Академический Документы

Профессиональный Документы

Культура Документы

3 DTunnel

Загружено:

Eva HariantoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3 DTunnel

Загружено:

Eva HariantoАвторское право:

Доступные форматы

Developers Tip

3D Tunnel Simulation Using the Material Softening Method in Phase2

How do I simulate the three-dimensional advance of a tunnel using Phase2? How do I get the proper deformation prior to support installation?

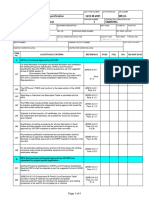

There are a variety of different methods for simulating the deformation that takes place prior to support installation. A preferred method, often used by Dr. Evert Hoek, is the material softening approach. The material softening method can be implemented as follows: 1) First, create a staged model in which the modulus of the excavation material is successively reduced, until the material is excavated. This allows you to construct a ground reaction curve, which is a plot of the boundary displacement (convergence), versus the material modulus at each stage. See Figure 1. Note: The modulus is reduced by assigning a new material at each stage, where each material has a successively lower modulus. To download a Phase2 example file, click phase2 material softening.zip and open the ground reaction.fea file.

Figure 1: Ground reaction curve obtained using staged material softening (modulus reduction).

2) The second step is to determine the amount of deformation which is to be allowed, prior to support installation. This can come from a number of sources including: i) a simple axisymmetric model of your tunnel ii) closed form and empirical formulas as exist in our RocSupport program iii) observation and experience. 3) The third step is to use the ground reaction curve (from step 1), and the tunnel convergence (from step 2), to determine the required material modulus that gives the desired convergence at support installation. Now you can create a staged excavation, with one stage used for the softening and the next stage used for the support installation. See Figure 2. To download a Phase2 file, click phase2_material_softening.zip and open the support_installation.fea file.

a)

b)

Figure 2: (a) intermediate stage -- excavation material with reduced modulus (b) final stage -- excavation material is removed, and support is installed

Other Methods

Other methods of simulating 3D tunnel advance, which can be achieved with Phase2: A number of customers use the load splitting feature of Phase2. Load splitting allows you to "split" the field stress induced load between any stages of the model, rather than applying the entire load in the first stage. This allows the user to gradually apply the field stress load, as excavation progresses. Another approach is to apply a set of tractions (pressures) on the excavation boundary and reduce their magnitude until you get the desired closure. The only problem with this is that for non-hydrostatic stress fields, the manual calculation of the normal and shear tractions on the boundary can be difficult and time-consuming, especially for complex geometries. An alternative approach to the material softening method, can be found on the Phase2 Advanced Tutorials page. With this method, the modulus of the material is staged using reduction factors, and the material stress is initialized as required with the custom load split option. The results of this method are identical to the method presented in this developers tip only the modeling procedure is different.

Related Articles

A paper published in the Canadian Geotechnical Conference in 2003 that demonstrates the usage of material softening in designing support systems can be found at Tunnel Support Design.pdf .

Вам также может понравиться

- ANSYS Mechanical APDL for Finite Element AnalysisОт EverandANSYS Mechanical APDL for Finite Element AnalysisРейтинг: 4.5 из 5 звезд4.5/5 (8)

- PLAXIS Tutorial ManualДокумент124 страницыPLAXIS Tutorial ManualPeteris Skels100% (2)

- 2D 1 TutorialДокумент202 страницы2D 1 TutorialWilliam Montiel CardozoОценок пока нет

- Finite Element Programming in Non-linear Geomechanics and Transient FlowОт EverandFinite Element Programming in Non-linear Geomechanics and Transient FlowОценок пока нет

- KCGM XD48 Presentation ProcessДокумент152 страницыKCGM XD48 Presentation ProcessAnonymous ObQnrU100% (3)

- Pneumatic Bench Vice Project-Report PDFДокумент30 страницPneumatic Bench Vice Project-Report PDFrahul bhatt100% (4)

- Tutorial 18 3D Tunnel Simulation Using Core ReplacementДокумент27 страницTutorial 18 3D Tunnel Simulation Using Core ReplacementDaniel CcamaОценок пока нет

- 2D2010 1 TutorialДокумент138 страниц2D2010 1 TutorialDemijan NikolovskiОценок пока нет

- Tutorial Plaxis 2d AeДокумент176 страницTutorial Plaxis 2d AeJonathan Mendoza ChavezОценок пока нет

- Tutorial 18 3D Tunnel Simulation Using Core ReplacementДокумент27 страницTutorial 18 3D Tunnel Simulation Using Core ReplacementAleksandar Milidrag100% (1)

- Tutorial 33 Two Tunnel Lining DesignДокумент37 страницTutorial 33 Two Tunnel Lining DesignTeofilo Augusto Huaranccay HuamaniОценок пока нет

- Tutorial 36 Embankment ConsolidationДокумент37 страницTutorial 36 Embankment ConsolidationMarcos MaОценок пока нет

- 2D 1 Tutorial - 02Документ200 страниц2D 1 Tutorial - 02Agus DaudОценок пока нет

- LSGAN2 Gabion Wall AnalysisДокумент4 страницыLSGAN2 Gabion Wall Analysisconsultor9010Оценок пока нет

- PLAXIS 2D Anniversary Edition - Tutorial Manual 7Документ22 страницыPLAXIS 2D Anniversary Edition - Tutorial Manual 7Jhonny CuriОценок пока нет

- PLAXIS 2D 2017 Tutorial Lesson01Документ23 страницыPLAXIS 2D 2017 Tutorial Lesson01Anonymous VJHwe0XBОценок пока нет

- Plaxis 2D2011 1 TutorialДокумент0 страницPlaxis 2D2011 1 TutorialPaul AlvesОценок пока нет

- 2727.PLAXIS - 2D - CEV22.01 - Tutorial - 01 - Settlement of Circular Footing On SandДокумент30 страниц2727.PLAXIS - 2D - CEV22.01 - Tutorial - 01 - Settlement of Circular Footing On SandLore Mendez TapieroОценок пока нет

- 3D2013 1 Tutorial NoRestrictionДокумент124 страницы3D2013 1 Tutorial NoRestrictionanalysethatОценок пока нет

- Polyflow Intro 13.0 Tut 01 2.5 Axi ExtrusionДокумент32 страницыPolyflow Intro 13.0 Tut 01 2.5 Axi Extrusionwoongs73Оценок пока нет

- PLAXIS Introductory 2014 - Tutorial Manual 11Документ104 страницыPLAXIS Introductory 2014 - Tutorial Manual 11المهندس أبو أسامةОценок пока нет

- Introductory2014 Lesson1 2DДокумент32 страницыIntroductory2014 Lesson1 2DMu HardiОценок пока нет

- Tutorial 24 Tunnel Lining DesignДокумент32 страницыTutorial 24 Tunnel Lining DesignMarcos MaОценок пока нет

- Tutorial 24 Tunnel Lining DesignДокумент31 страницаTutorial 24 Tunnel Lining DesignKingstonBlueОценок пока нет

- In The: Mineralized Zones in MinesightДокумент3 страницыIn The: Mineralized Zones in MinesightKenny CasillaОценок пока нет

- 2.5 D Cavity Balancing: S. Jin, Y.C. LamДокумент6 страниц2.5 D Cavity Balancing: S. Jin, Y.C. LamjayakumarjklОценок пока нет

- PLAXIS 2D 2018-Tutorial-Lesson01 PDFДокумент23 страницыPLAXIS 2D 2018-Tutorial-Lesson01 PDFJUAN PABLO FUENTESОценок пока нет

- PLAXIS - 2D - CEV22 - Tutorial - 01 - Settlement of A Circular Footing On SandДокумент26 страницPLAXIS - 2D - CEV22 - Tutorial - 01 - Settlement of A Circular Footing On Sandengkader bc143Оценок пока нет

- Drawdown Analysis For Tunnel ExcavationДокумент8 страницDrawdown Analysis For Tunnel ExcavationRaghvendra ShrivastavaОценок пока нет

- PLAXIS - 2D - CEV21 - Tutorial - 01 - Settlement of A Circular Footing On SandДокумент27 страницPLAXIS - 2D - CEV21 - Tutorial - 01 - Settlement of A Circular Footing On SandjayawiadnyanaОценок пока нет

- 05 CG03 (WC) Exercise 1-Elasto-Plastic Analysis of Drained FootingДокумент24 страницы05 CG03 (WC) Exercise 1-Elasto-Plastic Analysis of Drained FootingJoseph ButarbutarОценок пока нет

- Chapter 3Документ37 страницChapter 3kumarОценок пока нет

- Simulation of Blow Molding Using Ansys PolyflowДокумент6 страницSimulation of Blow Molding Using Ansys PolyflowAnonymous PufNjgОценок пока нет

- Vol 6 4 520 531 ABDULLAHI PDFДокумент12 страницVol 6 4 520 531 ABDULLAHI PDFafzal taiОценок пока нет

- PLAXIS - 2D - CEV21 - Tutorial - 07 - Dry Excavation Using A Tie Back Wall - ULSДокумент6 страницPLAXIS - 2D - CEV21 - Tutorial - 07 - Dry Excavation Using A Tie Back Wall - ULSjayawiadnyanaОценок пока нет

- Compass Users GuideДокумент28 страницCompass Users Guidericardogr2005-1Оценок пока нет

- Chapter 21. Terrain Settlement Analysis: Task SpecificationДокумент12 страницChapter 21. Terrain Settlement Analysis: Task Specification-Оценок пока нет

- The North American Port Pavement Design Manual PDFДокумент15 страницThe North American Port Pavement Design Manual PDFSi Zhang100% (1)

- RT 07b ERF SMM PDFДокумент16 страницRT 07b ERF SMM PDFAdrian García MoyanoОценок пока нет

- ITA-Working Group Research - Guidelines For Design of Shield Tunnel LiningДокумент49 страницITA-Working Group Research - Guidelines For Design of Shield Tunnel LiningrasanavaneethanОценок пока нет

- Exercise 2 - Embankment - PLAXIS Consolidation and Safety AnalysisДокумент19 страницExercise 2 - Embankment - PLAXIS Consolidation and Safety AnalysisRelu MititeluОценок пока нет

- Eurocode 7 Geotechnical Limit AnalysisДокумент19 страницEurocode 7 Geotechnical Limit AnalysisPurdiansyahОценок пока нет

- MyRTM Short Intro V2.0 20100407Документ3 страницыMyRTM Short Intro V2.0 20100407Alberto SanchezОценок пока нет

- Polyflow Extrusion WS03 Cooled DieДокумент34 страницыPolyflow Extrusion WS03 Cooled DieTheerapat TaweebraksaОценок пока нет

- Soil & Site Improvement GuideДокумент10 страницSoil & Site Improvement GuideFauzankalibataОценок пока нет

- Tutorial: 2D Adiabatic Compression (Layering) : C Fluent Inc. April 4, 2003Документ37 страницTutorial: 2D Adiabatic Compression (Layering) : C Fluent Inc. April 4, 2003Houssam BEN SALAHОценок пока нет

- Tutorial 09 Importing Slide Files + SSRДокумент14 страницTutorial 09 Importing Slide Files + SSRDaniel Ccama100% (1)

- Adv DM v6.2 Tut 01 Ic LayerДокумент35 страницAdv DM v6.2 Tut 01 Ic LayermkbОценок пока нет

- Tutorial 14 Geotextile Reinforced RampДокумент22 страницыTutorial 14 Geotextile Reinforced Rampatma galihОценок пока нет

- 2007 ICCIE37 - pp1111-1121Документ11 страниц2007 ICCIE37 - pp1111-1121faisal_latafiОценок пока нет

- 28 Stockholm-Benchmark Computer-Aided Design Arch DamsДокумент10 страниц28 Stockholm-Benchmark Computer-Aided Design Arch DamsChalang AkramОценок пока нет

- PLAXIS - 2D - CEV21 - Tutorial - 02 - Drained and Undrained Stability of An EmbankmentДокумент12 страницPLAXIS - 2D - CEV21 - Tutorial - 02 - Drained and Undrained Stability of An EmbankmentjayawiadnyanaОценок пока нет

- README Store Separation 2d PDFДокумент2 страницыREADME Store Separation 2d PDFrksomepalliОценок пока нет

- Constitutive ModelsДокумент8 страницConstitutive ModelsAnonymous D5s00DdUОценок пока нет

- MAUD Tutorial-Instrumental Broadening DeterminatioДокумент19 страницMAUD Tutorial-Instrumental Broadening DeterminatiojeОценок пока нет

- CYPE 3D-Practical ExampleДокумент62 страницыCYPE 3D-Practical ExampleAHMAD BALFAQIHОценок пока нет

- SAFE Appendix B - Deflection CalculationsДокумент9 страницSAFE Appendix B - Deflection CalculationsMahmood MuftiОценок пока нет

- PLAXIS 3D2017 Tutorial Lesson 01 FoundationДокумент25 страницPLAXIS 3D2017 Tutorial Lesson 01 Foundationrindra clarkОценок пока нет

- The Fabrication of Materials: Materials TechnologyОт EverandThe Fabrication of Materials: Materials TechnologyРейтинг: 5 из 5 звезд5/5 (1)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОт EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОценок пока нет

- Class Notes of Amino Acid MetabolismДокумент49 страницClass Notes of Amino Acid MetabolismShivanand Mali100% (1)

- Adsorption of CO On LTA Zeolite Adsorbents: An IR InvestigationДокумент7 страницAdsorption of CO On LTA Zeolite Adsorbents: An IR InvestigationDian Tetep DayenОценок пока нет

- BASF Patent On Double Contact Double AbsorptionДокумент4 страницыBASF Patent On Double Contact Double AbsorptionAОценок пока нет

- Research Papers Structure of The Novel Ternary Hydrides Li TT D (TT Si and Ge)Документ6 страницResearch Papers Structure of The Novel Ternary Hydrides Li TT D (TT Si and Ge)Fadjar MulyaОценок пока нет

- Coiled Tubing Acid Stimulation: The Case of Awi 8-7 Production Well in Salak Geothermal Field, IndonesiaДокумент7 страницCoiled Tubing Acid Stimulation: The Case of Awi 8-7 Production Well in Salak Geothermal Field, IndonesiaHafiizhNurrahmanОценок пока нет

- Introduction To Flip ChipДокумент58 страницIntroduction To Flip ChipLakshman Yandapalli100% (1)

- Comparative Assessment of The Stabilization of Lime-Stabilized Lateritic Soil As Subbase Material Using Coconut Shell Ash and Coconut Husk AshДокумент12 страницComparative Assessment of The Stabilization of Lime-Stabilized Lateritic Soil As Subbase Material Using Coconut Shell Ash and Coconut Husk AshEdem CHABIОценок пока нет

- Phosgenation A Handbook Hal 20 EnglishДокумент3 страницыPhosgenation A Handbook Hal 20 EnglishPriska Dewi AnjarsariОценок пока нет

- Le Nouveau Taxi! 1Документ32 страницыLe Nouveau Taxi! 1Jay Rắc RốiОценок пока нет

- Abg Analysis-1Документ22 страницыAbg Analysis-1PAMОценок пока нет

- Assay of Chloroquine Phosphate Experiment No.: Date: Aim: To Perform The Assay of Chloroquine Phosphate. Reference: RequirementsДокумент3 страницыAssay of Chloroquine Phosphate Experiment No.: Date: Aim: To Perform The Assay of Chloroquine Phosphate. Reference: RequirementsDinesh ThakkarОценок пока нет

- Moringa Oleifera Seed As Antibacterial Agent in Water TreatmentДокумент6 страницMoringa Oleifera Seed As Antibacterial Agent in Water TreatmentStephen MooreОценок пока нет

- Smaw 12 Module 1 Grade 12Документ39 страницSmaw 12 Module 1 Grade 12Francis Rico Mutia Rufon100% (14)

- Analysis of SalivaДокумент14 страницAnalysis of Salivajgbalanay8492antОценок пока нет

- Class X Science Pre Board Sample PaperДокумент23 страницыClass X Science Pre Board Sample PaperNasla ShiyasОценок пока нет

- GR 12 Biology Moddel ExamДокумент8 страницGR 12 Biology Moddel ExamDawit MarkosОценок пока нет

- Poster Making and Gallery WalkДокумент3 страницыPoster Making and Gallery WalkOdyssey Nicolle Esquejo LuisОценок пока нет

- Review of Related Literature and StudiesДокумент9 страницReview of Related Literature and StudiesJay-Ar S. SungaОценок пока нет

- FY 2018 Self Identified Generic Drug Facilities Sites and OrganizationsДокумент175 страницFY 2018 Self Identified Generic Drug Facilities Sites and OrganizationsDavid Paul HensonОценок пока нет

- Concrete Slump Test or Slump Cone TestДокумент4 страницыConcrete Slump Test or Slump Cone TestEljoy C. AgsamosamОценок пока нет

- 1P1 - Anna Kusumawati 323-329Документ7 страниц1P1 - Anna Kusumawati 323-329imam habibiОценок пока нет

- QCR W 2001Документ4 страницыQCR W 2001Madhan KannanОценок пока нет

- Algoritmos para BioreactoresДокумент4 страницыAlgoritmos para BioreactoresMarlon Arista VasquezОценок пока нет

- (De Dios) Science ProjectДокумент22 страницы(De Dios) Science ProjectRoucyzle Ynnah AcidoОценок пока нет

- D BlockДокумент17 страницD Block145556Оценок пока нет

- CATALOG Uniweld-Products TYPE17-2Документ13 страницCATALOG Uniweld-Products TYPE17-2Máy cầm tay Hoàng TrungОценок пока нет

- ECE OLED TechnologyДокумент22 страницыECE OLED Technologygourav VermaОценок пока нет

- A Helmholtz Free Energy Formulation of The Thermodynamic Properties of The Mixture (Water + Ammonia)Документ35 страницA Helmholtz Free Energy Formulation of The Thermodynamic Properties of The Mixture (Water + Ammonia)Marcelo SilvosaОценок пока нет