Академический Документы

Профессиональный Документы

Культура Документы

Robotic Trolley For Material Handling-Full Project

Загружено:

Abhinav AthavaleОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Robotic Trolley For Material Handling-Full Project

Загружено:

Abhinav AthavaleАвторское право:

Доступные форматы

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

ROBOTIC TROLLEY FOR MATERIAL HANDLING

A PRO1ECT REPORT

Submitted by

ABHILASH.1.K

ANOOP.M.N

ANOOP VARGHESE

BIBIN K ARAKKAL

In partial fulfillment for the award of the degree

Of

BACHELOR OF ENGINEERING

IN

MECHANICAL ENGINEERING

UDAYA SCHOOL OF ENGINEERING

ANNA UNIVERSITY: TIRUNELVELI 627 007

APRILL 2011

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

ROBOTIC TROLLEY FOR MATERIAL HANDLING

A PRO1ECT REPORT

Submitted by

ABHILASH.1.K (97808114001)

ANOOP.M.N (97808114007)

ANOOP VARGHESE (97808114008)

BIBIN K ARAKKAL (97808114013)

In partial fulfillment for the award of the degree

Of

BACHELOR OF ENGINEERING

IN

MECHANICAL ENGINEERING

UDAYA SCHOOL OF ENGINEERING

ANNA UNIVERSITY: TIRUNELVELI 627 007

APRILL 2011

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

ANNA UNIVERSITY: TIRUNELVELI 627 007

BONAFIDE CERTIFICATE

CertiIied that this project ROBOTIC TROLLEY FOR MATERIAL

HANDLING Is the bonaIide work oI ABHILASH.1.K, ANOOP.M.N,

ANOOP VARGHESE, BIBIN K ARAKKAL who carried out the project work

Under my supervision.

SIGNATURE SIGNATURE

Mr. K. HARI RAM, M.E, (Ph.D) Mr. P.REGHU, M.E

HEAD OF DEPARTMENT SUPERVISOR

Lecturer

Department of Department of

Mechanical Engineering Mechanical Engineering

Udaya school of Engineering Udaya school of Engineering

Vellamodi-629204 Vellamodi-629204

Submitted Ior the Anna University Examination, Held on udaya school oI

Engineering, Vellamodi on.........................

INTERNAL EXAMINER EXTERNAL EXAMINER

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

ACKNOWLEDGEMENT

II words are considered as symbol oI approval oI token oI acknowledges

then let the words play the heralding role oI expressing our gratitude. First oI all we

would like to thank almighty Ior his blessing and happiness he has showered on us.

First and Ioremost we are indented to Prof. R.SUBHASH

CHANDRABOSE. M.E, Ph.D., principal oI Udaya school oI Engineering Ior

providing us with suIIicient at college.

We express our proIound and sincere thanks to the chairman

Mr.C.THAYPARAN,M.E., who is the enriching keen interest in academic

pursuits.

We express our deep gratitude to Mr.K.HARI RAM, M.E, (Ph.D)., Head oI

the department Ior his valuable advices.

We proIoundly thank our internal supervisor Mr.P.REGHU, M.E., Ior his

valuable suggestion and encouragement rendered to us.

like to oIIer our thanks to all oI our MECHANICAL ENGINEERING

DEPARTMENT STAFF Ior their kind co-operation in bringing out oI this project

very successIully.

ABSTRACT

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

The main objective oI this project is to Iabricate a robotic trolley Ior material

handling in industries. In this project a robotic vehicle is Iabricated which runs like

a car by carrying tools Irom place to another. This is done by using a small sensor.

The trolley will stop when the trolley is unloaded.

i

TABLE OF CONTENTS

CHAPTER TITLE PAGE NO.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

ABSTRACT i

LIST OF FIGURES ii

1 INTRODUCTION 1

2 WORKING PRINCIPLE 3

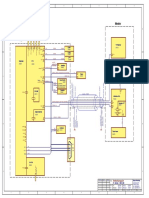

3 BLOCK DIAGRAM 5

4 FABRICATION OF PARTS 7

.1 PMDC MOTOR 8

.1.1 TORQUE CAPABILITIES

OF MOTOR 13

.2 RECHARGABLE BATTERY 15

.2.1 USAGE AND APPLICATIONS 16

.2.2 CHARGING AND DISCHARGING 17

.2.3 REVERSE CHARGING 19

.2. BATTERY TYPES 21

.3 PCB DESIGN 25

. IR SENSOR 29

5 VIEW THROUGH CAMERA 31

6 ADVANTAGES 33

ii

7 APPLICATIONS 35

8 CONCLUSION 37

9 BIBLIOGRAPHY 39

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

LIST OF FIGURES

No. TITLE PAGE NO.

1 BLOCK DIAGRAM 5

2 DC MOTOR 10

3 IR SENSORS 29

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

CHAPTER 1

INTRODUCTION

INTRODUCTION

Mobile robots have capability to move around in their environment and not

Iixed to one physical location. In contrast, industrial robots usually consist oI a

joint arm (multilinked manipulator) and gripper assembly (or end eIIecter) that is

attached to a Iixed surIace.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

Mobile robots are the Iocus oI a great deal oI current research and almost

every major university has one or more laboratory that Iocuses on mobile robot

research. Mobile robots are also Iound in industries; military and security

environments. They also appear as consumer products, Ior entertainment or to

perIorm certain tasks like vacuum.

2

CHAPTER 2

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

WORKING PRINCIPLE

3

WORKING PRINCIPLE

The sensor is connected at the bed oI the vehicle. This is used to check

the load in bed. The motor is connected with the wheel arrangement with the help

oI the spur gear.

When the Iirst user keep the tools in this vehicle the trolley moves

automatically to the second user.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

II the second user took the tools Irom the trolley the trolley stops with the

second user. AIter that when the second user keeps a tool it moves to the next user.

It can be used in industries, hospitals etc.

CHAPTER 3

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

BLOCK DIAGRAM

S

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

CHAPTER 4

FABRICATION OF PARTS

7

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

FABRICATION OF PARTS

4.1 PMDC MOTOR

An electric generator is a device that converts mechanical energy to

Electrical energy. The reverse conversion oI electrical energy into mechanical

energy is done by a motor; motors and generators have many similarities. A

generator Iorces electrons in the windings to Ilow through the external electrical

circuit. It is somewhat analogous to a water pump, which creates a Ilow oI water

but does not create the water inside. The source oI mechanical energy may be a

reciprocating or turbine steam engine, water Ialling through a turbine or

waterwheel, an internal combustion engine, a wind turbine, a hand crank,

compressed air or any other source oI mechanical energy.

8

A dynamo machine consists oI a stationary structure, which provides a

constant magnetic Iield and a set oI rotating windings which turn within that Iield.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

On small machines the constant magnetic Iield may be provided by one or more

permanent magnets; larger machines have the constant magnetic Iield provided by

one or more electromagnets, which are usually called Iield coils.

Large power generation dynamos are now rarely seen due to the now

nearly universal use oI alternating current Ior power distribution and solid

state electronic AC to DC power conversion. But beIore the principles oI AC

were discovered, very large direct-current dynamos were the only means oI

power generation and distribution. Now power generation dynamos are

mostly a curiosity.

The DC Motor or Direct Current Motor to give it its Iull title, is the most

commonly used actuator Ior producing continuous movement and whose speed oI

rotation can easily be controlled, making them ideal Ior use in applications were

speed control, servo type control, and/or positioning is required. A DC motor

consists oI two parts, a "Stator" which is the stationary part and a "Rotor" which is

the rotating part. The result is that there are basically three types oI DC Motor

available.

Brushed Motor - This type oI motor produces a magnetic Iield in a wound

rotor (the part that rotates) by passing an electrical current through a commutator

and carbon brush assembly, hence the term "Brushed". The stators (the stationary

part) magnetic Iield is produced by using either a wound stator Iield winding or by

permanent magnets. Generally brushed DC motors are cheap, small and easily

controlled.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

Brushless Motor - This type oI motor produce a magnetic Iield in the rotor

by using permanent magnets attached to it and commutation is achieved

electronically. They are generally smaller but more expensive than conventional

brushed type DC motors because they use "Hall eIIect switches in the stator to

produce the required stator Iield rotational sequence. But they have better

torque/speed characteristics, are more eIIicient and have

a longer operating liIe than equivalent brushed types.

Servo Motor - This type oI motor is basically a brushed DC motor

with some Iorm oI positional Ieedback control connected to the rotor shaIt.

They are connected to and controlled by a PWM type controller and are

mainly used in positional control systems and radio controlled models.

Normal DC motors have almost linear characteristics with their speed

oI rotation being determined by the applied DC voltage and their output

torque being determined by the current Ilowing through the motor windings.

The speed oI rotation oI any DC motor can be varied Irom a Iew revolutions

per minute (rpm) to many thousands oI revolutions per minute making them

suitable Ior electronic, automotive or robotic applications. By connecting

them to gearboxes or gear-trains their output speed can be decreased while at

the same time increasing the torque output oI the motor at a high speed.

A conventional brushed DC Motor consist basically oI two parts, the

stationary body oI the motor called the Stator and the inner part which

rotates producing the movement, called the Rotor or "Armature" Ior DC machines.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

The motors wound stator is an electromagnet which consists oI electrical

coils connected together in a circular conIiguration to produce a North-pole then a

South-pole then a North-pole etc, type stationary magnetic Iield system (as

opposed to AC machines whose stator Iield continually rotates with the applied

Irequency) with the current Ilowing within these Iield coils being known as the

motor Iield current.

The stators electromagnetic coils can be connected in series, parallel or both

together (compound) with the armature. A series wound DC motor has the stator

Iield windings connected in series with the armature while a shunt wound DC

motor has the stator Iield windings connected in parallel with the armature.

The rotor or armature oI a DC machine consists oI current carrying

conductors connected together at one end to electrically isolated copper segments

called the commutator. The commutator allows an electrical connection to be

made via carbon brushes (hence the name "Brushed" motor) to an external power

supply as the armature rotates. The magnetic Iield setup by the rotor tries to align

itselI with the stationary stator Iield causing the rotor to rotate on its axis, but

cannot align itselI due to commutation delays.

The rotational speed oI the motor is dependent on the strength oI the rotors

magnetic Iield and the more voltage that is applied to the motor the Iaster the rotor

will rotate. By varying this applied DC voltage the rotational speed oI the motor

can also be varied.

Conventional (Brushed) DC Motor

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

Permanent magnet

2pole

Permanent -Pole Wound

Field Motor Magnet Motor

Permanent magnet (PMDC) brushed motors are generally much smaller and

cheaper than their equivalent wound stator type DC motor cousins as they have no

Iield winding. In permanent magnet DC (PMDC) motors these Iield coils are

replaced with strong rare earth (i.e. Samarium Cobolt, or Neodymium Iron Boron)

type magnets which have very high magnetic energy Iields. This gives them a

much better linear speed/torque characteristic than the equivalent wound motors

because oI the permanent and sometimes very strong magnetic Iield, making them

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

more suitable Ior use in models, robotics and servos.

Although DC brushed motors are very eIIicient and cheap, problems

associated with the brushed DC motor is that sparking occurs under heavy

load conditions between the two surIaces oI the commutator and carbon

brushes resulting in selI generating heat, short liIe span and electrical noise

due to sparking, which can damage any semiconductor switching device

such as a 110SFET or transistor. To overcome these disadvantages,

Brushless DC Motors were developed.

The brushless DC motor (BDCM) is very similar to a permanent

magnet DC motor, but does not have any brushes to replace or wear out due

to commutator sparking. ThereIore, little heat is generated in the rotor

increasing the motors liIe. The design oI the brushless motor eliminates the need

Ior brushes by using a more complex drive circuit was the rotor

magnetic Iield is a permanent magnet which is always in synchronization

with the stator Iield allows Ior a more precise speed and torque control. Then

the construction oI a brushless DC motor is very similar to the AC motor

making it a true synchronous motor but one disadvantage is that it is more

expensive than an equivalent "brushed" motor design.

The control oI the brushless DC motors is very diIIerent Irom the

normal brushed DC motor, in that it this type oI motor incorporates some

means to detect the rotors angular position (or magnetic poles) required to

produce the Ieedback signals required to control the semiconductor

switching devices. The most common position/pole sensor is the Hall

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

element, but some motors use optical sensors. Using the Hall sensors

signals, the polarity oI the electromagnets is switched by the motor control

drive circuitry. Then the motor can be easily synchronized to a digital clock

signal, providing precise speed control. Brushless DC motors can be

constructed to have, an external permanent magnet rotor and an internal

electromagnet stator or an internal permanent magnet rotor and an external

electromagnet stator.

12

4.1.1 TORQUE CAPABILITIES OF MOTORS

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

When optimally designed Ior a given active current (i.e., torque current),

voltage, pole-pair number, excitation Irequency (i.e., synchronous speed), and core

Ilux density, all categories oI electric motors or generators will exhibit virtually the

same maximum continuous shaIt torque (i.e., operating torque) within a given

physical size oI electromagnetic core. Some applications require bursts oI torque

beyond the maximum operating torque, such as short bursts oI torque to accelerate

an electric vehicle Irom standstill. Always limited by magnetic core saturation or

saIe operating temperature rise and voltage, the capacity Ior torque bursts beyond

the maximum operating torque diIIers signiIicantly between categories oI electric

motors or generators.

Electric machines without a transIormer circuit topology, such as Field-

Wound (i.e., electromagnet) or Permanent Magnet (PM) Synchronous electric

machines cannot realize bursts oI torque higher than the maximum designed torque

without saturating the magnetic core and rendering any increase in current as

useless. Furthermore, the permanent magnet assembly oI PM synchronous electric

machines can be irreparably damaged, iI bursts oI torque exceeding the maximum

operating torque rating are attempted.

Electric machines with a transIormer circuit topology, such as Induction (i.e.,

asynchronous) electric machines, Induction Doubly-Fed electric machines, and

Induction or Synchronous Wound-Rotor Doubly-Fed (WRDF) electric machines,

exhibit very high bursts oI torque because the active current (i.e., Magneto-Motive-

Force or the product oI current and winding-turns) induced on either side oI the

transIormer oppose each other and as a result, the active current contributes nothing

to the transIormer coupled magnetic core Ilux density, which would otherwise lead

to core saturation.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

Electric machines that rely on Induction or Asynchronous principles short-

circuit one port oI the transIormer circuit and as a result, the reactive impedance oI

the transIormer circuit becomes dominant as slip increases, which limits the

magnitude oI active (i.e., real) current. Still, bursts oI torque that are two to three

times higher than the maximum design torque are realizable.

The Synchronous WRDF electric machine is the only electric machine with a

truly dual ported transIormer circuit topology (i.e., both ports independently

excited with no short-circuited port). The dual ported transIormer circuit topology

is known to be unstable and requires a multiphase slip-ring-brush assembly to

propagate limited power to the rotor winding set. II a precision means were

available to instantaneously control torque angle and slip Ior synchronous operation

during motoring or generating while simultaneously providing brushless power to

the rotor winding set the active current oI the Synchronous WRDF electric machine

would be independent oI the reactive impedance oI the transIormer circuit and

bursts oI torque signiIicantly higher than the maximum operating torque and Iar

beyond the practical capability oI any other type oI electric machine would be

realizable. Torque bursts greater than eight times operating torque have been

calculated.

14

4.2 RECHARGEABLE BATTERY

A rechargeable battery (also known as a storage battery) is a group oI one or

more secondary cells. Rechargeable batteries use electrochemical reactions that are

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

electrically reversible. Rechargeable batteries come in many diIIerent sizes and use

diIIerent combinations oI chemicals. Commonly used secondary cell

("rechargeable battery") chemistries are lead acid, nickel cadmium (NiCd), nickel

metal hydride (NiMH), lithium ion (Li-ion), and lithium ion polymer (Li-ion

polymer).

Rechargeable batteries can oIIer economic and environmental beneIits

compared to disposable batteries. Some rechargeable battery types are available in

the same sizes as disposable types. While the rechargeable cells have a higher

initial cost, rechargeable batteries can be recharged many times. Proper selection oI

a rechargeable battery system can reduce toxic materials sent to landIills compared

to an equivalent series oI disposable batteries. For example, battery manuIacturers

oI NiMH rechargeable batteries claim a service liIe oI 100-1000 charge cycles Ior

their batteries.

13

4.2.1 USAGE AND APPLICATIONS

Rechargeable batteries currently are used Ior applications such as automobile

starters, portable consumer devices, light vehicles (such as motorized wheelchairs,

golI carts, electric bicycles, and electric IorkliIts), tools, and uninterruptible power

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

supplies. Emerging applications in hybrid electric vehicles and electric vehicles are

driving the technology to reduce cost, reduce weight, and increase liIetime.

Unlike non-rechargeable batteries (primary cells), rechargeable batteries

have to be charged beIore use. The need to charge rechargeable batteries beIore use

deterred potential buyers who needed to use the batteries immediately. However,

new low selI discharge batteries allow users to purchase rechargeable battery that

already hold about 70 oI the rated capacity, allowing consumers to use the

batteries immediately and recharge later.

Grid energy storage applications use industrial rechargeable batteries Ior

load leveling, where they store electric energy Ior use during peak load periods,

and Ior renewable energy uses, such as storing power generated Irom photovoltaic

arrays during the day to be used at night. By charging batteries during periods oI

low demand and returning energy to the grid during periods oI high electrical

demand, load-leveling helps eliminate the need Ior expensive peaking power plants

and helps amortize the cost oI generators over more hours oI operation.

The National Electrical ManuIacturers Association has estimated that U.S.

demand Ior rechargeable is growing twice as Iast as demand Ior non rechargeable.

16

4.2.2 CHARGING AND DISCHARGING

During charging, the positive active material is oxidized, producing

electrons, and the negative material is reduced, consuming electrons. These

electrons constitute the current Ilow in the external circuit. The electrolyte may

serve as a simple buIIer Ior ion Ilow between the electrodes, as in lithium-ion and

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

nickel-cadmium cells, or it may be an active participant in the electrochemical

reaction, as in lead-acid cells.

Diagram oI the charging oI a secondary cell battery.

The energy used to charge rechargeable batteries mostly comes Irom AC

current (mains electricity) using an adapter unit. Most battery chargers can take

several hours to charge a battery. Most batteries can be charged in Iar less time than

the most common simple battery chargers are capable oI. Duracell and Rayovac

now sell chargers that can charge AA- and AAA-size NiMH batteries in just 15

minutes; Energizer sells chargers that can additionally charge C/D-size and 9 V

NiMH batteries. However, high rates oI charging (eg. 15 minute charger, 1 hour

chargers) will cause long term damage to NiMH and most other rechargeable

batteries.

Battery is susceptible to damage due to reverse charging iI they are Iully

discharged. Fully integrated battery chargers that optimize the charging current are

available.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

Also, attempting to recharge non-rechargeable batteries has a small chance

oI causing a battery explosion.

Flow batteries, which are not commonly used by consumers, are recharged

by replacing the electrolyte liquid.

Battery manuIacturers' technical notes oIten reIer to VPC. This is volts per

cell, and reIers to the individual secondary cells that make up the battery. For

example, to charge a 12 V battery (containing 6 cells oI 2 V each) at 2.3 VPC

requires a voltage oI 13.8 V across the battery's terminals.

Most NiMH AA or AAA batteries rate their cells at 1.2 V. However, this is

not a problem in most devices because alkaline batteries drop in voltage as the

energy is depleted. Most devices are designed to continue to operate at a reduced

voltage oI between 0.9 and 1.1 V

18

.. REVERSE CHARCINC

Reverse charging, which damages batteries, is when a rechargeable battery is

recharged with its polarity reversed. Reverse charging can occur under a number oI

circumstances, the three most common being:

O When a battery is incorrectly inserted into a charger.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

O When an automotive type battery charger is connected in reverse to the

battery terminals. This usually occurs when a completely discharged battery

is being charged, otherwise sparking will occur.

O When a series string is deeply discharged.

When one cell completely discharges ahead oI the rest, the stronger cells will

apply a reverse current to the discharged cell. This is commonly reIerred to as "cell

reversal". Cell reversal signiIicantly shortens the liIe oI the aIIected cell and

thereIore shortens the overall liIe oI the battery. In some extreme cases, the

reversed cell can begin to emit smoke or catch Iire. Some Ni-Cad type cells exhibit

a "memory" eIIect. Some Ni-Cad type cells that are not Iully charged and

discharged periodically can lose their ability to retain a Iull charge, i.e. exhibit

reduced capacity. Cycling a multi cell battery into deep discharge to overcome this

memory eIIect can cause cell reversal and do more harm than good. In critical

applications using Ni-Cad batteries, such as in aircraIt, each cell is individually

discharged by connecting a load clip across the terminals oI each cell, thereby

avoiding cell reversal, then charging the cells in series.

19

DEPTH UF DISCHARCE

Depth oI discharge (DOD) is normally stated as a percentage oI the nominal

ampere-hour capacity; 0 DOD means no discharge. Since the usable capacity oI a

battery system depends on the rate oI discharge and the allowable voltage at the

end oI discharge, the depth oI discharge must be qualiIied to show the way it is to

be measured. Due to variations during manuIacture and aging, the DOD Ior

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

complete discharge can change over time / discharge cycles. Generally a

rechargeable battery system will tolerate more charge/discharge cycles iI the DOD

is lower on each cycle.

ACTIVE COMPONENTS

Active components in a secondary cell are the chemicals that make up the

positive and negative active materials, and the electrolyte. The positive and

negative are made up oI diIIerent materials, with the positive exhibiting a reduction

potential and the negative having an oxidation potential. The sum oI these

potentials is the standard cell potential or voltage.

In primary cells the positive and negative electrodes are known as the

cathode and anode, respectively. Although this convention is sometimes carried

through to rechargeable systems especially with lithium-ion cells, because oI

their origins in primary lithium cells this practice can lead to conIusion. In

rechargeable cells the positive electrode is the cathode on discharge and the anode

on charge, and vice versa Ior the negative electrode.

20

4.2.4 COMMON RECHARGEABLE BATTERY TYPES

Nickel-cadmium battery (NiCd)

Created by Waldemar Jungner oI Sweden in 1899 which was based on

Thomas Edison's Iirst alkaline battery. Using nickel oxide hydroxide and metallic

cadmium as electrodes. Cadmium is a toxic element, and was banned Ior most uses

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

by the European Union in 200. Nickel-cadmium batteries have been almost

completely superseded by nickel-metal hydride batteries.

Nickel-metal hydride battery (NiMH)

First developed around 1980's. The battery has a hydrogen-absorbing alloy

Ior the negative electrode instead oI cadmium.

Lithium-ion battery

The technology behind lithium-ion battery has not yet Iully reached maturity.

However, the batteries are the type oI choice in many consumer electronics and

have one oI the best energy-to-mass ratios and a very slow loss oI charge when not

in use. The popularity oI lithium-ion batteries has spread as their technology

continues to improve.

Lithium sulfur battery

A new battery chemistry developed by Sion Power since 199. Claims

superior energy to weight than current lithium technologies on the market. Also

lower material cost may help this product reach the mass market. Not to be

conIused with lithium sulIur dioxide (Li-SO

2

) batteries which explode when

recharged.

Thin film battery (TFB)

An emerging reIinement oI the lithium ion technology by Excellatron. The

developers claim a very large increase in recharge cycles, around 0,000 cycles.

Higher charge and discharge rates. At least 5C charge rate. Sustained 60C

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

discharge, and 1000C peak discharge rate. And also a signiIicant increase in

speciIic energy, and energy density.

Also InIinite Power Solutions makes thin Iilm batteries (TFB) Ior micro-

electronics applications that are Ilexible, rechargeable, solid-state lithium batteries.

Smart battery

A smart battery has the voltage monitoring circuit built inside. Smart Battery

System Carbon Ioam-based lead acid battery. FireIly Energy has developed a

carbon Ioam-based lead acid battery with a reported energy density oI 30-0

more than their original 38 Wh/kg, with long liIe and very high power density.

RECENT DEVELOPMENTS

In 2007, assistant proIessor Yi Cui and colleagues at StanIord University's

Department oI Materials Science and Engineering discovered that using silicon

nanowires as the anode increases the volumetric charge density oI the anode by up

to a Iactor oI 10. See also Nanowire` battery.

Another development is the invention oI Ilexible batteries, which can be

made paper-thin. Ceramatec, a research and development subcompany oI

CoorsTek, is testing a battery which contains a chunk oI solid sodium metal mated

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

to a sulIur compound by an extraordinary, paper-thin ceramic membrane. The

membrane conducts ions back and Iorth to generate a current. The company claims

that it can cram about 0 kilowatt hours oI energy into a package about the size oI a

reIrigerator, and operate below 90 degrees Celsius. The company also claims that

their battery will allow Ior 3,650 discharge/recharge cycles (or roughly 1 per day

Ior one decade.)

23

ALTERNATIVES

Several alternatives to rechargeable batteries exist or are under development. For

uses like portable radios and Ilashlights, rechargeable batteries may be replaced by

clockwork mechanisms or dynamos which are cranked by the user to provide

power. For transportation, uninterruptible power supply systems and laboratories,

Ilywheel energy storage systems store energy in a spinning rotor Ior reconversion

to electric power when needed; such systems may be used to provide large pulses

oI power that would otherwise be objectionable on a common electrical grid.

A Iuture development could be ultracapacitors Ior transportation, using a large

capacitor to store energy instead oI the rechargeable battery banks used in hybrid

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

vehicles. One drawback to capacitors compared with batteries is that the terminal

voltage drops rapidly; a capacitor that has 25 oI its initial energy leIt in it will

have one-halI oI its initial voltage. Battery systems tend to have a terminal voltage

that does not decline rapidly until nearly exhausted. This characteristic complicates

the design oI power electronics Ior use with ultracapacitors. However, there are

potential beneIits in cycle eIIiciency, liIetime, and weight compared with

rechargeable systems.

24

4.3 PCB DESIGN

The PCB des i gn st ar t s r i ght Ir om t he sel ect i on oI t he

l ami nat es . The t wo mai n t ypes oI base l ami nat e are epoxy gl ass

and phenol i c paper l ami nat es are general l y used Ior s i mpl e

ci rcui t s. Though i t i s ver y cheap and can eas i l y be dr i l l ed,

phenol i c paper has poor el ect r i cal charact er i s t i cs and i t abs or bs

mor e moi st ure t han epoxy gl ass. Epoxy gl ass has hi gher

mechani cal st rengt h.

The i mpor t ant proper t i es t hat have t o be cons i dered Ior

sel ect i ng t he PCB s ubst rat e are t he di el ect r i c st rengt h, i ns ul at i on

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

res i s t ance, wat er absor pt i on propert y, coeI I. oI t her mal

expans i on, s hear st rengt h, har dnes s, di mens i onal s t abi l i t y et c.

4. 3. 1 PCB Fabri cati on

The Iabr i cat i on oI a PCB i ncl udes Iour st eps.

a) Prepar i ng t he PCB pat t er n.

b) Trans Ierr i ng t he pat t er n ont o t he PCB.

c) Devel opi ng t he PCB.

d) Fi ni s hi ng ( i . e. ) dr i l l i ng, cut t i ng, s moot hi ng, t ur ni ng et c.

2 3

Pat t er n des i gni ng i s t he pr i mar y st ep i n Iabr i cat i ng a PCB.

I n t hi s st ep, al l i nt erconnect i on bet ween t he component s i n t he

gi ven ci rcui t are conver t ed i nt o PCB t racks. Several Iact ors s uc h

as pos i t i oni ng t he di a met er oI hol es, t he ar ea t hat each component

woul d occupy, t he t ype oI end t er mi nal s houl d be cons i dered.

Transf erri ng t he PCB Pat tern

The copper s i de oI t he PCB s houl d be t horoughl y cl eaned

wi t h t he hel p oI al cohol i c spi r i t or pet r ol . It must be compl et el y

Iree Irom dus t and ot her cont a mi nant s.

The mi r r or i mage oI t he pat t er n must be car bon copi ed and t o

t he l a mi nat e t he compl et e pat t er n may now be made each res i s t ant

wi t h t he hel p oI pai nt and t hi n br ush.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

Devel opi ng

I n t hi s devel opi ng al l excess i ve copper i s r emoved Irom t he

board and onl y t he pr i nt ed pat t er n i s l eIt behi nd. About 100ml oI

t ap wat er s houl d be heat ed t o 75 C and 30. 5 grams oI FeCl

3

added t o i t , t he mi xt ure s houl d be t horoughl y s t i r red and a Iew

drops oI HCl may be added t o speed up t he process.

2 6

The board wi t h i t s copper s i de Iaci ng upward s houl d be pl aced

i n a Il at bot t omed pl ast i c t ray and t he aqueous sol ut i on oI FeCl

2

poured i n t he et chi ng pr ocess woul d t ake 0 t o 60 mi n t o

compl et e.

AIt er et chi ng t he board i t s houl d be was hed under r unni ng

wat er and t hen hel d agai nst l i ght . t he pr i nt ed pat t er n s houl d be

cl ear l y vi s i bl e. The pai nt s houl d be re moved wi t h t he hel p oI

t hi nner.

Fi ni s hi ng Touches

AIt er t he et chi ng i s compl et ed, hol e oI s ui t abl e dia met e r

shoul d be dr i l l ed, t hen t he PCB may be t i n pl at ed us i ng a n

ordi nar y 35 Wat t s sol der i ng r od al ong wi t h t he sol der core , t he

copper s i de may be gi ven a coat oI var ni s h t o prevent oxi dat i on.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

Dri l l i ng

Dr i l l s Ior PCB use us ual l y come wi t h ei t her a set oI col l ect s

oI var i ous s i zes or a 3-Jaw chuck. For accuracy however 3- j aw

chunks aren` t br i l l i ant and s mal l dr i l l bel ow 1 mm Ir om gr ooves

i n t he j aws prevent i ng good gr i ps.

2 7

Sol deri ng

Begi n t he cons t r uct i on by sol der i ng t he res i s t ors Iol l owed by

t he capaci t ors and t he LEDs di odes and IC s ocket s. Don` t t r y

sol der i ng an IC di r ect l y unl ess you t r us t your ski l l i n sol der i ng.

Al l component s s houl d be sol der ed as s hown i n t he Ii gur e. Now

connect t he swi t ch and t hen sol der / scr ew i I on t he PCB us i ng

mul t i pl e was hers or s paces. Sol der i ng i t di r ect l y wi l l onl y r educe

i t s hei ght above ot her component s and ha mper i n i t s eas y Ii xat i on

i n t he cabi net . Now connect t he bat t er y l ead.

Assembl i ng

The ci rcui t can be encl osed i n any ki nd oI cabi net . BeIor e

Ii t t i ng t he PCB s ui t abl e hol es must be dr i l l ed i n t he cabi net Ior

t he swi t ch, LED and buzzer. Not e t hat a rot ar y s wi t ch can be used

i nst ead oI a s l i de t ype.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

Swi t ch on t he ci rcui t t o be desi red range. It wi l l

aut omat i cal l y st ar t i t s t i mi ng cycl es. To be s ure t hat i t i s wor ki ng

proper l y wat ch t he LED Il as h. The component s are sel ect ed t o

t r i gger t he al ar m a Iew mi nut es beIore t he set l i mi t .

28

4.4 IR SENSORS

InIrared (IR) light is electromagnetic radiation with a wavelength longer than

that oI visible light, measured Irom the nominal edge oI visible red light at

0.7 micrometers, and extending conventionally to 300 micrometers. These

wavelengths correspond to a Irequency range oI approximately 30 to 1THz,

|1|

and

include most oI the thermal radiation emitted by objects near room temperature.

Microscopically, IR light is typically emitted or absorbed by molecules when they

change their rotational-vibration movements.

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

29

One is an inIrared FM transmitter in which audio inIormation is used to

modulate the chopping Irequency (30 to 250 KHz) oI an inIrared beam emitted by a

set oI LEDs.

The transmitter is capable oI driving up to 50 to 60 LEDs depending on

conIiguration (Total oI 250-300 mA maximum, typically 8 sets oI seven series

connected IR LEDs) See our article on InIrared Illuminators Ior more inIormation.

This FM method is Iar superior to ordinary AM methods where the IR beam is

amplitude modulated; being less susceptible to stray "noise" Irom 60 Hz AC

operated lamps. The transmitter and receiver can be operated Irom 12 volt supplies

so that eight AA cells can be used as a simple power source, since only 50 ma is

needed. The transmitter kit contains two IR LEDs, which is suIIicient Ior many

applications

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

The receiver unit consists oI a IR sensitive photodiode detector and a special

FM receiver with a nominal Irequency range oI 30 to 250 kHz, having a sensitivity

oI around one microvolt. A phase locked loop (PLL) detector recovers the audio

and Ieeds it to an audio power ampliIier with up to 500 milliwatts oI audio output.

Audio quality is excellent. Range is up to 100 Ieet without optics, a Iew hundred

Ieet with simple lenses and with suitable optics such as parabolic mirrors and

telescopes, ranges up to a Iew miles are possible.

It contains PC boards and all parts that are needed to complete one

transmitter and one receiver. Two may be used iI two channels are needed Ior

stereo. Applications include wireless audio links, private listening devices Ior TV

and radio, IR communications links, Iiber optic and inIrared experiments, and other

experiments with inIrared and optics. Since no radio signals are involved, no FCC

licensing is necessary.

CHAPTER 5

VIEW THROUGH CAMERA

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

31

Photo

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

32

CHAPTER 6

ADVANTAGES

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

33

ADVANTAGES

O Less manpower is needed

O Implementation is easy

O Fabrication coast is less

O User Iriendly

3

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

CHAPTER 7

APPLICATION

35

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

APPLICATION

O It can be used in industries

O It can be used in libraries

36

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

CHAPTER 8

CONCLUSION

37

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

CONCLUSION

We have designed and Iabricated a robotic trolley Ior material handling in

industries. With the help this trolley one can move tools Irom one place to another

or Irom one user to another. This is done with the help oI a sensor and a motor.

We have carried much conIidence in doing this project successIully. We

have learn about analysis oI a problem, how to solve it, design oI the trolley,

design oI parts ,Iabrication oI parts, material purchase, assembling oI parts and

successIul testing robotic trolley.

38

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

CHAPTER 9

BIBLIOGRAPHY

39

wwwf|na|yearpro[ectcom | wwwf|na|yearthes|scom

BIBLIOGRAPHY

O Robot Tactile Sensing:

R. Andrew Russell (1990)

O Fundamentals oI Mechanics oI Robotic Manipulators:

Marco Ceccarelli

O Robotics: Control, Sensing, Vision, and Intelligence:

K. S. Fu & R.C. Gonzalez & C.S.G. Lee

O The Robot Chronicles:

Asimov, Isaac (1996) |1995|

40

Вам также может понравиться

- BHA3000 Engineer Training SeriesДокумент90 страницBHA3000 Engineer Training SeriesMichael RaymondОценок пока нет

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionОт EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionОценок пока нет

- Operators Manual: For In-Vitro Diagnostic Use Only!Документ57 страницOperators Manual: For In-Vitro Diagnostic Use Only!Mina TariqОценок пока нет

- Medical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesОт EverandMedical Electronic Laboratory Equipment 1967-68: Pergamon Electronics Data SeriesОценок пока нет

- Diagrama de Interconexion XL 200 PDFДокумент9 страницDiagrama de Interconexion XL 200 PDFjoseОценок пока нет

- Panasonic Nn-sd691s St661s St651w Service ManualДокумент40 страницPanasonic Nn-sd691s St661s St651w Service ManualImraan RamdjanОценок пока нет

- Manual Tunturi T 40Документ15 страницManual Tunturi T 40Denis FilipanОценок пока нет

- User Manual - Be CLOT - 4.53Документ30 страницUser Manual - Be CLOT - 4.53Dharmesh PatelОценок пока нет

- EBA 20 - Instruction ManualДокумент44 страницыEBA 20 - Instruction ManualAlexander Guzmán Herrera0% (1)

- Máy điện giải Biocare 2000Документ22 страницыMáy điện giải Biocare 2000anhhp8xОценок пока нет

- Operator Manual 21.5Документ302 страницыOperator Manual 21.5mahmoud rekikОценок пока нет

- CL-2000i&2200i Installation Guidance V3.0 enДокумент79 страницCL-2000i&2200i Installation Guidance V3.0 enМаъмуржон БотировОценок пока нет

- ErbaLyte ServiceManualДокумент31 страницаErbaLyte ServiceManualBio-Scientific GroupОценок пока нет

- Vdocuments - MX - Chemray 240 Service Manual V10eДокумент44 страницыVdocuments - MX - Chemray 240 Service Manual V10eJoshua OkuraОценок пока нет

- Hameg hm5010 hm5011 Spectrum Analyzer Service Manual PDFДокумент40 страницHameg hm5010 hm5011 Spectrum Analyzer Service Manual PDFFrancisco Rodriguez MartinezОценок пока нет

- Myocardial Infraction Alert System Using RFID TechnologyДокумент5 страницMyocardial Infraction Alert System Using RFID TechnologyInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Humacount 30ts 60ts UserДокумент106 страницHumacount 30ts 60ts UserStefan JovanovicОценок пока нет

- Centurion Scientific k2042 User Service ManualДокумент56 страницCenturion Scientific k2042 User Service ManualqaayazОценок пока нет

- BC-2800 Operation Maunal (1.8)Документ283 страницыBC-2800 Operation Maunal (1.8)Tekniah GlobalОценок пока нет

- Service Manual For XL-100 With ISEДокумент317 страницService Manual For XL-100 With ISESIELAB C.A.Оценок пока нет

- Maroche Atom ServДокумент33 страницыMaroche Atom ServAlexeyОценок пока нет

- Operator Manual For Chem 7Документ92 страницыOperator Manual For Chem 7Hồ Thế NguyênОценок пока нет

- BC-2100 Operation Manual (1.7)Документ272 страницыBC-2100 Operation Manual (1.7)Sanjay KumarОценок пока нет

- LAURA Smart - MANUAL - EN - P-PI-110-14-E - 01-2014 PDFДокумент40 страницLAURA Smart - MANUAL - EN - P-PI-110-14-E - 01-2014 PDFreza rifqil azizОценок пока нет

- Homa 2 CalculatorДокумент7 страницHoma 2 CalculatorElisa BarcelosОценок пока нет

- Service Manual: For Blood Glucose Analysers of The Eco-SeriesДокумент31 страницаService Manual: For Blood Glucose Analysers of The Eco-SeriesАлександр БлаговОценок пока нет

- (WWW - Manuallib.com) - OLYMPUS AU 400 - 600 - 640 ManualДокумент42 страницы(WWW - Manuallib.com) - OLYMPUS AU 400 - 600 - 640 ManualAbhijit PathakОценок пока нет

- Manual OrionДокумент103 страницыManual OrionQuốc LừngОценок пока нет

- Humalyzer 2000 PDFДокумент53 страницыHumalyzer 2000 PDFCamilo RamosОценок пока нет

- Brochure-EC9004 Semi-Auto Chemistry AnalyzerДокумент2 страницыBrochure-EC9004 Semi-Auto Chemistry AnalyzerSumit AhirОценок пока нет

- AbstractДокумент3 страницыAbstractrrrajendra26Оценок пока нет

- FUS-2000 User Manual 1011491 2017-10Документ230 страницFUS-2000 User Manual 1011491 2017-10Enkhsaikhan GereldambaОценок пока нет

- Pictus 700 Biochemistry AnalyzerДокумент2 страницыPictus 700 Biochemistry AnalyzerHA FidОценок пока нет

- Medonic M51 5-Part Hematology System Explore Your PossibilitiesДокумент4 страницыMedonic M51 5-Part Hematology System Explore Your PossibilitiesReckyDarmawanОценок пока нет

- Operator Manual For CHEM5V3 - v2012.01.01 (2020 - 08 - 20 02 - 50 - 44 UTC)Документ84 страницыOperator Manual For CHEM5V3 - v2012.01.01 (2020 - 08 - 20 02 - 50 - 44 UTC)Arnoldo FelixОценок пока нет

- AbacusДокумент81 страницаAbacusPeter SaiyaОценок пока нет

- INS00060 ECL 412 - EN - User Manual - A-l25RZTUQYHДокумент86 страницINS00060 ECL 412 - EN - User Manual - A-l25RZTUQYHBereket TeketelОценок пока нет

- VTiQ Reference Manual E (Version 2.0 September 2018)Документ204 страницыVTiQ Reference Manual E (Version 2.0 September 2018)KhalidОценок пока нет

- ABI - 7900HT SDS User GuideДокумент384 страницыABI - 7900HT SDS User Guidesalman672003Оценок пока нет

- Test Loader ExplainationДокумент2 страницыTest Loader ExplainationKP ServiceОценок пока нет

- 14 10 2013 Readwell Touch User ManualДокумент121 страница14 10 2013 Readwell Touch User ManualnmakrygОценок пока нет

- Unit Ibiasing of Discrete BJT and MosfetДокумент57 страницUnit Ibiasing of Discrete BJT and MosfetVijayakumar SОценок пока нет

- Chem 7Документ2 страницыChem 7Rosa Maria Mosqueda Vazquez100% (1)

- DC-30 Auto Hematology Anazlyer Operational Manual-ILONGCAREДокумент133 страницыDC-30 Auto Hematology Anazlyer Operational Manual-ILONGCAREJason WangОценок пока нет

- PDFДокумент526 страницPDFjairodiaz88Оценок пока нет

- Technical Manual for Hema Star II Hematology AnalyzerДокумент33 страницыTechnical Manual for Hema Star II Hematology AnalyzerEslam Maher100% (1)

- SUIT Protocol Description v8.0-1Документ59 страницSUIT Protocol Description v8.0-1ahmed1319Оценок пока нет

- HumaLyzer Primus User ManualДокумент62 страницыHumaLyzer Primus User Manualansarhussain012Оценок пока нет

- Automatic Control of Hydraulic Machine Using PLCДокумент5 страницAutomatic Control of Hydraulic Machine Using PLCIJSTEОценок пока нет

- Acl9000 PDFДокумент391 страницаAcl9000 PDFRENE ALEJANDRO ILLESCA NEIRAОценок пока нет

- AbacusДокумент97 страницAbacusأنور مازوز أبو يوسفОценок пока нет

- Syst 917 PDFДокумент462 страницыSyst 917 PDFCorina StanculescuОценок пока нет

- Mcm14 TransducerДокумент1 страницаMcm14 Transducertmya06Оценок пока нет

- DT-96 / DT-72 / DT-48: Auto-Tune Pid Temperature ControllerДокумент4 страницыDT-96 / DT-72 / DT-48: Auto-Tune Pid Temperature ControllerS AОценок пока нет

- Beckman Coulter Manual UsuarioДокумент196 страницBeckman Coulter Manual UsuarioJosé CamposОценок пока нет

- Jetking Hardware Course ContentsДокумент6 страницJetking Hardware Course ContentsSyedОценок пока нет

- Operation Manual: Automated Hematology AnalyzerДокумент116 страницOperation Manual: Automated Hematology AnalyzerSidharth WalavalkarОценок пока нет

- Flyer Hemolyzer 3 ProДокумент4 страницыFlyer Hemolyzer 3 Prolantip rujitoОценок пока нет

- RF Integrated Circuits Mid-Term ExamДокумент1 страницаRF Integrated Circuits Mid-Term Examsreekanth2728Оценок пока нет

- 3ADW000163R0201 - Technical Guide - e - B PDFДокумент28 страниц3ADW000163R0201 - Technical Guide - e - B PDFAhmed MoustafaОценок пока нет

- Review On Frequency Control of Power Systems With Wind Power Penetration51Документ8 страницReview On Frequency Control of Power Systems With Wind Power Penetration51Mohamed BerririОценок пока нет

- Fitness Calculator Python ProjectДокумент12 страницFitness Calculator Python ProjectNishitha NeelamОценок пока нет

- User'S Manual: Multisync X551Uhd Multisync X651Uhd-2Документ56 страницUser'S Manual: Multisync X551Uhd Multisync X651Uhd-2Fernando Totoli FerreiraОценок пока нет

- Sigma-Amelung Trintity PC AMAX200 - Circuit DiagramДокумент5 страницSigma-Amelung Trintity PC AMAX200 - Circuit DiagramSoporte CicomerxОценок пока нет

- Samsung QE65Q8 QWH00Документ82 страницыSamsung QE65Q8 QWH00pedro perezОценок пока нет

- Digital Multimeter: Instruction ManualДокумент1 страницаDigital Multimeter: Instruction Manualphuong leОценок пока нет

- Electrical Safety ChecklistДокумент2 страницыElectrical Safety ChecklistmailxzОценок пока нет

- Analysis of Non-Salient Pole Synchronous Generator Using Phasor DiagramsДокумент19 страницAnalysis of Non-Salient Pole Synchronous Generator Using Phasor DiagramsNavitha RodriguesОценок пока нет

- Product Sheet: Nibp100D Noninvasive Blood Pressure Monitoring SystemДокумент3 страницыProduct Sheet: Nibp100D Noninvasive Blood Pressure Monitoring SystemSadegh ShebaniОценок пока нет

- Operating Systems From 0 To 1 PDFДокумент311 страницOperating Systems From 0 To 1 PDF3charlie52Оценок пока нет

- GPS900 Quick Guide enДокумент12 страницGPS900 Quick Guide enFlorin Marian IftimeОценок пока нет

- Pulse Oximeter Schematics Rev DДокумент2 страницыPulse Oximeter Schematics Rev DRene Gonzales VasquezОценок пока нет

- Dell Inspiron 5379 5579 7773 16888-1 Starlord ROR-L A00Документ106 страницDell Inspiron 5379 5579 7773 16888-1 Starlord ROR-L A00Jerzy LisowskiОценок пока нет

- Devising a solar powered standalone vehicle using GSM communication network for remote control and surveillanceДокумент3 страницыDevising a solar powered standalone vehicle using GSM communication network for remote control and surveillancePooja BanОценок пока нет

- Bio BatteryДокумент11 страницBio BatteryGurubasamma LОценок пока нет

- Emission and Interaction from Domestic Installations in the Low Voltage Electricity NetworkДокумент158 страницEmission and Interaction from Domestic Installations in the Low Voltage Electricity Networkrobert_rjcОценок пока нет

- Low Cost PCO Billing Meter PDFДокумент1 страницаLow Cost PCO Billing Meter PDFShrivlsi RamОценок пока нет

- Curriculum of Bachelor in Industrial EngineeringДокумент138 страницCurriculum of Bachelor in Industrial EngineeringPratikshya DevkotaОценок пока нет

- Review of Related LiteratureДокумент4 страницыReview of Related LiteratureMaria Blessie Navarrete100% (1)

- MS Progress Presentation M Ejaz MalikДокумент8 страницMS Progress Presentation M Ejaz Malikijaz sajjadОценок пока нет

- 126 UpdatedДокумент112 страниц126 UpdatednumantariqОценок пока нет

- Genway WL CM 03NL User ManualДокумент28 страницGenway WL CM 03NL User ManualVlad PetrescuОценок пока нет

- Sheet 3: DC and Synchronous MachinesДокумент8 страницSheet 3: DC and Synchronous MachinesMohammed Montaser50% (2)

- History of ICTДокумент20 страницHistory of ICTZakwan HamdanОценок пока нет

- Quantum Q-VISION HF Series BrochureДокумент6 страницQuantum Q-VISION HF Series BrochureReverieM100% (1)

- High-Efficiency Pure Sine Wave InverterДокумент5 страницHigh-Efficiency Pure Sine Wave Invertermariojrm74Оценок пока нет

- Tnstrument Transformers (CT, PT) TheoryДокумент6 страницTnstrument Transformers (CT, PT) TheorySARAVANAОценок пока нет

- High Power Programmable DC Power Supply: User ManualДокумент203 страницыHigh Power Programmable DC Power Supply: User Manualahsen siddiqueОценок пока нет

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesОт EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentОт EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentРейтинг: 4.5 из 5 звезд4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyОт EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyОценок пока нет

- Asset Integrity Management for Offshore and Onshore StructuresОт EverandAsset Integrity Management for Offshore and Onshore StructuresОценок пока нет

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successОт EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Build Your Own Electric Vehicle, Third EditionОт EverandBuild Your Own Electric Vehicle, Third EditionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeОт EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeРейтинг: 4 из 5 звезд4/5 (130)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureОт EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureРейтинг: 3.5 из 5 звезд3.5/5 (48)

- Implementing an Integrated Management System (IMS): The strategic approachОт EverandImplementing an Integrated Management System (IMS): The strategic approachРейтинг: 5 из 5 звезд5/5 (2)

- Handbook on Battery Energy Storage SystemОт EverandHandbook on Battery Energy Storage SystemРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksОт EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksОценок пока нет

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)

- The Rare Metals War: the dark side of clean energy and digital technologiesОт EverandThe Rare Metals War: the dark side of clean energy and digital technologiesРейтинг: 5 из 5 звезд5/5 (2)

- ISO 50001: A strategic guide to establishing an energy management systemОт EverandISO 50001: A strategic guide to establishing an energy management systemОценок пока нет

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОт EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsОценок пока нет

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesОт EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertРейтинг: 3 из 5 звезд3/5 (2)

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyОт EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyРейтинг: 5 из 5 звезд5/5 (3)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionОт EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionРейтинг: 4.5 из 5 звезд4.5/5 (16)