring and Broaching Processes ExplainedVikas PotluriОценок пока нет

- Manufacturing of Spur Gear: Aim of The ExperimentДокумент5 страницManufacturing of Spur Gear: Aim of The ExperimentParameshwara MeenaОценок пока нет

- Toothed GearingДокумент33 страницыToothed GearingpvkkrОценок пока нет

- IndexingДокумент25 страницIndexingJaymin PatelОценок пока нет

- Mechanical Drives Gear SelectionДокумент46 страницMechanical Drives Gear Selectionganga6013Оценок пока нет

- Lathe Accessories and Attachments Lathe Accessories:: 1. Face PlateДокумент7 страницLathe Accessories and Attachments Lathe Accessories:: 1. Face PlateRohan SahaОценок пока нет

- 507 Mechanical Movemets PDFДокумент132 страницы507 Mechanical Movemets PDFDario_ScribОценок пока нет

- Gear and Gear TrainДокумент21 страницаGear and Gear Trainm_er100Оценок пока нет

- ClutchesДокумент17 страницClutchesRanjit RajendranОценок пока нет

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureДокумент16 страницDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaОценок пока нет

- Machine Elements, Power Transmission Devices-pages-BY MBOKEHДокумент93 страницыMachine Elements, Power Transmission Devices-pages-BY MBOKEHAvopaul ZeОценок пока нет

- Tool Makers Microscope PPT - Siddhant SinghДокумент15 страницTool Makers Microscope PPT - Siddhant SinghSiddhant Singh100% (1)

- Design of Jigs Fixtures and Press ToolsДокумент4 страницыDesign of Jigs Fixtures and Press ToolsKarthic EaswarОценок пока нет

- Force MeasurementДокумент18 страницForce MeasurementKali DasОценок пока нет

- Production Technology Lab FileДокумент45 страницProduction Technology Lab FileSakshi RoyОценок пока нет

- Instructions For Build Your Own Maglev TrainДокумент3 страницыInstructions For Build Your Own Maglev TrainTakeuchi Kyousuke TakatoОценок пока нет

- Injection Mould Unit-IIДокумент103 страницыInjection Mould Unit-II20PP001 balaji suresh bhaleОценок пока нет

- GearsДокумент22 страницыGearsAnurag MidhaОценок пока нет

- MBEYA UNIVERSITY OF SCIENCE AND TECHNOLOGY COLLEGE OF ENGINEERING AND TECHNOLOGY KINEMATICS OF MACHINE TOOLSДокумент37 страницMBEYA UNIVERSITY OF SCIENCE AND TECHNOLOGY COLLEGE OF ENGINEERING AND TECHNOLOGY KINEMATICS OF MACHINE TOOLSSadikiel100% (1)

- Gear Terminology: Pitch Circle: Addendum Circle: Dedendum Circle: ClearanceДокумент11 страницGear Terminology: Pitch Circle: Addendum Circle: Dedendum Circle: ClearanceFawad HassanОценок пока нет

- Ramsey BE66 - Blinky Eyes Animated Display PDFДокумент16 страницRamsey BE66 - Blinky Eyes Animated Display PDFAl PetitОценок пока нет

- 1 1 4 A PulleydrivessprocketsДокумент4 страницы1 1 4 A Pulleydrivessprocketsapi-30839565067% (3)

- Ch21 Fundamentals of Cutting2Документ70 страницCh21 Fundamentals of Cutting2manojc68Оценок пока нет

- Types of Angles in Drill BitsДокумент2 страницыTypes of Angles in Drill BitsAbdul AhadОценок пока нет

- Belts, Gears & Gear Trains ExplainedДокумент13 страницBelts, Gears & Gear Trains Explainedbhaskarrajusa8034Оценок пока нет

- Student Copy-Manufacturing Process SelectionДокумент49 страницStudent Copy-Manufacturing Process SelectionAnishMendisОценок пока нет

- Tools, Jigs and Die Design GuideДокумент2 страницыTools, Jigs and Die Design GuideTamirat Nemomsa100% (1)

- Chapter 2-Gear SystemДокумент26 страницChapter 2-Gear SystemNui Yuhu KuwОценок пока нет

- GEARS: AN OVERVIEW OF COMMON GEAR TYPESДокумент18 страницGEARS: AN OVERVIEW OF COMMON GEAR TYPESVasudev GuptaОценок пока нет

- Hello World DДокумент1 страницаHello World DIhsan NordinОценок пока нет

- Hospital Fire DrillДокумент58 страницHospital Fire DrillWan SamiraОценок пока нет

- 1-Status Comformation For Undergraduate Project ReportДокумент1 страница1-Status Comformation For Undergraduate Project ReportWan SamiraОценок пока нет

- 2 TitleДокумент1 страница2 TitleWan SamiraОценок пока нет

- 1-Status Comformation For Undergraduate Project ReportДокумент1 страница1-Status Comformation For Undergraduate Project ReportWan SamiraОценок пока нет

- MembranesДокумент6 страницMembranesWan SamiraОценок пока нет

- Lamp IranДокумент10 страницLamp IranWan SamiraОценок пока нет

- New Microsoft PowerPoint PresentationДокумент1 страницаNew Microsoft PowerPoint PresentationWan SamiraОценок пока нет

- Chapter 1 (A) - Stress and Strain RenewДокумент65 страницChapter 1 (A) - Stress and Strain RenewWan SamiraОценок пока нет

- English Financial Assistance ApplicationДокумент4 страницыEnglish Financial Assistance ApplicationAlyssa JenningsОценок пока нет

- Clinical Case Report No 2Документ11 страницClinical Case Report No 2ملک محمد صابرشہزاد50% (2)

- Heat Exchanger Sodium SilicateДокумент2 страницыHeat Exchanger Sodium SilicateChristopher BrownОценок пока нет

- Pictorial History of AOTAДокумент5 страницPictorial History of AOTAThe American Occupational Therapy Association0% (4)

- Female Reproductive System Histology IДокумент5 страницFemale Reproductive System Histology ISolomon Seth SallforsОценок пока нет

- Health 6 Q 4 WK 6 Module 6 Version 4Документ16 страницHealth 6 Q 4 WK 6 Module 6 Version 4Kassandra BayogosОценок пока нет

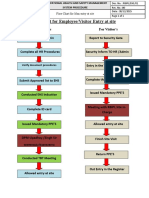

- fLOW CHART FOR WORKER'S ENTRYДокумент2 страницыfLOW CHART FOR WORKER'S ENTRYshamshad ahamedОценок пока нет

- Nicenstripy Gardening Risk AssessmentДокумент38 страницNicenstripy Gardening Risk AssessmentVirta Nisa100% (1)

- Classification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialsДокумент5 страницClassification of Nanomaterials, The Four Main Types of Intentionally Produced NanomaterialssivaenotesОценок пока нет

- PDS in Paschim MidnaporeДокумент12 страницPDS in Paschim Midnaporesupriyo9277Оценок пока нет

- Aphasia PDFДокумент4 страницыAphasia PDFRehab Wahsh100% (1)

- Schneider Electric PowerPact H-, J-, and L-Frame Circuit Breakers PDFДокумент3 страницыSchneider Electric PowerPact H-, J-, and L-Frame Circuit Breakers PDFAnonymous dH3DIEtzОценок пока нет

- Aplikasi Berbagai Jenis Media Dan ZPT Terhadap Aklimatisasi Anggrek VandaДокумент15 страницAplikasi Berbagai Jenis Media Dan ZPT Terhadap Aklimatisasi Anggrek VandaSihonoОценок пока нет

- Practice of Epidemiology Performance of Floating Absolute RisksДокумент4 страницыPractice of Epidemiology Performance of Floating Absolute RisksShreyaswi M KarthikОценок пока нет

- Endocrown Review 1Документ9 страницEndocrown Review 1Anjali SatsangiОценок пока нет

- Bentel J408Документ64 страницыBentel J408Bojan MarkovicОценок пока нет

- BCM Continuous ImprovementДокумент22 страницыBCM Continuous ImprovementnikoОценок пока нет

- Proper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle JДокумент15 страницProper Operating Room Decorum: Lee, Sullie Marix P. Maderal, Ma. Hannah Isabelle Jjoannamhay ceraldeОценок пока нет

- Sigma monitor relayДокумент32 страницыSigma monitor relayEdwin Oria EspinozaОценок пока нет

- Cell City ProjectДокумент8 страницCell City ProjectDaisy beОценок пока нет

- 8-26-16 Police ReportДокумент14 страниц8-26-16 Police ReportNoah StubbsОценок пока нет

- Lesson 1 CA 3Документ13 страницLesson 1 CA 3myndleОценок пока нет

- Maximizing Oredrive Development at Khoemacau MineДокумент54 страницыMaximizing Oredrive Development at Khoemacau MineModisa SibungaОценок пока нет

- Abstract - Tropen Tag 2011 PDFДокумент634 страницыAbstract - Tropen Tag 2011 PDFzmoghesОценок пока нет

- Chemical and Physical Properties of Refined Petroleum ProductsДокумент36 страницChemical and Physical Properties of Refined Petroleum Productskanakarao1Оценок пока нет

- Base para Detectores de Humo y Temperatura KIDDE KI-SBДокумент2 страницыBase para Detectores de Humo y Temperatura KIDDE KI-SBAnderson CastañedaОценок пока нет

- Erapol EHP95AДокумент2 страницыErapol EHP95AMohammad Doost MohammadiОценок пока нет

- g21 Gluta MsdsДокумент3 страницыg21 Gluta Msdsiza100% (1)

- COVID 19 Impacts On The Construction IndustryДокумент46 страницCOVID 19 Impacts On The Construction IndustryAlemayehu DargeОценок пока нет

- New Microsoft Excel WorksheetДокумент4 страницыNew Microsoft Excel WorksheetRaheel Neo AhmadОценок пока нет

- Becky Lynch: The Man: Not Your Average Average GirlОт EverandBecky Lynch: The Man: Not Your Average Average GirlРейтинг: 4.5 из 5 звезд4.5/5 (12)

- Horse Training 101: Key Techniques for Every Horse OwnerОт EverandHorse Training 101: Key Techniques for Every Horse OwnerРейтинг: 4.5 из 5 звезд4.5/5 (27)

- Crazy for the Storm: A Memoir of SurvivalОт EverandCrazy for the Storm: A Memoir of SurvivalРейтинг: 3.5 из 5 звезд3.5/5 (217)

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsОт EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsРейтинг: 4 из 5 звезд4/5 (49)

- Elevate and Dominate: 21 Ways to Win On and Off the FieldОт EverandElevate and Dominate: 21 Ways to Win On and Off the FieldРейтинг: 5 из 5 звезд5/5 (4)

- Life Is Not an Accident: A Memoir of ReinventionОт EverandLife Is Not an Accident: A Memoir of ReinventionРейтинг: 3.5 из 5 звезд3.5/5 (7)

- Endure: How to Work Hard, Outlast, and Keep HammeringОт EverandEndure: How to Work Hard, Outlast, and Keep HammeringРейтинг: 4.5 из 5 звезд4.5/5 (283)

- What Winners Won't Tell You: Lessons from a Legendary DefenderОт EverandWhat Winners Won't Tell You: Lessons from a Legendary DefenderРейтинг: 4.5 из 5 звезд4.5/5 (7)

- Bloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyОт EverandBloodlines: The True Story of a Drug Cartel, the FBI, and the Battle for a Horse-Racing DynastyРейтинг: 4 из 5 звезд4/5 (8)

- Sprawlball: A Visual Tour of the New Era of the NBAОт EverandSprawlball: A Visual Tour of the New Era of the NBAРейтинг: 4 из 5 звезд4/5 (11)

- The Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItОт EverandThe Perfect Mile: Three Athletes, One Goal, and Less Than Four Minutes to Achieve ItОценок пока нет

- The Teen’s Living Guide: Unlocking Your Potential for a Remarkable JourneyОт EverandThe Teen’s Living Guide: Unlocking Your Potential for a Remarkable JourneyРейтинг: 5 из 5 звезд5/5 (76)

- The Truth About Aaron: My Journey to Understand My BrotherОт EverandThe Truth About Aaron: My Journey to Understand My BrotherОценок пока нет

- Summary: Range: Why Generalists Triumph in a Specialized World by David Epstein: Key Takeaways, Summary & Analysis IncludedОт EverandSummary: Range: Why Generalists Triumph in a Specialized World by David Epstein: Key Takeaways, Summary & Analysis IncludedРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Badasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersОт EverandBadasses: The Legend of Snake, Foo, Dr. Death, and John Madden's Oakland RaidersРейтинг: 4 из 5 звезд4/5 (15)

- The Inside Game: Bad Calls, Strange Moves, and What Baseball Behavior Teaches Us About OurselvesОт EverandThe Inside Game: Bad Calls, Strange Moves, and What Baseball Behavior Teaches Us About OurselvesРейтинг: 4 из 5 звезд4/5 (7)

- Body Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialОт EverandBody Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialРейтинг: 4 из 5 звезд4/5 (2)

- Patriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionОт EverandPatriot Reign: Bill Belichick, the Coaches, and the Players Who Built a ChampionРейтинг: 3.5 из 5 звезд3.5/5 (30)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsОт EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsОценок пока нет

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderОт EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderРейтинг: 4 из 5 звезд4/5 (283)

- Earnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyОт EverandEarnhardt Nation: The Full-Throttle Saga of NASCAR's First FamilyРейтинг: 3.5 из 5 звезд3.5/5 (7)