Академический Документы

Профессиональный Документы

Культура Документы

Epigen 4029FC

Загружено:

Anton PrabawaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Epigen 4029FC

Загружено:

Anton PrabawaАвторское право:

Доступные форматы

CHEMPROOF HB COATING FC epigen 4029FC

4029 was designed as the ultimate chemical resistant high build coating. 4029FC has increased resistance to chemicals and higher strength but requires consideration for a very short pot life and fast cure. 4029FC is based on high performance Novalac resin technology with a fast acting cycloaliphatic amine, and maintains solventless character to meet the highest standards of chemical resistance and corrosion protection achievable. Primarily a barrier coating or lining suited to treatment of steel, concrete and brick in applications where acids, alkalis, organic solvents, or a number of chemicals in process give rise to problematic conditions. Novalac functionality and high cross linking density is the key stone of 4029FC technology which also contains a unique fill that offers high resistance to erosion and abrasion without compromising chemical resistance.

TYPICAL APPLICATIONS Acid Bunds Rail Cars Steelwork Coating Solvent Extraction Systems Ducting Systems Sulfur Pits Tanks & Vessels Scrubbers Pipelines & Valves Acid Sumps & Drains Acid Fume Proof Roofing Concrete Repair

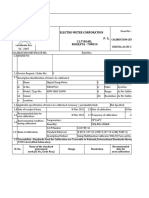

PROFILE

Ratio by weight Pot Life minutes @ 24 C Mixed consistency @ 24 oC Specific gravity when mixed Kg/m for 500 micron Tack free time @ 24 C

o 2 o

4 parts A to 1 part B <20 Viscous Flowable Liquid 1.6 0.8 60 minutes

TYPICAL CURED PROPERTIES

Compressive strength ASTM D695, Mpa Tensile strength ASTM D638, Mpa >115 >26 >50 84 3.0 125

o

FEATURES

Flexural strength ASTM D790, Mpa

Superior Novalac polymer system Highly erosion resistant fill Application DFT up to 1000 micron in the one coat Free of all solvents - zero VOC Outstanding resistance to chemicals & acids Versatility in application - can be used with GF Suitable in patching or repair of mortar Fast Cure allows rapid return to service

Hardness, Shore D Dielectric constant ASTM D150 (150KHz) Maximum exposure temperature, o C Heat deflection temperature ASTM D648, C Thin Film Gel , (min recoat time) Minutes Maximum recoat time, Hours Ultimate cure time to Service , Hours

85 20 24 24

This information is supplied as an indicative reference only. Caution should be used where direct comparisons are to be made.

CHEMPROOF HB COATING FC epigen 4029FC

SURFACE PREPARATION Methods for substrate preparation may include chemical means such as washing & etching, high pressure water blasting, or traditional abrasive blasting techniques . Caution should be maintained in selecting a technique that provides satisfactory anchor for the lining. Specialist advice is available from Peerless Industrial Systems to ensure the correct preparation procedure is employed for specific applications.

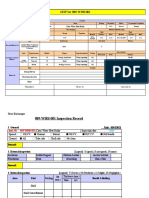

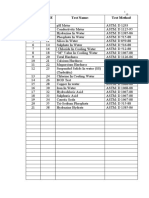

CHEMICAL RESISTANCE Tested at 21oC. Samples cured for 10 days at 25oC. Curing at elevated temperatures will improve chemical resistance. 1 = Continuous or long term immersion 2 = Short term immersion 3 = Splash and spills 4 = Avoid contact

Acetic Acid, 10 % 1 Acetone 1 Acetic Acid, Glacial 2 Ammonium Chloride 1 Hydrochloric Acid, 5 % 1 Beer 1 Hydrochloric Acid, 10 % 1 Dichloromethane 2 Hydrochloric Acid, conc 1 Diesel Fuel 1 Nitric Acid, 5 % 1 Isopropyl Alcohol 1 Nitric Acid, 10 % 2 Kerosene 1 Phosphoric Acid, 10 % 1 Petrol 1 Phosphoric Acid, 35 % 1 Salt Water 1 Sulfuric Acid, 30 % 1 Sewage 1 Sulfuric Acid, 70 % 1 Skydrol 1 Sulfuric Acid, 98 % 1 Sodium Cyanide 1 Ammonium Hydroxide, 5 % 1 Sodium Hypochlorite 1 Ammonium Hydroxide, 20 % 1 Toluene 2 Potassium Hydroxide, 5 % 1 Trichloroethane 1 Potassium Hydroxide, 20 % 1 Wine 1 Sodium Hydroxide, 20 % 1 Xylene 1 Sodium Hydroxide, 50 % 1 This information is supplied as an indicative reference only. Caution should be used where direct comparisons are to be made.

APPLICATION Mixing of product should be carried out using slow speed mixers and completed by adding to the part A, the part B. Ensure the mix is homogeneous and free from lumps. Avoid air entrainment. 4029FC can be applied either by airless spray, brush or roller. Since it does not contain solvents, application by spray allows the application of high film thicknesses in single coats, and ensures that all material purchased actually contributes to the final DFT. 4029FC is a higher viscosity than conventional solvent containing coatings and application may require more specialised practices but is generally compensated for by the speed of application and need to apply fewer coats. Epigen Diluent maybe added to 4029FC to control viscosity under some circumstances. Avoid excessive additions and do not add Diluent in confined spaces or near naked flame. Do not add thinners to extend pot life. In concrete correction applications, blow holes, cracks, or significant damage maybe faired by mixing 1 part 4029FC with 1.5parts 30/50 sand and applying the paste to the damaged areas. This practice should be employed after the first coat application when the extent of degradation becomes apparent and before second coat application. 4029FC is a functional, industrial finish and is not developed to possess asthetic properties such as high gloss which would enable it to be used where appearance is particularly important.

Note : Under acidic conditions, 4029FC has been designed to change colour allowing OH&S steps to be taken in cleaning up spills or as a warning to beware. CURE Variations in cure may arise due to the amount of material being applied, the thickness of material being applied, the surface temperature, and the product temperature. The cure may be increased by heating product or by leaving mixed material stand for 15 minutes before use. The cure may be decreased by cooling the product before mixing.

EPIGEN

PRODUCTS MANUFACTURED BY

Peerless Industrial Systems Pty Ltd

ABN 14 097 615 391 73 Robinson Ave, Belmont, WA 6104 PO Box 407, Cloverdale, WA 6985 Phone: (08) 9477 3788 Fax: (08) 9477 3766 Email: epigen@iinet.net.au www.epigen.com.au

4029FC:2003/Apr

Вам также может понравиться

- Hempadur Primer 15300Документ2 страницыHempadur Primer 15300anto081287Оценок пока нет

- Design of Modern Pharmaceutical Facilities Osd 2379 1764 1000202 PDFДокумент28 страницDesign of Modern Pharmaceutical Facilities Osd 2379 1764 1000202 PDFnoumanОценок пока нет

- Gear Box No Load Run Test ReportДокумент1 страницаGear Box No Load Run Test ReportPRABHUDAYAL SHARMAОценок пока нет

- 400 MM Digital Clamp Meter Make-Kyoritsu Model-KEW SNAP 2009R, SL No-W8039512Документ20 страниц400 MM Digital Clamp Meter Make-Kyoritsu Model-KEW SNAP 2009R, SL No-W8039512Ashutosh MondalОценок пока нет

- SK Fert F50ag-MsdsДокумент6 страницSK Fert F50ag-MsdsEmadОценок пока нет

- Vinyl Ester-Glass Flake PaintДокумент4 страницыVinyl Ester-Glass Flake PaintSimbu ArasanОценок пока нет

- Carta de Colores SigmaДокумент2 страницыCarta de Colores SigmaVictor Chicaíza100% (2)

- Viscotaq Application Manual English April 2011 PDFДокумент40 страницViscotaq Application Manual English April 2011 PDFhenry307Оценок пока нет

- HSS Canusa PDFДокумент2 страницыHSS Canusa PDFresp-ectОценок пока нет

- Paint Products For Systems (Sitra)Документ1 страницаPaint Products For Systems (Sitra)Mahmoud TahaОценок пока нет

- Index: 3-A Sanitary Standards, 3-A Accepted Practices, & P3-A Sanitary StandardsДокумент4 страницыIndex: 3-A Sanitary Standards, 3-A Accepted Practices, & P3-A Sanitary Standardsveeru singhОценок пока нет

- Elastopor H 1221/92: Technical Data SheetДокумент2 страницыElastopor H 1221/92: Technical Data SheetLassad ZitouniОценок пока нет

- Keranol Fu 320Документ2 страницыKeranol Fu 320shankarkl100% (1)

- Fenomastic Hygiene Emulsion SilkДокумент4 страницыFenomastic Hygiene Emulsion Silkمحمد عزتОценок пока нет

- Tds - Polpox Ep Hs 942Документ3 страницыTds - Polpox Ep Hs 942hemantrulzОценок пока нет

- Resin R3X1080 - Material Safety Data Sheet - Part BДокумент5 страницResin R3X1080 - Material Safety Data Sheet - Part BRavie OuditОценок пока нет

- Zinc Plating Reports 01Документ2 страницыZinc Plating Reports 01Amandeep Singh100% (1)

- Schedule - BДокумент17 страницSchedule - B123agattarОценок пока нет

- Iso 7202 2012 en PDFДокумент11 страницIso 7202 2012 en PDFBenouna FertОценок пока нет

- Bayblend MTR HP-1Документ2 страницыBayblend MTR HP-1TECHОценок пока нет

- Polyken Utility Tape 900 910 908 911 920Документ2 страницыPolyken Utility Tape 900 910 908 911 920Tracy EvansОценок пока нет

- Rescobond AA-22S PDSДокумент1 страницаRescobond AA-22S PDSIfrahim AwanОценок пока нет

- 4.2.1 HVA Adhesive Anchor: Anchoring SystemsДокумент15 страниц4.2.1 HVA Adhesive Anchor: Anchoring SystemsechavarriОценок пока нет

- Instion Test Record-PaintingДокумент1 страницаInstion Test Record-PaintingkeronsОценок пока нет

- Hempadur Avantguard 750 1736g - Product DatasheetДокумент2 страницыHempadur Avantguard 750 1736g - Product DatasheetWisnu Wardhana0% (1)

- SDS Nitoflor FC150 SeaДокумент34 страницыSDS Nitoflor FC150 SeaAzmi NordinОценок пока нет

- Sigmaprime 700Документ7 страницSigmaprime 700Trịnh Minh KhoaОценок пока нет

- ISO-14236-2000 Traducido EspañolДокумент11 страницISO-14236-2000 Traducido EspañolPablo A.100% (1)

- Api 5l PDFДокумент2 страницыApi 5l PDFtomj9104Оценок пока нет

- Carbomastic 15 PDSДокумент2 страницыCarbomastic 15 PDSAnonymous 4fVUDODОценок пока нет

- Tivar 88-2: Drop-In Liners Solve Flow ProblemsДокумент1 страницаTivar 88-2: Drop-In Liners Solve Flow Problemsacas35100% (1)

- Foster Adhesive: Technical Data SheetДокумент2 страницыFoster Adhesive: Technical Data SheetMounir BoutaghaneОценок пока нет

- Renderoc TGДокумент2 страницыRenderoc TGMansoor Ali50% (2)

- Blasting & Painting ReportДокумент2 страницыBlasting & Painting ReportSanjay KumarОценок пока нет

- Ari 495-99Документ6 страницAri 495-99DanZel DanОценок пока нет

- Seta Verification Materials: STVM MTVMДокумент2 страницыSeta Verification Materials: STVM MTVMdchyОценок пока нет

- Ti en 001Документ397 страницTi en 001benjapb92Оценок пока нет

- SEIP For 089-WHB-001: Claus Waste Heat BoilerДокумент6 страницSEIP For 089-WHB-001: Claus Waste Heat BoilerThinh NguyenОценок пока нет

- Data Sheet: TechnicalДокумент2 страницыData Sheet: TechnicaljasonОценок пока нет

- Arkema - FDS Fluidiram 780Документ9 страницArkema - FDS Fluidiram 780PeligriОценок пока нет

- Amercoat 68hs - Ingles 2015Документ6 страницAmercoat 68hs - Ingles 2015Peter CallánОценок пока нет

- Codap 2005 Division 1 Accueil SNCTДокумент45 страницCodap 2005 Division 1 Accueil SNCTbecemОценок пока нет

- Scope: Painting ProcedureДокумент2 страницыScope: Painting Procedureคุณพ่อน้อง บิ๊กบอสОценок пока нет

- Apcs 17a 85710Документ2 страницыApcs 17a 85710jojo_323Оценок пока нет

- Corr Shield NT 4292Документ9 страницCorr Shield NT 4292Donatas BertasiusОценок пока нет

- Paint Certificate - Sample PDFДокумент25 страницPaint Certificate - Sample PDFMarhadi Adi100% (1)

- Most Frequently Used PaintsДокумент12 страницMost Frequently Used PaintssmartcharlinОценок пока нет

- POLYPOXY-NF Technical Data SheetДокумент2 страницыPOLYPOXY-NF Technical Data SheetCommando crawlerОценок пока нет

- Standard Specification FOR Pipeline Internal CoatingДокумент2 страницыStandard Specification FOR Pipeline Internal CoatingRanjan KumarОценок пока нет

- Mandolite 550 DSДокумент4 страницыMandolite 550 DSnrd9771Оценок пока нет

- Equipment For Tank InspectionДокумент1 страницаEquipment For Tank InspectionasikurОценок пока нет

- Baracarb® 600Документ9 страницBaracarb® 600Nural MuradliОценок пока нет

- Nitocote PE135 : Constructive SolutionsДокумент2 страницыNitocote PE135 : Constructive SolutionsMPS KALIBARUОценок пока нет

- Dion FR 9300Документ6 страницDion FR 9300Peñaloz GustavoОценок пока нет

- Carbothane 134 HG PDSДокумент2 страницыCarbothane 134 HG PDSfazeel mohammedОценок пока нет

- Nitocote EN901Документ4 страницыNitocote EN901ArieIndrawanОценок пока нет

- F013Документ2 страницыF013Sai PrasathОценок пока нет

- Brochure Coating Raw Materials For Building Protection 14-06-2011 EДокумент32 страницыBrochure Coating Raw Materials For Building Protection 14-06-2011 EΣταύρος ΒουγιουκλίδηςОценок пока нет

- 134 TDS Updated Feb 2016 78-8141-8528-2 Rev AДокумент6 страниц134 TDS Updated Feb 2016 78-8141-8528-2 Rev AUriel GarciaОценок пока нет

- Conplast: Retarding Water Reducing AdmixtureДокумент4 страницыConplast: Retarding Water Reducing AdmixtureBinoy Sankar SarkerОценок пока нет

- D Hudson Ormus Gold Australian PatentДокумент26 страницD Hudson Ormus Gold Australian PatentDOMINO66100% (1)

- CorrosionДокумент171 страницаCorrosionMohamed Yosri100% (8)

- James Grimshaw and Cheng Hua - The Conversion of Isosafrole To Piperonal and Anethole To Anisaldehyde: Electrochemical Active Manganese OxideДокумент3 страницыJames Grimshaw and Cheng Hua - The Conversion of Isosafrole To Piperonal and Anethole To Anisaldehyde: Electrochemical Active Manganese OxideRoundSTICОценок пока нет

- EXP 8 Chloride EstimationДокумент6 страницEXP 8 Chloride EstimationNAVEEN SHANKAR S 20BEE056Оценок пока нет

- STSE AssignmentДокумент3 страницыSTSE AssignmentpaulineОценок пока нет

- UntitledДокумент289 страницUntitledDeepanshu digariОценок пока нет

- Green Preparation Method of Sodium Alginate Based On Choline-Based Deep Eutectic Solvent (Examples)Документ6 страницGreen Preparation Method of Sodium Alginate Based On Choline-Based Deep Eutectic Solvent (Examples)MARÍA JOSÉ DAVID PUERTAОценок пока нет

- Experiment No.6 Exsiccated Sodium PhosphateДокумент2 страницыExperiment No.6 Exsiccated Sodium PhosphateBlazy InhumangОценок пока нет

- A Rapid Spectrophotometric Method For The Determination of Trace Level Silver Using 1, 5-Diphenylthiocarbazone in Aqueous Micellar SolutionsДокумент19 страницA Rapid Spectrophotometric Method For The Determination of Trace Level Silver Using 1, 5-Diphenylthiocarbazone in Aqueous Micellar SolutionsderyhermawanОценок пока нет

- Word Equations HelpДокумент2 страницыWord Equations HelprochelleОценок пока нет

- Rs KJ Fefjr Jax Jksxu) Èkqykbz Fcvqfeul) Dkyk) Vey) (KKJ) Ikuh VKSJ Dyksjhu Fojksèk Osq Fy, Fof'Kf"VДокумент11 страницRs KJ Fefjr Jax Jksxu) Èkqykbz Fcvqfeul) Dkyk) Vey) (KKJ) Ikuh VKSJ Dyksjhu Fojksèk Osq Fy, Fof'Kf"VRoushan KumarОценок пока нет

- Chlor-Alkali Production by Electrochemical ProcessДокумент54 страницыChlor-Alkali Production by Electrochemical Processkivumbi AchileoОценок пока нет

- M Topics Chemistry TP 10.1 - 10.6Документ258 страницM Topics Chemistry TP 10.1 - 10.6hataf bayarОценок пока нет

- Meeegs, Akola.: Mock Test - 3Документ2 страницыMeeegs, Akola.: Mock Test - 3Mayur BelsareОценок пока нет

- Qualitative Analysis PDFДокумент36 страницQualitative Analysis PDFjitin yadavОценок пока нет

- Identification of Functional Groups of Organic Compounds (1049)Документ7 страницIdentification of Functional Groups of Organic Compounds (1049)RA.RAMESHОценок пока нет

- Metals and Non Metals - NotesДокумент13 страницMetals and Non Metals - NotesmittalshivamОценок пока нет

- Servo Material Safety Data SheetsДокумент329 страницServo Material Safety Data SheetsganeshsaligramaОценок пока нет

- A Manual of Agricultural Chemistry (1913)Документ440 страницA Manual of Agricultural Chemistry (1913)Luděk Spurný100% (1)

- Analyzing Contaminated Soil (Project)Документ7 страницAnalyzing Contaminated Soil (Project)Jivitesh SharmaОценок пока нет

- MGC 130117Документ17 страницMGC 130117Maryem SafdarОценок пока нет

- (Chemistry 16) Naming Compounds Packet (6 Worksheets) PDFДокумент11 страниц(Chemistry 16) Naming Compounds Packet (6 Worksheets) PDFRo-Ann Salỏn NosotrosОценок пока нет

- SPMRSM 2019 Paper1 Q PDFДокумент28 страницSPMRSM 2019 Paper1 Q PDFSiti Hajar Abd HamidОценок пока нет

- CaPNaK Chart Intro CurrentДокумент2 страницыCaPNaK Chart Intro CurrentIrina Elena50% (2)

- Astm Methods WATER22Документ40 страницAstm Methods WATER22rizwan chОценок пока нет

- Resin Purolite A-300Документ6 страницResin Purolite A-300Cah Logoe DewweОценок пока нет

- Elements and The Periodic Table: Mendeleev's ProposalДокумент1 страницаElements and The Periodic Table: Mendeleev's Proposal예준오Оценок пока нет

- Solutions To Preparatory Problems: Problem 1. Graphite OxideДокумент25 страницSolutions To Preparatory Problems: Problem 1. Graphite OxideNebojsaZecОценок пока нет

- 12 Eng Chemistry Lab ManualДокумент130 страниц12 Eng Chemistry Lab Manualbugged2Оценок пока нет

- HKDSE Chemistry Bridging Programe 1CДокумент76 страницHKDSE Chemistry Bridging Programe 1Cthe222Оценок пока нет