Академический Документы

Профессиональный Документы

Культура Документы

BPM800 BPM Vs BAM - Rev 1

Загружено:

api-3752216Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BPM800 BPM Vs BAM - Rev 1

Загружено:

api-3752216Авторское право:

Доступные форматы

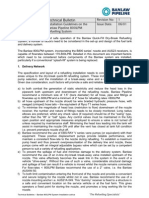

Document title: BPM800 vs BAM800 Revision No: 1

Description: Key Variations Between The Issue Date: 02/06

Banlaw BPM800 Series & BAM800

Series Nozzles

This document outlines key variations between the outgoing BAM800 series

refuelling nozzle and the recently released BPM800 series nozzles. These key

changes should be observed to prevent cross-matching of parts and therefore

avoid the associated risks – also detailed below.

1.0 Retainers

The BPM800-025 Retainer incorporates 2 key differences to the earlier BAM800-

025 Retainer.

PRESSURE SENSING

PORT

16.00

1. AUS21A-025 RETAINER

BAM800 SERIES REFUELLING NOZZLES

REVISED CONTOUR

18.00

2. BP800-025 RETAINER

BPM800 SERIES REFUELLING NOZZLES

Figure 1.0 – BAM800 vs BPM800 Retainers

CONFIDENTIAL INFORMATION Hydrocarbon Management Specialists 1

BPM800 vs BAM800 Rev 1 © 2006 BANLAW PTY LTD

Should either Retainer be installed into the wrong nozzle, the following

consequences may occur:

• Incorrect shut-off pressure: the location of the pressure sensing port on

each Retainer is unique to the type of nozzle. Installation of the wrong

Retainer will alter the shut-off pressure of the nozzle leading to either

premature nozzle shut-off or increased pressurisation of the fuel tank.

• Fuel Leakage: the trailing edge profile of the Retainer suits the specific

type of sleeve seal – either O’ring (BAM series) or one-piece seal (BPM

series). Installation of the wrong Retainer may lead to minor leakage of

fuel from between the Retainer and Sleeve when the nozzle is in the OFF

position or disconnected from the Receiver.

2.0 Sleeves

The BPM800-024 Sleeve incorporates 2 key differences to the earlier BAM800-

024 Sleeve:

1. the use of twin (series) AUS22-020 U-seals as opposed to the earlier pair

of AUS21A-020 U-seals.

2. a one-piece moulded and vulcanised face seal replacing the inner and

outer o’rings used in the BAM series. The profile of this one-piece seal has

been custom designed to suit the dual role of providing a seal between the

Sleeve and Retainer and an effective seal between opposing faces of the

Sleeve and the Receiver during refuelling. Bench testing and field trials

have demonstrated the superior performance, durability and longevity of

the one-piece seal.

AUS21A-020 U-SEALS

AUS22-020 U-SEALS

OUTER

O'RING

MOULDED

INNER FACE SEAL

O'RING

1. BAM800 SLEEVE 2. BPM800 SLEEVE

Figure 2.0 – BAM800 vs BPM800 Sleeves

Should either Sleeve be installed into the wrong nozzle, leakage may occur

between the Retainer and Sleeve when the nozzle is in the OFF position or

disconnected from the Receiver – see also “Fuel Leakage” in section 1.0.

CONFIDENTIAL INFORMATION Hydrocarbon Management Specialists 2

BPM800 vs BAM800 Rev 1 © 2006 BANLAW PTY LTD

3.0 Piston Springs

Different springs are used within the BPM and BAM nozzles to achieve

equivalent shut-off pressures. Whilst springs may at first glance to appear the

same, proper stock control and part number identification must be maintained to

minimise the risk of cross-matching.

Table 3.0 identifies the springs and their respective dimensions.

Spring Settings Part No. Free Length OD Wire Dia. Total Coils

Light, Light-Med, AUS21A029 86.9 ± 0.5mm 34.0 3.15 8.5

Medium

BP800-029 85.0 ± 0.5mm 34.0 3.15 8.5

Med-Heavy, AUS21A027 127 ± 1mm 35 3.15 12.2

Heavy

BP800-027 119 ± 1mm 35 3.15 12.2

Table 3.0 – Piston Spring Dimensions

The use of an incorrect spring will create the following risks:

1. incorrect shut-off pressure of the nozzle causing either premature

nozzle shut-off or increased pressurisation of the fuel tank.

2. overstressing the spring causing yielding and subsequent loss of

properties. Any spring outside the specs detailed in Table 3.0 should be

discarded.

Please do not hesitate to contact Banlaw or your nearest authorised Banlaw

Distributor should you have any queries regarding this document or any quality

Banlaw product.

BANLAW PTY LTD

Ph: 61 2 49724777

Fax: 61 2 49714910

Email: sales@banlaw.com.au

www.banlaw.com.au

Distributor & Business Manager – Systems Engineering Manager

Development Manager Development & Support (Mechanical)

Steve Clayton John Gregory Adam Peattie

0409 045017 0408 492408 0412 704838

steve@banlaw.com.au john@banlaw.com.au adam@banlaw.com.au

CONFIDENTIAL INFORMATION Hydrocarbon Management Specialists 3

BPM800 vs BAM800 Rev 1 © 2006 BANLAW PTY LTD

Вам также может понравиться

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionОт EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionОценок пока нет

- M18 061 eДокумент3 страницыM18 061 eFalgon IslamОценок пока нет

- BPM800 BPM800 Repair - Rev 1Документ7 страницBPM800 BPM800 Repair - Rev 1api-3752216Оценок пока нет

- BPM800 BPM800 - Rev 1Документ16 страницBPM800 BPM800 - Rev 1api-3752216Оценок пока нет

- AMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitДокумент10 страницAMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitIrfan05100% (1)

- Solar SB 16-002Документ3 страницыSolar SB 16-002jussmeeeОценок пока нет

- AGM2005-30 CMZ500700 Maintenance Seal Kit PDFДокумент12 страницAGM2005-30 CMZ500700 Maintenance Seal Kit PDFvangОценок пока нет

- Steyr Marine Engines: Spare Parts CatalogueДокумент151 страницаSteyr Marine Engines: Spare Parts CatalogueMartin FrancoОценок пока нет

- SB-128 enДокумент8 страницSB-128 enhamdan loadingОценок пока нет

- Manual Generador KatoДокумент160 страницManual Generador Katomass72100% (4)

- Maytag Triple Lip and Bearing Kit Installation InstructionsДокумент8 страницMaytag Triple Lip and Bearing Kit Installation InstructionsSamurai Appliance Repair ManОценок пока нет

- Service Bulletin: Safety Recall: 2015-16 CR-V Replacement Engine Short Block Out of SpecificationДокумент4 страницыService Bulletin: Safety Recall: 2015-16 CR-V Replacement Engine Short Block Out of SpecificationOscar GonzálezОценок пока нет

- AA02193C STRG Pin Wear Checks and SizesДокумент8 страницAA02193C STRG Pin Wear Checks and SizesSebastiao DuarteОценок пока нет

- Five Inch Borewell Submersible Pump ManualДокумент39 страницFive Inch Borewell Submersible Pump ManualNavaneethan NatarajanОценок пока нет

- Milnor 450 ManuaДокумент199 страницMilnor 450 Manuaruel millerОценок пока нет

- Pib 机械密封冲管性能升级Документ6 страницPib 机械密封冲管性能升级xlzyydf2015Оценок пока нет

- HPT Stage 1 Blades and Duct SegmentsДокумент28 страницHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekОценок пока нет

- PC400LC-8 SN A88001-UpДокумент365 страницPC400LC-8 SN A88001-Upleo_bh6141Оценок пока нет

- YC4A90 T20 (A93A1) 中英文图册Документ68 страницYC4A90 T20 (A93A1) 中英文图册Khee SoonОценок пока нет

- BSM80C 275afДокумент10 страницBSM80C 275afjose vargasОценок пока нет

- MC-10165512-0001 Subaru Forester FB25 RECALLДокумент8 страницMC-10165512-0001 Subaru Forester FB25 RECALLFelipe TeareОценок пока нет

- SB300 T 1000-0163-4 PDFДокумент19 страницSB300 T 1000-0163-4 PDFJagmohan SinghОценок пока нет

- YoshimuraДокумент7 страницYoshimuraNguon MadolyОценок пока нет

- VSP 267Документ11 страницVSP 267JS VivasОценок пока нет

- PETRO Banlaw RefuellingДокумент4 страницыPETRO Banlaw Refuellingpaulm3565Оценок пока нет

- 2.5 Mobiak Angle Valve (MBK281-2.5) UL ListedДокумент2 страницы2.5 Mobiak Angle Valve (MBK281-2.5) UL ListedAhmed SalahОценок пока нет

- Electronic Parts Catalog - Option DetailДокумент2 страницыElectronic Parts Catalog - Option Detailnaya aninditaОценок пока нет

- Rcrit 07V020 8472Документ34 страницыRcrit 07V020 8472Halit ÖzkanОценок пока нет

- Lit2323 r7 Ch400b Parts ListДокумент28 страницLit2323 r7 Ch400b Parts ListRoman cupulОценок пока нет

- Catalogue 4530Документ115 страницCatalogue 4530pedro henrique rodriguesОценок пока нет

- Parts 160kwFGWДокумент42 страницыParts 160kwFGWMichael Luis MercadoОценок пока нет

- Dokumen - Tips Dv200 Manual Master1Документ45 страницDokumen - Tips Dv200 Manual Master1Fermín Duarte RodríguezОценок пока нет

- Service Bulletin S - 7: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 29.09.95Документ4 страницыService Bulletin S - 7: Technical Information To All The Owners of Sulzer S 20 Type Diesel Engines 29.09.95Diego ReggianiniОценок пока нет

- 206-19-42 July 2019Документ9 страниц206-19-42 July 2019turboshaftОценок пока нет

- Stategen - Lister-Petter Alpha Range Acc - PartsДокумент48 страницStategen - Lister-Petter Alpha Range Acc - PartsDevang RathodОценок пока нет

- AMM - 01-Aug-2019 - 79-21-10-400-004-A - Installation of The Lubrication UnitДокумент11 страницAMM - 01-Aug-2019 - 79-21-10-400-004-A - Installation of The Lubrication UnitIrfan05Оценок пока нет

- Amana Parts ListДокумент13 страницAmana Parts ListRAJESH BHANDERIОценок пока нет

- Removal of The Oil Inlet Cover AssemblyДокумент5 страницRemoval of The Oil Inlet Cover AssemblySonny RaymundoОценок пока нет

- Eo A320 009.16 Engine Change Rev. 04Документ30 страницEo A320 009.16 Engine Change Rev. 04likephungproОценок пока нет

- BSM90C-3150AF: Product Information PacketДокумент10 страницBSM90C-3150AF: Product Information PacketRoberto CОценок пока нет

- C1021CE Dual LineДокумент52 страницыC1021CE Dual LineVINIT KUMAR SINGHОценок пока нет

- Breaker 6901152 enUS SM 06-12Документ200 страницBreaker 6901152 enUS SM 06-12Rosa Chura AlarconОценок пока нет

- Section 8 - BPW Quick ReferenceДокумент43 страницыSection 8 - BPW Quick ReferenceSanhory Abd AlgaderОценок пока нет

- 327730Документ8 страниц327730isaias ramirezОценок пока нет

- SPARE PARTS CATALOGUE - Steyr MotorsДокумент113 страницSPARE PARTS CATALOGUE - Steyr Motorsbelah1100Оценок пока нет

- Camiseta de O500Документ5 страницCamiseta de O500Miguel CardenasОценок пока нет

- CW Series Air Compressor Parts List and ManualДокумент17 страницCW Series Air Compressor Parts List and ManualrobertОценок пока нет

- D601000439 Man 001Документ25 страницD601000439 Man 001Riski KurniawanОценок пока нет

- Enduro 690 2014 PartesДокумент28 страницEnduro 690 2014 PartesRafael CollíОценок пока нет

- Raw Water Pump SW9051-01Документ3 страницыRaw Water Pump SW9051-01Aleks BaggiОценок пока нет

- Service News: Gearbox Seal MD 100W-200-300-400-600-1000 Priority: II GAC: 58 ECB AIF1237 Date:29/3/2000Документ3 страницыService News: Gearbox Seal MD 100W-200-300-400-600-1000 Priority: II GAC: 58 ECB AIF1237 Date:29/3/2000Francisco Noel Bermúdez BritoОценок пока нет

- CДокумент17 страницCjack michael chang garridoОценок пока нет

- Engine Steyr Mo256k43 - 01Документ171 страницаEngine Steyr Mo256k43 - 01Cristian TamașОценок пока нет

- Locitte 577 Fast Cure Pipe LEM BESI KACA LASДокумент384 страницыLocitte 577 Fast Cure Pipe LEM BESI KACA LASnoviОценок пока нет

- Industrial Gas Generator Illustrated Parts CatalogueДокумент23 страницыIndustrial Gas Generator Illustrated Parts CataloguejuanaОценок пока нет

- Lincoln Helios (India) Limited: Operation & Maintenance ManualДокумент50 страницLincoln Helios (India) Limited: Operation & Maintenance Manualprem sagarОценок пока нет

- Blackhawk Pump Manual 2018Документ75 страницBlackhawk Pump Manual 2018Ivan MaltsevОценок пока нет

- MAN ShaftErrosion SL2008-498Документ18 страницMAN ShaftErrosion SL2008-498flipflop12100% (1)

- G300 Brake BleederДокумент7 страницG300 Brake BleederluisОценок пока нет

- Technical Bulletins TB - Dual Tanks 0300Документ4 страницыTechnical Bulletins TB - Dual Tanks 0300api-3752216Оценок пока нет

- Wiggins Vents Info Wiggins VentsДокумент2 страницыWiggins Vents Info Wiggins Ventsapi-3752216Оценок пока нет

- Technical Bulletins TB - Quick-Fill Tank VentsДокумент13 страницTechnical Bulletins TB - Quick-Fill Tank Ventsapi-3752216Оценок пока нет

- PhoneList (FirstName)Документ35 страницPhoneList (FirstName)api-3752216100% (3)

- Technical Bulletins TB - Quick-Fill Tank VentsДокумент13 страницTechnical Bulletins TB - Quick-Fill Tank Ventsapi-3752216Оценок пока нет

- Technical Bulletins TB - 800LPM Installation AdviceДокумент4 страницыTechnical Bulletins TB - 800LPM Installation Adviceapi-3752216Оценок пока нет

- Technical Bulletins TB - Fluid Theory 0400Документ8 страницTechnical Bulletins TB - Fluid Theory 0400api-3752216Оценок пока нет

- Technical Bulletins TB - Nozzle Shut-Off MechanismДокумент4 страницыTechnical Bulletins TB - Nozzle Shut-Off Mechanismapi-3752216Оценок пока нет

- Technical Bulletins TB - Multi Compartment Tanks 0300Документ4 страницыTechnical Bulletins TB - Multi Compartment Tanks 0300api-3752216Оценок пока нет

- Oil Sampling Valve Oil Sampling Valve0001Документ1 страницаOil Sampling Valve Oil Sampling Valve0001api-3752216Оценок пока нет

- Technical Bulletins TB - 800LPM Installation Advice 0601Документ5 страницTechnical Bulletins TB - 800LPM Installation Advice 0601api-3752216Оценок пока нет

- Technical Bulletins TB - 1000LPM Installation Advice 0601 - 1Документ5 страницTechnical Bulletins TB - 1000LPM Installation Advice 0601 - 1api-3752216Оценок пока нет

- Bam 800 T004 - Nozzle Flow Testing GuidelinesДокумент11 страницBam 800 T004 - Nozzle Flow Testing Guidelinesapi-3752216100% (1)

- Bam 800 T001 - Air TestДокумент2 страницыBam 800 T001 - Air Testapi-3752216Оценок пока нет

- Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection SystemДокумент3 страницыScully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection Systemapi-3752216100% (1)

- Technical Bulletins Hydrostatic Pressure & Flow Test Results Rev3Документ1 страницаTechnical Bulletins Hydrostatic Pressure & Flow Test Results Rev3api-3752216Оценок пока нет

- Risk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3Документ39 страницRisk Analysis Refueling Nozzles RA Refuelling Nozzles - Generic Rev3api-3752216100% (1)

- Fast Fill Couplers NEW FJ Broch PG 12Документ1 страницаFast Fill Couplers NEW FJ Broch PG 12api-3752216Оценок пока нет

- Installation Guidelines Installation Guidlines On The Installation of 800LPM Refueling SystemДокумент1 страницаInstallation Guidelines Installation Guidlines On The Installation of 800LPM Refueling Systemapi-3752216Оценок пока нет

- Filtered Vents FilteredVentДокумент2 страницыFiltered Vents FilteredVentapi-3752216Оценок пока нет

- Installation Guidelines Installation and Inspection Guidlines For The AUS 25A Quick Fill VentsДокумент1 страницаInstallation Guidelines Installation and Inspection Guidlines For The AUS 25A Quick Fill Ventsapi-3752216Оценок пока нет

- Fuel Trial Results Fuel TrialsДокумент2 страницыFuel Trial Results Fuel Trialsapi-3752216Оценок пока нет

- Banlaw Sales Brochures FillSafeДокумент2 страницыBanlaw Sales Brochures FillSafeapi-3752216Оценок пока нет

- Banlaw Sales Brochures Filtered VentДокумент2 страницыBanlaw Sales Brochures Filtered Ventapi-3752216Оценок пока нет

- Scully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection SystemДокумент3 страницыScully Systems - Scully Systems Electronic Tank Truck Equipment - Files Banlaw FillSafeTM Electronic Overfill Protection Systemapi-3752216100% (1)

- Fast Fill Couplers LubeCentralhfcouplingsДокумент2 страницыFast Fill Couplers LubeCentralhfcouplingsapi-3752216Оценок пока нет

- Fill Safe General Operating Instructions 08-05Документ1 страницаFill Safe General Operating Instructions 08-05api-3752216Оценок пока нет

- Fast Fill Couplers LC Hi-Flow FlyerДокумент3 страницыFast Fill Couplers LC Hi-Flow Flyerapi-3752216Оценок пока нет

- Fast Fill Couplers FF Coupling Price List-06Документ1 страницаFast Fill Couplers FF Coupling Price List-06api-3752216Оценок пока нет

- Fast Fill Couplers Flush Face Flyer - PDДокумент2 страницыFast Fill Couplers Flush Face Flyer - PDapi-3752216Оценок пока нет

- Assessing The Impact of Industrial RobotsДокумент14 страницAssessing The Impact of Industrial RobotsKarthik SRSОценок пока нет

- Ufc 3 430 09Документ106 страницUfc 3 430 09carlcrowОценок пока нет

- IFFCO Urea ProcesspdfДокумент3 страницыIFFCO Urea ProcesspdfBalas43Оценок пока нет

- How Electric Cars Work: A Guide to EV TechnologyДокумент4 страницыHow Electric Cars Work: A Guide to EV TechnologyCarla LoiaconoОценок пока нет

- YM80SA Abrasive Belt Polishing Machine-Operation ManualДокумент7 страницYM80SA Abrasive Belt Polishing Machine-Operation ManualAgha Ali KhanОценок пока нет

- Symmetry & Crystal StructuresДокумент37 страницSymmetry & Crystal StructuresNurnajihah Sukimi JiehaОценок пока нет

- CH 1Документ13 страницCH 1badgujar_bandhuОценок пока нет

- Wiring Diagram FH, NH: GroupДокумент110 страницWiring Diagram FH, NH: GroupStefan AslamОценок пока нет

- ECU MS 3 Sport GT3 Cup Manual Setup GuideДокумент26 страницECU MS 3 Sport GT3 Cup Manual Setup GuideAngel LópezОценок пока нет

- Curriculum Vitae Yosep Kurniawan Basa SogenДокумент19 страницCurriculum Vitae Yosep Kurniawan Basa Sogenyosep kurniawanОценок пока нет

- Wet Steam Washing SystemДокумент7 страницWet Steam Washing SystemPrudhvi Raj100% (1)

- SteckДокумент354 страницыStecknaruto100% (1)

- 2013 Midterm 3Документ16 страниц2013 Midterm 3billbyoag123Оценок пока нет

- MANUAL Vdocuments - Site FG Wilson P88e1Документ287 страницMANUAL Vdocuments - Site FG Wilson P88e1eletronica55100% (2)

- Elective 4 Module1Документ27 страницElective 4 Module1kentong compraОценок пока нет

- Pipe Sizes and Flow Rates for Air Flush DrillingДокумент14 страницPipe Sizes and Flow Rates for Air Flush DrillingzapspazОценок пока нет

- Measuring Instrument Accuracy LimitsДокумент2 страницыMeasuring Instrument Accuracy LimitsDan DanubiusОценок пока нет

- GH G ConversionДокумент146 страницGH G ConversionjorgeОценок пока нет

- Distillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedДокумент3 страницыDistillation and Vapor Pressure Test of Gasoline Fuel: Fuels TestedReyes, Ishmael Edward John U.Оценок пока нет

- Lab 5Документ9 страницLab 5Cem UsmangilОценок пока нет

- VS1-2 Manual PDFДокумент284 страницыVS1-2 Manual PDFJorge InostrozaОценок пока нет

- Nutrition For AthletesДокумент37 страницNutrition For AthletesAnonymous e1sArVj5zl100% (1)

- Electrical Network of The Automotive Multi-Sectional Thermoelectric Generator With MPPT Based Device UsageДокумент10 страницElectrical Network of The Automotive Multi-Sectional Thermoelectric Generator With MPPT Based Device UsageMouna MorchidОценок пока нет

- Microcontroller-Based Power Monitoring for COE RoomsДокумент8 страницMicrocontroller-Based Power Monitoring for COE Roomskenneth_molenilla1475Оценок пока нет

- Separating Acetic Acid and Water by DistillationДокумент8 страницSeparating Acetic Acid and Water by DistillationSuzanne Clariz M. BaltazarОценок пока нет

- Current Transformer - Electrical Notes & ArticlesДокумент47 страницCurrent Transformer - Electrical Notes & Articlesnomy158100% (1)

- Repair Manual B200Документ460 страницRepair Manual B200slawny7789% (9)

- Rectification ProcessДокумент5 страницRectification ProcessDilnaz TegispayОценок пока нет

- 3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhaДокумент3 страницы3/27/2016 Portable AC On Rent Pune - Portable AC Rentals Pune - AC Rentals Pune On SulekhadcoolsamОценок пока нет

- High Voltage Products Reliable Products - EN PDFДокумент102 страницыHigh Voltage Products Reliable Products - EN PDFSiva ReddyОценок пока нет