Академический Документы

Профессиональный Документы

Культура Документы

Maintainance Management

Загружено:

Simar KaurИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Maintainance Management

Загружено:

Simar KaurАвторское право:

Доступные форматы

AEREN FOUNDATIONS

Maharashtra Govt. Reg. No.: F-11724

AN ISO 9001 : 2008 CERTIFIED INTERNATIONAL B-SCHOOL

MARKS:80

SUB:MAINTENANCEMANAGEMENT

N.B. : 1) Please read the cases carefully 2) All questions are compulsory 3) Figures in the right margin indicate full marks 4) Total marks : 80 CASE 1 : Somalu Industries in Andhra Pradesh, is facing frequent break down. Its managing director, Mr D V K Soma Reddy is quite perturbed about these breakdowns. He was in the United States and worked there in sophisticated plants and also worked in Gulf countries, but never faced so many break downs. From Somalu Industries, internal records, the number of Breakdowns of Equipments, over the past 2 years are as furnished below : No. of Breakdowns No. of months of occurrence 0 3 1 7 2 1 3 3 4 2 Total 24

It has been worked out that each break down costs are average of Rs 3,000/preventive maintenance services can be hired at a cost of Rs 1500 per month, and is expected that preventive maintenance service, will limit the break downs to an average of one break down per month only. In this case, you are required to find out i) which maintenance arrangement is preferable; ii) the current break down maintenance policy or a preventive service contact; iii) Please give elaborate reasons for your comments on this case. (25 Marks)

CASE 2 : In Noida, the work shop of Mr Jagadhry has twenty identical machines. Senior Maintainance Supervisor, Mr B N Singh has recorded the failure pattern of the machines in Yagerdhry Industries. Mr B N Singh, did his B E(Mechanical), from Roorkee and after working for BHEL, a stint of 5 years, he went to Africa on deputation. After returning from Africa, Mr B N Singh opted for Jagudhry Industries, since Mr Jagudhry was personally known to him and Mr Jagudhry has an analytical bent of mind and always encouraged research/analysis. B N Singh has recorded the failure pattern of the machines in the following manner : Esimated Time (In months) After Maintenance Attention 1 2 3 4 5 6 Probability of Failure 0.20 0.15 0.15 0.15 0.15 0.20

Mr B N Singh, observed that it gots Rs 1500 to attend a failed machine and rectify the same. He also computed the cost of servicing the broken down machines. 1) In this case, you are required to find expected value of elapsed time (in month), i.e. the internal between two successfive break downs in months.

2) Expected no. of break downs per machine per year. 3) Total number of expected break downs for 20 machines per year. 4) Cost of servicing the driven down machine per year. 5) Give your elaborate comments on the findings, its interpretation and you suggestions for improved method or alternative method. (25 Marks)

CASE 3 : The dramatic success of the Japanese had been attributed to a large extent to the quality of their manufacturing goes quality is multi-dimensional but reliability is a key component of quality. In fact, product reliability was the top priority of the Japanese firms. Japanese automobile and other products have been highly successful in the US market and also gained a high market share. In fact, product quality are exceptional reliability of Japanese products, is the key reason for this. Reliability considers the performance of a product for long time. The random of interest concern the amount of elapsed time between failures after a product is placed into service. Thus, reliability is time based concept of quality. It is the probability that a product will operate adequately for or given period in the intended application. Sony, as an electronics manufacturer has gone above what many other electronic companies as such. Sony has brought great many inventions which have benefited mankind. Sony continues to innovate and has become a world class leader in reliable electronics. In this case, you are required to answer the following : 1) What is the link between reliability and maintenance, please elaborate. 2) List the aspects of from producers point of view. 3) What are the risks of poor reliability borne by the consumer. 4) What are the needs for Total Productive Maintenance. 5) What do you mean by Reliability Engineering and Reliability Quantification.

6) How `Failure Rate is computed. (30 Marks)

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

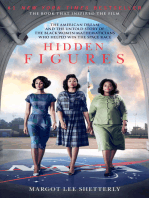

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Short Transmission Line Model: I I V V I ZДокумент4 страницыShort Transmission Line Model: I I V V I ZAlmer Jun GualdrapaОценок пока нет

- All-Wheel Drive Four-Wheel Drive Systems and Strategies PDFДокумент7 страницAll-Wheel Drive Four-Wheel Drive Systems and Strategies PDFjohn ayengahОценок пока нет

- Olevia LT26HVX LCD TV Service ManualДокумент35 страницOlevia LT26HVX LCD TV Service Manual33bОценок пока нет

- True RMS Voltmeter: Instruction ManualДокумент124 страницыTrue RMS Voltmeter: Instruction ManualRafa DuverheisenОценок пока нет

- Islic™: Intelligent Subscriber Line Interface CircuitДокумент24 страницыIslic™: Intelligent Subscriber Line Interface CircuitMark MeiОценок пока нет

- Multi-Battery IsolatorsДокумент4 страницыMulti-Battery IsolatorstoxicelОценок пока нет

- Computer System ServicingДокумент11 страницComputer System ServicingArman Santiago100% (1)

- Waterproof and Cleanroom Luminaires PDFДокумент13 страницWaterproof and Cleanroom Luminaires PDFdwi wahyu sugiartoОценок пока нет

- Mitsubishi E700 Variable Frequency Drive (VFD) Instruction ManualДокумент322 страницыMitsubishi E700 Variable Frequency Drive (VFD) Instruction ManualMROstop.com75% (4)

- 7 1 2 Valerio - LippariniДокумент35 страниц7 1 2 Valerio - LippariniDILLIBABU EОценок пока нет

- 1C - Communication Networks - Circuit SwitchingДокумент14 страниц1C - Communication Networks - Circuit SwitchingDang KhueОценок пока нет

- Time-Domain Modelling of Turbo-Compressors in Direct Injection Diesel EnginesДокумент13 страницTime-Domain Modelling of Turbo-Compressors in Direct Injection Diesel Enginesjossy2Оценок пока нет

- Techsheet KX6control 2010Документ5 страницTechsheet KX6control 2010mathousalasОценок пока нет

- User Guide For Adjustable Delay Timer Relay 12V & 24V 10AДокумент2 страницыUser Guide For Adjustable Delay Timer Relay 12V & 24V 10AThai TaОценок пока нет

- Bose: Competing by Being Truly DifferentДокумент4 страницыBose: Competing by Being Truly DifferentAngela AngelesОценок пока нет

- Kawai CN34 Owner's ManualДокумент132 страницыKawai CN34 Owner's ManualFlorin AlexeОценок пока нет

- HD Led Projector: User's ManualДокумент14 страницHD Led Projector: User's Manualmr_silencioОценок пока нет

- Automatic Street Light Control by Detecting Vehicle MovementДокумент5 страницAutomatic Street Light Control by Detecting Vehicle MovementBhupendra(Rahul...) kumarОценок пока нет

- Ventilator-Centrifugal-CBD-Sodeca 575 Lei 1570mchДокумент5 страницVentilator-Centrifugal-CBD-Sodeca 575 Lei 1570mchSilviu-Ionut DumitracheОценок пока нет

- Aoc 152v Tsum16akДокумент49 страницAoc 152v Tsum16akedyОценок пока нет

- SPCD3C2Документ15 страницSPCD3C2ARA CESPEDES JORGEОценок пока нет

- UPS Battery Maintenance 101 - EC&MДокумент6 страницUPS Battery Maintenance 101 - EC&MZiad BadrОценок пока нет

- ATX PC Power Supply Diagnostic FlowchartДокумент31 страницаATX PC Power Supply Diagnostic FlowchartWali SauyunanОценок пока нет

- Team08 Final Design Report PDFДокумент221 страницаTeam08 Final Design Report PDFCraneo LocoОценок пока нет

- Aftershokz AF800 ManualДокумент9 страницAftershokz AF800 Manualhe4gsОценок пока нет

- A Practical Training From Reil (Rajasthan Electronics & Instruments LTD.) INДокумент38 страницA Practical Training From Reil (Rajasthan Electronics & Instruments LTD.) INRishi Raj RathoreОценок пока нет

- PSoC3 Architecture TRM 001-50235Документ456 страницPSoC3 Architecture TRM 001-50235nickynick2007Оценок пока нет

- Delta-Q IC Series: User Manual: Important Safety and Operating InstructionsДокумент5 страницDelta-Q IC Series: User Manual: Important Safety and Operating InstructionsGaryОценок пока нет

- Application of Transistor As AnДокумент16 страницApplication of Transistor As AnSudhagar KingОценок пока нет

- Parker Pneumatic Sensors PDFДокумент25 страницParker Pneumatic Sensors PDFyouri59490Оценок пока нет