Академический Документы

Профессиональный Документы

Культура Документы

Meter Tubes 3sec DS

Загружено:

FrankИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Meter Tubes 3sec DS

Загружено:

FrankАвторское право:

Доступные форматы

DAN-3MT-3M-08/01 May, 2002

3 Section and Flow Conditioning Plate Meter Tubes

Instruments You Can Trust

Daniel Meter Tubes are more than just fabricated pipe with an orifice fitting. They are accurate, dependable instruments because of Daniels dedicated approach to quality. Extra steps taken during every phase of meter tube design and production separate Daniel Meter Tubes from all the rest. The Daniel 3 section meter tube is available with any style Senior or Junior orifice fitting, Simplex plate holder or orifice flanges. The assembly contains an inlet spool of the minimum length prescribed by the 14.3 standard. The second section begins with a concentric, flange mounted tube bundle meeting the 2000 API 14.3 requirements and a " thick spacer plate to ease tube removal for inspection. The outer end of section 2 contains the orifice flange or fitting. The third or downstream section follows and contains 2 branch connections and is extra long to allow for the addition of extra branch connections in the field, if desired. The standard meter tube has flanged outer ends (beveled shown). Other end connections are available on request.

Features:

Dowel pin alignment, close tolerance male/female flange or knock out dowel pins insure that the bores of sections two and three are matched without offsets. One " and one " branch connection on the downstream for thermowell or other uses standard. Beveled, flanged or reduced ends as well as any available weld fitting can be furnished on the ends of the tubes. Hydrostatically tested after manufacture. Each orifice fitting is tested for tap hole and orifice plate seal integrity after the meter tube has been pressure tested.

Inspection/Testing: Daniel maintains rigid inspection

procedures during manufacturing of meter tubes. Micrometer and internal surface roughness readings are recorded and supplied with each meter tube. Customer or third party inspectors are welcome to verify these readings. Radiography of welds is another service that is available.

Fabrication: Fabrication of your instrument includes attaching the orifice fitting to the meter tube to make an integral primary measuring element. For welding operations, Daniel uses automatic welding machines and rotating positioners. Highly skilled, "code qualified" welders are employed to turn out highest quality on each job. Special internal jigs and fixtures are used to insure smooth inlet and outlet surfaces without steps or offsets. All welds receive expert grinding by experienced craftsmen.

Material Selection: Daniel uses special cold drawn seamless tubing or honed pipe in the fabrication of meter tubes. The strict requirements for internal roundness and surface finish preclude the use of standard commercial pipe in most cases. Daniel maintains a large inventory of this special pipe to rapidly complete your order.

DAN-3MT-3M-08/01 May, 2002

Pressure Rating 150# 300# 600# 900# 1500# 2500#

3 Section Meter Tube Catalog Numbers 2-12 with Senior Fitting 10 & 12 with Junior Fitting Flange by Flange by Weld by Flange by Flange by Weld by Weld Flange Weld Weld Flange Weld (Flangnek) (Flanged) (Weldnek)* (Flangnek) (Flanged) (Weldnek)* 3M-011 3M-013 3M-015 3M-016 3M-017 3M-018 3M-101 N/A 3M-021 3M-103 N/A 3M-023 3M-105 3M-185 3M-025 High Pressure 3 Section Meter Tubes 3M-106 3M-186 3M-026 3M-107 3M-187 3M-027 3M-108 3M-188 3M-028 3M-201 3M-203 3M-205 3M-206 3M-207 3M-208 N/A N/A 3M-285 3M-286 3M-287 3M-288

2-8 with Simplex 2-12 with Orifice Flanges Pressure Flange by Raised Face Weldneck Rating Weld Weld by Weld (Flangnek) (Weldnek)* 150# 3M-071 N/A N/A 300# 3M-073 3M-30RW N/A 600# 3M-075 3M-60RW 3M-705 High Pressure High Pressure 3M-90RW 900# 3M-076 3M-706 3M-150RW 1500# 3M-077 3M-707 3M-250RW 2500# 3M-078 3M-708 *Two Section Meter Tubes When Using Weldnek Fittings

Senior and Simplex fittings are also available in 10,000 psi rating in some sizes. All units are also available with Ring Type Joint (RTJ) flanges on request. Sizes larger than 12 available on request.

Packing/Shipping: Daniel bolts together all meter tubes, when size permits, before shipment. This saves the user time and field labor costs. Fittings are protected by heavy lumber, and the tube flanges by special-cut protectors. Painting/Coating: The Daniel standard paint is a basic enamel type. Special coatings such as multi-coat offshore systems are available on request.

A SPECIAL NOTE: The use of factory original Daniel parts will assure your Senior, Junior and Simplex Orifice fittings will stay within original specifications and operate properly.

3-Section Meter Tube with Tube Bundle U D

1/2

3/4

Flange model tube bundle vane plus 1/2 thick spacer plate

Senior, Simplex, Junior Orifice Fitting or Orifice Flange

Standard Lengths Size 2* 3 4 6 8 10 12 U Upstream N/A 7-5 9-9 14-8 19-8 24-10 29-8 D Downstream N/A 4-0 4-0 5-0 5-0 6-0 7-0 V (vane location) N/A 13 D 13 D 13 D 13 D 13 D 13 D

Note: Straightening vanes are not available in 2" line size (See Daniel Profiler DAN-1852-2M)

Lengths shown are suitable for any piping configuration and up to .67 beta ratio. Daniel meter tubes can be supplied in many combinations and configurations. Any of the orifice fittings, plate holders or orifice flanges can be included in a meter tube. Each 3 section standard meter tube is equipped with a flange mounted tube bundle straightener* in accordance with April 2000 API 14.3 and a " thick spacer to facilitate tube removal for inspection. Downstreams are longer than minimum required to allow for field installation of additional branch connections if required. *Not available in some sizes/schedules.

To specify a 3 section meter tube, use the designation "3M" followed by the type orifice holding device. Ex. 4" 600# 3 section meter tube with flanged ends using a Senior fitting, flangneck style is specified as 4"-3M-015. The same unit with a weldneck style Simplex is specified as 4"-3M-705. When ordering, specify pipe schedule and end configuration. Larger size and custom meter tube designs are available on request.

The Daniel Flow Conditioning Plate three section meter tube is available with any style Senior or Junior orifice fitting, Simplex plate holder or orifice flanges. The assembly contains an inlet spool of the minimum length determined during testing to the API 14.3 standard. The flange union between the first and second sections contains the ProfilerTM and a " thick spacer plate to facilitate tube removal for inspection. The outer end of section 2 contains the orifice flange or fitting. The third or downstream section fol

lows and contains 2 branch connections. Other or addi tional connections can be supplied in this section on request. These meter tubes are for use in any piping configuration with beta ratios to .67. Downstream sections are extra long to allow for the addition of extra branch connections in the field, if desired. The standard meter tube has beveled outer ends. Flanges or other end connections are available on request.

Flow Conditioning Plate Meter Tube Catalog Numbers 2-12 with Senior Fitting 10 & 12 with Junior Fitting Flange by Flange by Flange by Flange by Weld by Weld by Pressure Weld Flange Weld Flange Weld Weld Rating (Flangnek) (Flanged) (Weldnek)* (Flangnek) (Flanged) (Weldnek)* 150# 3MP-011 3MP-101 N/A 3MP-021 3MP-201 N/A 300# 3MP-013 3MP-103 N/A 3MP-023 3MP-203 N/A 600# 3MP-015 3MP-105 3MP-185 3MP-025 3MP-205 3MP-285 2-8 with Simplex Weld by Flange by Pressure Weld Weld Rating (Flangnek) (Weldnek)* 150# 3MP-071 N/A 300# 3MP-073 N/A 600# 3MP-075 3MP-705 *Two Section Meter Tube When Using Weldnek Fittings 2-12 with Orifice Flanges Raised Face Weld Neck N/A 3MP-30RW 3MP-60RW

Consult Factory for High Pressure Applications

Daniel Flow Conditioning Plate

The Daniel Flow Conditioning Plate has been tested and shown to be in full compliance with the requirements of API 14.3 April 2000. The Flow Conditioning Plate both removes swirl and creates a fully developed flow profile at the orifice. Use of this unit allows shortened upstream straight pipe lengths of 17 diameters. Beta ratio limit is .67 as with the tube bundle. Available in flange mounted model only. Also available in RTJ style on request.

3-Section Meter Tube With Daniel Flow Conditioning Plate U

1/2

3/4

Daniel Flow Conditioning Plate plus 1/2 spacer plate

Senior, Simplex, Junior Orifice Fitting or Orifice Flange

Size 2 3 4 6 8 10 12

U Upstream 3-0 4-5 5-9 8-8 11-7 14-7 17-5

Standard Lengths D Downstream 3-0 4-0 4-0 5-0 5-0 6-0 7-0

"P" Profiler Locations 7.5 D 7.5 D 7.5 D 7.5 D 7.5 D 7.5 D 7.5 D

Lengths shown are suitable for any piping configuration and up to .67 beta ratio. Reference API 14.3, April 2000. Daniel meter tubes can be supplied in many combinations and configurations. Any Senior, Junior, Simplex or orifice flange can be included in a meter tube. Each Flow Conditioning Plate meter tube is equipped with a flange mounted Conditioning Plate and a " thick spacer* to facilitate tube removal for inspection. Upstream lengths shown are minimum, but can be increased any amount to meet installation requirements. Downstreams are longer than minimum to allow for field installation of additional branch connections if required. *Not used with RTJ Style

To specify a 3 section Flow Conditioning Plate meter tube, use the designation "3MP" followed by the type orifice holding device. Example 4" 600# 3 section meter tube with beveled ends using a Senior fitting, flangneck style is specified as 4"-3MP-015. The same unit with a weldneck style Simplex is 4"-3MP-705. When ordering, specify pipe schedule and end configuration. Larger size, higher pressure rating and custom meter tube designs are available on request.

DAN-3MT-3M-08/01 May, 2002

Orifice Fitting Styles

Meter Tube End Modifications

Several common and frequently used end modifications are shown here to illustrate types available. Daniel will custom build risers, flanges, ells, reducers and couplings, expertly fabricated to meet your specifications. When ordering special end tube modfications, please specify full information for both upstream and downstream tube sections.

Flanged 19 Tube Concentric Bundle

Available in either line mounted or flange mounted styles. These units effectively remove swirl that has been introduced by upstream piping components. Individual tubes and bundle diameter are sized to meet the requirements of API 14.3 April 2000. These units allow the use of a 29D upstream meter tube section in any piping configuration with a .67 beta ratio limit.

Flangnek

Weldnek

Daniel Division Headquarters Houston, Texas, USA, T: (713) 467-6000, F: (713) 827-3880 Calgary, Alberta, Canada, T: (403) 279-1879, F: (403) 236-1337 Stirling, Scotland - UK, Mid-East & Africa,T: +44 01786 433400, F: +44 01786 433401 Singapore - Asia Pacific, T: +65-6777-8211, F: +65-6770-8001 USA Toll Free 1-888-FLOW-001 www.daniel.com Daniel is a wholly owned subsidiary of Emerson Electric Co., and a division of Emerson Process Management

The Daniel logo is a registered trademark of Daniel Industries, Inc. The Emerson logo is a registered trademark and service mark of Emerson Electric Co.

2002 Daniel Measurement and Control, Inc., all rights reserved.

Printed in USA ,

DAN-3MT-5M-05/02

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- cHIPSET AND CONTROLLERДокумент9 страницcHIPSET AND CONTROLLERMelody MwhengwereОценок пока нет

- GH13 Heavy Duty Body Installation Manual PDFДокумент132 страницыGH13 Heavy Duty Body Installation Manual PDFPrashant Sharma100% (14)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- TIA Workshop ITBДокумент48 страницTIA Workshop ITBFirman Suhendra100% (1)

- Piping Hydrotest Procedure - Oil - Gas - WorldДокумент3 страницыPiping Hydrotest Procedure - Oil - Gas - WorldFrank100% (6)

- Fire Protection Engineering Summer 2001Документ33 страницыFire Protection Engineering Summer 2001Hany RifaatОценок пока нет

- Model"Dc": Dual Chamber Orifice FittingДокумент13 страницModel"Dc": Dual Chamber Orifice FittingFrankОценок пока нет

- Hospital Management Information SystemДокумент47 страницHospital Management Information SystemNisarg100% (1)

- Ef3602 9Документ2 страницыEf3602 9AwanОценок пока нет

- TG-5 Relay SettingДокумент10 страницTG-5 Relay Settingbasil100% (1)

- PC210-240-7K M Ueam001704 PC210 PC230 PC240-7K 0310 PDFДокумент363 страницыPC210-240-7K M Ueam001704 PC210 PC230 PC240-7K 0310 PDFCarlos Israel Gomez100% (10)

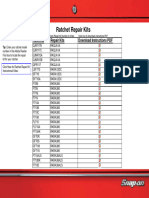

- Repair KitsДокумент14 страницRepair KitsFrankОценок пока нет

- Thermowells: Thermo Sensors CorporationДокумент23 страницыThermowells: Thermo Sensors CorporationFrankОценок пока нет

- D2.9 - Canadian Building Code-1Документ2 страницыD2.9 - Canadian Building Code-1FrankОценок пока нет

- User Manual: Revision 15.0Документ35 страницUser Manual: Revision 15.0FrankОценок пока нет

- CMVR ProcedureДокумент14 страницCMVR ProcedureSoumil GuptabhayaОценок пока нет

- Email Id of Controllers PDFДокумент10 страницEmail Id of Controllers PDFAbhishek KumarОценок пока нет

- System Failure AnalysisДокумент9 страницSystem Failure AnalysisHermance Yosepf Setiarto Harimurti50% (2)

- Fi SlingДокумент4 страницыFi SlingSony TogatoropОценок пока нет

- BX Tuner ManualДокумент4 страницыBX Tuner ManualdanielthemanОценок пока нет

- Status of ECSS E-30 - Space Engineering Handbooks On CDROM: Structural Materials Handbook, Insert Design Handbook and Adhesive Bonding HandbookДокумент1 страницаStatus of ECSS E-30 - Space Engineering Handbooks On CDROM: Structural Materials Handbook, Insert Design Handbook and Adhesive Bonding HandbookNetrom09Оценок пока нет

- Design of BaseplateДокумент9 страницDesign of BaseplatejohnОценок пока нет

- Logic GatesДокумент19 страницLogic GatesblazespiritОценок пока нет

- Government College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusДокумент111 страницGovernment College of Engineering SALEM 636011.: Electronics and Communication Engineering Curriculum and SyllabusSalma Mehajabeen ShajahanОценок пока нет

- ZX60-P105LNДокумент4 страницыZX60-P105LNMuhammad AsadОценок пока нет

- Principles of Accounting, Volume 2: Managerial AccountingДокумент59 страницPrinciples of Accounting, Volume 2: Managerial AccountingVo VeraОценок пока нет

- BC Ii 800Документ38 страницBC Ii 800Pop Ciprian100% (2)

- Chapter 1 Introduction To PSoCДокумент32 страницыChapter 1 Introduction To PSoCtptuyen2246Оценок пока нет

- Ref: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BДокумент125 страницRef: Bboneblk - SRM Beaglebone Black System Reference Manual Rev BhernangycОценок пока нет

- Workstation-Sub Micro Space PlanДокумент21 страницаWorkstation-Sub Micro Space Planarnella_hОценок пока нет

- DPP Series 1 PDFДокумент1 страницаDPP Series 1 PDFsukainaОценок пока нет

- How To Use MySQL With ErlangДокумент2 страницыHow To Use MySQL With ErlangarthurbulivaОценок пока нет

- Plotting in MatlabДокумент7 страницPlotting in Matlabpride3351Оценок пока нет

- Answers of Chapter (8) : Course: Operating SystemДокумент7 страницAnswers of Chapter (8) : Course: Operating SystemasdОценок пока нет

- Terminal - Exam - Section 4A-4B - Signal & System FA14 COMSATДокумент3 страницыTerminal - Exam - Section 4A-4B - Signal & System FA14 COMSATAli RazaОценок пока нет

- Abu Dhabi Certification Scheme For Assistant EngineerДокумент12 страницAbu Dhabi Certification Scheme For Assistant EngineersureshОценок пока нет

- Network Management Card - Installation Manual - EngДокумент30 страницNetwork Management Card - Installation Manual - EngZunaira ShafiОценок пока нет