Академический Документы

Профессиональный Документы

Культура Документы

Fish Bone Diagram

Загружено:

Saurabh RaiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fish Bone Diagram

Загружено:

Saurabh RaiАвторское право:

Доступные форматы

Report on GPDP Project in an Edible Oil Industry in India

Chapter 6.0: Cause Effect Analysis & Generating GP options 6 .0 CAUSE EFFECT ANALYSIS & GP OPTIONS

The cause effect analysis was carried out of all the identified waste streams/problem areas. Following are the waste streams/problem areas for which cause effect analysis was carried out: Waste Stream-1 Waste Stream-2 Waste Stream-3 Waste Stream-4 Waste Stream-5 Waste Stream-6 Waste Stream-7 Waste Stream-8 : : : : : : : : Oil loss in DOC Oil loss in Refinery Hexane loss in Solvent Extraction Plant Waste water generation & its treatment Energy loss Inadequate steam generation leading to high oil & hexane loss Inadequate Air Pollution Control Devices (APCD) Improper material handling & house keeping practices

The objectives of cause effect analysis were to generate Green Productivity options for reduction/elimination of waste streams and evolve solutions for problem areas for generating Green Productivity options. For this purpose appropriate tools and techniques such as Fishbone Diagram (Ishikawa Diagram), Eco-mapping, brainstorming etc. were used. The detail of the cause effect analysis is presented below for all the waste streams & problem areas.

6.1

OIL LOSS IN DOC (HIGH RESIDUAL OIL CONTENT IN DOC) General observations & present practices

6.1.1 (A)

Out of the 19.75% oil content in the seed, an average of 18.57% oil is extracted and the remaining is lost and goes along with DOC, i.e. an extraction efficiency of about 94%. The loss of oil is due to combined effect of several causes at various process stages, each one having some effect on oil extraction efficiency. The residual oil content in DOC varies from 0.7% to 1.5%. The average residual oil content in RPL is 1.18% as compared to 0.5% in Japan. In India, there is no established benchmark for oil loss in DOC.

National Productivity Council, New Delhi (India)

Page:6. 1

Report on GPDP Project in an Edible Oil Industry in India

This oil loss of 1.18% (out of 19.75% oil content in seed) amounts to about 990 tones of oil loss per year. A 10% reduction in this oil loss would save about 99 T/year amounting to about Rs.21.8 lakh/year. Calculation: Seed Processed Average oil content in seed Average oil extracted from seed Crude oil production Cost of crude oil DOC Production Cost of DOC Cost of waste stream: Oil loss in DOC = 10% reduction in oil loss in DOC = [10%x1.18%X1, 00, 000 T/yr seedx84%] Saving potential 99 t @ Rs 22/kg) = (B) Concerned process steps: PREPARATORY: Cracker Cooker Flaker Extractor DTDC 1.18% (goes with DOC) 99 T oil/yr Rs. 21.8 lakh/year = = = = = = = 300 TPD = 19.75% 18.57% 18,000 T/yr Rs.22, 000/T 83,000 T/yr Rs. 7,000/T 1,00,000 T/yr

SEP:

(C)

Environmental pollution problem:

This does not contribute direct environmental pollution problem. But the productivity of the organization goes down in the form of loss of product. 6.1.2 Cause effect analysis The various tools for the identification of the causes of oil loss in DOC have been applied. In line with identification of causes & their effect, a fish bone diagram-(Isikawa Diagram) was prepared showing causes of total oil loss with respect to man, machine, material, methods and environment and is presented in Figure-6.1.

National Productivity Council, New Delhi (India)

Page:6. 2

Report on GPDP Project in an Edible Oil Industry in India

Figure-6.1: Fishbone Diagram depicting Soy Oil loss

Inadequate Temp Machine Environment Non Compliance

Poor splitting Inadequate oil separation Less residence time Inadequate ETP High oil presence in wastewater

Inadequate steam supply in SEP

Less Vacuum High residual oil in DOC

Improper Cooker

Inadequate Capacity Less heating surface area for indirect steam

Man Improper house keeping Inadequate training

Less drainage time for miscella Inadequate spray of hexane

Improper cracking

Presence of stone Worn Out rollers Poor Maintenance

Improper Extractor Unskilled labour Mind set

Worn out rollers

Insufficient Residence time

Improper Flaker

Leakage from oil

handling pumpsWearing off of oil seal Improper addition of Caustic

Excess water addition

Faulty water flow meter

Absence of flow meter

No proper working Instruction Faulty bleaching Process Combined degumming & Neutralisation

Distribution loss Inadequate Boiler capacity

Oil Loss

High moisture content Green seed Damaged seed Excess foreign matter

Improper steam supply No proper record keeping Inadequate Cracking & Flaking Improper seed preparation

Inadequate cooking Absence of flow meter & instant measurement of FFA

Poor quality of seed

Considering average thickness instead of standard deviation Faulty quality control of flake thickness

Poor quality of bleaching earth

Improper Cleaning of seed Poor maintenance of pumps & glands Method

Excess use of bleaching earth Improper addition of Caustic

Faulty flow meter

Thick flaking

Power interruption

Excess addition of water No proper working Instruction Material

Improper seed preparation

High residual oil in DOC

National Productivity Council, New Delhi (India)

Page:6. 3

Report on GPDP Project in an Edible Oil Industry in India

Causes for oil loss in DOC: Various causes identified for the oil loss in DOC are summarized below: 1. Less efficient Cracking: wide variation in seed size and there is no grading of seed, worn out Roller, stone in seed 2. Inadequate Cooking: small size of cooker, less heating surface 3. Less efficient Flaking: worn out Roller, inadequate Cracking & Cooking 4. Less efficient Extraction: low drainage time, improper hexane spray, inadequate Cracking, Cooking & Flaking The details of the causes are discussed subsequently:

6.1.2.1

Cause:

Less Efficient Cracking

Best practices: The best practice of cracking recommends that the cleaned seed should be cracked by shear action to 4 - 6 pieces. There should not be any whole grain seed. This enables the seed for proper cooking & flaking. Inefficient cooking & flaking results in high oil content in DOC.

Field study data:

C racking:

Cleaned Seed

Percentage size distribution of cracked seed Half Seed 34% < Half Seed 37% Whole Seed 29% Whole Seed

E scaped seed

E scaped seed

Half Seed

< Half Seed

Cracked seed along w ith Whole seed

Figure-6.2 Seed cracking & size distribution of cracked seeds

National Productivity Council, New Delhi (India)

Page:6. 4

Report on GPDP Project in an Edible Oil Industry in India

The cleaned seed is passed through cracker to break the seed into four to six pieces. A representative sample was collected at the inlet of the flaker and sieved to separate whole seeds, half seeds and less than half seeds to find out the cracking efficiency of the cracker. The seed cracking & size distribution of cracked seed is given at Figure-6.2. The percentages of whole and half seed are very high. The reasons for inefficient cracking was attributed to the following: There is large variation in seed sizes The rollers were found to be damaged by way of pitting of surfaces as well as blunting of cutting edges. This is due to presence of stone in the seed and excess use of the existing rollers.

Conduction of trials: The trials were conducted to establish the relation between whole bean content in crushed bean & thickness of flake and between thickness of flake and extraction yield. The trial results are given below:

Trial: Relationship between whole bean content in crushed bean and thickness of flake Higher content of thick flakes brought about higher remaining oil content and the large amount of whole bean in crushed soybean led to higher content of thick flakes. This relationship was determined quantitatively as shown in Table 6.1

Table-6.1 :

Relationship between whole bean content and flake thickness No.1 Narrow 3.3% Ordinary 0.36mm 68% 30% 0% Ordinary 5.4% Ordinary 0.38mm 82% 50% 4% No.2 Narrow 3.2% Ordinary 0.35mm 60% 25% 0%

Seed Cracker Clearance roller of crushing Ordinary

Whole bean after Cracker 8.1% Flakes Clearance Thickness of flake Average >0.35mm >0.40mm >0.45mm 80% 54% 9% Ordinary 0.39mm

National Productivity Council, New Delhi (India)

Page:6. 5

Report on GPDP Project in an Edible Oil Industry in India

Trial: Relationship between thickness of flake and extraction yield Soybean flakes were separated into two portions i.e.(<0.35mm and >0.35mm thickness) by hand and extracted with hexane for 90 min. in laboratory.

Table 6.2:

Relationship between flake thickness and oil yield Oil yield 19.42% 19.25% Difference 0.17%

Thickness of flakes <0.35mm >0.35mm

The results shown in Table 6.1 & 6.2 indicate that it is very important for low oil content in DOC to decrease the whole soybean contained in crushed bean and to keep the uniform thickness of flakes (0.33-0.37). Observations: Based on the above analysis, it was identified that the existing cracking efficiency was lower. The identified reasons are summarized below: (i) (ii) (iii) Effects: Inefficient cracking leads to higher percentage of off-sized cracked seed (powder or hole seed content) adversely affecting further process steps such as cooking and flaking and ultimately oil extraction. Wide variation in seed size and no grading of seed Worn out roller Presence of stone in the seeds

GP option evolved: To minimize the adverse effect due to less efficient cracking, following GP options were evolved: 1. 2. 3. Installation of Seed grader with conveyance system for the grading of seed before cracking. Replacement of worn-out roller of the cracker. Putting in operation the existing de-stoner equipment.

National Productivity Council, New Delhi (India)

Page:6. 6

Report on GPDP Project in an Edible Oil Industry in India

6.1.2.2

Cause Inadequate Cooking

Best practices: As reported by management, the best practices of cooking recommend following controlled parameters for adequate cooking of seeds. Temperature during cooking Residence time in the Cooker Moisture in the cooked seed 800C 45 to 60 minutes max. 10%

Field study data: Cooking of cracked seeds before flaking is required to plasticise the kernel particles. Plasticity is essential to produce optimum thick flakes. It has been observed that the residence time available in the cooker was only 15-20 minutes, which is less than the desired value of 45-60 minutes. The heating surface area of the cooker was found to be inadequate. The temperature of the cooker is maintained through direct steam as well as indirect steam. There is no temperature gauge installed to control the temperature inside the cooker. The inadequate cooking in the cooker leads to poor flaking and extraction of oil and finally contribute in increasing the oil content in DOC The details of the study to identify the causes of inadequate cooking is given below:

1.

Presently a sample is drawn into a polyethylene bag in which thermometer is inserted to measure temperature which is done generally two hourly. As there is no temperature gauge installed, a continuous controlled temperature cannot be ensured at all time. A thermo-couple installed on the cooker frequently comes under maintenance due to dust deposition, which leads to erroneous reading, and therefore it has been taken out.

2.

As regards to maintaining requisite moisture percentage direct steam is supplied into the cooker, which (in addition to increasing moisture percentage) contributes in cooking purpose. The indirect steam also contributes in cooking. At times when moisture percentage in seeds is higher, addition of direct steam would increase further moisture beyond desirable limit. To avoid the same, the direct steam supply needs to be reduced. But this leads to inadequate cooking of the material because indirect heating alone is not sufficient to raise the temperature to the desired extent. In such cases, the residence time needs to be increased or feed rate needs to be reduced.

National Productivity Council, New Delhi (India)

Page:6. 7

Report on GPDP Project in an Edible Oil Industry in India

Observation: Keeping specially the situation in higher moisture seed, limiting direct steam, as the present heat transfer area of indirect steam pipe is inadequate and to improve the cooking, the heat transfer area of indirect steam pipe has to be increased.

Effects: Inadequate cooking has adverse effect in terms of improper flaking due to inadequate plasticity, which ultimately affects in terms of oil loss.

GP option evolved: To minimize the adverse effect due to inadequate cooking, following GP options were evolved: 1. 2. Increase the heating surface area in the cooker by adding more steam pipes (limpets) Install a new cooker of requisite size.

6.1.2.3

Cause:

Less efficient flaking

Best practices: The best practices of flaking recommend that the thickness of flakes vary between 0.33mm to 0.37mm. Flake thickness more than 0.37mm leads to high oil content in DOC. Thinner flakes (less than 0.33mm thickness) generate more sediments and inhibits during extraction which is carried out by spraying hexane over the flakes in the extractor. Field study data: The flakers in the preparatory section have been examined and found that uneven roller gap in one of the flakers results in the thicker flakes. The rest of the flakers required proper maintenance. The roller gap has to make uniform for uniform flake thickness. Thicker flake leads to high oil content in DOC. The diagram given below shows the details:

F laking :

Cracked & Conditioned Seed

Flakes

National Productivity Council, New Delhi (India)

Page:6. 8

Report on GPDP Project in an Edible Oil Industry in India

The conditioned cracked seed passes through the flaker to produce flakes. The optimum thickness of the flakes is 0.33mm- 0.37mm. To find out the uniformity of flakes produced by flaker, the samples were collected and measured for the flakes thickness distribution. The measured variation in flake thickness and percentage distribution of flakes thickness is given at Figure 6.3.

Percentage Distribution of Flake thickness 0.25-0.32 mm 17% 0.33-0.37 mm 13% 0.38-0.43 mm 58%

0.25-0.32

> 0.43 mm 12%

Flake thickness range % in total 17% 0.25-0.32 13% 0.33-0.37 58% 0.38-0.43 12% >0.43

0.33-0.37

0.38-0.43

> 0.43

0.7 0.6

0. 59

Thickness of the flake

0.5

0. 45 0. 44 0. 41 0. 45 0. 44

0. 5 0. 47

0.4

0. 42 0. 42 42 0. 0. 41 0. 41 0. 41 0.41 0. 4 0. 4 0. 4 0. 4 0 . 4 0. 4 0. 4 0 . 4 0 . 4 0. 4 0. 4 0. 4 0. 4 0 . 4 0. 4 0. 4 0. 4 0. 39 0. 39 0. 3 9 0. 383. 3 83 383 383 383 383 383 383 3 80. 380. 383 383. 3 83. 38 3 383 383 383 383 383 383 383 383 383 383 380. 383 383 383. 3 83. 38 3 383 380. 3 8 383 383 383 383 383 383 3 83. 380. 383 383 3 83. 3 83 38 3 383 383 3 83 383 383 383 383 383 383 3 83 380. 383 383 3 8 0 0. 0. 0. 0. 0. 0. 0 . 83 3 0. 0 0 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0 . 3 0. 0. 0 0 0. 0. 383 83 0. 0. 0. 0. 0. 0 . 0 0. 0. 3 0. 0. 0 0. 0. 0. 0. 0. 0. 0. 0. 0. 0. 0 . 0. 3 0. 0. 83 0.37 0. 36 0. 36 0. 36 0. 35 0. 35 0. 35 0 . 34 0. 31 0.29 0. 25 0. 3 0. 3 0. 31 0. 28 0. 3 0. 31 0. 3

0.3 0.2

0.29

0.1 0

10 13 16 19 22 25 28 31 34 37 40 43 46 49 52 55

sa m p l e n o .

Se r i e s 1

Ser i es 3

Se r i es 4

Ser i es 2

Figure-6.3: Measured variation in thickness of flakes & percentage distribution

The average of the flakes have been found to be 0.38 mm-0.43mm thick. The percentage of thick flakes (>0.38mm) is as high as 70% which is undesirable for proper extraction in extractor, resulting high residual oil content in DOC. The capillary paths must be short so that the distance over which diffusion occurs is as short as possible. These thick flakes are causing high residual oil (1.2%) in DOC against the achievable 0.7-0.9% residual oil.

National Productivity Council, New Delhi (India)

Page:6. 9

58

Report on GPDP Project in an Edible Oil Industry in India

The unit had already made some attempts to bring down this residual oil level to <1.2% but it yielded poor quality of oil with impurities like phosphetides. This has occurred due to the excessive extraction of oil from the flakes, which are having optimum thickness of (0.33-0.37mm). The residual oil of 1.2% is the average content in DOC. Among the DOC, residual oil varies from 0.5% to >2.5% depending upon the thickness of the flakes. It was observed that flakes produced from the centre of the flaker are comparatively thicker than flakes produced from the ends. This is due to excessive wear occurring at the centre compared to the ends because of more material passing through the centre. Moreover every day 7.83 tons of foreign matter (1.82% of raw material) passes through the flaker. The foreign material mostly silica related only, is abrasive.

Excessive wear at the centre

FLAKER R OLLS

FLAKER R OLLS

Figure-6.4: Uneven gap between rollers affecting efficiency of Flaker

Observations:

Based on the above analysis and study, it was identified that the flaking is inefficient. The identified reasons are summarized below: i) ii) Worn-out flaker roller Inadequate cracking and cooking

Effects: It is clear that there is direct relationship between flake thickness & residual oil content in DOC. As the thickness of the flake increases, oil content in DOC increases. GP option evolved: To minimize the adverse effect due to high thickness of flakes, following GP options were evolved: a) Repair worn-out roller of the flaker b) Replace irreparable roller of the flaker.

National Productivity Council, New Delhi (India)

Page:6. 10

Report on GPDP Project in an Edible Oil Industry in India

6.1.2.4

Cause:

Less efficient extraction

Best practices: The best practices of extraction recommend that the spray of hexane should be done uniformly over larger surface area of flakes/collets. The residence time in the extractor should be between 1.5 hrs to 2.5 hrs. There should adequate drainage time to drain out Miscella from wet DOC.

Field study data: It has been observed that the existing hexane spray system does not provide uniform quantity of hexane spray over the flakes/collets. There are no baffles to divert the flow of hexane at different angles to reach over maximum surface area of flakes/collets. It needs modification. Also, only two baskets are kept for draining the Miscella from wet DOC. It has been observed that the hexane concentration in wet DOC is more due to less drainage time. This helps in carrying oil along with DOC and result in high oil content in DOC. In addition, high concentration of hexane in wet DOC leads to high load on desolventisation process in DTDC.

Observations: Based on the above study, it was identified that the extraction efficiency was poor due to following reasons: i) ii) Low drainage time in the extractor Inefficient hexane spray system

Effects: Poor extraction leads to high residual oil content in DOC.

GP option evolved: To increase the extraction efficiency, following GP options were evolved: a) b) Increase the hexane drainage time in Extractor Improve the hexane spray system

National Productivity Council, New Delhi (India)

Page:6. 11

Report on GPDP Project in an Edible Oil Industry in India

6.2

OIL LOSS IN REFINERY General observations & present practices

6.2.1 (A)

The unit is processing 30,000 Ton crude oil in a year. The average refinery losses are 7%. The oil loss results in low yield of refined oil, high pollution load to the ETP and generation of low cost by-product like soap stock. There is room for improvement and even by reduction of 0.35% in present losses may lead to saving of Rs. 23.1 lakh per annum. The details are discussed as below: Average Crude Oil processed Average Refined Oil production = = 100 TPD 93 TPD = = 30,000 T/yr 27,900 T/yr

Cost of waste stream: Oil loss in Refinery 0.35% reduction in oil loss in Refinery [0.35% X30,000 T/yr oil] Saving potential 105 T @ Rs 22/kg) = = = 7% of the crude oil processed 105 T oil/yr Rs. 23.1 lakh/year

(B)

Concerned process steps: SHORT-MIX PLANT BLEACHER DE-ODORISER DEGUMMING & NEUTRALISATION BLEACHING DE-ODORISATION

(C)

Environmental pollution problem:

This is the major area of environmental pollution. The wastewater from the short-mix plant, spent bleaching earth from bleacher and odiferous compond come out from the de-odoriser are the major water, solid and air pollution.

6.2.2 Cause effect analysis The various tools for the identification of the causes of oil loss in Refinery have been applied. In line with identification of causes & their effect, a fish bone diagram was prepared showing causes of total oil loss with respect to man, machine, material, methods & environment and has already been explained in Figure-6.1.

National Productivity Council, New Delhi (India)

Page:6. 12

Report on GPDP Project in an Edible Oil Industry in India

Causes for oil loss in refinery: The various causes identified for the oil loss in Refinery are summarized as under: 1. Excess water addition in hydration & neutralization: faulty Flow Meter 2. Absence of one washing separator 3. Possibilities of excess caustic addition in neutralization: no Flow Meter, manual dosing, excess Saponification 4. Use of low grade bleaching earth: high oil carry over (in spent bleaching earth.), possibilities of color reversal 5. Improper bleaching earth addition: addition of powder in place of slurry 6. Oil leakage from pump: worn out seal The details of the causes are discussed subsequently.

6.2.2.1

Cause:

Excess water addition in hydration & Neutralisation

Best practices: The best practice of water addition for degumming is quantity of water (in %) should be in equal proportion to the percentage of gum present in the crude oil. Similarly, the water is required for the Caustic Preparation depends on the concentration required to neutralize the Free Fatty Acid. In addition, water is used for flushing of separator. Observations & field study data: The hot water is mixed with the oil for hydrolysis of gum and subsequently separation in the separator. The quantity of water should be equal to the quantity of gum present in the crude oil. However, due to faulty water meter/ flow meter, the water addition was found to be at higher rate. The monitoring results are tabulated below: Location of water flow meters Before Hydration Tank-1 Before Hydration Tank-2 For flushing water at separator-2 For flushing water at separator-4 Water flow rate as per flow meters (lit. per hour) 122 88 155 170 TOTAL

National Productivity Council, New Delhi (India)

Measured water flow rate (lit. per hour) 130 267 360 410

Water saving after calibration (lit. per day) 192 3,580 4,920 5,760 14,452

Page:6. 13

Report on GPDP Project in an Edible Oil Industry in India

Estimated total water saving

= =

14.0 m3/day (approx.) 4,200 m3/annum

The reaction of water with oil & fats i.e. hydrolysis of oil & fats is given below: NaOH & Water Tri-glyceride Di-glyceride +FFA Heat Hydrolysis of Fats & oil EFFECTS: Excess water addition hydrolyses the oil and forms emulsion and reduces concentration of soap stock, leading to excess refinery oil loss and generation of excess wastewater.

GP option evolved: To minimize the adverse effect due to excess water addition, following GP options were evolved:

a)

The existing water flow meter should be rectified/ calibrated to give accurate reading

6.2.2.2

Cause:

Absence of one washing separator

Best practices: As per the recommendation of ALFA Level (Supplier of Short-Mix Plant), the degumming, neutralization & washing Operations should be carried out in three different separators. There are two sets of separators. Therefore, for 100TPD production, the total number of separators should be 6. But in RPL, there are only 5 separators. The present practice is degumming & Neutralisation operations are carried out in one separator and two separators are use at a time for degumming & Neutralisation. But for washing only one separator is used. Therefore, there is high load on the washing separators and it affects the quality of neutral oil and results in refinery loss.

Observations & field study data: The analysis results of TFM concentration in wastewater indicate that there is problem in washing of neutral oil through single separator instead of recommended two separators. To explore possibilities of reducing oil loss, trials were conducted.

National Productivity Council, New Delhi (India)

Page:6. 14

Report on GPDP Project in an Edible Oil Industry in India

Trials: The wash water quality and characteristics at different flow rates /processing of oil through the existing washing separator have been monitored & analysed. The results are discussed below: Case (I): Oil Flow rate : 5000 litres/hr Wash water quantity: 1205 l/h Characteristics of wash water: pH COD TFM FFA Case (II): 11.1 58,500 mg/l 1.36% 52.12%

Oil Flow rate : 2500 litres/hr i.e. at 50% Wash water quantity: 1200 l/h Characteristics of wash water: pH COD TFM FFA 10.4 14,700 mg/l 0.32% 24.01%

Case (I):

Water required for processing of oil at 5000 litres/hr = 1205 litres/hr Total TFM loss = 16.39 litres/hr Water required for processing of oil at 2500 litres/hr = 2400 litres/hr Total TFM loss = 7.68 litres/hr

Case (II):

Therefore, total difference in TFM loss due to single washing separator is 113% i.e. 174 litres/day.

Effects: Wastewater difficult to treat because of the presence of hydrated soluble gums. More oil loss in refinery.

GP option evolved: To minimize the adverse effect due to lack of one washing separator, following GP options were evolved: a) Use of 2 Washing Separators in place of one. b) Separate degumming and Neutralisation.

National Productivity Council, New Delhi (India) Page:6. 15

Report on GPDP Project in an Edible Oil Industry in India

6.2.2.3

Cause: Possibilities Neutralisation

of

excess

caustic

addition

in

Best practices: To neutralize the Free Fatty Acid (FFA) present in the crude oil, caustic lye at 16 to 20 degree Boumen is added. The quantity of caustic solution addition depends on the quantity of FFA present in the crude oil. About 20% excess caustic is added for effective neutralization of FFA and reduction of color.

Observations & field study data: There is no flow meter installed to know the quantity of caustic being added. It is judged by checking pH, which indicates that the solution has come to the alkaline range only. But how much excess caustic has been added, is still unknown to the operator.

Effects: The excess alkali saphonify the neutral oil and leads to more refining loss. It generates lower cost soap-stock, which consume more Sulphuric acid for acid oil production and generates more acidic wastewater. Thus resulting more pollution. This also results in the wastage of raw material, adding to the cost of production.

GP option evolved: To minimize the adverse effect due to excess caustic addition, following GP option was evolved: a) Installation of automatic caustic dosing system

6.2.2.4

Cause:

Use of low grade bleaching earth

BEST PRACTICES: The bleaching earth is used to reduce the colour to the desired level. There should not be problem of colour reversal and retain lesser oil in the spent bleaching earth.

OBSERVATIONS & FIELD STUDY DATA: The unit is using Indian earth during season (i.e. from October to March). As per the management opinion, during this time, the color of the oil is not permanent & it is easily come down to desired level through Indian earth.

National Productivity Council, New Delhi (India) Page:6. 16

Report on GPDP Project in an Edible Oil Industry in India

Whereas, during off season (i.e. from April to September), the unit is using Tonsil to reduced the permanent colour up to desired level. The unit is facing color reversal problem from the market. Therefore, the APO-Oil Expert suggested using Tonsil in place of local Indian Bleaching Earth for better stability of oil.

Characteristics & cost of different bleaching earth: a) Indian Earth: b) Tonsil: Bleaching efficiency Cost Oil content in spent bleaching earth Consumption of bleaching earth = = = = 75% Rs. 30,000/- per ton. 19 to 20% 6 kg/T of oil Bleaching efficiency Cost Oil content in spent bleaching earth Consumption of bleaching earth = = = = 65- 70% Rs. 18,000/- per ton. 22 to 25% 6 kg/T of oil

Effects:

The local bleaching earth does not give stability to the colour of refined oil. Further, the efficiency of colour removal is not effective.

GP option evolved: To minimize the adverse effect due to the use of local (Indian) bleaching earth, following GP options were evolved: a) Use of Tonsil in place of Local (Indian) bleaching earth.

6.2.2.5

Cause:

Improper bleaching earth addition

Best practices: The bleaching earth should be added in slurry form instead of powder. The slurry should be prepared with the neutral oil to be bleached separately and mixed into the bleacher.

National Productivity Council, New Delhi (India)

Page:6. 17

Report on GPDP Project in an Edible Oil Industry in India

Observations & field study data: The bleaching earth is dosed through hopper into the bleacher. The dosing is adjusted based on the flow rate & color of oil, quality of bleaching earth. The bleaching earth freely falls on the surface of the oil in the bleacher. Effects: The fine powder of bleaching earth is being sucked during charging into the bleacher over the oil surface due to vacuum in the system. This is a loss of bleaching earth. The mixing of powdered bleaching earth is not uniform results in ineffective bleaching of neutral oil. GP option evolved: To minimize the adverse effect due to wrong method of bleaching earth addition, following GP options were evolved: a) Addition of bleaching earth slurry in place of powder. b) Lowering the pipe and dip in the oil. 6.2.2.6 Cause: Oil leakage from pump

Best practices: The oil is transferred at various stages by means of pumps. The seal of the pumps should be properly maintained so that there should not be any spillage/leakage from the pump gland. Observations & field study data: It has been found that the gland seal of transfer pump transferring crude oil, neutral oil, bleached oil and refined oil were faulty. It was not replaced/maintained for the long time resulting in the leakage of oil through gland seal. Effects: The oil leakage results in a low yield of refined oil. It creates major pollution load in the wastewater once it mixed into the waste streams. Further, it is the loss of resources. GP option evolved: To minimize the adverse effect due to oil leakage from pump, following GP options were evolved: a) Preventive maintenance of gland seal & timely replacement

National Productivity Council, New Delhi (India)

Page:6. 18

Report on GPDP Project in an Edible Oil Industry in India

6.3

HEXANE LOSS IN SEP General observations & present practices

6.3.1 (A)

The hexane is used as a solvent for the extraction of oil. On an average, specific hexane loss/ consumption is in the range of 4.93 (3.64- 5.4) litres per ton of seed processed compared to 1.0 to 1.5 litres per ton in Japan. The hexane loss is due to following points: Carry over along with crude oil Uncondensed vapor going through final vent of recuperation unit Carry over with meal drying air in Meal Dryer Carry over with DOC Hexane loss from Leakage

Carryover along with Crude oil: Stripping is the final step in separating the hexane from Miscella and is carried at 1200C and 380 mm Hg vacuum. The desired vacuum is 450mmHg. Live steam is also sparged. It was estimated that hexane loss through crude oil accounts for 2-3% of total losses.

Uncondensed vapor going through final vent of recuperation unit: Wet DOC entering into the DTDC contains approximately 30-40% solvent. Since wet DOC has less draining time available in extractor, the solvent content in DOC is high. Only two hoppers are provided to collect the solvent draining from wet DOC by gravity. Sufficient draining time curtails desolventisation load on DTDC. Uncondensed vapour loss through final vent accounts for 10-12% of total loss. This is due to the inefficiency of condensers. In addition to this, air ingress takes place from the DOC outlet due to lack of rotary valve at DOC outlet. This leads to lower condensation temperature at which solvent does not condense.

National Productivity Council, New Delhi (India)

Page:6. 19

Report on GPDP Project in an Edible Oil Industry in India

Wet DOC Solvent Vapor

Air ingress

Desolventiser

Scerewconveyor for tranferof DOC

Toaster

Air inlet

Dryer Cooler

Air outlet

Figure- 6.5: DTDC stages Recuperation system is provided to absorb the uncondensed vapour before going to the final vent. The system contains mineral oil in closed system, which absorbs uncondensed vapour and release upon heating the recovery system. Due to fluctuation in the steam supply and insufficient heating surface available for solvent release from absorbing oil in recovery system, hexane concentration increases in the mineral oil and, therefore, mineral oil does not absorb uncondensed vapour efficiently.

Carryover with meal drying air in Meal Dryer: There is 70%-80% of total hexane loss in meal drying section. This is due to the incomplete desolventisation of DOC in desolventisation section. In most of the plants, which have reduced their hexane loss to 1-1.5 lit/ton, a counter current DTDC with four desolventisation trays and four toasting trays, has been provided. Steam is given from the bottom of the section and it travels towards the upper section where the DOC falls from top to bottom. Heat is transferred efficiently from the steam to meal. In lower trays, steam loses temperature by supplying its specific heat to the final traces of solvent contained by meal and in the upper tray steam condenses to give its latent heat to the meal to vaporise the solvent. In this unit DTDC contains only two desolventisation trays and two toasting trays. Steam is supplied at the bottom of the two toasting sections through a 50mm perforated coil placed at the circumference of the tray, and passes to the upper trays through the meal outlets. Since the DTDC is inadequately designed desolventisation remains incomplete and the residual hexane is being carried over to the dryer section where it is being exposed to large quantity of air/ hot air. The residual hexane carried by the air is impossible to recover.

National Productivity Council, New Delhi (India)

Page:6. 20

Report on GPDP Project in an Edible Oil Industry in India

Meal outlet

Meal Outlet

Sparge Ste

Sparge steam coil

Figure-6.6: Internal arrangement of DTDC

National Productivity Council, New Delhi (India)

Page:6. 21

Report on GPDP Project in an Edible Oil Industry in India

Carryover with DOC: Hexane carried over with DOC is estimated to be 5-7% of the total hexane loss. The DOC contains average residual oil content of 1.18%, which also contains some hexane. This adds to the problem of incomplete desolventisation. Improving the process conditions in desolventisation section can bring down the entrapped solvent percentage in DOC.

Hexane loss (emission) from Leakage The poor maintenance of the extractor gear box and DTDC shaft leads to leakage of hexane from the system. Though the concentration is negligible but smell of hexane from the gearbox of extractor and DTDC shaft has been observed.

Field data Reported hexane loss = During season (Oct-March)= Off season (April-Sep.) = interruption) Best figure for hexane loss = 4.93 lit/T of seed 3.64 lit/T (continuous operation, less interruption.) 5.40 lit/T (non continuous operation, more 1.0 to 1.5 lit/t of seed (Japan)

Cost of waste stream: 10% reduction = 0.49% (4.93 lit/T 4.43 lit/T) Saving potential (0.49 lit//Tx1 lakh T/yr @ Rs. 19 per lit.) = = 49300 lit/yr 9.4 lakh per year

(B)

Concerned process steps: PREPARATORY : Cracker Cooker Flaker Extractor DTDC

SEP

(C)

Environmental pollution problem:

The fugitive hexane emission generates air pollution. Also, excess concentration of hexane in the air may lead to fire hazard.

National Productivity Council, New Delhi (India)

Page:6. 22

Report on GPDP Project in an Edible Oil Industry in India

6.1.3 Cause effect analysis The various tools for the identification of the causes of oil loss in DOC have been applied. In line with identification of causes & their effects, a fish bone diagram was prepared showing causes of hexane loss with respect to man, machine, material, methods and environment and is presented in Figure-6.7.

Causes for hexane loss: 1. Inadequate vacuum in DTDC & distillation: inadequate steam, inadequate cooling & condenser 2. Inadequate de-solventisation in DTDC: inadequate steam, inadequate heating surface area 3. Inadequate drainage in extractor: inadequate drainage time, higher hexane concentration in wet DOC 4. Inadequate recuperation: inadequate absorption/release of hexane 5. Inadequate crude oil stripping: inadequate steam & vacuum, inadequate condenser size. The details of the causes are discussed subsequently:

6.3.2.1

Main Cause: Inadequate vacuum in DTDC & distillation

Best practices: The vacuum in DTDC & distillation is required for efficient separation of hexane from the DOC & crude oil respectively. The desired vacuum should be 5 to 10mm/wc. The constant and uniform steam supply is required for better performance of SEP.

Field study data: Presently, vacuum in system is 380 mmHg at stripper condenser against desired vacuum of 450 mmHg. There is fluctuation of steam due to power interruption and poor performance of Boiler. Previous year, the unit faced 189 times power failure up to 78 hrs and steam interruptions of 249 times up to 421 hrs. The steam used in the DTDC and distillation is 50-54 MT and 28 MT/day respectively. The cooling water temperature was monitored to be 25-27 deg C, whereas in Japan the temperature used is 6 deg C through refrigeration plant. The difference of temperature at the inlet & outlet of cooling tower is 5 deg C. Cooling water temperature affects the condensation of the hexane vapor.

National Productivity Council, New Delhi (India)

Page:6. 23

Report on GPDP Project in an Edible Oil Industry in India

Figure-6.7: Fishbone diagram depicting hexane loss

Inadequate steam supply in SEP Machine Environment Large quantity of hydro carbons discharged into atmosphere.

Fluctuation in steam pressure High DTDC Inadequate bed thickness Insufficient Boiler capacity

Man

Work instruction not duly followed Negligence of plant periodic maintenance Mind set Shortage of skilled manpower

Inadequate Design Insufficient contact between DOC and steam Less heating surface area for indirect steam

Improper Extractor

Less drainage time for miscella

Less absorption of hexane by Mineral oil

Inadequate recuperation system

Poor recovery of Hexane Inadequate recovery facility Inadequate recuperation system

Inadequate Vacuum Improper Condensation

Air ingressment Absence of rotary valve at out let Fouling of condenser

Leakage through Extractor Sealing

Considering average thickness instead of standard deviation Faulty quality control of flake thickness Improper flaking Improper Cleaning

Insufficient plasticity Worn out flaker rollers Improper flake thickness

Hexane Loss

Improper seed preparation Inadequate Cracking & Flaking

Inadequate cooking Hexane retention in DOC High residual oilby residual oil

High solvent seed ratio

Presence of foreign matter, which is being considered as seed

Common condensation High moisture in seed of vapour High moisture in collets Method Material

Power interruption Damaged / green seed

National Productivity Council, New Delhi (India)

Page:6. 24

Report on GPDP Project in an Edible Oil Industry in India

Observation: Based on the above analysis, it was identified that the existing vacuum in the system is inadequate. The identified reasons are summarised below: (i) (ii) Inadequate supply of steam (quantity & pressure) Poor vapour condensation due to high temperature of cooling water

Effects: Inadequate vacuum leads to poor separation of hexane in the DTDC and distillation unit increasing the specific consumption of hexane. The quality of crude oil & DOC may further degrade due to presence of high concentration of hexane.

GP option evolved: To minimize the adverse effect due to inadequate vacuum in the system, following GP options were evolved: 1. 2. Ensure adequate steam (quantity & pressure) Provide cold/chilled water for effective condenser cooling

6.3.2.2

Main Cause: Inadequate desolventisation in DTDC

Best practices: The wet DOC passes through desolventisation unit of DTDC where steam is used to increase the temperature of DOC to 90 -110 deg C. It also helps in blending of wet DOC to loosen the DOC for hexane escape. The bed thickness in the desolventisation column is normally kept at 400mm and steam pressure at 2.0 Kg/cm2

Field study data: The steam supply from Boilers is not meeting the demand. Presently, the steam supplied to the DTDC is 50-54 MT/day against desired value of 55-60 MT/day. The heating surface area in the DT is not sufficient to transfer heat through existing limpets. Further, the bed thickness was also found to be more, hindering the heat transfer.

Trials Conducted:

National Productivity Council, New Delhi (India)

Page:6. 25

Report on GPDP Project in an Edible Oil Industry in India

Two trials were conducted to reduce hexane loss from existing DTDC by doing little modifications. Trial-1: Bed thickness reduced from 400mm to 250mm keeping direct steam & indirect steam in the desolventisation compartment constant. Bed thickness reduced from 400mm to 250mm and direct steam increased from 2 Kg/cm2 to 2.5 Kg/cm2 without changing indirect steam supply. Height of bed Hexane loss in MD discharging gas

Trial-2:

Direct steam

* 2. 0 kg/m2 400mm 2.053 ppm, (100%) 2.0 400 1,642 ppm (80%) 2.5 250 1,241 ppm (60%) 2 2.0Kg/m 400 mm: standard condition during usual operation (i) However, increase in direct steam in the DTDC brought about lower Urease Activity (UA) which is used as an indicator for proper heat treatment of DOC for animal feeding. Since the presently available seed is having very low UA compared to the previous few years due to unfavorable weather conditions, the feasibility of implementation of this trial can be worked out.

Conclusion: 1. As shown in the above Table, the hexane loss was decreased substantially by increasing the direct steam in DTDC and decreasing the height of bed. The desirable UA should not be greater than 0.3 mg/M/gm/at 30 oC and not less than 0.1 mg/M/gm/at 30 oC. If the value is less than 0.1 mg/M/gm/at 30 o C, the available lysine content will be low and, hence Poultry Farm will not accept. Also, if the value is greater than 0.3 mg/M/gm/at 30 oC, it will retard the growth of chicken. Therefore, the permissible value is between 0.1 to 0.3 mg/M/gm/at 30 oC.

2.

Due to variation in quality of the seed, the effect of UA were found out, and is tabulated below: Different process stages of seed Urease activity Today's value (mg/M/gm/at 30 oC) 1.8 1.5 0.7 0.07 to 0.1 3-years before (mg/M/gm/at 30 oC) 2.5 2.4 1.5 0.25

Seed Flakes Expander DOC

National Productivity Council, New Delhi (India)

Page:6. 26

Report on GPDP Project in an Edible Oil Industry in India

Operational Control: By increasing direct steam in Desolventisation compartment of DTDC, UA will go down. By increasing the retention time in cooker, indirect steam can be increased; thus reducing the value of UA.

Observation: Based on the above analysis, it was identified that the existing steam supply to the SEP is not sufficient. The identified reasons are summarised below: (iii) (iv) Low capacity & efficiency of existing Boilers Inadequate heating surface area in DT.

Effects: Inadequate supply of steam and less heating surface area leads to hexane being carried over through meal dryer air, resulting more hexane losses.

GP option evolved: To minimize the adverse effect due to inadequate steam supply & less heating surface area in DT, following GP options were evolved: 1. 2. Ensure adequate steam supply Increasing heating surface by providing more limpets in DT

6.3.2.3

Main Cause: Inadequate drainage in the extractor

It has already been discussed in WASTE STREAM- " RESIDUAL OIL CONTENT IN DOC"

6.3.2.4

Main Cause: Inadequate recuperation

Best practices: The function of recuperation unit is to recover the uncondensed hexane vapor from the common condenser (DTDC & Distillation). The mineral oil is used as an absorbent to recover the hexane after heating it through Plate Heat Exchanger (PHE).

National Productivity Council, New Delhi (India)

Page:6. 27

Report on GPDP Project in an Edible Oil Industry in India

Field study data: A trial has been conducted by increasing the flow rate of mineral oil to reduce the hexane concentration in the final vent but this lowers down the temperature of mineral oil. Therefore, the need of increasing the heating surface area of Plate Heater Exchanger came into existence for proper absorption and release of hexane at desired production rate. The increase in flow rate of chilled water in vent condenser further results in lowering the mineral oil temperature before absorption results in better recuperation. Observation: Based on the above trial, it was identified that the existing recuperation system is inadequate. The identified reasons are summarized below: (i) (ii) (iii) Low flow rate of mineral oil Less Heating surface area of Plate Heat Exchanger (PHE) Low flow rate of chilled water

Effects: Due to poor recuperation system, the recovery of the uncondensed hexane in the common condenser is low resulting in high hexane loss.

GP option evolved: To minimize the adverse effect due to inadequate recuperation system, following GP options were evolved: 1. 2. 3. 6.3.2.5 Increase mineral Oil Flow rate Increase heating surface area of PHE Increase chilled water flow rate in vent condenser Main Cause: Inadequate crude oil stripping

Best practices: Stripping of crude oil is carried out to remove traces of hexane present in the crude oil. The minimum flash point test for crude oil should be more than 120 deg C. The vacuum maintained for efficient stripping should be 450 mmHg. FIELD STUDY DATA: The vacuum in the stripper was found to be 380 mmHg. The flash point has been analyzed to be more than 120 deg C. The hexane carried along with crude oil has been estimated to be 1-2%.

National Productivity Council, New Delhi (India)

Page:6. 28

Report on GPDP Project in an Edible Oil Industry in India

It can be further improved, if vacuum in the system could be increased upto 450 mmHg. The problem was discussed with the external consultant and was found that the size of the condenser is small. The separate condenser with ejector is required for better stripping.

Observation: Based on the above study, it was identified that the existing oil stripping system is inadequate. The identified reasons for this is: (i) Inadequate vacuum due to small sized condenser

Effects: Due to poor oil stripping, the hexane loss increases. It also affects the quality of the crude oil.

GP option evolved: To minimize the adverse effect due to inadequate stripping, following GP option was evolved: 1. Install separate condenser with steam ejector in stripper to increase vacuum

6.4

WASTEWATER FROM REFINERY & ITS TREATMENT PROBLEM" General observations & present practices

6.4.1 (A)

The major sources of wastewater generation are (i) refinery process wastewater and (ii) acid oil recovery plant (AORP) process wastewater. In refinery, process wastewater is generated from washing of traces of soap stock present in the oil after degumming & Neutralisation operation in the washing separator. The quantity of wastewater generation from refinery is 62 m3/day. The flow and characteristics of wastewater is discussed in Chapter-5. The seal cooling wastewater in refinery also discharged along with washing wastewater. This results in high wastewater generation. The quantity of seal cooling wastewater is about 25-30 m3/day. The characteristics of wastewater are discussed in Chapter-5.

National Productivity Council, New Delhi (India)

Page:6. 29

Report on GPDP Project in an Edible Oil Industry in India

In AORP, the process wastewater is generated from reaction tank. The quantity of wastewater from AORP is 25 m3/day. The characteristics of wastewater are discussed in Chapter-5. The flow meters installed in the short-mixed plant for water addition was found to be faulty. It was crosschecked with the bucket-stop watch method. Due to faulty water flow meters, the excess water addition to the ETP is 14 m3/day. The washing operation is carried out through single separator instead of recommended two by the supplier. Analysis results shows there was high Pollution load due to non-availability of one washing separator. The wastewater generated from refinery section & acid oil recovery plant is treated in the existing ETP The performance evaluation of ETP (discussed in chapter-5) indicates the poor performance of ETP.

Baseline data: Sources of water Average Cost of Raw Water Cost of soft water Total water in circuit (450 m3/d) 150 m3/d recycled Areas of water loss: ETP discharge Evaporation from Cooling Towers Moisture added in products Direct steam evaporation Other discharges-blow down, Softener's backwash etc. Average makeup water Annual cost of make up water (soft) (B) Concerned process steps Refinery Section : Washing separator Seal Cooling Water Separator cleaning Reaction Tank Settling Tank = = 300 m3 per day Rs. 18 lakhs per year = Bore Well & Tankers = Rs. 15 per m3 = Rs. 20 per m3 300 m3/d make up

Acid Oil Recovery Plant (AORP) :

National Productivity Council, New Delhi (India)

Page:6. 30

Report on GPDP Project in an Edible Oil Industry in India

(C)

Environmental pollution problem:

The wastewater from above mentioned sources create high pollution load. Presently the treated wastewater from ETP is not meeting the discharge standard stipulated by the M.P. Pollution Control Board, therefore it is polluting the receiving media.

Causes of waste water generation & its treatment problem 1. High water consumption in short mix plant due to faulty Flow Meter 2. Discharge of Seal Cooling Water to ETP 3. High pollution load due to non-availability of one washing separator in shortmix plant. 4. Poor performance of the existing ETP due to high pollution load from Refinery washing separator and Reaction & settling tanks of Acid Oil Recovery Plant. The details of the causes are discussed subsequently.

6.4.2.1

Cause: High water consumption in short mix plant due to faulty flow meter Refer: " Oil loss in refinery"

6.4.2.2

Cause: " Discharge of seal cooling water to ETP"

Best Practices: The seal cooling water used in the separator flows indirectly and there is no mixing/contamination of oil/soap-stock during degumming and neutralisation or washing of oil. It should be in a closed circuit and not be discharged into the drain.

Field study: Presently the seal cooling water is mixed in the slop oil tank along with refinery wash water and sent to the ETP for treatment. The excess quantity of wastewater generated due to mixing of seal cooling water was monitored to be 25-30 m3/day.

Observation: Keeping in mind the scarcity of water in the region and scope of recycling of seal cooling water after minor treatment, the potential of recycling of seal cooling water was recommended.

National Productivity Council, New Delhi (India)

Page:6. 31

Report on GPDP Project in an Edible Oil Industry in India

Effect: The mixing of seal cooling water into the other wastewater streams results in the high hydraulic load to the ETP.

GP options: To minimize the adverse effect due to mixing of seal cooling water into the other wastewater streams, following GP option was evolved: 1. Provide separate collection & treatment systems for seal cooling water & recycle.

6.4.2.3

Cause: " High pollution load due to scarcity of one washing separator in short-mix plant " Refer: " Oil loss in refinery "

6.4.2.4

Cause: " Poor performance of the existing ETP due to high pollution load from Refinery washing separator and Reaction & settling tanks of Acid Oil Recovery Plant "

Best Practices: The wastewater generated from refinery & acid oil recovery plant should be pretreated to recover free oil & soap-stock. The nature of Refinery wastewater is alkaline and AORP wastewater is acidic. It should be mixed properly before treatment in the ETP. A proper retention time need to be provided for breaking the oil emulsion.

Field study: The wastewater from Refinery is pre-treated in the Slop Oil Tank for the recovery of free oil and soap-stock. The retention time in the slop oil is not adequate resulting in poor recovery. It increases the pollution load to the ETP. The acidic wastewater from AORP is not mixed properly with the alkaline wastewater of refinery in the channel. It results in poor splitting of oil emulsion, high consumption of lime and inconsistent characteristic at the inlet of ETP. It leads to poor operation & maintenance of ETP. The detailed performance evaluation of the ETP has been discussed in Chapter-5.

National Productivity Council, New Delhi (India)

Page:6. 32

Report on GPDP Project in an Edible Oil Industry in India

Observation: The performance evaluation of the ETP shows that the treated wastewater is not meeting the discharge standard stipulated by the Pollution Control Board. Further, the treated water not meeting the various process water quality for recycling into the system. Effect: Due to poor performance of ETP, the treated wastewater does not meet the norms stipulated by law. GP options: To minimize the adverse effect due to poor performance of the ETP, following GP option was evolved: 1. Design & Upgradation of the ETP to treat & meet surface discharge standards stipulated by the Madhya Pradesh Pollution Control Board.

6.5

ENERGY LOSS General observations & present practices

6.5.1(A)

Following areas have been identified during detailed study as energy loss areas where the potential of energy saving exists: (B) Cooling Tower (electrical energy) Thermic Fluid Heater De-odoriser (steam) Steam distribution lines (un-insulated) Steam loss (steam trap) Concerned process steps: (D) Cooling of water in SEP & Refinery by Cooling Tower Diesel fired Thermic Fluid Heater Generation of high vacuum in de-odorisation Steam pipelines, flanges & valves. Steam trap.

Environmental pollution problem:

The electrical & thermal energies losses are directly or indirectly affects the environment. The coal used for steam and power generation pollutes the environment. It is also a loss of natural resources.

National Productivity Council, New Delhi (India)

Page:6. 33

Report on GPDP Project in an Edible Oil Industry in India

6.5.2 Cause effect analysis: The critical examination of production processes and utilities led to identification of the causes for energy loss in the plant as mentioned in section 6.5.1(B). . The causes are summaries below:

Causes of energy loss: 1. 2. 3. 4. 5. High electricity consumption due to Aluminium Blade in Cooling Towers fans. Higher cost of energy due to diesel as fuel in Thermic Fluid Heater Supply of low pressure steam ( 7 Kg/cm2 against 10 Kg/cm2 required) Heat losses from un-insulated steam lines, flanges and valves Passing of steam traps leading to steam loss

The details of the causes are discussed below: 6.5.2.1 Cause: High electrical consumption due to Aluminium Blade in Cooling Towers

Best practices: Being lighter in weight and less power consumption, the utilities of FRP blade is increasing day-by day over aluminium blade. Most of the units have already installed cooling tower with FRP blade. Observation & field study: The blades of the Cooling towers have been found to be made up of Aluminium. There are two Cooling Towers for the Solvent Extraction Plant. The capacity of each pump is 15 HP. Similarly, there are two Cooling towers in the Refinery Section, each fan of 10 HP capacity. Studies suggested that fan with FRP blade consumes 20-25% less current than that of fan with Aluminium blade of similar dimensions. The monitored data on electrical consumption with Aluminium blade is given below: Particulars Load on AL Fan SEP-Tower-1 SEP-Tower-2 Refinery Tower-1 Refinery-Tower 2 Total Current 10.7 Amp 10.7 Amp 8.5 Amp 9.5 Amp 39.4 Amp

Keeping in view the electrical saving potential of 20-25%, the replacement of Aluminium blade with FRP was recommended.

National Productivity Council, New Delhi (India)

Page:6. 34

Report on GPDP Project in an Edible Oil Industry in India

GP option: To minimize the adverse effect of Aluminium blade, following GP option was evolved. Replace Aluminium Fan Blade with FRP Blade in Cooling Towers

6.5.2.2

Cause: Higher cost of energy due to diesel as fuel in Thermic Fluid Heater

Best practices: With the rapid increase in the cost of diesel compared to coal, the coal-fired Thermic Fluid Heater is a better option.

Observation & field study: Thermic Fluid Heater is used to raise temperature of circulating fluid to 240oC which in turn is used to heat the bleached oil in de-odorize. The diesel consumption in thermic fluid heater is 500 litres/day costing Rs. 9,500/- per day..

Effect: The operating cost of diesel-fired thermic fluid heater is more than the coal-fired thermic fluid heater leading to high-energy cost.

GP option: To minimize the adverse effect of diesel fired Thermic Fluid Heater, following GP option was evolved. 1. Replacement of diesel by Coal in Thermic Fluid Heater Cause: Supply of low pressure steams (7 Kg/cm2 against 10 Kg/cm2 required).

6.5.2.3

Best practices: The vacuum required in the existing de-odorizer is 730 mmHg. For this, the appropriate sized nozzle should be installed in the steam ejector. The designed nozzle of the ejector is to function at 10kg/cm2.

National Productivity Council, New Delhi (India)

Page:6. 35

Report on GPDP Project in an Edible Oil Industry in India

Observation & field study: Steam ejector is the source of vacuum in De-odoriser in the Refinery section. An ejector with motive steam pressure of 7 Kg/cm2 was installed. Due to inadequate supply of steam from the boiler, both in quantity & pressure, the required vacuum is not achieved. Because of low vacuum in De-odoriser, steam consumption increased. There is a proposal to install 15 TPH, 14.5 Kg/cm2 pressure Fluidized Bed Combustion (FBC) Boiler. After installation of FBC Boiler, the requisite steam, both in quantity & pressure would be available in the de-osoriser.

Effect: It results in high steam consumption.

GP option: To minimize the adverse effect due to low vacuum generating nozzle, following GP option was evolved. 1. Installation of high vacuum generating nozzle

6.5.2.4

Cause: Heat losses from un-insulated steam line, flanges & valves.

Best practices: The pipe-lines carrying steam and flanges, to connect the two steam pipelines, and valves, to control the supply of steam, should be insulated by appropriate insulating material for reduction of heat loss from the surface.

Observation & field study: During detailed study, it has been observed that steam insulation over the steamcarrying pipeline is not present in various portions. The flanges & valves in most of the cases are un-insulated leading to loss of thermal energy through radiation. It increases the steam demand and, consequently leads to high fuel consumption. The un-insulated portion of the steam pipelines was measured. The total number of un-insulated flanges and valves present in the steam carrying pipelines has also been quantified. The details are: Total length of un-insulated pipelines Number of un-insulated flanes Number of un-insulated valves

National Productivity Council, New Delhi (India)

=20 metres =30 =40

Page:6. 36

Report on GPDP Project in an Edible Oil Industry in India

Effect: It results in high steam consumption.

GP option: To minimize the adverse effect due to un-insulated steam pipe-lines, flanges & valves, following GP option was evolved. 1. Provide insulation to expose steam line, flanges & valves.

6.5.2.5

Cause: By-passing of steam traps leading to steam loss.

Best practices: Steam traps are provided to trap un-condensed steam at the Condensate pipeline for recycling.

Observation & field study: Most of the steam traps are bypassed because in the existing Boiler the steam requirement is not fully met in the process. The rapid gain in temperature in the production unit is achieved through bypassing of steam traps. It is expected that reduction of nearly 15-20% steam consumption can be achieved if bypass is closed. Effect: It results in high steam consumption.

GP option: With the new FBC Boiler, the required steam quality as well as quantity is ensured and hence, to minimize the adverse effect due to by-passing of steam traps, following GP option was evolved. 1. Entire steam bypass should be closed and the bypass connections may be disconnected with condense line.

National Productivity Council, New Delhi (India)

Page:6. 37

Report on GPDP Project in an Edible Oil Industry in India

6.6

INADEQUATE STEAM GENERATION LEADING TO HIGH OIL & HEXANE LOSS General observations & present practices

6.6.1(A)

The unit has two stationary grate coal-fired water tube boilers. The rated capacities of boilers are 6TPH & 3TPH. But due to high demand, the boilers operate at Maximum Continuous Rating (MCR). The efficiency of boiler is only 65%. There is problem of fluctuation of steam resulting in high residual oil content in DOC and hexane loss. In addition, there is no recovery of heat from the flue gas.

(B)

Concerned process steps:

AREA

Boiler

(E)

Environmental pollution problem:

The running of boilers at MCR with low efficiency leading to excess pollution in the environment.

Causes for inadequate steam generation: The inadequate steam generation is evident from the performance evaluation of existing Boilers carried out during detailed study. Therefore, main cause of the inadequate steam generation is less efficient boilers.

6.6.2 Cause:

Less efficient boiler

Best practices: The boiler should supply appropriate steam at desired pressure in the Solvent Extraction Plant for efficient distillation of Miscella and desolventisation of wet DOC. The efficiency of boiler should be about 75-80% for proper burning of coal and efficient utilization of heat. Therefore, the Upgradation/replacement of the boilers is suggested.

Field visit and observation: The unit has two stationary grate coal-fired water tube boilers. The rated capacities of boilers are 6TPH & 3TPH.

National Productivity Council, New Delhi (India)

Page:6. 38

Report on GPDP Project in an Edible Oil Industry in India

The boilers capacities were assessed with heat transfer area & existing grate area and it was worked out that with manual firing boiler can generate steam of 5.4 TPH & 2.3 TPH respectively at Maximum Continuous Rating (MCR). In normal operating condition, the Boiler can generate only 7.55 TPH. It is suggested that Boiler should not operate at MCR, otherwise it will increase the boiler maintenance cost. The average steam requirement of plant is 8.1 TPH. In order to meet the process steam requirement, the boiler should always operate at the peak load. Even the Boiler operating at the peak load, the quantity as well as quality of the steam can not meet to fulfill the process requirement. During the course of study, it was observed that deteriorating steam quality is due to carryover of water. Steam pressure is inadequate in certain processes increasing the cycle time as well as material losses etc.

Need & reasons for installing FBC boiler: Constraints in existing steam generation capacity: Calculated steam generation capacity & shortfall is discussed below:

Boiler

Heat Transfer Area ft2

Grate Area ft2

Grate Loading Factor Kg/Ft2/Ft

Coal Firing Rate Kg/Hr

Big

2450

75

Small

1280

35

13 (with WHR) 12

975

Steam Generation (Calculated) @4.5 @ 5.5 Lb/Ft2 Kg/Kg Coal TPH Basis TPH 5.4 5.01

Ave. Gen. TPH 5.3

420 1395

2.3

2.70

Total steam generation Total steam demand(185 T/d+10 T/d loss)/24 Constraints: shortfall at MCR (8.1-7.75) Shortfall at NCR (8.1-7.25

2.45 7.55 7.55 8.10 0.35 0.85

Due to shortfall, inadequate steam supplies as a result of lower pressure & more wetness in steam. Therefore, to increase steam generation (quantity & quality) further may not be possible with existing boilers as already operating at MCR. So, need for more efficient FBC boiler

Effect: The low efficient boilers lead to high oil content in DOC and hexane loss in SEP.

National Productivity Council, New Delhi (India)

Page:6. 39

Report on GPDP Project in an Edible Oil Industry in India

GP options: In order to maintain the required quality & quantity of steam, following GP options were evolved: 1. 2. Improve the efficiency of the boiler by installing Waste Heat Recovery (WHR) system (For Short Term Measure) Install more efficient Fluidized Bed Combustion (FBC) boiler of higher capacity (For medium term measure). LEADING TO AIR POLLUTION IN WORK

6.7

FUGITIVE EMISSION ENVIRONMENT

6.7.1(A)

General observation & present practices

The seed is un-bagged and poured into the hopper manually. From hopper, seed is transferred to the Vibrating Screen for cleaning. The dust & other foreign materials in the seed are sucked by Dust Extraction System and taken to the Cyclone, the Air Pollution Control Devices [APCD]. It was observed that un-bagging, transferring, screening gives rise to dust emission. The high fugitive dust emission is also attributed to the poor performance of existing APCD including dust extraction system. The seed is conveyed by means of Redler / In-Mass conveyors and bucket elevators to & from seed cleaner to storage silos/ day silo. Normally, poor seed cleaning, open conveyors and absence of dust extraction system at seed transfer points leads to dust entrainment into the environment (B) Concerned process steps: Cleaning section vibratory screen Areas: (C) Seed unloading & vibrating screening system Bucket Elevator discharge to Cracking Section

Environmental pollution problem: The fine dust (not collected in cyclone) released to atmosphere, pollutes the surrounding environment.

Causes of fugitive emission: 1 2 Inadequate extraction of fine dust from vibrating screen, fine dust escaping from Cyclone discharge through Chimney Inadequate extraction & control of fine dust emitted from the seed at Bucket Elevator discharging to Cracker

National Productivity Council, New Delhi (India) Page:6. 40

Report on GPDP Project in an Edible Oil Industry in India

6.7.2.1

Cause: Inadequate extraction of fine dust from vibrating screen, fine dust escaping from Cyclone discharge through Chimney

Best Practices: The dust in the seed should be sucked by proper dust extraction followed by air pollution control devices (APCD) before discharging into the atmosphere.

Field measurement data-& observation The procured seed contain 2.5 to 3.25% foreign matters. The dust concentration is in the range of 1.0 to 1.5%. During seed cleaning operation, the heavy foreign matters get separated by vibratory screen. The fine dust is sucked through the existing dust extraction system followed by Cyclone. A stack monitoring study was carried out for the performance evaluation of the dust extraction system. The detail is discussed in Chapter-5. Though the cyclone efficiency is 88.5%, the SPM at the outlet is more (330 mg/Nm3) than the regulatory norms (150 mg/Nm3). Therefore, dust extraction and control system need to be modified.

Effects: Due to poor performance of dust extraction system & air pollution control devices (APCS), the dust spread over in the working environment and affects the health of the workers.

GP options: To minimize the adverse effect due to poor extraction of dust in the seed cleaning section, following GP options were evolved: 1. Improve extraction capacity/efficiency by way of additional extraction point & higher extraction capacity. Install bag filter house in place/in addition to cyclone for capturing fine dust.

2.

6.7.2.2

Cause: Inadequate extraction & control of fine dust emitted from the seed at Bucket Elevator discharging to Cracker

Best Practices: The seed transfer points should be connected with the common dust extraction system followed by Air Pollution Control Devices.

National Productivity Council, New Delhi (India)

Page:6. 41

Report on GPDP Project in an Edible Oil Industry in India

Field measurement data & observation: The seed containing high dust is not cleaned properly in the seed cleaning section through the vibrating screen and the dust extraction & control system. Subsequently, the dust carries over to the preparatory section. Therefore, during transfer of seed from day-silo to the cracker through the conveyor, the free dust partly come out at the transfer point.

Effects: The dust generation at the transfer point in the preparatory section badly effects the working environment. The dust is deposited over the machines of the preparatory section. Further, due to running of machines like cracker, flaker etc., dust reintrapped into the working environment.

GP options: To minimize the adverse effect due to poor extraction of dust in the seed cleaning section and subsequently dust generation in the preparatory section, following GP options were evolved: 1. Improve extraction capacity/efficiency by way of additional extraction point & higher extraction capacity. Install bag filter house in place/in addition to cyclone for capturing fine dust.

2.

The above options are already discussed in previous section.

6.8 IMPROPER MATERIAL HANDLING & HOUSE KEEPING PRACTICES A study was conducted to assess prevailing material handling and house keeping practices. Keeping in view improvement in productivity in terms of saving of time (man-power and machine hour), material and space. The observation of the study is mentioned at section 5.2 in Chapter-5. In view of the observations, measures have been recommended for improvement in material handling and house keeping practices. Section/unit wise recommendation is given in Table-6.3.

National Productivity Council, New Delhi (India)

Page:6. 42

Report on GPDP Project in an Edible Oil Industry in India

Table-6.3

Sr. No. 1.0 Truck Movement and Parking area: (Refer Figure-6.8)

Recommendations for material handling & House keeping Seed Charging Section Recommendations

Token system should be introduced based on FIFO (First-in-first-out)

systems for parking Trucks in specified location. 2.0 Seed Unloading Area (Refer Figure-6.9)

A plat form should be constructed and used for unloading the soybean

bags After charging soybean in the hopper, the empty bags should be kept in a grill. A grill similar to cattle track should be provided in the area where trucks are parked during charging. 3.0 Seed Sampling Area (Refer Figure-6.10)

During sieving operation, the material should be collected directly in a

bag. Stacking area should be specified and marked. The ramp should be constructed connecting sampling area and charging area so that the material is moved through optimum route and safe walking conditions. Trucks should be cleaned in charging area so as to collect the material in the Grill. Preparatory Section Recommendations

Sr. No. 1.0 For continuous improvement in shop floor activities, conduct regular housekeeping audit based on 5S Checklist provided (refer Annexure-6.1) Solvent Extraction Plant Recommendations

Sr. No. 1.0 For continuous improvement in shop floor activities, conduct regular housekeeping audit based on 5S Checklist provided (refer Annexure-6.1). Refinery Section Sr. Recommendations No. 1.0 For continuous improvement in shop floor activities, conduct regular housekeeping audit based on 5S Checklist provided (refer Annexure-6.1).

National Productivity Council, New Delhi (India)

Page:6. 43

Report on GPDP Project in an Edible Oil Industry in India

Sr. No. 1.0 Filling of oil in Drums (Refer Figure-6.11)

Oil Packing Section Recommendations

Filling of oil and weighment should be carried out simultaneously to avoid

double handling of drums as well as the spillage of oil 2.0 Oil Filling and Packaging Section (Refer Figure-6.12)

A chute should be constructed to move the material from first floor to

3.0 ground floor. Separate designated area should be used to store empty tins, jars, filled tins, jars and packing materials. Open rack should be provided to store packing materials Rack should be provided to store 15 litres filled jars in storage area The stacks with proper length, breadth and height shall be marked in the storage area. The stack card should be introduced to keep proper accounting of stocks Worktable of filling 15 litres tins and jars should be shifted to packing area

Oil Filling and Packing of 15 litres tins (Refer Figure-6.13)

A taper should be provided in oil opening to eliminate the spillage of oil.

4.0 Oil Filling and Packing of 5 litres jar (Refer Figure-6.14)

The empty jars should be stored near work center. For continuous improvement in shop floor activities, conduct regular

housekeeping audit based on 5S Checklist provided DOC Packing Section Recommendations

Sr. No. 1.0 Stacking area should be marked with stacking plan as well as stack no. DOC should be stacked based on FIFO (first-in-first-out) system Storage area for empty gunny bags, trolley, bin etc. Area for storage of trolleys are not specified resulting in blockage of space It should be standard practice to fill the bags to appropriate height to avoid spillage during movement and packing. Jute thread should be kept collected properly in a bin. For continuous improvement in shop floor activities, conduct regular housekeeping audit based on 5S Checklist provided

National Productivity Council, New Delhi (India)

Page:6. 44

Report on GPDP Project in an Edible Oil Industry in India

Stores Section Sr. Recommendations No. 1.0 For continuous improvement in shop floor activities, conduct regular housekeeping audit based on 5S Checklist provided (refer Annexure-6.1) Laboratory Section Sr. Recommendations No. 1.0 For continuous improvement in shop floor activities, conduct regular housekeeping audit based on 5S Checklist provided (refer Annexure6.1). Mechanical Workshop Sr. Recommendations No. 1.0 For continuous improvement in shop floor activities, conduct regular housekeeping audit based on 5S Checklist provided (refer Annexure6.1). Electrical Workshop Sr. Recommendations No. 1.0 For continuous improvement in shop floor activities, conduct regular housekeeping audit based on 5S Checklist provided (refer Annexure-6.1) ETP & Boiler Section Sr. Recommendations No. 1.0 For continuous improvement in shop floor activities, conduct regular housekeeping audit based on 5S Checklist provided (refer Annexure-6.1)

National Productivity Council, New Delhi (India)

Page:6. 45

Report on GPDP Project in an Edible Oil Industry in India

National Productivity Council, New Delhi (India)

Page:6. 46

Report on GPDP Project in an Edible Oil Industry in India

National Productivity Council, New Delhi (India)

Page:6. 47

Report on GPDP Project in an Edible Oil Industry in India

National Productivity Council, New Delhi (India)

Page:6. 48

Report on GPDP Project in an Edible Oil Industry in India

National Productivity Council, New Delhi (India)

Page:6. 49

Report on GPDP Project in an Edible Oil Industry in India

National Productivity Council, New Delhi (India)

Page:6. 50

Report on GPDP Project in an Edible Oil Industry in India

National Productivity Council, New Delhi (India)

Page:6. 51

Report on GPDP Project in an Edible Oil Industry in India

National Productivity Council, New Delhi (India)

Page:6. 52

Report on GPDP Project in an Edible Oil Industry in India

6.9

SUMMARY OF CAUSE-EFFECT ANALYSIS

The summary of cause-effect analysis as mentioned in section 6.1 through section 6.8 is compiled and presented at Table 6.4 for ease in understanding and interpretation.

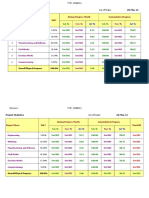

Table-6.4: Waste Streams Oil Loss DOC

Cause of waste streams/problem areas & their effect Effects Less efficient cracking leads to inefficient cooking, flaking and extraction subsequently. Inadequate cooking leads to incomplete flaking and extraction subsequently As the thickness of the flake increases, oil content in DOC increases.