Академический Документы

Профессиональный Документы

Культура Документы

MSDS Blades 6-12-01

Загружено:

Wisnu Akhmad SИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MSDS Blades 6-12-01

Загружено:

Wisnu Akhmad SАвторское право:

Доступные форматы

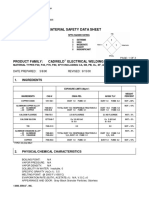

MATERIAL SAFETY DATA SHEET Lenox Saw Blades

SECTION I: GENERAL INFORMATION

Manufacturers Name: Lenox Tools Address: 301 Chestnut Street East Longmeadow, MA 01028-0504 Product Name: Lenox Saw Blades Chemical Name and Synonyms: Carbon Steel Alloy Steel High Speed Steel Carbide Emergency Telephone Number: (413) 525-3961 MSDS Date: December 1, 2010 Chemical Family: Steel; Refractory Metal Carbide Formula: Metal and Carbide Materials, see Section 2 below

SECTION 2: HAZARDOUS INGREDIENTS

Lenox saw blades are manufactured from metals into solid, stable and inert blades, and are coated with a water-based paint(s). Under normal sawing conditions, the saw blades are considered to be articles in that they do not release more than very small quantities of hazardous chemicals and do not cause physical or health hazards as defined in the OSHA Hazard Communication Standard. Hazardous chemicals may be released if the blades are welded, cut, grinded, melted or otherwise physically altered. This MSDS was prepared to address the potential for exposure to dust and/or fume generated from the saw blade. Beyond the scope of this MSDS, the material being cut may contain hazardous chemicals and therefore needs to be evaluated with effective controls instituted to prevent exposure. The actual composition of the saw blades varies depending on the type of saw blade and the grade of steel it is made from each blade may contain any of the following ingredients:

SAW BLADE METAL COMPONENTS1

INGREDIENT

Carbon Chromium Cobalt Iron Manganese Molybdenum Nickel Silicon Tungsten Vanadium

MAX % <2 <5 <9 <90 <2 <10 <2 <2 <7 <3

CAS NUMBER

7440-44-0 7440-47-3 7440-48-4 7439-89-6 7439-96-5 7439-98-7 7440-02-0 7440-21-3 7440-33-7 7440-62-2

OSHA PEL (mg/M3) Not Established 1 (as metal) 0.1 10 (as oxide fume) 5 Ceiling 15 (insoluble) 1 15 Not Established 0.5 Ceiling, respirable

2006 ACGIH TLV (mg/M3) Not Established 0.5 0.02 5 (as oxide dust or fume) 0.2 10 (insoluble) 1.5 (elemental) 10 5-TWA; 10-STEL (metal) 0.05 (as oxide)

The metal alloy may also contain less than one percent of sulfur, phosphorous, aluminum, copper, tin, calcium antimony, niobium, and arsenic. 1Occupational exposure limits are Time Weighted Average (TWA) values unless otherwise noted, and Total Particulate (OSHA) unless otherwise noted.

MATERIAL SAFETY DATA SHEET

LENOX SAW BLADES

Lenox Tools

CARBIDE-TIPPED TOOTH AND GRIT COMPONENTS

Selected Lenox Saw Blades have carbide tipped teeth or carbide grit cutting surfaces; the following metals are present in the carbide teeth and grit:

INGREDIENT

Cobalt Tantalum Carbide Tungsten Carbide

MAX % <11 <3 <87

CAS NUMBER

7440-48-4 12070-06-3 12070-12-1

OSHA PEL (mg/M3) 0.1 Not Established Not Established

2006 ACGIH TLV (mg/M3) 0.02 Not Established 5-TWA; 10-STEL

The carbide tooth and grit alloy may also contain less that one percent of chromium carbide.

LENOX ARMOR CT GOLD COATINGS

Selected Lenox Saw Blades have a gold coating that contains the following ingredients:

INGREDIENT

Titanium Aluminum

MAX % 20-40 20-40

CAS NUMBER

440-32-6 7429-90-5

OSHA PEL (mg/M3) Not Established 15 (metal)

2006 ACGIH TLV (mg/M3) Not Established 10 (metal)

LENOX DIAMOND GRIT COATINGS

Selected Lenox Saw Blades have a diamond grit coating that contains the following ingredients:

INGREDIENT

Carbon Chromium Iron Manganese Silicon

MAX % <2 <1 <99 <2 <2

CAS NUMBER

7440-44-0 7440-47-3 7439-89-6 7439-96-5 7440-21-3

OSHA PEL (mg/M3) Not Established 1 (as metal) 10 (as oxide fume) 5 Ceiling 15

2006 ACGIH TLV (mg/M3) Not Established 0.5 5 (as oxide dust or fume) 0.2 10

The grit coating may also contain less than one percent of copper and nickel.

SECTION 3: PHYSICAL DATA

Boiling point Melting point Solubility in water Appearance Evaporation Rate N/A Approximately 2800F Insoluble metal blade N/A Vapor pressure Vapor density Specific gravity (H20=1) Percent volatile Odor N/A N/A Approx. 8 N/A None

SECTION 4: FIRE AND EXPLOSION DATA

Saw blades are made from non-combustible metals.

SECTION 5: HEALTH HAZARD DATA

The following health hazard data addresses exposure to elevated concentrations of airborne dusts and/or fumes generated from physical dissociation of the saw blade metal. ROUTE OF ENTRY Inhalation Eye Contact Skin Contact Ingestion EMERGENCY FIRST AID Move person to fresh air. Seek medical attention as appropriate. Flush eyes with large amounts of water. Slivers may occur. Get medical attention. Vacuum or brush off excess dust. Slivers may occur. Wash area with soap and water. Seek medical attention or call a Poison Control Center.

Various health hazards may occur if high concentrations of the saw blade metal dust and/or fume are inhaled or ingested:

Page 2 of 3

MATERIAL SAFETY DATA SHEET Aluminum: Irritation eyes and respiratory system. Carbon - Irritation eyes, skin, and respiratory system.

LENOX SAW BLADES

Lenox Tools

Chromium - Irritation eyes, skin, and respiratory system, sensitization dermatitis, lung fibrosis; oxidizing chromium metal may generate hexavalent chromium, which is a human carcinogen (OSHA, IARC, and NTP). Cobalt - Cough, dypsnea, wheezing, decreased pulmonary function, weight loss, dermatitis, diffuse nodular fibrosis, respiratory hypersensitivity, asthma. Possible human carcinogen (IARC). Iron - Benign pneumoconiosis (siderosis). Manganese - Parkinsons, asthenia, insomnia, mental confusion, metal fume fever, dry throat, tightness in chest, dypsnea, rales, flu-like fever, low back pain, vomiting, malaise, fatigue, kidney damage. Molybdenum - Irritation to eyes, skin, respiratory system, anorexia, incoordination, dypsnea, anemia. Nickel - Sensitization dermatitis, allergic asthma, pneumonitis. Reasonably anticipated to cause cancer (IARC and NTP). Silicon - Irritation to respiratory system. Titanium: Irritation of eyes, skin, digestive, respiratory system, respiratory disease. Tungsten - Irritation to eyes, skin, respiratory system, diffuse pulmonary fibrosis, loss of appetite, nausea, coughing, blood changes. Tungsten Carbide - Irritation to eyes, skin, and respiratory system, skin sensitization, diffuse pulmonary fibrosis, loss of appetite, nausea, cough, blood changes. Vanadium - Irritation to eyes skin, respiratory system, fine rales, wheezing, bronchitis, and dypsnea.

SECTION 6: REACTIVITY DATA

Stability: Saw blades are stable. Incompatibility: Reaction with strong acids and oxidizers may release hydrogen gas and other reaction by products. Hazardous Decomposition Products: Metallic oxides and/or metal fumes from welding, burningor melting operations. Polymerization: Will not occur.

SECTION 7: SPILL OR LEAK PROCEDURES

Saw blade dust should be cleaned up to avoid airborne dust generation or release to the environment. Dust disposal must follow all applicable federal, state and local laws and regulations.

SECTION 8: SPECIAL PROTECTION INFORMATION

Ventilation: Mechanical ventilation should be used to capture, exhaust and collect airborne dusts and fumes. Personal Protective Equipment: Eyes: ANSI Z87.1 approved eye protection needs to be worn when the potential for eye contact with the saw blade, dusts or fumes exists. At a minimum, side shields on ANSI Z87 safety spectacles must be worn. Skin: Cut resistant gloves when handling the saw blades; other body protection as appropriate. Respiratory System: NIOSH approved respirators with P-100 filters should be worn when the potential for exposure to metal particulates is anticipated to be in the range of or above respective occupational exposure limits. A comprehensive respiratory protection program is required for personnel wearing respiratory protection.

SECTION 9: SPECIAL PRECAUTIONS

Saw blades may be coated with a thin layer of preservative oil as a rust inhibitor. The blades may also be painted and stenciled. These coatings are not believed to create any occupational health or physical hazards.

SECTION 10: ENVIRONMENTAL REPORTING

Releases of ingredients in the saw blades to the environment may be reportable to federal, state and or local agencies.

Page 3 of 3

Вам также может понравиться

- Esab Sds Can332-C Ercuni 70-30Документ5 страницEsab Sds Can332-C Ercuni 70-30jromero_rpgОценок пока нет

- Msds Cobalt PDFДокумент3 страницыMsds Cobalt PDFwangchao821Оценок пока нет

- MSDS Steel Sheet Safety DataДокумент4 страницыMSDS Steel Sheet Safety Datachinck83Оценок пока нет

- Safely weld alloys with MSDSДокумент2 страницыSafely weld alloys with MSDSElMacheteDelHuesoОценок пока нет

- 51 EX Msds 9-07Документ3 страницы51 EX Msds 9-07Mohamed AdelОценок пока нет

- 32 EX Msds 9-07Документ3 страницы32 EX Msds 9-07Mohamed AdelОценок пока нет

- MSDS METAL CORED WIREДокумент2 страницыMSDS METAL CORED WIREElMacheteDelHuesoОценок пока нет

- Mild Steel Solid Mig Wire MSDSДокумент2 страницыMild Steel Solid Mig Wire MSDSsalcabesОценок пока нет

- Material Safety Data Sheet: Welding Alloys USA IncДокумент4 страницыMaterial Safety Data Sheet: Welding Alloys USA IncShenny AldanaОценок пока нет

- M S D S: Aterial Afety ATA HeetДокумент4 страницыM S D S: Aterial Afety ATA HeetJhony MedranoОценок пока нет

- Member of the BÖHLER -UDDEHOLM Group MATERIAL SAFETY DATA SHEETДокумент6 страницMember of the BÖHLER -UDDEHOLM Group MATERIAL SAFETY DATA SHEETantoncanuckОценок пока нет

- Material Safety Data Sheet: I. Product IdentificationДокумент2 страницыMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoОценок пока нет

- Carbon Steel and HSLA Plate MSDSДокумент7 страницCarbon Steel and HSLA Plate MSDSShawn ChiassonОценок пока нет

- Material Safety Data Sheet: Section 1 - IdentificationДокумент4 страницыMaterial Safety Data Sheet: Section 1 - IdentificationAmjad MehmoodОценок пока нет

- 1 TufTrak EC SMAW Msds 2-10Документ3 страницы1 TufTrak EC SMAW Msds 2-10mohamed AdelОценок пока нет

- La 71 MSDSДокумент2 страницыLa 71 MSDSdeepak2803Оценок пока нет

- M S D S: Aterial Afety ATA HeetДокумент4 страницыM S D S: Aterial Afety ATA HeetJhony MedranoОценок пока нет

- Material Safety Data Sheet: I. Product IdentificationДокумент2 страницыMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoОценок пока нет

- MSDS for US Forge E 6010 Covered ElectrodeДокумент3 страницыMSDS for US Forge E 6010 Covered Electrodemohamed AdelОценок пока нет

- Aluminum Safety Data Sheet SummaryДокумент6 страницAluminum Safety Data Sheet SummarySaul MontielОценок пока нет

- Coreshield 8003 - ESABДокумент6 страницCoreshield 8003 - ESABBiju_PottayilОценок пока нет

- Flux Core Welding WireДокумент3 страницыFlux Core Welding Wiremuhamad bukhari abu hassanОценок пока нет

- Superinox 2C MSDS Ador WeldingДокумент9 страницSuperinox 2C MSDS Ador WeldingyogipatilОценок пока нет

- Material Safety Data Sheet: I. Product IdentificationДокумент2 страницыMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoОценок пока нет

- Copper BasedДокумент4 страницыCopper Basedcpmc66Оценок пока нет

- I. Product Identification: Material Safety Data SheetДокумент5 страницI. Product Identification: Material Safety Data SheetSteel BridgeОценок пока нет

- Nickel Base Welding Wire MSDS Provides Health and Safety InformationДокумент7 страницNickel Base Welding Wire MSDS Provides Health and Safety InformationLawrence Lancy LoboОценок пока нет

- SDS Underwater Cutting Rods 2018 PDFДокумент8 страницSDS Underwater Cutting Rods 2018 PDFVictor AcostaОценок пока нет

- MSDS AlloysДокумент15 страницMSDS AlloysMaryam EradewiОценок пока нет

- MsdsДокумент5 страницMsdsLisa NurhasanahОценок пока нет

- MSDS Tungsten Electrode Safety DataДокумент2 страницыMSDS Tungsten Electrode Safety DataSerkan ApayОценок пока нет

- Material Safety Data Sheet: I. Product IdentificationДокумент2 страницыMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoОценок пока нет

- Steel Mill Electric Arc Furnace Dust MSDS (NA) 12-8-08Документ15 страницSteel Mill Electric Arc Furnace Dust MSDS (NA) 12-8-08Agustine SetiawanОценок пока нет

- Material Safety Data Sheet (MSDS) : Section I - IdentificationДокумент2 страницыMaterial Safety Data Sheet (MSDS) : Section I - IdentificationSalem GarrabОценок пока нет

- Welding Fume HazardsДокумент6 страницWelding Fume HazardsEko SusantoОценок пока нет

- Msds Diamond WheelsДокумент4 страницыMsds Diamond WheelsThuý VyОценок пока нет

- MSDS NiCrДокумент2 страницыMSDS NiCrBety FajriaОценок пока нет

- Safety Data Sheet: 1. Product and Company IdentificationДокумент8 страницSafety Data Sheet: 1. Product and Company IdentificationThonny BarreraОценок пока нет

- Material Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?Документ9 страницMaterial Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?haharameshОценок пока нет

- Acero HSДокумент2 страницыAcero HSEdgar MOrenoОценок пока нет

- Material Safety Data Sheet: I. Product IdentificationДокумент2 страницыMaterial Safety Data Sheet: I. Product Identificationmohamed AdelОценок пока нет

- Brass Alloys Material Safety Data SheetДокумент3 страницыBrass Alloys Material Safety Data SheetALEJANDRA FONTALVO STUDENTОценок пока нет

- Material Safety Data Sheet Thoriated TungstensДокумент5 страницMaterial Safety Data Sheet Thoriated TungstensveraОценок пока нет

- Material Safety Data Sheet: I. Product IdentificationДокумент2 страницыMaterial Safety Data Sheet: I. Product IdentificationadityadhОценок пока нет

- Aluminum MSDS Safety GuideДокумент14 страницAluminum MSDS Safety GuidesachedalОценок пока нет

- MsdsДокумент3 страницыMsdsTobi MazzoccaОценок пока нет

- SDS-metal DustДокумент10 страницSDS-metal DustAzuan MABKОценок пока нет

- Gas Metal Arc Welding WiresДокумент3 страницыGas Metal Arc Welding Wiresmuhamad bukhari abu hassanОценок пока нет

- Safety Data Sheet: 1. Product and Company IdentificationДокумент5 страницSafety Data Sheet: 1. Product and Company Identificationmohamed AdelОценок пока нет

- Hot-Dip Galvanizing Material Safety Data SheetДокумент5 страницHot-Dip Galvanizing Material Safety Data SheetyeezeeОценок пока нет

- Safety Info Sheet Stainless SteelДокумент7 страницSafety Info Sheet Stainless SteelKSBОценок пока нет

- SDS HTW 50 2020Документ3 страницыSDS HTW 50 2020Ari RosyadiОценок пока нет

- 4 EC SMAW Msds 5-08Документ4 страницы4 EC SMAW Msds 5-08Mohamed AdelОценок пока нет

- MSDS SoldaduraДокумент4 страницыMSDS SoldaduraJosé YáñezОценок пока нет

- ALCOTEC (MSDS) GTAW-ALUMINUM WELD WIRE 7994-N Expires 17-05-01Документ9 страницALCOTEC (MSDS) GTAW-ALUMINUM WELD WIRE 7994-N Expires 17-05-01PubcrawlОценок пока нет

- Material Safety Data Sheet: Product Name: RD-260 Classification: AWS A5.1 E6013Документ3 страницыMaterial Safety Data Sheet: Product Name: RD-260 Classification: AWS A5.1 E6013tamharОценок пока нет

- Rci RodДокумент2 страницыRci Rodabdul rochimОценок пока нет

- Anodic Oxidation of Aluminium and Its Alloys: The Pergamon Materials Engineering Practice SeriesОт EverandAnodic Oxidation of Aluminium and Its Alloys: The Pergamon Materials Engineering Practice SeriesРейтинг: 5 из 5 звезд5/5 (1)

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)От EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)Оценок пока нет

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesОт EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesОценок пока нет

- Art 1207-1257 CCДокумент5 страницArt 1207-1257 CCRubz JeanОценок пока нет

- Capetown Halal RestaurantsДокумент1 страницаCapetown Halal RestaurantsKhawaja UsmanОценок пока нет

- Isavasya UpanishadДокумент5 страницIsavasya UpanishadskmrrlОценок пока нет

- Cambridge O Level Biology: Example Candidate ResponsesДокумент120 страницCambridge O Level Biology: Example Candidate ResponsesQari MushtaqОценок пока нет

- Yoga For The Primary Prevention of Cardiovascular Disease (Hartley 2014)Документ52 страницыYoga For The Primary Prevention of Cardiovascular Disease (Hartley 2014)Marcelo NorisОценок пока нет

- Affidavit of Loss Drivers License AffidavitДокумент2 страницыAffidavit of Loss Drivers License AffidavitJov May Dimco50% (2)

- Appellate Tribunal Inland Revenue Rules, 2010Документ18 страницAppellate Tribunal Inland Revenue Rules, 2010Shahbaz KhanОценок пока нет

- Boundless - 5 Steps For High Impact Work ExperienceДокумент3 страницыBoundless - 5 Steps For High Impact Work ExperienceCameron WinnettОценок пока нет

- CES Wrong Answer SummaryДокумент4 страницыCES Wrong Answer SummaryZorg UAОценок пока нет

- Council Of Architecture Scale Of ChargesДокумент4 страницыCouncil Of Architecture Scale Of ChargesAshwin RajendranОценок пока нет

- Duties of Trustees ExplainedДокумент39 страницDuties of Trustees ExplainedZia IzaziОценок пока нет

- Ys 1.7 Convergence PramanaДокумент1 страницаYs 1.7 Convergence PramanaLuiza ValioОценок пока нет

- Economy 1 PDFДокумент163 страницыEconomy 1 PDFAnil Kumar SudarsiОценок пока нет

- Facebook Use Case Diagram Activity Diagram Sequence DiagramДокумент21 страницаFacebook Use Case Diagram Activity Diagram Sequence DiagramSaiОценок пока нет

- Phonetics Exercises PDFДокумент2 страницыPhonetics Exercises PDFShanti YuliastitiОценок пока нет

- Talha Farooqi - Assignment 01 - Overview of Bond Sectors and Instruments - Fixed Income Analysis PDFДокумент4 страницыTalha Farooqi - Assignment 01 - Overview of Bond Sectors and Instruments - Fixed Income Analysis PDFMohammad TalhaОценок пока нет

- Anti Viral DrugsДокумент6 страницAnti Viral DrugskakuОценок пока нет

- The Cult of Demeter On Andros and The HДокумент14 страницThe Cult of Demeter On Andros and The HSanОценок пока нет

- Tong Hop Bai Tap Tieng Anh 8 Chuong Trinh Moi Co Dap AnДокумент317 страницTong Hop Bai Tap Tieng Anh 8 Chuong Trinh Moi Co Dap Anmrxuan tesol93Оценок пока нет

- Ar 318Документ88 страницAr 318Jerime vidadОценок пока нет

- Biological Control in Brazil An OverviewДокумент10 страницBiological Control in Brazil An OverviewGustavo Ferreira MoraisОценок пока нет

- Find Bridges in a Graph Using DFSДокумент15 страницFind Bridges in a Graph Using DFSVamshi YadavОценок пока нет

- Laporan Keuangan Tahun 2018Документ264 страницыLaporan Keuangan Tahun 2018Weni PatandukОценок пока нет

- Alice Corporation Pty. Ltd. v. CLS Bank International and CLS Services Ltd.Документ4 страницыAlice Corporation Pty. Ltd. v. CLS Bank International and CLS Services Ltd.Rachel PauloseОценок пока нет

- Solving Problems Involving Simple Interest: Lesson 2Документ27 страницSolving Problems Involving Simple Interest: Lesson 2Paolo MaquidatoОценок пока нет

- Conduct effective meetings with the right typeДокумент5 страницConduct effective meetings with the right typeRio AlbaricoОценок пока нет

- The Art of Communication PDFДокумент3 страницыThe Art of Communication PDFHung Tran JamesОценок пока нет

- 2 Obligations General Provisions 1156 1162Документ15 страниц2 Obligations General Provisions 1156 1162Emanuel CenidozaОценок пока нет

- All India Ticket Restaurant Meal Vouchers DirectoryДокумент1 389 страницAll India Ticket Restaurant Meal Vouchers DirectoryShauvik HaldarОценок пока нет

- Miles and Snow's Organizational StrategiesДокумент15 страницMiles and Snow's Organizational StrategiesVirat SahОценок пока нет