Академический Документы

Профессиональный Документы

Культура Документы

Bellows Axial Stroke Dim

Загружено:

anandh1985Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bellows Axial Stroke Dim

Загружено:

anandh1985Авторское право:

Доступные форматы

Welded Bellows

Material 316L

For higher operating temperatures | up to 500.000 load alternation | not magnetic | extremely corrosion-resistant

[%]

Si

Mn

0.03

1.0

2.0

0.045

0.03

Rp 0.2

Rm

E-Module

Density

Temp.

Permeab.

[N/mm2]

[N/mm2]

[N/mm2]

[kg/dm3]

[C]

[r]

300

600

200 000

8.0

Bending angle

Bending radius

lf

0,53

0,50

0,65

0,55

0,80

1,35

0,90

1,20

1,15

0,90

1,60

1,85

2,30

1,10

1,05

0,70

1,25

1,80

1,80

0,90

1,80

2,50

1,00

2,00

2,30

1,45

3,30

2,40

0,85

3,60

2,70

Spring constant

(axial direction)

lc

0,27

0,27

0,27

0,20

0,35

0,36

0,32

0,45

0,43

0,37

0,40

0,50

0,55

0,43

0,35

0,33

0,44

0,45

0,50

0,33

0,50

0,75

0,40

0,50

0,50

0,50

0,70

0,50

0,33

0,75

0,55

1.003

1.005

Effective area

50

OD

12,7

13

16

16,2

20

31,5

26

31,5

35

31,5

37

41

49

39

34,9

35

41

46

51

48

56

72

51

59

71

62,5

88

76

62

95

88

Ni

Profiel width

40

ID

4,8

6

8

8,6

9

9

13

16

16

18,5

19

21

21

21

21,1

24

26

26

31

35

36

36

38

39

46

46

46

51

52

52

60

Mo

Wall thickness

of membarnes

25

Free

bellows length

16

Compressed

bellows length

10

Outside

diameter

DN

Inside

diameter

Types

-250/+350

Cr

16.018.0 2.03.0 10.014.0

Welding lip grp.

Characteristics

Fe

Res.Bal.

z Gr.

0,36

1

0,32

1

0,48

1

0,55

1

0,60

1

1,18

3

0,80

3

1,15

3

1,35

3

0,85

3

1,55

3

1,90

3

2,10

3

1,40

3

1,10

3

0,70

3

1,40

3

1,90

3

1,90

4

0,80

1

2,00

4

3,43

4

1,00

2

2,00

4

2,40

4

1,50

3

3,00

4

2,60

4

0,60

1

3,40

4

2,80

5

t

0,08

0,08

0,08

0,05

0,08

0,10

0,08

0,13

0,13

0,10

0,13

0,13

0,15

0,13

0,10

0,10

0,13

0,13

0,13

0,10

0,13

0,20

0,10

0,13

0,13

0,13

0,20

0,15

0,10

0,20

0,15

b

4,00

3,50

4,00

3,80

5,50

11,00

6,50

7,75

9,50

6,50

9,00

10,00

14,00

9,00

6,90

5,50

7,50

10,00

10,00

6,50

10,00

18,00

6,50

10,00

12,50

8,30

21,00

12,50

5,00

21,50

14,00

EA

0,70

0,80

1,30

1,30

1,90

4,30

3,40

5,00

5,90

5,30

6,90

8,40

11,30

7,80

6,60

7,20

9,40

11,10

14,20

14,00

17,60

25,80

16,10

19,90

28,50

24,00

39,20

33,30

26,10

46,70

45,10

SRCz

80,00

105,00

60,00

25,00

55,00

55,00

55,00

95,00

49,00

95,00

70,00

75,00

65,00

49,00

75,00

82,00

135,00

75,00

65,00

90,00

65,00

90,00

110,00

65,00

60,00

130,00

96,00

85,00

120,00

75,00

80,00

phi

1,62

1,41

1,72

1,95

1,72

2,15

1,76

2,09

2,21

1,55

2,40

2,66

2,46

2,06

1,81

1,15

1,96

2,37

2,13

0,95

2,05

2,73

1,12

1,94

1,94

1,38

1,95

1,96

0,55

2,05

1,82

R

15,90

17,50

17,00

14,00

21,70

25,30

23,40

28,10

28,70

29,50

28,10

31,30

37,30

31,50

28,60

34,00

33,40

33,90

38,90

43,80

42,00

51,70

45,90

44,30

50,30

52,10

64,50

52,60

65,10

68,50

61,30

Status

Metal

Axial stroke

Analysis

new

new

new

rev.

rev.

rev.

new

rev.

For sizes above ID 65 see separate sheet.

Sizes, technical data, materials

All stated values are referring to following operating conditions:

Differential pressure

Pi = 0, Pa = 1bar

Operating temperature OT = room temperature

Baking temperature

HT = 80C

Number of cycles

Nz = 10.000 cycles

For other operating conditions please use our "Checklist for bellows inquiries".

Our design department will calculate your bellows design.

Do you have an application with other sizes?

Please contact us. We are manufacturing other sizes on demand.

COMVAT AG (Switzerland)

Issue 0407. Technical specifications are subject to change.

www.comvat.com

Welded Bellows

Material 316L

For higher operating temperatures | up to 500.000 load alternation | not magnetic | extremely corrosion-resistant

Si

Mn

0.03

1.0

2.0

0.045

0.03

Rp 0.2

Rm

E-Module

Density

Temp.

Permeab.

[N/mm2]

[N/mm2]

[N/mm2]

[kg/dm3]

[C]

[r]

300

600

200 000

8.0

400

z Gr.

2,80

4

2,65

4

2,90

4

3,60

5

2,50

5

3,80

5

2,80

5

1,40

5

4,20

5

4,60

6

3,10

5

4,60

5

3,00

5

3,10

5

3,20

5

3,40

5

3,30

5

2,50

5

3,20

5

3,10

5

3,40

5

3,50

5

3,50

5

3,20

5

3,50

5

3,60

5

6,00

6

4,50

6

t

0,15

0,15

0,15

0,20

0,15

0,20

0,15

0,15

0,20

0,25

0,15

0,25

0,20

0,15

0,20

0,20

0,20

0,25

0,15

0,15

0,20

0,20

0,20

0,20

0,20

0,20

0,30

0,40

b

EA SRCz

12,50

49,00 95,00

12,00

54,70 95,00

12,50

62,20 95,00

21,25

81,20 85,00

14,00

71,90 80,00

22,00

88,90 80,00

15,00

89,50 70,00

10,00

80,40 145,00

22,25 105,10 80,00

29,00 122,00 95,00

15,00 110,70 75,00

23,75 131,40 135,00

25,00 150,00 40,00

15,00 136,30 75,00

15,00 162,30 100,00

17,50 225,70 140,00

15,00 234,50 200,00

25,00 277,40 200,00

15,00 283,10 100,00

14,50 302,80 95,00

17,50 312,90 148,00

17,50 379,00 160,00

17,50 490,00 160,00

17,50 572,00 200,00

25,00 745,40 150,00

20,00 818,20 200,00

40,00 1.286,20 150,00

40,00 1.553,60 350,00

phi

1,78

1,62

1,66

1,72

1,33

1,74

1,34

0,73

1,78

1,77

1,35

1,76

1,07

1,22

1,17

1,05

1,02

0,68

0,90

0,85

0,91

0,85

0,76

0,64

0,61

0,61

0,78

0,54

Status

lf

2,40

2,35

2,40

3,50

2,25

3,70

2,80

1,45

4,20

4,75

2,60

4,40

4,25

2,50

2,60

2,60

2,60

4,20

2,50

2,15

2,80

3,00

2,80

3,20

3,30

3,20

7,50

5,00

Ni

1.003

1.005

Profiel width

lc

0,50

0,55

0,60

0,75

0,55

0,75

0,60

0,50

0,70

0,85

0,60

0,90

0,80

0,55

0,70

0,75

0,75

2,00

0,65

0,65

0,75

0,75

0,70

0,80

0,90

0,80

2,00

1,45

Mo

Bending angle

320

OD

90

94

100

120

108

125

120

110

135

149

132

150

160

145

157

185

186

210

203

209

215

235

265

285

330

340

440

480

Cr

16.018.0 2.03.0 10.014.0

Spring constant

(axial direction)

250

ID

65

70

75

77,5

80

82

90

90

90,5

92

102

102,5

110

115

127

150

156

160

173

180

180

200

230

250

280

300

360

400

Wall thickness

of membarnes

200

Free

bellows length

160

Compressed

bellows length

100

Outside

diameter

DN

63

Inside

diameter

Types

-250/+350

Welding lip grp.

Characteristics

Fe

Res.Bal.

Bending radius

[%]

Effective area

Metal

Axial stroke

Analysis

R

61,10

66,50

70,70

85,00

77,80 rev.

87,20 rev.

85,70

94,30

90,00

102,00 new

91,60

104,40

122,70

98,20 new

112,80

133,30

135,30

273,00

142,70

148,30

154,90

167,90

185,50

213,80

249,90

245,60

366,70 new

394,70

For sizes up to ID 60 see separate sheet.

Sizes, technical data, materials

All stated values are referring to following operating conditions:

Differential pressure

Pi = 0, Pa = 1bar

Operating temperature OT = room temperature

Baking temperature

HT = 80C

Number of cycles

Nz = 10.000 cycles

For other operating conditions please use our "Checklist for bellows inquiries".

Our design department will calculate your bellows design.

Do you have an application with other sizes?

Please contact us. We are manufacturing other sizes on demand.

COMVAT AG (Switzerland)

Issue 0407. Technical specifications are subject to change.

www.comvat.com

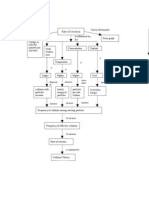

Technical Manual

Bellows movements (axial, lateral, angular) / Abbreviations

If

General

OD

ID

Ic

If

le

z

Compressed length per convolution [mm]

Free length per convolution [mm]

Extended length per convolution [mm]

Axial stroke per convolution [mm]

Lf

Lc

Le

Free bellows length [mm]

Compressed bellows length [mm]

Extended bellows length [mm]

Z

Zc

Ze

Axial stroke of edge welded bellows [mm]

Compression stroke of edge welded bellows [mm]

Extension stroke of edge welded bellows [mm]

SRCz

SRz

Fsrz

Fzp

Rz

Spring constant per convolution in axial direction [N/mm]

Spring rate of edge welded bellows in axial direction [N/mm]

Tensile force of edge welded bellows in axial direction [N]

Compressive force in axial direction [N]

Resulting axial force [N]

Lmin

Lmax

Minimum installed length from flange to flange [mm]

Maxiumum installed length from flange to flange [mm]

Lcy

Ley

Zy

Minimum installed length for a given lateral stroke [mm]

Maximum installed length for a given lateral stroke [mm]

Axial stroke of edge welded bellows for lateral offset [mm]

Yc

Ye

Lateral stroke of edge welded bellows at Lcy [mm]

Lateral stroke of edge welded bellows at Ley [mm]

SRCy

SRy

Fsry

Fyp

Ry

Spring constant per convolution in lateral direction [N/mm]

Spring rate of edge welded bellows in lateral direction [N/mm]

Tensile force of edge welded bellows in lateral direction [N]

Compressive force in lateral direction [N]

Resulting lateral force [N]

Lmin

Lmax

Minimum installed length from flange to flange [mm]

Maxiumum installed length from flange to flange [mm]

RP

R

Rotation point of angular movement

Bending radius [mm]

Bending angle of edge welded bellows []

Lmax

Ze

Lmin

Lf

Zc

Le

Axial stroke

Lc

Yc / Ye

Lmin

Lcy

Ley

Lmax

Zy

Ry

Lateral stroke

Inside diameter [mm]

Outside diameter [mm]

Number of convolutions [pairs of mebranes]

Wall thickness of membranes [mm]

Effektive area [cm2]

Weight of edge welded bellow [g]

EA

Rz (+)

Angular stroke

ID

OD

n

t

EA

G

RP

R

Issue 0706. Technical specifications are subject to change.

COMVAT AG (Switzerland)

www.comvat.com

Вам также может понравиться

- Electrical Steel CoilsДокумент16 страницElectrical Steel CoilsX800XLОценок пока нет

- Calculo Flecha TerminadoДокумент149 страницCalculo Flecha TerminadoSebastián ValenciaОценок пока нет

- MIKI Electromagnetic Toothed ClutchДокумент7 страницMIKI Electromagnetic Toothed Clutchaiyubi2Оценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Product Catalog PDFДокумент38 страницProduct Catalog PDFMbaye DiagneОценок пока нет

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- RJ45 Modular Jack With Magnetic Filter: Section 11Документ20 страницRJ45 Modular Jack With Magnetic Filter: Section 11hendpraz88Оценок пока нет

- Weights and Costing TemplateДокумент18 страницWeights and Costing TemplategirishОценок пока нет

- CWST Part III SlabДокумент825 страницCWST Part III SlabSakthivel ParamasivamОценок пока нет

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- Press Drop-Fire Figthing BalantangДокумент2 страницыPress Drop-Fire Figthing BalantangDian ArdiansyahОценок пока нет

- Datasheet Ar450fДокумент2 страницыDatasheet Ar450fjuanОценок пока нет

- Nippon Pulse: Your Partner in Motion ControlДокумент2 страницыNippon Pulse: Your Partner in Motion ControlElectromateОценок пока нет

- CA 65-250R 60Hz 2014 CurvasДокумент1 страницаCA 65-250R 60Hz 2014 Curvasjafa2098Оценок пока нет

- SW/SP/SH Series: Soul of Special AutomationДокумент20 страницSW/SP/SH Series: Soul of Special AutomationelecompinnОценок пока нет

- Cable ScunДокумент8 страницCable ScunPoppy IrawanОценок пока нет

- Berat BesiДокумент20 страницBerat BesiklarastevieОценок пока нет

- Aerial Bundle Conductor Abc CableДокумент1 страницаAerial Bundle Conductor Abc CableBrianОценок пока нет

- Nippon Steels ShapesДокумент6 страницNippon Steels ShapesP.S.J.SarmaОценок пока нет

- Hot Rolled China SteelДокумент43 страницыHot Rolled China Steeledgarc999Оценок пока нет

- Teague's ShaftДокумент145 страницTeague's ShaftBUDAPESОценок пока нет

- Jis G3101 1995Документ3 страницыJis G3101 1995Kholer BurgmanОценок пока нет

- Din 6799 - Freios CavaleirosДокумент3 страницыDin 6799 - Freios CavaleirostimanelОценок пока нет

- Gage Block TolerancesДокумент6 страницGage Block TolerancesAna Gabriela OjedaОценок пока нет

- Tech - Values SFS PDFДокумент88 страницTech - Values SFS PDFLuis MartinsОценок пока нет

- Materials Data For Design: Title 4. Design and CheckingДокумент124 страницыMaterials Data For Design: Title 4. Design and Checkingkhx2Оценок пока нет

- Alustar (Perfis & Secções)Документ49 страницAlustar (Perfis & Secções)Jeovani DanielОценок пока нет

- Rohm - Spindles and ChucksДокумент12 страницRohm - Spindles and ChucksGatyo GatevОценок пока нет

- Bevel Gears Component GeneratorДокумент5 страницBevel Gears Component Generatordinhtam13Оценок пока нет

- 8.BCW - N (466) - M (1196,356)Документ3 страницы8.BCW - N (466) - M (1196,356)carloОценок пока нет

- Cjenik Borera KAILДокумент15 страницCjenik Borera KAILamojodiОценок пока нет

- X-Enp (Metal Deck Nail)Документ10 страницX-Enp (Metal Deck Nail)jojo_323Оценок пока нет

- Breviar Structura CortДокумент30 страницBreviar Structura CortStefanОценок пока нет

- Fishing Bumper Subtype KXJДокумент2 страницыFishing Bumper Subtype KXJAliОценок пока нет

- Metal Bellows Coupling Series KGEДокумент1 страницаMetal Bellows Coupling Series KGEDani GhОценок пока нет

- Catalogo de Ejes CromsteelДокумент20 страницCatalogo de Ejes CromsteelJhonFerneyBohorquezSaldarriagaОценок пока нет

- Serie 523 - ISO 15552Документ69 страницSerie 523 - ISO 15552NixiusОценок пока нет

- Honeywell Sensing Potentiometers 380 Rv4 485 53c 385 Datasheet 32301266 A enДокумент47 страницHoneywell Sensing Potentiometers 380 Rv4 485 53c 385 Datasheet 32301266 A enJose CaballeroОценок пока нет

- GegegegesДокумент6 страницGegegegesDominic TimotiusОценок пока нет

- Torsion Report PDFДокумент31 страницаTorsion Report PDFSheikh BajunaidОценок пока нет

- Vergleichstabelle Von Verschiedenen Stahlsorten Nach Werkstoff-NummernДокумент6 страницVergleichstabelle Von Verschiedenen Stahlsorten Nach Werkstoff-NummerndarkquinkОценок пока нет

- Datasheet Resistencias SMDДокумент3 страницыDatasheet Resistencias SMDjeisonpantoja0% (1)

- 9 Regular Machining Dimension Tolerance 01Документ1 страница9 Regular Machining Dimension Tolerance 01OllenkОценок пока нет

- 70ksi Grade MIG Solid Wire: Code DataДокумент2 страницы70ksi Grade MIG Solid Wire: Code Datarahman2007Оценок пока нет

- En 50889Документ2 страницыEn 50889pankajnbiОценок пока нет

- DBL NyyДокумент5 страницDBL NyyReyadkeylanyОценок пока нет

- Cu2 Uk Ud Uk CK: CTM yДокумент1 страницаCu2 Uk Ud Uk CK: CTM yManupriya KapleshОценок пока нет

- NPM S160 SpecsheetДокумент2 страницыNPM S160 SpecsheetElectromateОценок пока нет

- Loading Units BS 6700 (1997)Документ1 страницаLoading Units BS 6700 (1997)Mohammed Basheer100% (6)

- Bulletin 140U/Ue: Molded Case Circuit BreakersДокумент64 страницыBulletin 140U/Ue: Molded Case Circuit BreakersVictor De La TorreОценок пока нет

- Project: Cgmppharma Column Stirrup CalculationДокумент4 страницыProject: Cgmppharma Column Stirrup CalculationumarОценок пока нет

- CT27-Jumbo Hollow Sections 03-12-03Документ8 страницCT27-Jumbo Hollow Sections 03-12-03chernl2004Оценок пока нет

- Experiment 6 - Torsion of BarДокумент14 страницExperiment 6 - Torsion of BarWee Chuan YeanОценок пока нет

- ARNOLD - Thread Forming ScrewДокумент4 страницыARNOLD - Thread Forming ScrewgirishawantiОценок пока нет

- New - LWH enДокумент7 страницNew - LWH enRodica PuscauОценок пока нет

- KDC InstallationДокумент2 страницыKDC InstallationJIANG LUОценок пока нет

- RCD Lecture 1Документ26 страницRCD Lecture 1Walter CatapangОценок пока нет

- Dynamometers 161011144109Документ28 страницDynamometers 161011144109Mr.S UpenderОценок пока нет

- Concept MapДокумент1 страницаConcept MapMonis Diana Abu BakarОценок пока нет

- Cantilever Retaining WallДокумент5 страницCantilever Retaining WallAditya Singh ChauhanОценок пока нет

- #Derivation of Mechanical Properties For SandДокумент8 страниц#Derivation of Mechanical Properties For SandkingmajorОценок пока нет

- EPRI TR 1004019 Guide For Develping and Managing An IRT Program PDFДокумент108 страницEPRI TR 1004019 Guide For Develping and Managing An IRT Program PDFLuis GonzalezОценок пока нет

- Model Calculation of Heat Balance of Wood PyrolysiДокумент10 страницModel Calculation of Heat Balance of Wood PyrolysiqwerОценок пока нет

- DuctilityДокумент3 страницыDuctilityCarlo CastorОценок пока нет

- TM - Chapter 1 Exercises PDFДокумент6 страницTM - Chapter 1 Exercises PDFVõ Văn VũОценок пока нет

- Lab Report 1Документ5 страницLab Report 1yosaОценок пока нет

- Novw 266861 - DBДокумент47 страницNovw 266861 - DBathalia athisaОценок пока нет

- Narayana... Iit Jee PaperДокумент26 страницNarayana... Iit Jee PaperAbhishek KumarОценок пока нет

- Anchor Bolt Loading Calculation For 101-B-10 29.02.16Документ6 страницAnchor Bolt Loading Calculation For 101-B-10 29.02.16kkaranagОценок пока нет

- Electromagnetic Plunger With Stopper DynamicsДокумент28 страницElectromagnetic Plunger With Stopper DynamicsCatanescu Alexandru-LaurentiuОценок пока нет

- Soalan Set1Документ13 страницSoalan Set1Aziz BakarОценок пока нет

- Densification and Microstructure of Si3N4-TiN Ceramic CompositesДокумент5 страницDensification and Microstructure of Si3N4-TiN Ceramic CompositesThiago Do Santos FerreiraОценок пока нет

- Structural Applications of Taylor Fluid Viscous Dampers: @seismicisolationДокумент50 страницStructural Applications of Taylor Fluid Viscous Dampers: @seismicisolationsaber javidОценок пока нет

- Blue Moon Approach To Rare Events: Molecular Simulation September 2004Документ9 страницBlue Moon Approach To Rare Events: Molecular Simulation September 2004Della KhoirunnisaОценок пока нет

- Mechanical Vibration: Course InstructorsДокумент26 страницMechanical Vibration: Course Instructorspavan_1988Оценок пока нет

- Taller 1 - Veronica OñateДокумент11 страницTaller 1 - Veronica OñateVeronica OñateОценок пока нет

- Workshop Mass TransferДокумент2 страницыWorkshop Mass TransferYessica Viviana Solano PradoОценок пока нет

- Footing Design CalculationsДокумент5 страницFooting Design CalculationsArnold VercelesОценок пока нет

- 2.3 Section Properties of Built-Up Steel Sections PDFДокумент5 страниц2.3 Section Properties of Built-Up Steel Sections PDFthongchai_007Оценок пока нет

- Solid State Chemistry and It Applications Answer For QuestionДокумент32 страницыSolid State Chemistry and It Applications Answer For QuestionĐặng Vũ Hoàng Đức89% (9)

- Flow Regimes On Sieve Trays For Gas Liquid ContactingДокумент196 страницFlow Regimes On Sieve Trays For Gas Liquid ContactingGrant FirthОценок пока нет

- QDeform 2 HomeДокумент1 страницаQDeform 2 HomeakjeevananthamОценок пока нет

- ITT American Electric Horizontal Luminaire Series 13 & 14 Spec Sheet 2-81Документ8 страницITT American Electric Horizontal Luminaire Series 13 & 14 Spec Sheet 2-81Alan MastersОценок пока нет

- Bluebook (EN1993 1 1, HyperBeam, 17 Dec 2013)Документ138 страницBluebook (EN1993 1 1, HyperBeam, 17 Dec 2013)Peyman MznОценок пока нет

- Steam Stop ValveДокумент15 страницSteam Stop Valveankur raiОценок пока нет

- A Brief History of Time: From the Big Bang to Black HolesОт EverandA Brief History of Time: From the Big Bang to Black HolesРейтинг: 4 из 5 звезд4/5 (2193)

- A Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceОт EverandA Beginner's Guide to Constructing the Universe: The Mathematical Archetypes of Nature, Art, and ScienceРейтинг: 4 из 5 звезд4/5 (51)

- Quantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessОт EverandQuantum Spirituality: Science, Gnostic Mysticism, and Connecting with Source ConsciousnessРейтинг: 4 из 5 звезд4/5 (6)

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseОт EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseРейтинг: 3.5 из 5 звезд3.5/5 (69)

- Strange Angel: The Otherworldly Life of Rocket Scientist John Whiteside ParsonsОт EverandStrange Angel: The Otherworldly Life of Rocket Scientist John Whiteside ParsonsРейтинг: 4 из 5 звезд4/5 (94)

- Summary and Interpretation of Reality TransurfingОт EverandSummary and Interpretation of Reality TransurfingРейтинг: 5 из 5 звезд5/5 (5)

- Packing for Mars: The Curious Science of Life in the VoidОт EverandPacking for Mars: The Curious Science of Life in the VoidРейтинг: 4 из 5 звезд4/5 (1395)

- Bedeviled: A Shadow History of Demons in ScienceОт EverandBedeviled: A Shadow History of Demons in ScienceРейтинг: 5 из 5 звезд5/5 (5)

- Knocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldОт EverandKnocking on Heaven's Door: How Physics and Scientific Thinking Illuminate the Universe and the Modern WorldРейтинг: 3.5 из 5 звезд3.5/5 (64)

- Lost in Math: How Beauty Leads Physics AstrayОт EverandLost in Math: How Beauty Leads Physics AstrayРейтинг: 4.5 из 5 звезд4.5/5 (125)

- The Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectОт EverandThe Simulated Multiverse: An MIT Computer Scientist Explores Parallel Universes, The Simulation Hypothesis, Quantum Computing and the Mandela EffectРейтинг: 4.5 из 5 звезд4.5/5 (20)

- Midnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterОт EverandMidnight in Chernobyl: The Story of the World's Greatest Nuclear DisasterРейтинг: 4.5 из 5 звезд4.5/5 (410)

- Too Big for a Single Mind: How the Greatest Generation of Physicists Uncovered the Quantum WorldОт EverandToo Big for a Single Mind: How the Greatest Generation of Physicists Uncovered the Quantum WorldРейтинг: 4.5 из 5 звезд4.5/5 (8)

- Mastering Logical Fallacies: The Definitive Guide to Flawless Rhetoric and Bulletproof LogicОт EverandMastering Logical Fallacies: The Definitive Guide to Flawless Rhetoric and Bulletproof LogicРейтинг: 4 из 5 звезд4/5 (91)

- Black Holes: The Key to Understanding the UniverseОт EverandBlack Holes: The Key to Understanding the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (13)

- Chernobyl 01:23:40: The Incredible True Story of the World's Worst Nuclear DisasterОт EverandChernobyl 01:23:40: The Incredible True Story of the World's Worst Nuclear DisasterРейтинг: 4 из 5 звезд4/5 (264)

- The Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismОт EverandThe Tao of Physics: An Exploration of the Parallels between Modern Physics and Eastern MysticismРейтинг: 4 из 5 звезд4/5 (500)

- The Beginning of Infinity: Explanations That Transform the WorldОт EverandThe Beginning of Infinity: Explanations That Transform the WorldРейтинг: 5 из 5 звезд5/5 (60)

- Infinite Powers: How Calculus Reveals the Secrets of the UniverseОт EverandInfinite Powers: How Calculus Reveals the Secrets of the UniverseРейтинг: 4.5 из 5 звезд4.5/5 (126)

- Quantum Physics: What Everyone Needs to KnowОт EverandQuantum Physics: What Everyone Needs to KnowРейтинг: 4.5 из 5 звезд4.5/5 (49)

- The Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОт EverandThe Magick of Physics: Uncovering the Fantastical Phenomena in Everyday LifeОценок пока нет

- The Reality Revolution: The Mind-Blowing Movement to Hack Your RealityОт EverandThe Reality Revolution: The Mind-Blowing Movement to Hack Your RealityРейтинг: 4.5 из 5 звезд4.5/5 (19)

- The Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceОт EverandThe Physics of God: How the Deepest Theories of Science Explain Religion and How the Deepest Truths of Religion Explain ScienceРейтинг: 4.5 из 5 звезд4.5/5 (23)