Академический Документы

Профессиональный Документы

Культура Документы

RFID 212855 Sharpshooter Brochure

Загружено:

Balluff SensorsИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RFID 212855 Sharpshooter Brochure

Загружено:

Balluff SensorsАвторское право:

Доступные форматы

Vision based error proofing

SHARPSHOOTER

Ser i es

2

Balluff Sharpshooter

Series

The best combination of vision sensing simplicity and functionality

In most production situations, vision

systems can be overkill too expensive,

too much functionality, and just too

complex. Instead, Balluff Sharpshooter

sensors are easy to set up, simple to

use, and quicker to return your initial

investment.

The Sharpshooter is a powerful error

proofing tool that can be used in

almost any area of your manufacturing

process. It provides reliable part or

feature presence/absence and position

detection, plus dimension verification

and accurate barcode reading with crisp

and reliable resolution. The Sharpshooter

has far more functionality than any

discrete sensor, sensor array, or vision

product in its class.

The Sharpshooter simplifies complex sensing applications.

Increases Productivity

n Improves line speed and error proofing by eliminating

the need for manual inspection

n Minimizes false code reads with very high code

resolution for greater reliability

n Catches errors sooner to reduce unplanned downtime

and scrap

n Reduces planned downtime with greater functionality

and flexibility

Increases Product Quality

n Eliminates unreliable manual inspection

n Allows 100% quality checking instead of audit checking

n Provides the resolution needed for reliable quality inspection

n Enables automated barcode reading

Reduces Costs

n Single-unit operation replaces

expensive, cumbersome multi-

sensor solutions

n Four models with multiple

performance levels to choose

from provide multiple price

points based on functionality

n Single easy to use software

package minimizes setup time

and cuts startup costs

n Provides vision performance at

smart sensor pricing

Actual Size

Handling and

automation Automotive

Plastic

and rubber Packaging

Pharmaceuticals

and cosmetics

Foods and

beverages Medical devices

3

www.balluff.com/sharpshooter

PC and Net wor k Conf i gur at i on

Standard

Seven flexible software tools to choose from including:

edge finding, brightness, contrast, contour, and basic

two-axis pattern matching tools

Multiple tools can be used in a single job with up to

four pass/fail outputs

External trigger, job switching, and illumination

control I/O

DHCP Ethernet capability

Advanced

Basic seven tools plus 360 geometric pattern

matching software tool

All software tools follow part rotation for greatest

flexibility and reliability

Configurable and flexible output logic links any tool or

combination of tools to any of three discrete outputs

DHCP Ethernet capability

Ident i f i cat i on

Detect and identify Barcodes and Data Matrix codes

1D codes: detect or read most common barcodes

2D codes: verify or read ECC 200 Data Matrix codes

to a minimum of 0.10 mm code module size

Verify characters

Output codes via serial interface RS232

St and-Al one Conf i gur at i on Tool

Stand-Alone

No PC required for setup

Panel mount Configurator unit uses simple push

buttons and a 3.5" LCD color graphic interface

Choose one inspection tool from a library of seven

Multiple Sharpshooter sensors can be individually set

up and monitored by a single Configurator to minimize

hardware costs

Provides "best in class"

functionality at a low cost

AND

OR

Exclusive OR

NOT AND

NOT OR

NOT Exclusive OR

NOT

Majority selector

Logical connections

4

Pass

All connectors are present and capacitors

are in correct orientation

Fail

Bad orientation

Missing connector

El ect roni cs St andar d Ver si on

Assembly Verification

Inspect a circuit board to ensure that all connectors are present and verify the correct orientation of all the capacitors.

Shar pshoot er

Ser i es

Sharpshooter can replace many different discrete and analog sensor functions

along with entire sensor arrays in a single error proofing device.

See addi t i onal appl i cat i ons at www.bal l uf f .com/ shar pshoot er .

Pass

Bottle cap liner is present

and intact

Packagi ng St andar d Ver si on

Conformance/Presence Check

Inspect a bottle cap to determine the

presence and the integrity of the cap liner.

Fail

Liner damaged

Packagi ng St and-Al one Ver si on

Optical Character Verification

Confirm that product codes are printed on labels

by using BVS-C with Configurator.

Pass

Correct characters

are printed on label

Fail

Incorrect characters

are printed on label

Pass

All pills are present in package

Fail

Missing pill

Phar maceut i cal St andar d Ver si on

Package Presence Verification

Verify the presence of all the pills packaged in a blister pack.

P

P

PP

C

EE

As

Contrast Character

Verification

Pattern

Match

Pattern

Match

5

www.balluff.com/sharpshooter

Shar pshoot er

Ser i es

Application examples

Packagi ng BVS ID

Verify Barcodes

Codes are read irrespective of slight changes

in position

High detection rate

Packagi ng BVS ID

Verify Data Matrix Codes

Codes are read irrespective of the position

High detection rate

ECC 200 compliant

Packagi ng Advanced Ver si on

In-line Quality Conformance

Verify presence of caps on bottles.

Packagi ng Advanced Ver si on

Package Flap Detection

Detect if major and minor flaps are in proper

position on package.

Aut omot i ve St andar d Ver si on

Dimensional Gauging/Component Inspection

Inspect fuel injector for verification/presence of

electrical cap, injector nozzle, o-ring, and gauging

for the proper injector width.

Pass

Verify presence of components

and proper injector width

Fail

Missing o-ring

Missing cap

Aut omot i ve Advanced Ver si on

Geometric Pattern Matching Searches

X, Y, and 360 Rotation for Geometric

Features

Verify presence of bearings and size of gaps.

Pass

Bearings present;

gaps correct

Fail

Incorrect gap

A

D

Pass

Bottle caps are present

Fail

Missing cap

Pass

Proper flap seal

Fail

Flap position failures

Edge

Position

Brightness

Edge

Count

Edge

Position

Width

Barcode Data

Matrix

Code

Geometric

Pattern

Match

P

Ve

Part identification

Process monitoring

Print monitoring

Part identification

Process monitoring

Print monitoring

Width

6

Shar pshoot er

Ser i es

Multiple functions in one sensor

B

V

S

-

E

S

t

a

n

d

a

r

d

B

V

S

-

E

A

d

v

a

n

c

e

d

B

V

S

-

C

w

i

t

h

c

o

n

f

i

g

u

r

a

t

o

r

B

V

S

-

E

I

d

e

n

t

i

f

i

c

a

t

i

o

n

Check brightness Checks whether the brightness (gray values) in

the selected image area is greater than a configured threshold.

Identify different types and parts

Check illumination brightness

Detect the function of a display

Compare contrast Determines whether a certain contrast is present in the image.

Monitor presence of labels

Detect a label

Check completeness

Monitor position Checks the relative object position in the image.

Monitor level

Position parts and products

Position labels

Count edges Counts the gray value edges in the image area.

Monitor the number of pins on ICs

Check threads for completeness

Verify boxes in a stack

Compare width Compares the absolute distance between two edges in an image.

Check for presence (e.g. lids)

Differentiate parts

Verify dimensions

Check contour Checks the shape of an object.

Check for absence of burrs and flashing

Check stamped parts

Differential parts shapes

Nominal/Actual comparison

Detect pattern Detects patterns and differentiates objects using image

comparison. Digital patterns are extracted from the image and compared with the

pattern of a reference object.

Check parts quality

Differentiate types

360 position detection Detects patterns based on a taught geometric pattern of

a reference image area.

Align parts

Inspection irrespective of the position

Align multiple inspection tools

Compare character (OCV) Compares characters from taught references.

Check label text

Monitor printing (e.g. ensure correct dates for different lots)

Check logos

Detect and identify barcode and Data Matrix code

Code verification

Documentation of parts used

Monitor print quality

Sharpshooter BVS vision sensors offer

several tools for reliable monitoring of your

production processes. Simply select the

right version according to your needs. The

Sharpshooter BVS offers proven solutions

to help you reliably error proof your sensing

applications.

7

www.balluff.com/sharpshooter

Shar pshoot er

Ser i es

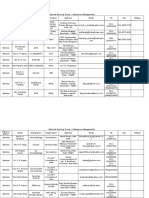

The possibilities at a glance

The following chart provides an overview of

different functions and features to help you

select the right Sharpshooter vision sensor

for your application.

Features BVS-E Standard BVS-E Advanced BVS-E Identification BVS-C with configurator

Tools 7 8 3 7

Tools per inspection Limited only by memory Limited only by memory Limited only by memory 1

Inspections 20 20 20 20

Connection Multiple sensors

in the network

Multiple sensors

in the network

Multiple sensors

in the network

Stand-alone with Configurator

Interface Ethernet Ethernet Ethernet/serial None

Connection

type

PNP

NPN

Focal length 6 mm

8 mm

12 mm

16 mm

Parameter

configuration

ConVis

Configurator

The benefits to you

Short setup times

and convenient format

changing on the PC

Flexible adaptation to

your process through

simple switching of

multiple jobs

Simultaneous

checking of multiple

features

Includes all the functions

of the Standard BVS-E,

plus:

Logical linking of

tools to the outputs

Faster CPU for higher

processing rates

360 position

detection

1D codes:

detects or reads all

common barcodes

2D codes:

detects or reads

Data Matrix codes

Verify characters

Output via serial

interface RS232

Easy to retrofit into your

equipment

Configurator for fast startup

Simple to make on-site

corrections during the process

Continuous status monitoring

on the display

Operated without a PC

8

Shar pshoot er

Ser i es

Flexible choices and powerful tools

PC/ Net wor k Use

Benefits of the BVS-E and Identification

Simple Windows

/ConVis software

interface for quick and easy setup

Network multiple BVS sensors for easy

access and use

Inspect many features in one job, multiple

jobs are stored internally

Easily set up and inspect barcodes

Recommended

accessories

Power Supply I/O

Mounting

brackets

Lighting

Connection

cable

Configuration

cable

BVS ConVis

software

BVS Moni t or

Benefits of the BVS-M

Allows for inspection monitoring without

using a PC

Change of job via monitor

View a single or multiple cameras via

Ethernet connection

Password protected

Recommended

accessories

Power Supply I/O

Mounting

brackets

Lighting

Connection

cable

Configurator

cable

Configurator

Features

Built in lens and ring light

Status LEDs

Triggers external light

source

Up to four pass/fail outputs

and trigger input

Additional RS232 port on

BVS-ID sensor

Features

Simple push button

interface

Graphic based monitor for

easy set up and monitoring

Built in Ethernet port

Separate 24V power

connection

St and-Al one Use

Benefits of the BVS-C

Perfect for simple inspections without using

a PC

Good for stand-alone machine needs

Allows continuous status monitoring via the

Configurator

Features

Same hardware features of

BVS-E, less Ethernet port

GUI and push button used

on Configurator interface

Provide image or statistical

monitoring online

Power Supply

Multiple BVS-E Sensors

9

www.balluff.com/sharpshooter

Shar pshoot er

Ser i es

Sharpshooter interface

BVS-E Shar pshoot er PC Int er f ace

Step 2

Configure

Set up position compensation

and inspection tools.

Step 3

Run

Configure the outputs and

evaluate the results.

Tool Panel

All the

properties at

a glance

Setup steps

Configuration

in three easy

steps

ROI Region of

Interest

Image area used for

tool comparison/

measurement

Frame

buffer

Multiple

image

reviewing

Built-in help and

overview function

Quick dynamic help

reference

Function tabs

Easy access to

image viewing,

statistics data,

and output setup

Step 1

Connect

Easily connect the sensor to

the Configurator.

Step 2

Configure

Select the appropriate tool and

define image settings.

BVS-C Shar pshoot er Conf i gur at or Int er f ace

Built in image

monitor

Simple

push button

interface

Measurement

status and

display

Status

indicators

For a step-by-step setup

demonstration visit:

www. balluff.com/sharpshooter

Step 3

Run

Set the tool parameters, outputs,

and test your inspection.

Monitoring screen

Image setup screen

Tool setup screen

Step 1

Connect

Easily connect the PC to the sensor

via Ethernet, configure image and

trigger, set reference image.

10

Shar pshoot er

Ser i es

BVS-E ConVis

PC software versions

Series

Version

Lens, focal length

PNP Ordering code

Part number

NPN* Ordering code

Part number

Supply voltage U

S

Switching inputs*

Switching outputs

Output current

Configuration interface

Parameter configuration

Typ. detection rate

Image sensor

Assured working distance (see chart below)

Field of view (horizontal x vertical)

Lighting (integrated)

Alignment aid

Dimensions

Connection

Degree of protection per IEC 60529

Ambient temperature range T

a

Display

There are three Sharpshooter BVS-E lens choices (see the image area size and working

distance chart on page 11). The BVS-E has two versions; both of which use the same easy

3-step setup ConVis

configuration software. The standard tool set provides seven flexible

inspection and measurement tools for simple X and Y based inspections. The BVS-E versions

can also use the BVS-M to monitor any BVS-E connected to a network.

The advanced BVS provides the same seven tools, but also includes 360 part location

compensation with an advanced Geometric Pattern Matching tool and flexible output logic.

* Trigger and select inputs are PNP based

Advanced Sensor Out put Logi c

NOT

AND

NAND

OR

NOR

XOR (EXCLUSIVE OR)

XNOR (EXCLUSIVE NOR)

MAJORITY

Boolean logic gates

Advanced output capability

Use logical operation on one or

more tools to create a single output

For further information

using logic gates, visit

www.balluff.com/sharpshooter.

Output setup

Combine multiple tools and configurations

Easily manage complex output

functionality

11

www.balluff.com/sharpshooter

BVS-E BVS-E BVS-E BVS-M Monitor

Standard Advanced Standard Advanced Standard Advanced

Wide angle lens Wide angle lens Standard lens Standard lens Telephoto lens Telephoto lens

BVS000E BVS000L BVS0003 BVS000J BVS0005 BVS000K BAE00EH

BVS OI-3-005-E BVS OI-3-055-E BVS OI-3-001-E BVS OI-3-051-E BVS OI-3-003-E BVS OI-3-053-E BAE PD-VS-002-E

BVS000C BVS000R BVS0004 BVS000P BVS0006 BVS000N

BVS OI-3-006-E BVS OI-3-056-E BVS OI-3-002-E BVS OI-3-052-E BVS OI-3-004-E BVS OI-3-054-E

24 V DC 10 % 24 V DC 10 % 24 V DC 10 % 24 V DC 10 %

1 Trigger, 1 Select 1 Trigger, 1 Select 1 Trigger, 1 Select

1 lighting synchronization,

3 configurable

1 lighting synchronization,

3 configurable

1 lighting synchronization,

3 configurable

100 mA 100 mA 100 mA

Ethernet 10/100 Base T Ethernet 10/100 Base T Ethernet 10/100 Base T Ethernet 10/100 Base T/Serial RS 232

ConVis

for Windows ConVis

for Windows ConVis

for Windows Built in G.U.I.

180 Hz

(depending on

evaluation function)

480 Hz

(depending on

evaluation function)

180 Hz

(depending on

evaluation function)

480 Hz

(depending on

evaluation function)

180 Hz

(depending on

evaluation function)

480 Hz

(depending on

evaluation function)

CMOSSWVGA 640480 CMOSSWVGA 640480 CMOSSWVGA 640480

50...1000 mm 50...1000 mm 50...1000 mm

36x25 mm to 330x232 mm 2518 mm to 460380 mm 1612 mm to 317237 mm

LED, incident light (red), deselectable LED, incident light (red), deselectable LED, incident light (red), deselectable

4 LED green, deselectable 4 LED green, deselectable 4 LED green, deselectable

585240 mm 585240 mm 585240 mm 969642.4 mm

2 connectors M12 (8- and 4-pin) 2 connectors M12 (8- and 4-pin) 2 connectors M12 (8- and 4-pin) 2 connectors M12 (8- and 4-pin)

IP 54 IP 54 IP 54 IP 40

10...+55 C 10...+55 C 10...+55 C 10...+55 C

3.5 color LCD

6 mm

l ens

8 mm

l ens

12 mm

l ens

6 mm lens

8 mm lens

12 mm lens

50 mm

150 mm

500 mm

2000 mm

1000 mm

Working distance and field of view

6 mm Lens 36 x 25 mm 109 x 75 mm 362 x 251 mm 724 x 503 mm

8 mm Lens 25 x 18 mm 75 x 54 mm 249 x 182 mm 498 x 363 mm 995 x 726 mm

12 mm Lens 16 x 12 mm 47 x 36 mm 156 x 118 mm 312 x 237 mm 624 x 474 mm

12

Series

Version

Lens, focal length

PNP* Ordering code

Part number

Supply voltage U

B

Switching inputs*

Switching outputs

Interface

Rated operating current I

e

Configuration interface

Parameter configuration

Typ. detection rate

Image sensor

Assured working distance (see chart below)

Field of view (horizontalvertical)

Lighting

Dimensions

Connection

Degree of protection per IEC 60529

Ambient temperature range T

a

Display

12

Supports:

Direct part mark

Printed codes

Data Matrix codes

ECC 200 compliant

Readable barcodes

Interleaved 2-of-5

Code 39

Code 128

Pharmacode

Codabar

EAN 8

EAN 13

UPC-E

Postnet

IMB

PDF 417

Shar pshoot er

Ser i es

BVS-E Identification

The Sharpshooter ID can check the marking on your products regardless of whether you

label them with 1D codes (barcodes) or 2D codes (Data Matrix codes). The BVS-ID reads the

most common codes on the market with one of the highest code module resolutions available

in its price range. This provides higher reading throughput and greater read reliability. Text

and sequences of numbers such as code plain text can be verified using OCV. The result:

"Inspection OK" or "Inspection not OK". If you need to view the read code data to find out which

parts are being processed, you can output it via the RS232 or Ethernet interface.

The BVS-E Identification uses the same easy 3-step setup ConVis

configuration software as

the BVS-E sensors. The BVS-E Identification version can also use the BVS-M to monitor any

BVS-E connected to the network.

* Trigger and select inputs are PNP based

Minimum code module resolution

with 12 mm lens at 50 mm

13

www.balluff.com/sharpshooter

Vision sensor Vision sensor Vision sensor BVS-M Monitor

BVS-E Identification BVS-E Identification BVS-E Identification

Standard lens, 8 mm Telephoto lens, 12 mm Telephoto lens, 16 mm

BVS0001 BVS000T BVS000Y BVS00EH

BVS ID-3-001-E BVS ID-3-003-E BVS ID-3-007-E BAE PD-VS-002-E

24 V DC 10 % 24 V DC 10 % 24 V DC 10 % 24 V DC 10 %

1 Trigger, 1 Select 1 Trigger, 1 Select 1 Trigger, 1 Select

1 lighting synchron., 1 PNP 1 lighting synchron., 1 PNP 1 lighting synchron., 1 PNP

RS232 RS232 RS232

100 mA 100 mA 100 mA

Ethernet 10/100 Base T/Serial RS232 Ethernet 10/100 Base T/Serial RS232 Ethernet 10/100 Base T/Serial RS232 Ethernet 10/100 Base T

ConVis for Windows ConVis for Windows ConVis for Windows Built in G.U.I.

3...15 Hz (depending

on evaluation function)

3...15 Hz (depending

on evaluation function)

3...15 Hz (depending

on evaluation function)

CMOS-SW-VGA 640480 CMOS-SW-VGA 640480 CMOS-SW-VGA 640480

50...1000 mm 50...1000 mm 150...1000 mm

2518 mm 498363 mm 1612 mm 312237 mm 3426 mm 229172 mm

LED, incident light (red), deselectable LED, incident light (red), deselectable LED, incident light (red), deselectable

585240 mm 585240 mm 585240 mm 969642.4 mm

2 connectors M12 (8- and 4-pin) 2 connectors M12 (8- and 4-pin) 2 connectors M12 (8- and 4-pin) 2 connectors M12 (8- and 4-pin)

IP 54 IP 54 IP 54 IP 40

10...+55 C 10...+55 C 10...+55 C 10...+55 C

3.5 color LCD

8 mm

l ens

12 mm

l ens

16 mm

l ens

8 mm lens

12 mm lens

16 mm lens

50 mm

150 mm

500 mm

2000 mm

1000 mm

Working distance and field of view

8 mm Lens 25 x 18 mm 75 x 54 mm 249 x 182 mm 498 x 363 mm 995 x 726 mm

12 mm Lens 16 x 12 mm 47 x 36 mm 156 x 118 mm 312 x 237 mm 624 x 474 mm

16 mm Lens 34 x 26 mm 114 x 86 mm 229 x 172 mm 457 x 344 mm

14

The Sharpshooter BVS-C has two lens types to choose from (see the image area size and

working distance chart on page 15). The BVS-C versions use a simple to use Configurator

display interface and a single tool operation to provide a solution for stand-alone applications at

a cost effective price.

The Configurator has a built-in 3.5" color LCD monitor and simple push-button interface.

A single Configurator can be used to individually set up multiple BVS-C sensors and can

individually monitor each sensor. In addition, the BVS-C offers password protection and an

Optical Character Verification (OCV) tool instead of a Contour tool.

Shar pshoot er

Ser i es

BVS-C Stand-Alone version

15

www.balluff.com/sharpshooter

Series BVS-C BVS-C Configurator with display

Version Standard Standard

Lens, focal length Standard lens Telephoto lens

PNP* Ordering Code BVS0008 BVS0007 BVS002R

Part number BVS OI-3-011-C BVS OI-3-013-C BAE PD-VS-001-C

Supply voltage U

S

24 V DC 10 % 24 V DC 10 % 24 V DC 10 %

Switching inputs* 1 Trigger, 1 Select 1 Trigger, 1 Select

Switching outputs 1 lighting synchronization,

3 configurable

1 lighting synchronization,

3 configurable

Output current 100 mA 100 mA Powered by BVS

Parameter setting Configurator Configurator Built in G.U.I.

Typ. detection rate 180 Hz

(depending on evaluation function)

480 Hz

(depending on evaluation function)

Image sensor CMOSSWVGA 640480 CMOSSWVGA 640480

Assured working distance (see chart below) 50...1000 mm 50...1000 mm

Field of view (horizontalvertical) 2518 mm to 498363 mm 1612 mm to 312237 mm

Lighting (integrated) LED, incident light (red),

deselectable

LED, incident light (red),

deselectable

Dimensions 585240 mm 585240 mm 969642.4 mm

Connection 2 connectors M12 (8-pin) 2 connectors M12 (8-pin) 1 connector M12 (8-pin)

Degree of protection per IEC 60529 IP 54 IP 54 IP 40

Ambient temperature range T

a

10...+55 C 10...+55 C 10...+55 C

Display 3.5 color LCD

8 mm

l ens

12 mm

l ens

* Trigger and select inputs are PNP based

8 mm lens

12 mm lens

50 mm

150 mm

500 mm

2000 mm

1000 mm

Working distance and field of view

8 mm Lens 25 x 18 mm 75 x 54 mm 249 x 182 mm 498 x 363 mm 995 x 726 mm

12 mm Lens 16 x 12 mm 47 x 36 mm 156 x 118 mm 312 x 237 mm 624 x 474 mm

16

Shar pshoot er

Ser i es

Lighting options

Series BAE LX-VS BAE LX-VS BAE LX-VS BAE LX-VS

Version Background light Backlight Backlight Background light

Ordering code BAE000E BAE000F BAE000H BAE00C5

Part number BAE LX-VS-HR025 BAE-LX-VS-HR050 BAE-LX-VS-HR100 BAE LX-VS-HR150

Supply voltage U

S

24 V DC 24 V DC 24 V DC 24 V DC

Operating current 225 mA < 250 mA < 400 mA 500 mA

Trigger none none

Light field size 2525 mm 5050 mm 100100 mm 150100 mm

Emitter, light type LED, red light LED, red light LED, red light LED, red light

Wavelength 617 nm 617 nm 617 nm 617 nm

Dimension 105809.5 mm 105809.5 mm 1551309.5 mm 105809.5 mm

Mounting M4 screws M4 screws M4 screws M4 screws

Connection M12 connector, 4-pin M12 connector, 4-pin M12 connector, 4-pin M12 connector, 4-pin

Housing material Anodized aluminum Anodized aluminum Anodized aluminum Anodized aluminum

Optical surface Glass Glass Glass Glass

Weight 66 g 155 g 340 g 435 g

Enclosure rating IP 54 IP 54 IP 54 IP 54

Polarity reversal protected Yes yes yes Yes

Short circuit protected Yes yes yes Yes

Ambient temperature range T

a

10...+55 C 10...+55C 10...+55C 10...+55 C

Storage temperature range 25...+75 C 25...+75 C 25...+75 C 25...+75 C

80 9.5

9

5

1

0

5

3

0

0

5

0

4

6

3

2

.

5

5

50

50

15

15

4

M12x1

4

.

4

130

1

4

5

1

5

5

3

0

0

1

0

0

4

6

3

2

.

5

5

100

100

15

15

M12x1

9.5

4

4

.

4

No vision-based application can reliably

succeed without the proper lighting. Balluff

provides cost effective, high-quality LED

based illumination options to maximize the

reliability of any Sharpshooter application.

Backlight

Diffuse area lighting

Good for silhouette and

contour illumination

Available in red

Spot Light

Specific features can

be highlighted and

illuminated for better

feature detection

Available in red or white

Ring Light

Good for low shadow,

on-axis, even

illumination

Available in red or

white

Bar Lights

Can provide good

illumination from multiple

angles by combining

several together

Available in red, white,

and infrared

Dark Field Light

Highlight edges or

sharp features

Light must be

located close to the

object

Available in red

Light field 25x25 mm Light field 50x50 mm Light field 150x100 mm Light field 100x100 mm

17

www.balluff.com/sharpshooter

BAE LX-VS BAE LX-VS BAE LX-VS BAE LX-VS BAE LX-VS BAE LX-VS

Dark field light Spot Spot Ring light Ring light Ring light

BAE00AM BAE002R BAE002T BAE000J BAE000K BAE00AN

BAE LX-VS-DR090 BAE LX-VS-SR030-S75 BAE LX-VS-SW030-S75 BAE-LX-VS-RR100 BAE-LX-VS-RI100 BAE LX-VS-RW100

24 V DC 24 V DC 24 V DC 24 V DC 24 V DC 24 V DC

< 225 mA < 100 mA < 100 mA < 800 mA

< 1300 mA

(in max. operation)

< 800 mA

< 1300 mA

(in max. operation)

700 mA

1200 mA

none 5...24 V DC 5...24 V DC 5...24 V DC 5...24 V DC 5...24 V DC

90 mm 30 mm 30 mm 100/60 mm 100/60 mm 100/60 mm

LED, red light LED, red light LED, white light LED, red light LED, infrared LED, white light

617 nm 630 nm 617 nm 875 nm

1551309.5 mm 4089 mm 4089 mm 11620.5 mm 11620.5 mm 11620.5 mm

M4 screws M3 screws M3 screws M4 screws M4 screws M4 screws

M12 connector, 4-pin M8 connector, 4-pin M8 connector, 4-pin M12 connector, 4-pin M12 connector, 4-pin M12 connector, 4-pin

Anodized aluminum Anodized aluminum Anodized aluminum Anodized aluminum Anodized aluminum Anodized aluminum

PMMA PMMA PMMA Glass Glass Glass

250 g 160 g 160 g 360 g 360 g 360 g

IP 40 IP 65 IP 65 IP 54 IP 54 IP 54

yes yes yes yes yes yes

yes yes yes yes yes yes

10...+55C 10...+40C 10...+40C 10...+55C 10...+55C 10...+55 C

25...+75C 25...+70 C 25...+70 C 25...+75 C 25...+75 C 25...+75 C

6

.

4

M8x1

40

3

.

2

8

9

2

30

8

.

5

Reflective Card (BOS R-35)

Balluffs BOS R-35 is a low cost, thin profile,

adhesive backing reflector that can be used as

an alternative to a backlight where applicable.

Ordering code: BAM00W9

Diffuser (BAM OF-VS-001-D-RX100)

Ensure even light without disturbing reflections

in applications with reflective surfaces. The

diffuser is made of high-quality glass and

can be installed directly on the Ring light.

Ordering code: BAM01A7

Diffuser

attachment

18

Series BAE LX-VS BAE LX-VS

Style Bar light Bar light

Ordering code BAE00AP BAE00AZ

Part number BAE LX-VS-LR085 BAE LX-VS-LR170

Supply voltage U

B

24 V DC 24 V DC

Operating current Normal 200 mA 400 mA

Boost 500 mA 800 mA

Trigger 5...24 V DC 5...24 V DC

Mode Normal

Boost

Light field size 1079 mm 10170 mm

Emitter, light type LED, red light LED, red light

Wavelength 617 nm 617 nm

Dimension 113.51318 mm 197.51318 mm

Attachment M4 screws M4 screws

Connection M12 connector, 4-pin M12 connector, 4-pin

Housing material Anodized aluminum Anodized aluminum

Optical surface Glass Glass

Weight 80 g 110 g

Degree of protection per IEC 60529 IP 54 IP 54

Polarity reversal protected Yes Yes

Short-circuit protected Yes Yes

Ambient temperature range T

a

10...+55 C 10...+55 C

Storage temperature range 25...+75 C 25...+75 C

Light field 85 mm Light field 170 mm

Shar pshoot er

Ser i es

Lighting options

19

www.balluff.com/sharpshooter

BAE LX-VS BAE LX-VS BAE LX-VS BAE LX-VS

Bar light Bar light Bar light Bar light

BAE00AT BAE00AY BAE00AR BAE00AW

BAE LX-VS-LI085 BAE LX-VS-LI170 BAE LX-VS-LW085 BAE LX-VS-LW170

24 V DC 24 V DC 24 V DC 24 V DC

200 mA 400 mA 200 mA 400 mA

400 mA 800 mA 500 mA 900 mA

5...24 V DC 5...24 V DC 5...24 V DC 5...24 V DC

1071 mm 10170 mm 1083 mm 10170 mm

LED, infrared LED, infrared LED, white light LED, white light

875 nm 875 nm

113.51318 mm 197.51318 mm 113.51318 mm 197.51318 mm

M4 screws M4 screws M4 screws M4 screws

M12 connector, 4-pin M12 connector, 4-pin M12 connector, 4-pin M12 connector, 4-pin

Anodized aluminum Anodized aluminum Anodized aluminum Anodized aluminum

Glass Glass Glass Glass

80 g 110 g 80 g 110 g

IP 54 IP 54 IP 54 IP 54

Yes Yes Yes Yes

Yes Yes Yes Yes

10...+55 C 10...+55 C 10...+55 C 10...+55 C

25...+75 C 25...+75 C 25...+75 C 25...+75 C

2.3

both sides 63

lowered (2)

Light field 85 mm Light field 170 mm Light field 85 mm Light field 170 mm

20

Use Connection cables for

Vision Sensors BVS-E and BVS-C

Parameterization cable for

Vision Sensors BVS-E

Style Straight female Straight female/RJ45

Connector diagram

and wiring

PIN 1: white PIN 5: brown

PIN 2: green PIN 6: pink

PIN 3: yellow PIN 7: blue

PIN 4: gray PIN 8: red

Power supply max. U

B

10...30 V DC 10...30 V DC

Cable Molded Molded

No. of wires cross-section 80.25 mm 40.34 mm

Degree of protection per IEC 60529 IP 68 IP 65

Ambient

temperature

range T

a

PUR 25...+70 C

PUR shielded 25...+80 C

PVC

Cable material Color Length Ordering code

Part number

PUR Black 2 m

PUR Black 5 m BCC02H1

BKS-AD-05-RJ45/GS180-05

PUR Black 10 m BCC02H2

BKS-AD-05-RJ45/GS180-10

PUR shielded Black 5 m BCC0995

BCC M418-0000-1A-046-PS0825-050

PUR shielded Black 10 m BCC0996

BCC M418-0000-1A-046-PS0825-100

PVC Gray 2 m

PVC Gray 5 m

PVC Gray 10 m

Accessor i es

Connectors for quick integration

II

Shield to knurl

Shield

to knurl

Shield

to

housing

Other cable materials, colors

and lengths on request.

21

www.balluff.com/sharpshooter

Connection cable for

configurator BVS-C

Connection cable for ring, background,

dark field and line lights

Connection cable for spotlights

Straight female/straight female Straight female Straight female

PIN 1: brown

PIN 2: white

PIN 3: blue

PIN 4: black

PIN 1: brown

PIN 2: white

PIN 3: blue

PIN 4: black

10...30 V DC 250 V DC 30 V DC

Molded Molded Molded

80.25 mm 40.34mm 40.34mm

IP 68 per BWN Pr. 20 IP 68 IP 67

20...+80 C 25...+80 C 25...+80 C

5...+80 C 5...+80 C

Ordering code

Part number

BCC06ER BCC032F BCC02N2

BCC M418-M418-5A-322-PS0825-020 BCC M415-0000-1A-003-PX0434-020 BCC M314-0000-10-003-PX0434-020

BCC06EP BCC032H BCC02N3

BCC M418-M418-5A-322-PS0825-050 BCC M415-0000-1A-003-PX0434-050 BCC M314-0000-10-003-PX0434-050

BCC032J BCC02N4

BCC M415-0000-1A-003-PX0434-100 BCC M314-0000-10-003-PX0434-100

BCC0367 BCC02PL

BCC M415-0000-1A-003-VX8434-020 BCC M314-0000-10-003-VX8434-020

BCC0368 BCC02PM

BCC M415-0000-1A-003-VX8434-050 BCC M314-0000-10-003-VX8434-050

BCC0369 BCC02PN

BCC M415-0000-1A-003-VX8434-100 BCC M314-0000-10-003-VX8434-100

Accessor i es

Connectors for quick integration

32.2

II

Shield to knurl

22

Accessor i es

Mechanical accessories for easy installation

Description Mounting bracket Mounting bracket

Style for Vision Sensor BVS and ring light BAE for strip and background light BAE

Use for mounting on base plates or use of clamping

cylinders and mounting system BMS

for mounting on base plates or use of clamping

cylinders and mounting system BMS

Ordering code BAM01AC BAM01AE

Part number BAM MB-XA-003-B03-1 BAM MB-XA-002-B02-1

Material Anodized aluminum Anodized aluminum

33.1

50

102

4.2

3

0

1

0

80

11

6

.6

13.99

52

7

5

25 25

40

2

5 5

0

61.75

8

.

7

4

.2

2

1

.

2

8.55

61.75

30

A B

A

B

3

0

3

5

55

4

3

60

30

3

40

4

0

.6

5

0

40

1

8

.

5

1

7

.

2

6.6

30

Mounting rods 12 mm, anodized aluminum

1 45 1 45

150

1

1

.

9

5

The mounting rods are knurled

full-length. This prevents any

position change.

Ordering code Part number Size

BAM002R BMS RS-M-D12-0150-00 150 mm

BAM002T BMS RS-M-D12-0250-00 250 mm

BAM002V BMS RS-M-D12-1000-00 1000 mm

(for user assembly)

Special Accessories

Ordering code Part number

FHW0025 LD-AJ

FHW00IA 2A-2D

FHW003P SCSSR-2D

SCSSR-2D

2A-2D

LD-AJ

23

www.balluff.com/sharpshooter

Accessor i es

Mechanical accessories for easy installation

Mounting bracket Lock Display housing

for Vision Sensor BVS for Vision Sensor BVS focus ring for configurator with display BAE PD-VS-001-C

for mounting on base plates or use of clamping

cylinders and mounting system BMS

for locking the preset focus for mounting of clamping cylinders and

mounting system BMS

BAM00WN BAM01JH BAM01A8

BVS Z-MB-01 BAM FK-VS-002-02-1 BAM PC-AE-002-1

GD-Zn Anodized aluminum Anodized aluminum

38

3

2

.

5

2

5

4

.2

7.5

7

.

5

1.35

3.75

3

.

7

5

8

3

.

7

5

3

1

0

6

106

4

5

TS 35/7.5

EN 50022

45

For clamping cylinder

BMS CS-M-D12-IZ

Description Cross-connector Base holder Base holder Clamping cylinder

Style For 2 rods 12 mm For 1 rod 12 mm (vertical or horizontal) For clamping cylinders

Use Connecting element for

2 rods

For mounting on base

plates or extrusions

For mounting on base

plates or extrusions

For retaining holders,

sensors and reflectors

Ordering code BAM002Z BAM002W BAM0044 BAM0031

Part number BMS CC-M-D12-B-00 BMS CU-M-D12-A040-00 BMS CU-M-D12-IO60-01 BMS CS-M-D12-IZ

Material Anodized aluminum Anodized aluminum Stainless steel GD-Zn

33.5

3

1

0

20 0.2

8

.

4

3

0

50.7

61.3

M5 nut

O

c

:

.

\

c

.

8

8

1

0

/

G

/

|

a

|

.

\

c

.

2

1

2

8

b

b

E

E

d

|

|

|

c

|

2

0

1

0

-

1

1

P

|

c

d

u

:

|

s

p

e

c

i

c

a

t

i

o

n

s

,

a

v

a

i

l

a

b

i

l

i

t

y

,

a

n

d

p

r

i

c

i

n

g

a

r

e

s

u

b

j

e

c

t

t

o

c

h

a

n

g

e

w

i

t

h

o

u

t

n

o

t

i

c

e

.

USA

Balluff Inc.

8125 Holton Drive

Florence, KY 41042

Phone: (859) 727-2200

Toll-free: 1-800-543-8390

Fax: (859) 727-4823

E-Mail: balluff@balluff.com

Canada

Balluff Canada, Inc.

2840 Argentia Road, Unit #2

Mississauga, Ontario L5N 8G4

Phone: (905) 816-1494

Toll-free: 1-800-927-9654

Fax: (905) 816-1411

E-Mail: balluff.canada@balluff.ca

Mexico

Balluff de Mexico S.A. de C.V

Prol. Av. Luis M. Vega #109

Col. Ampliacion Cimatario

Queretaro, QRO 76030

Phone: (++52 442) 212-4882, 224-3583, 224-3171

Fax: (++52 442) 214-0536

E-Mail: balluff.mexico@balluff.com

www.bal l uf f .com/ shar pshoot er

Shar pshoot er

Ser i es

Connectivity and Accessories

Photoelectric Sensors

Various sensing ranges

Diffuse, retro-reflective, thru-beam

and background suppression modes

Detects targets regardless of material

composition

www.balluff.com/photoelectric

Proximity Sensors

Up to 50 mm of range

Suitable for metallic targets

Immune to hostile environments

www.balluff.com/inductive

Network Connectivity

EtherNet/IP, DeviceNet, PROFIBUS,

PROFINET, CC-Link

Input and Output Capable Modules

Full line of network cables,

accessories and auxilliary power

cordsets

Standard Connectivity

Standard M8 and M12 cordsets,

3-wire & 4-wire, PVC, PUR & TPE

Standard DIN connectors

Multiple interface blocks

www.balluff.com/connectivity

RFID Tags and Readers

Allows users to store data at

inspection points

Variety of tag sizes to choose from

Reliable technology with up to 50 mm

read/write distance

www.balluff.com/rfid

Self-contained Error Proofing System

Balluff also provides a read-only version of our Industrial RFID

BIS L series that can read a pre-programmed tag with a

corresponding BVS Sharpshooter

job number and automatically

switch the BVS to that job number providing a reliable and self-

contained error proofing station.

Provide flexible and reliable

dynamic job changing without

an external controller

Maximize error proofing

in flexible palletized

product manufacturing

Contact Balluff today for more information.

Visit the Sharpshooter

website to:

- download software

- find data sheets

- see product applications

- watch videos

Вам также может понравиться

- Steel Coil AlignmentДокумент1 страницаSteel Coil AlignmentBalluff SensorsОценок пока нет

- Welding Select BrochureДокумент32 страницыWelding Select BrochureBalluff SensorsОценок пока нет

- Distributed Modular I/O Quick Start Guide For 4 Port IO-Link MasterДокумент8 страницDistributed Modular I/O Quick Start Guide For 4 Port IO-Link MasterBalluff SensorsОценок пока нет

- Automotive - Vacuum Pressure Detection On GrippersДокумент1 страницаAutomotive - Vacuum Pressure Detection On GrippersBalluff SensorsОценок пока нет

- Balluff Product News Catalog - Winter 2012Документ212 страницBalluff Product News Catalog - Winter 2012Balluff SensorsОценок пока нет

- Linear 130005 Micro Pulse CatalogДокумент132 страницыLinear 130005 Micro Pulse CatalogBalluff SensorsОценок пока нет

- Balluff 315634 Object Detection CatalogДокумент612 страницBalluff 315634 Object Detection CatalogBalluff SensorsОценок пока нет

- Object Detection 171129 Ultra Frame Sensors BrochureДокумент10 страницObject Detection 171129 Ultra Frame Sensors BrochureBalluff Sensors100% (1)

- Linear 180269 Micro Pulse Pro Compact BrochureДокумент6 страницLinear 180269 Micro Pulse Pro Compact BrochureBalluff SensorsОценок пока нет

- Linear 210292 Micro Pulse PF BrochureДокумент6 страницLinear 210292 Micro Pulse PF BrochureBalluff SensorsОценок пока нет

- Networking - 187722 - Passive Connectivity Overview BrochureДокумент6 страницNetworking - 187722 - Passive Connectivity Overview BrochureBalluff SensorsОценок пока нет

- Networking CatalogДокумент268 страницNetworking CatalogBalluff SensorsОценок пока нет

- ObjectDetection - 164999 - Robot Zone Limit Systems BrochureДокумент8 страницObjectDetection - 164999 - Robot Zone Limit Systems BrochureBalluff SensorsОценок пока нет

- Object Detection 180659 Capacitive Sensors CatalogДокумент116 страницObject Detection 180659 Capacitive Sensors CatalogBalluff Sensors100% (1)

- ObjectDetection - 183351 - Ultrasonic Sensors BrochureДокумент16 страницObjectDetection - 183351 - Ultrasonic Sensors BrochureBalluff SensorsОценок пока нет

- Object Detection 184258 BNS CatalogДокумент180 страницObject Detection 184258 BNS CatalogBalluff SensorsОценок пока нет

- Object Detection 219166 Global Line BrochureДокумент36 страницObject Detection 219166 Global Line BrochureBalluff SensorsОценок пока нет

- Rfid 184259 Rfid CatalogДокумент228 страницRfid 184259 Rfid CatalogBalluff SensorsОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Lab 11 12 ECA HIGH AND LOW PASSДокумент32 страницыLab 11 12 ECA HIGH AND LOW PASSAmna EjazОценок пока нет

- MF 3854 WDДокумент96 страницMF 3854 WDRizwanAli100% (1)

- Ibm 3592 Tape Cartridge CatalogueДокумент4 страницыIbm 3592 Tape Cartridge CatalogueamsfibОценок пока нет

- Literature Study Nift ChennaiДокумент5 страницLiterature Study Nift ChennaiAnkur SrivastavaОценок пока нет

- Edge Wall Final-ModelДокумент1 страницаEdge Wall Final-ModelAbanoub ShakerОценок пока нет

- BextexДокумент14 страницBextexBishawnath RoyОценок пока нет

- Articles On Organic Agriculture Act of 2010Документ6 страницArticles On Organic Agriculture Act of 2010APRIL ROSE YOSORESОценок пока нет

- Z PurlinДокумент2 страницыZ PurlinAddrien DanielОценок пока нет

- Lancaster LinksДокумент3 страницыLancaster LinksTiago FerreiraОценок пока нет

- Unit of Work Football Y9Документ5 страницUnit of Work Football Y9api-282209830Оценок пока нет

- How To Effectively Implement DCIM and Bridge The Gap Between IT and FacilitiesДокумент11 страницHow To Effectively Implement DCIM and Bridge The Gap Between IT and FacilitiesAbednego TariganОценок пока нет

- BBRAUNДокумент9 страницBBRAUNLuis RosasОценок пока нет

- Procedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0Документ13 страницProcedimiento de Test & Pruebas Hidrostaticas M40339-Ppu-R10 HCL / Dosing Pumps Rev.0José Angel TorrealbaОценок пока нет

- Generator ProtectionДокумент11 страницGenerator Protectionyogeshsahu100% (2)

- Diagram of Vitamix Blade Blade Assembly: InstructionsДокумент5 страницDiagram of Vitamix Blade Blade Assembly: InstructionsRenato PurcinoОценок пока нет

- Procedure Checklist For Fm200 InstallationДокумент2 страницыProcedure Checklist For Fm200 InstallationJibril Lamai0% (1)

- The Organization & Structure of Banks & Their IndustryДокумент19 страницThe Organization & Structure of Banks & Their Industryrachim04Оценок пока нет

- Premier MДокумент44 страницыPremier Mthebetterman0511Оценок пока нет

- Desktop 10 QA Exam Prep Guide PDFДокумент16 страницDesktop 10 QA Exam Prep Guide PDFShiva RungtaОценок пока нет

- Statistics - Frequency Table and GraphДокумент9 страницStatistics - Frequency Table and GraphTopheng D. SamaritaОценок пока нет

- Second Invitation OriginalДокумент4 страницыSecond Invitation Originalsudhakar80Оценок пока нет

- High Impact Presentation SkillsДокумент5 страницHigh Impact Presentation SkillsMohd AqminОценок пока нет

- Mohiuddin Ahmad and Rafiqul Tarefder Department of Civil Engineering, University of New MexicoДокумент1 страницаMohiuddin Ahmad and Rafiqul Tarefder Department of Civil Engineering, University of New MexicoMohiuddin AhmadОценок пока нет

- Suzuki G13ba EnginДокумент4 страницыSuzuki G13ba EnginYoga A. Wicaksono0% (1)

- Teaching and Learning With Technology: An IntroductionДокумент4 страницыTeaching and Learning With Technology: An IntroductionAphril Joy LlorenteОценок пока нет

- Subject Orientation: Empowerment TechnologiesДокумент10 страницSubject Orientation: Empowerment TechnologiesJessa GuerraОценок пока нет

- Contact List For All NWGДокумент22 страницыContact List For All NWGKarthickОценок пока нет

- III Sem Jan 2010 Examination Results SwatisДокумент21 страницаIII Sem Jan 2010 Examination Results SwatisAvinash HegdeОценок пока нет

- Template Extended-AbstractДокумент3 страницыTemplate Extended-AbstractGraita PurwitasariОценок пока нет

- BK3251 BekenДокумент13 страницBK3251 BekenDanny DurhamОценок пока нет