Академический Документы

Профессиональный Документы

Культура Документы

Aircraft Fueling BAA HEATHROW Operational Safety Instruction

Загружено:

singlebiker77Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Aircraft Fueling BAA HEATHROW Operational Safety Instruction

Загружено:

singlebiker77Авторское право:

Доступные форматы

Operational Safety Instruction

Date: Subject: 10TH DECEMBER 2001 FUELLING OF AIRCRAFT OSI/35/01

It is the responsibility of all employers to ensure that relevant OSIs are brought to the attention of their staff. However, individuals remain responsible for their own actions and those who are in any doubt should consult their Supervisor or Manager.

PURPOSE 1. The purpose of the OSI is to provide supplementary instructions for the fuelling of aircraft, in addition to the guidance provided by CAA in CAP 74. In addition this document also seeks to draw to the attention of all aircraft operators and fuelling organisations the amendments and subsequent publication of the Third Edition of CAP 74. This OSI supersedes OSI/04/89 - Fuelling of Aircraft. The Civil Aviation Authority publication Aircraft Fuelling - Fire Prevention and Safety Measure - CAP 74, Third Edition contains standard procedures to be followed and practices to be observed when the fuelling of aircraft is taking place. The procedures and practices in CAP 74 are advisory but shall be fully observed at this aerodrome except where otherwise supplemented in this instruction. It is recommended that companies purchase their own copies of CAP 74. Copies of CAP 74 - Third Edition can be obtained under a new ISBN 0 86039 7947 from: Westward Documedia Ltd 37 Windsor Street Cheltenham GL52 2DG Tel: 01242 283100 (printing) or 235151 (mail order) Fax: 01242 584 139 www.documedia.co.uk 5. Companies operating at Heathrow shall be aware of and have regard for the following documents (and subsequent amendments) relating to Fuelling issued by HAL: OSI/51/97 - Emergency Stop Buttons OSI/11/00 - Spillage Reporting Procedures Copies may be obtained from HAL Airside Operations on 020 8745 5326 or internally on HAL x 55326.

2. 3.

4.

DEFINITION 6. For the purpose of this instruction, the use of the term fuelling embraces both fuelling and defuelling.

SUPERVISION OF FUELLING 7. Aircraft operating companies shall appoint a competent person to ensure the observance of correct fuelling procedures and for the liaison with the fuel companys fuelling operatives. Such a person may be a maintenance engineer, crew member or other person instructed in the requirements of the supervisory task. This aircraft operator or appointed agent shall identify - himself to the fuelling company operator so that there is an obvious contact if a problem occurs. Note that the functions associated with this role can be carried out by different people. The aircraft operator or appointed agent shall be familiar with the safety measures for the refuelling operation as given in CAP 74 - Third Edition, OSI/51/97, this Instruction and the Fuelling organizations operating procedures. This will ensure interoperability of procedures which is essential for the safe conduct of the fuelling operations. 8.1 Specific fuelling procedures shall be agreed between the Airline and contract holder which reflect the type (e.g. up-to plane, -- into-plane) of fuelling service agreed. The fuelling operative or appointed agent shall remain in the vicinity of the aircraft whilst refuelling operations are in progress and should ensure correct positioning of refuelling vehicles. Drivers are reminded of OSI/51/97 that the emergency stop areas and the area immediately in front of them are not obstructed with vehicles or equipment. Parking in front of the emergency stop points is not permitted. The aircraft operator or appointed agent shall ensure that there is adequate restraint of the aircraft by ensuring that the wheels are adequately chocked and confirming that the brakes are applied (unless this is not recommended for the particular type of aircraft), or that an acceptable alternative is in place. They shall also ensure the correct positioning of service equipment. The technical aspects of the aircraft fuelling operation may be undertaken by other competent persons (e.g fuelling company employee), appointed by the airline and instructed in the requirements of aircraft fuelling.

8.

8.2

8.3

8.4

8.5

CLEAR EXIT PATHS 9. The fuelling operative shall ensure that a clear path is maintained from the aircraft to allow for the quick removal of fuelling tankers . Fuelling equipment should be positioned so that there is no requirement for vehicles to reverse before departure. 9.1 All vehicles and equipment shall be positioned to allow the unobstructed exit of person/s from the aircraft in an emergency.

9.2

Hydrant Dispenser vehicles enable the fuel to be transferred from the hydrant system to the aircraft. These vehicles do not carry significant amounts of fuel to be regarded as hazardous and therefore do not present a significant risk in the event of a fuel fire. CAP 74 - section 4.6.1 ( that a clear path is maintained for the quick removal of fuelling vehicles...) need not apply to Hydrant Dispensing vehicles, subject to the fuelling company carrying out a risk assessment of the operation.

FUELLING ZONE 10. During fuelling operations, air and fuel vapour are displaced from the aircraft fuel tanks. - CAP 74 requires the establishment of Fuelling Zones. For the purpose of this OSI these zones shall be regarded as extending not less than 6 meters radially from vent points, hydrant valves and aircraft fuelling connections . 10.1 Aircraft Auxiliary Power Units (APUs) which have an exhaust efflux discharging into the fuelling zone should, if required to be in operation during fuelling, be started before filler caps are removed or fuelling connections made. Ground Power Units (GPUs) may be operated provided they are positioned not less than 6 meters from aircraft filling and venting points, hydrant valves and other fuelling equipment when in use. Vehicle engines shall not be left running unnecessarily in the fuelling zones.

10.2

10.3

FIRE EXTINGUISHERS 11. Fuelling companies are responsible for ensuring that fire extinguishers for the protection of the fuelling equipment are readily available before the transfer of fuel begins. These extinguishers shall be maintained to the standards recommended by the manufacturers, and fuelling company personnel shall be trained in their use.

HYDRANT REFUELLING 12. Hydrant refuelling facilities are currently provided on most aircraft stands. The fuel is transferred from the hydrant system to the aircraft by Hydrant dispensers. These units are regarded as mobile fuelling equipment, and it is the responsibility of the fuelling company to ensure that the vehicle deadman system is operational and the pit valve lanyard is connected and easily accessible. It is in the interest of safe fuelling that other vehicles keep clear for a distance of 6 meters of the hydrant couplings and hoses at all times.

EMERGENCY FUEL STOP-BUTTONS 13. All staff shall be familiar with the operation of the Emergency Fuel Stop-buttons (OSI 51/97) and how to summon the Airport Fire Service. 13.1 Hydrant refuelling on a stand on which an Emergency Fuel Stop -button is unserviceable shall not take place unless an alternative method of emergency shut down is implemented. This may take the form of radio contact between the fuelling operator and a location with an operable Emergency Fuel Stopbutton..

PRECAUTIONS DURING THE FUELLING OPERATION - GENERAL GUIDELINES 14. The aircraft operator shall ensure that all personnel working on, inside or in the immediate vicinity of the aircraft are made aware that fuelling is taking place. 14.1 All vehicles and equipment should be positioned such that: 14.1.1 Access to aircraft for rescue and fire fighting vehicles is not obstructed. 14.1.2 A clear route is maintained to allow their rapid removal from the aircraft in an emergency (exception as in paragraph 9.2). 14.1.3 The evacuation routes from occupied portions of the aircraft, including chute deployment areas, are not obstructed. 14.1.4 Sufficient clearance is maintained between the fuelling equipment and the aircraft wing as fuel is transferred. 14.1.5 They are not positioned beneath the fuel vents. 14.2 If an auxiliary power unit located within the fuelling zone or which has an exhaust efflux discharging into the zone is stopped for any reason during a fuelling operation it should not be restarted until the flow of fuel has ceased and there is no risk of igniting fuel vapours. In the event of an emergency, such as a bomb alert, fire on any aircraft or adjacent stands, refuelling is to cease. The fuelling operative is to establish from Airside Operations Safety Unit (AOSU) on 020 8745 6024 or internally on HAL x 56024 the extent of the emergency, and fuelling can re-commence when the aircraft operator has advised that it is safe to do so.

14.3

15.

Additional Precautions to be taken when Passengers remain on board during Fuelling operations. 15.1 To reduce turnaround time and for Security reasons, it is the responsibility of the -aircraft operator to determine whether fuelling of its aircraft should take place with passengers on board or boarding (embarking or disembarking) and the method by which this is carried out. When passengers are embarking or disembarking, their route shall avoid any fuelling zone areas and they shall be under the direct supervision of airline staff. At all times No Smoking is to be strictly enforced. Passenger/Baggage reconciliation on the ramp shall be carried out away from all fuelling zones.

15.2

15.3

FUEL SPILLAGE 16. In the event of a fuel spillage, action should be taken immediately to stop the fuel flow and the aircraft commander/crew must be informed. 16.1 It is the responsibility of the Airline or its appointed agent to ensure that all fuel spillages are reported to the Airport Fire Service (AFS) on 020 8759 1212 or internally on HAL x 222 as per OSI/11/00 Spillage reporting procedures. In the case of a spillage occurring which measures greater than two meters in diameter the aircraft operator shall: 16.2.1 Consider evacuation of the area. It is generally safer upwind and upslope of any fuel spillage. 16.2.2 Prevent the movement of persons or vehicles into the affected area and ensure that all activities in the vicinity are restricted to reduce the risk of ignition. 16.2.3 Ensure that engines of vehicles within 6 meters of a spillage should not be started until the area is declared safe. 16.3 If a large scale spillage occurs, steps should be taken, providing there is no danger to staff involved, to isolate or contain the spillage. A spillage of a volume equal to or greater than 450 litres may cause marked pollution, as the impact is determined by the quantity and location of the spill. It is therefore important to correctly assess the size of the spill to assist HAL in determining if any necessary remedial action is to be taken to provide protection from the spilled fuel escaping the balancing ponds and entering the local water courses. Companies must ensure that all in-house spillage reporting procedures are fully understood by all employees. Companies must ensure that spillage clean-up, reporting procedures and incident records are available for audit purposes by HAL.

16.2

16.4

16.5

16.6

FUELLING OF AIRCRAFT IN HANGARS

17.

Companies involved in fuelling in aircraft hangars should carry out a risk assessment of this activity and be satisfied with the safety procedures applied.

ENQUIRIES 18. Any enquiries regarding this instruction should be addressed to the Head of Service Delivery - Airside Operations on 020 8745 5923.

Issued on behalf of Managing Director Distribution: Lists A - E

Вам также может понравиться

- 03 Fdny Apparatus FdnyДокумент35 страниц03 Fdny Apparatus FdnyHualy DelgadoОценок пока нет

- Minimum Equipment List Handling: I. PurposeДокумент7 страницMinimum Equipment List Handling: I. PurposebnolascoОценок пока нет

- Hazardous Area ClassificationsДокумент1 страницаHazardous Area ClassificationsAndrew Bull100% (2)

- 3024 L5A Winter Court (Kyuden Kakita)Документ130 страниц3024 L5A Winter Court (Kyuden Kakita)DruzillaNevenОценок пока нет

- Safety Guide-Rep112 PDFДокумент56 страницSafety Guide-Rep112 PDFMax Martin100% (1)

- Best Books Years 5Документ6 страницBest Books Years 5MagelicanОценок пока нет

- Aerodrome Safety For Airside DriversДокумент1 страницаAerodrome Safety For Airside DriversayamayamОценок пока нет

- Draft Circular On Procedures For Ground HandlingДокумент19 страницDraft Circular On Procedures For Ground HandlingRaqeeb Rahman0% (1)

- Ramp Safety PracticesДокумент76 страницRamp Safety PracticesSEBI P RAJA BABUОценок пока нет

- Emergency Action PlansДокумент26 страницEmergency Action PlansChristopher CelisОценок пока нет

- Vernacular HungarianДокумент51 страницаVernacular HungariandeltagОценок пока нет

- 1 - Introduction Fire MarshalДокумент96 страниц1 - Introduction Fire MarshalcherifОценок пока нет

- 010-11 Search and RescueДокумент42 страницы010-11 Search and RescuePedro PinhoОценок пока нет

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7От EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Оценок пока нет

- USCG Safety Managment System SMS Manual PDFДокумент201 страницаUSCG Safety Managment System SMS Manual PDFAulia Mahkota AlamОценок пока нет

- Essendon Airport Safety TrainingДокумент24 страницыEssendon Airport Safety TrainingallanepОценок пока нет

- Car Carrier Accidents - A Catalyst For ChangeДокумент16 страницCar Carrier Accidents - A Catalyst For ChangeAdrian NegoiţăОценок пока нет

- CrowdДокумент83 страницыCrowdSiddharth SinghОценок пока нет

- 10.1.1.476.5960-Fsa Cruise ShipsДокумент17 страниц10.1.1.476.5960-Fsa Cruise ShipsJay Jay0% (1)

- Fire MatrixДокумент1 страницаFire MatrixPio RodolfoОценок пока нет

- Airside Safety RegulationsДокумент45 страницAirside Safety RegulationsRas BaneasaОценок пока нет

- Sms 20150424Документ204 страницыSms 20150424alonso_rОценок пока нет

- M4-1-SMS - Aerodrome - Safety Performance and MonitoringДокумент43 страницыM4-1-SMS - Aerodrome - Safety Performance and MonitoringNhut NguyenОценок пока нет

- EAPPRI 1 2 RWY IncursionДокумент90 страницEAPPRI 1 2 RWY Incursioncsfekete1976Оценок пока нет

- Taxiway IncursionДокумент3 страницыTaxiway IncursionDhruv Joshi100% (1)

- Hand Book of Establishment of Hight Speed Craft OperationДокумент40 страницHand Book of Establishment of Hight Speed Craft OperationRogerio GuahyОценок пока нет

- Aircraft Refuelling Procedure and PrecautionsДокумент12 страницAircraft Refuelling Procedure and PrecautionsMiju MizajОценок пока нет

- Safety Risk Assessment For UAVДокумент16 страницSafety Risk Assessment For UAVStalin FernandezОценок пока нет

- Airport Parts 1B (GROUP 1)Документ33 страницыAirport Parts 1B (GROUP 1)Benedict CarandangОценок пока нет

- Aerodynamics Air Ontario 1363 (Final)Документ35 страницAerodynamics Air Ontario 1363 (Final)AlvinWongОценок пока нет

- GroundhandlngДокумент44 страницыGroundhandlnghuouinkyouma100% (1)

- Fuel Servicing of Aircraft, Kelompok 777Документ13 страницFuel Servicing of Aircraft, Kelompok 777Rahmat0% (1)

- AOI 13 Airside Driving Training and Regulations of Airside Safety PDFДокумент23 страницыAOI 13 Airside Driving Training and Regulations of Airside Safety PDFSatyendra PandeyОценок пока нет

- Model Ship Security Plan TemplateДокумент22 страницыModel Ship Security Plan Templateвалентин бараблевОценок пока нет

- Guidance On The Use of Emissions Trading For AviationДокумент47 страницGuidance On The Use of Emissions Trading For AviationПитер ГамильтонОценок пока нет

- Building Laws Key AnswerДокумент10 страницBuilding Laws Key AnswerJett SorianoОценок пока нет

- STW 43-3-2 - Model Course - Security Awareness Training For Seafarers With Designated Security Duties-52-55Документ4 страницыSTW 43-3-2 - Model Course - Security Awareness Training For Seafarers With Designated Security Duties-52-55Ronald LIIIОценок пока нет

- Safety Environmental Management System (Sems) Standards ManualДокумент26 страницSafety Environmental Management System (Sems) Standards ManualrwerwerwОценок пока нет

- Ground Support Equipment Safety Inspection Program 2014Документ25 страницGround Support Equipment Safety Inspection Program 2014TonyОценок пока нет

- NPS - Port Security Strategy 2012Документ497 страницNPS - Port Security Strategy 2012wvwmasterОценок пока нет

- MSC.1-Circ.1327-Guidelines For The Fitting and Use of Fall Prevention Devices (FPDS)Документ6 страницMSC.1-Circ.1327-Guidelines For The Fitting and Use of Fall Prevention Devices (FPDS)CaptShivraj ManeОценок пока нет

- IOSA Checklist: ISM Edition 9 - Effective September 1, 2015Документ75 страницIOSA Checklist: ISM Edition 9 - Effective September 1, 2015Andrei NecuţăОценок пока нет

- 690-5 - Helicopter and EquipmentДокумент23 страницы690-5 - Helicopter and EquipmentДмитрий SolodОценок пока нет

- MSC 128 PDFДокумент8 страницMSC 128 PDFsynerticОценок пока нет

- AHM 176A Acceptance and Carriage of Passengers With Reduced MobilityДокумент8 страницAHM 176A Acceptance and Carriage of Passengers With Reduced MobilitybfibingierОценок пока нет

- Briefing Points For RampДокумент2 страницыBriefing Points For RampAnmol Jakhmola100% (1)

- DFW Ground Vehicles ManualДокумент129 страницDFW Ground Vehicles ManualBrayanpОценок пока нет

- 9 ClassesДокумент26 страниц9 Classesmvijayk3Оценок пока нет

- INS N IBSДокумент37 страницINS N IBSamirsyawal87Оценок пока нет

- Icao Doc 2618 PDFДокумент20 страницIcao Doc 2618 PDFPete Andre100% (1)

- TSO C172 Cargo Tie-Down Straps DatasheetДокумент4 страницыTSO C172 Cargo Tie-Down Straps DatasheetlucholadeОценок пока нет

- Maxsea Professional Marine Software User Guide V10.3Документ353 страницыMaxsea Professional Marine Software User Guide V10.3Alejandro Getino CarbajoОценок пока нет

- HSE Aircraft Turnround HSG209Документ22 страницыHSE Aircraft Turnround HSG209Panayiotis GrОценок пока нет

- Grid MapДокумент20 страницGrid MapMd Arifur RahmanОценок пока нет

- Chapter I - Situational AwarenessДокумент6 страницChapter I - Situational AwarenessDmcLyn UntalОценок пока нет

- AHM640 Ramp Error Codes PDFДокумент9 страницAHM640 Ramp Error Codes PDFNarablues IndonesiaОценок пока нет

- ABC Helipad Manual v2.0Документ2 страницыABC Helipad Manual v2.0Jared AlpayОценок пока нет

- MSC 1-Circ 1447-GuidelinesForTheDevelopmentOfPlansAndProceduresForRecoveryOfPersonsFromTheWater (Secretariat) PDFДокумент4 страницыMSC 1-Circ 1447-GuidelinesForTheDevelopmentOfPlansAndProceduresForRecoveryOfPersonsFromTheWater (Secretariat) PDFFaris HarunОценок пока нет

- Syllabus Air Ground CollaborativeДокумент25 страницSyllabus Air Ground CollaborativeirbasukirahardjocesОценок пока нет

- EASA Operators With Approval To Carry Dangerous Goods As Cargo (Aeroplanes)Документ52 страницыEASA Operators With Approval To Carry Dangerous Goods As Cargo (Aeroplanes)SpassОценок пока нет

- Airline Cabin Crew Training Syllabus PDFДокумент2 страницыAirline Cabin Crew Training Syllabus PDFVyl CebrerosОценок пока нет

- Gosm Orm enДокумент76 страницGosm Orm eneihab tahaОценок пока нет

- The Philosophy On Safe Carriage of Dangerous GoodsДокумент2 страницыThe Philosophy On Safe Carriage of Dangerous GoodsNuran Dursunoğlu100% (1)

- LimitationДокумент75 страницLimitationEdwar ZulmiОценок пока нет

- Airport Emergency Planning (Virtual Training)Документ2 страницыAirport Emergency Planning (Virtual Training)Marius BuysОценок пока нет

- Afoshstd91 501Документ381 страницаAfoshstd91 501Thomas M RiddleОценок пока нет

- DGCA Aircraft Refuelling Procedures IndiaДокумент9 страницDGCA Aircraft Refuelling Procedures Indiapawan737ngОценок пока нет

- Narrative Environmental CampДокумент11 страницNarrative Environmental CampJhun Dalingay DumaumОценок пока нет

- Cebu Cyberzone - Building Specs - 5.29.14Документ3 страницыCebu Cyberzone - Building Specs - 5.29.14AThaddeusAntonioОценок пока нет

- Portland, Maine Building Permit ApplicationДокумент6 страницPortland, Maine Building Permit ApplicationEvan CarrollОценок пока нет

- QFRS Media Misrepresentations and Duty of Care ConcernsДокумент16 страницQFRS Media Misrepresentations and Duty of Care ConcernsThe World Fire Safety FoundationОценок пока нет

- ButilacetatДокумент6 страницButilacetatmicaziv4786Оценок пока нет

- Risk Assessment - FireДокумент2 страницыRisk Assessment - FireMahdi DwaikatОценок пока нет

- Annotatedbibliography HDДокумент9 страницAnnotatedbibliography HDapi-202480675Оценок пока нет

- FBI and Fire DevelopmentДокумент15 страницFBI and Fire Developmentagung100% (1)

- Fire Watch TrainingДокумент7 страницFire Watch TrainingMadhan MОценок пока нет

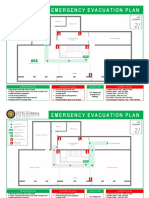

- Emergency Evacuation Plan: CTE BuildingДокумент11 страницEmergency Evacuation Plan: CTE BuildingRhanie MaghacotОценок пока нет

- How Many Extinguishers Are RequiredДокумент3 страницыHow Many Extinguishers Are RequiredBe ReevОценок пока нет

- Promat Durasteel Guide To High Performance DoorsДокумент24 страницыPromat Durasteel Guide To High Performance Doorstrozza28Оценок пока нет

- NCR FIRE INCIDENTS Annual 2021Документ13 страницNCR FIRE INCIDENTS Annual 2021Ivan NagalОценок пока нет

- ClassNK Instruction - FFA - E80e - PanamaДокумент14 страницClassNK Instruction - FFA - E80e - Panamafajee_faridОценок пока нет

- Msds Octagon Process OCCДокумент5 страницMsds Octagon Process OCCMark Evan SalutinОценок пока нет

- Robert Owen Wilcoxon. An Account of The Last Days at Dunkirk and The Story of The Heroic Men and The 'Little Ships'Документ7 страницRobert Owen Wilcoxon. An Account of The Last Days at Dunkirk and The Story of The Heroic Men and The 'Little Ships'Annette Edwards100% (3)

- Explain What The Misfortune Was and What You Have Learnt From The Incident. Begin Your Story With: "I Was Awakened by The Sound of Voices "Документ2 страницыExplain What The Misfortune Was and What You Have Learnt From The Incident. Begin Your Story With: "I Was Awakened by The Sound of Voices "InsyirahОценок пока нет

- Individual Movement TechniquesДокумент8 страницIndividual Movement TechniquesLaboratory in the WildОценок пока нет

- Bandung Sea of FireДокумент5 страницBandung Sea of FireFadil Ajie100% (2)

- Back FireДокумент3 страницыBack FireAnoj pahathkumburaОценок пока нет

- Bharat Sookshma & Laghu Udyam PoliciesДокумент16 страницBharat Sookshma & Laghu Udyam PoliciesHARMAN SINGHОценок пока нет