Академический Документы

Профессиональный Документы

Культура Документы

Ansys 1

Загружено:

sathish_mecОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ansys 1

Загружено:

sathish_mecАвторское право:

Доступные форматы

Analysis of Machine Elements using COSMOSWorks

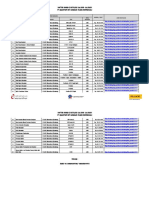

Table of Contents

Table of Contents Preface

Intended Audience for this Text Using this COSMOSWorks User Guide Instructors Preface

i

vii vii vii ix

Introduction

Finite Element Analysis Nodes, Elements, Degrees of Freedom, and Equations COSMOSWorks Elements Solid Elements Solid Element Degrees of Freedom Shell Elements Shell Elements Degrees of Freedom Meshing a Model Introduction to the COSMOSWorks User Interface Orientation and Set-up of SolidWorks Work Environment Orientation to the COSMOSWorks Work Environment Property Managers and Dialogue Boxes

Chapter 1

I-1 I-2 I-3 I-3 I-4 I-4 I-5 I-5 I-7 I-7 I-11 I-12

Basic Stress Analysis Using COSMOSWorks

Learning Objectives Problem Statement Creating a Static Stress Analysis Study Assigning Material to the Model Applying Restraints Applying Loads Meshing the Model Running the Solution Examination of Results Default COSMOSWorks Graphical Results Results Predicted by Classical Stress Equations COSMOSWorks Results for Stress in Y-Direction Using the Probe Tool Summary Exercises i

1-1 1-1 1-1 1-3 1-4 1-6 1-8 1-11 1-13 1-14 1-14 1-15 1-16 1-18 1-25 1-26

Analysis of Machine Elements using COSMOSWorks Chapter 2

Curved Beam Analysis

Learning Objectives Problem Statement Creating a Static Analysis (Study) Assign Material Properties to the Model Applying Restraints Applying Load(s) Inserting Split Lines Applying Force to an Area Bounded by Split Lines Meshing the Model Solution Examination of Results Analysis of von Mises Stresses Within the Model Verification of Results Results Predicted by Classical Stress Equations Comparison with Finite Element Results Assessing Safety Factor for the Curved Beam Reaction Forces Logging Out of the Current Analysis Exercises

Chapter 3

2-1 2-1 2-1 2-2 2-4 2-6 2-7 2-8 2-11 2-12 2-14 2-15 2-14 2-18 2-18 2-20 2-23 2-28 2-29 2-30

Stress Concentration Analysis

Learning Objectives Problem Statement Create a Static Analysis (Study) Defeaturing the Model Assign Material Properties to the Model Apply Restraints and Loads Meshing the Model Solution Examination of Results Stress Plots Creating a Copy of a Plot Displacement Plot Creating New Studies Study Using a High Quality Elements and COARSE Mesh Size Study Using a High Quality Elements and DEFAULT Mesh Size Study Using a High Quality Elements and FINE Mesh Size Study Using High Quality Elements and Mesh CONTROL Results Analysis Create Multiple Viewports What Can Be Learned from this Example? ii

3-1 3-1 3-1 3-2 3-3 3-4 3-5 3-6 3-8 3-8 3-8 3-11 3-13 3-15 3-15 3-20 3-21 3-21 3-26 3-26 3-28

Table of Contents

Other Uses of the Copy Feature Comparison of Classical and FEA Results Exercises

Chapter 4

3-28 3-32 3-33

Thin and Thick Wall Pressure Vessels

Learning Objectives Thin-Wall Pressure Vessel Problem Statement Defining Options at Start of a Study Creating a Static Analysis Using Shell Elements Assigning Material Properties Assigning Loads and Restraints Symmetry Restraints Applied Pressure Load Applied Meshing the Model Solution Results Analysis 4-1 4-1 4-1 4-4 4-10 4-10 4-11 4-11 4-14 4-14 4-15 4-16 4-21 4-21 4-21 4-22 4-22 4-25 4-27 4-27 4-27 4-29 4-29 4-31 4-34 4-38

Thick Wall Pressure Vessel

Problem Statement Defining the Study Assign Material Properties Define Restraints and Loads Mesh the Model Solution Results Analysis Displacement Analysis Von Mises Stress Analysis Tangential Stress Analysis Adjusting Stress Magnitude Display Parameters Using Section Clipping to Observe Stress Results Exercises

Chapter 5

Interference Fit Analysis

Learning Objectives Problem Statement Interference Check Creating a Static Analysis (Study) Assign Material Properties to the Model Defeature the Model Apply Loads and Restraints iii

5-1 5-1 5-1 5-2 5-3 5-4 5-5 5-6

Analysis of Machine Elements using COSMOSWorks

Un-suppress Part of the Model to Use Symmetry Define Symmetry Restraints Apply Restraints to Eliminate Rigid Body Motion Define a Shrink Fit Mesh the Model and Run the Solution Examination of Results Default Stress Plot Stress Plots in the Cylindrical Coordinate System Circumferential (Tangential or Hoop) Stress Radial Stress Verification of Results Stress Predicted by Classical Interference Fit Equations Stress Predicted by Finite Element Analysis Radial Stress Comparison Circumferential Stress Comparison Quantifying Radial Displacements Generating a Report Exercises

Chapter 6

5-6 5-7 5-8 5-10 5-13 5-14 5-14 5-17 5-17 5-20 5-22 5-22 5-23 5-23 5-25 5-26 5-28 5-31

Contact Analysis in a Trunion Mount

Learning Objectives Problem Statement Preparing the Model for Analysis Add Reference Planes Insert Split Lines Creating the Assembly Model Create a Finite Element Analysis (Study) Assign Material Properties Cut Model on Symmetry Plane Assign Restraints and Loads Symmetry and Immovable Restraints Contact/Gaps Restraints Apply a Directional Load to the Pin Meshing the Model and Running the Solution Results Analysis Von Mises Stress ISO Clipping Animating Stress Results Displacement Results Contact Pressure/Stress Exercises 6-1 6-1 6-2 6-3 6-4 6-5 6-10 6-10 6-10 6-14 6-14 6-14 6-16 6-19 6-19 6-19 6-20 6-22 6-23 6-24 6-26

iv

Table of Contents Chapter 7

Bolted Joint Analysis

Learning Objectives Problem Statement Create a Static Analysis Assign Material Properties to the Model Apply Loads and Restraints Traditional Loads and Restraints Define Bolted Joint Restraints Define Local Contact Conditions Mesh the Model and Run Solution Results Analysis (Downward Load) Von Mises Stress Bolt Forces Define a New Study with the Applied Load Reversed Results Analysis (Upward Load) Von Mises Stress Bolt Forces (Upward Load) Bolt Clamping Pressure Summary Exercises 7-1 7-1 7-2 7-2 7-3 7-3 7-4 7-11 7-13 7-14 7-14 7-15 7-16 7-17 7-17 7-17 7-22 7-26 7-27

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Reinforced - Concrete Design IIДокумент54 страницыReinforced - Concrete Design IIgendadeyu552625Оценок пока нет

- Quantum Information and FoundationsДокумент510 страницQuantum Information and FoundationsBrent AllieОценок пока нет

- Aisi 4340 Alloy Steel (Uns g43400)Документ4 страницыAisi 4340 Alloy Steel (Uns g43400)Fazry NurokhmanОценок пока нет

- E2906E2906M-13 Standard Practice For Acoustic Pulse Reflectometry Examination of Tube BundlesДокумент6 страницE2906E2906M-13 Standard Practice For Acoustic Pulse Reflectometry Examination of Tube BundlesMohamed100% (1)

- RCC DomesДокумент3 страницыRCC Domesvaibhavamore0% (1)

- Shaft Model With Mathlook EquationsДокумент112 страницShaft Model With Mathlook EquationsMoisés MachadoОценок пока нет

- 3D NLS Grafiy EngДокумент64 страницы3D NLS Grafiy Engmedellincolombia100% (1)

- Engineering DrawingДокумент22 страницыEngineering DrawingCarlo CaniedoОценок пока нет

- Surface Modelling: Nozzle: Transition PieceДокумент6 страницSurface Modelling: Nozzle: Transition Piecesathish_mecОценок пока нет

- AutocadДокумент12 страницAutocadsathish_mec0% (1)

- 3ds Max ShortcutsДокумент26 страниц3ds Max Shortcutssathish_mecОценок пока нет

- A Study of Verbs Compounded With Aus, Ein, Etc., As Contrasted With Those Compounded With Heraus, Hinaus, Herain, Hinein, EtcДокумент152 страницыA Study of Verbs Compounded With Aus, Ein, Etc., As Contrasted With Those Compounded With Heraus, Hinaus, Herain, Hinein, EtcEnkindooОценок пока нет

- Source: "Sears and Zemansky's University Physics With: Fig. 1. The Work Done On A Baseball Moving inДокумент8 страницSource: "Sears and Zemansky's University Physics With: Fig. 1. The Work Done On A Baseball Moving inMaria Diane DizonОценок пока нет

- Is - 00191 - 2007 PDFДокумент14 страницIs - 00191 - 2007 PDFSangita GhaisasОценок пока нет

- PL Fluke Biomedical (Ekatalog Link) 2018 - 2020Документ2 страницыPL Fluke Biomedical (Ekatalog Link) 2018 - 2020lukas adi nugrohoОценок пока нет

- Lect 1 & Lect 2 Selection of Materials: October 2018Документ14 страницLect 1 & Lect 2 Selection of Materials: October 2018Enriqe PuentesОценок пока нет

- Notes 2Документ65 страницNotes 2Aamir khanОценок пока нет

- GR 9 Eng BaselineДокумент12 страницGR 9 Eng BaselineMalie SibisiОценок пока нет

- EC 6702 Ocn Two MarksДокумент24 страницыEC 6702 Ocn Two MarksManiKandan SubbuОценок пока нет

- ResumeДокумент2 страницыResumeapi-252798605Оценок пока нет

- Fluid Report Exp 5Документ9 страницFluid Report Exp 5Hon Siong LinОценок пока нет

- Diagramas Momento CurvaturaДокумент21 страницаDiagramas Momento CurvaturaCarlosAlbertoBarriosnuevosPelaezОценок пока нет

- Aggregates in ConcreteДокумент16 страницAggregates in Concretevinaykrishna123Оценок пока нет

- Stellite 21 DS01-22208 (S R0808)Документ2 страницыStellite 21 DS01-22208 (S R0808)teacgОценок пока нет

- Presentation For FPGA Image ProcessingДокумент14 страницPresentation For FPGA Image ProcessingSaad KhalilОценок пока нет

- Self Evaluation Test-Sets and RelationsДокумент3 страницыSelf Evaluation Test-Sets and RelationsShamim RahmatОценок пока нет

- UV IR Filter SpectraДокумент12 страницUV IR Filter SpectrajacekwikloОценок пока нет

- Shreyas Pawale ResumeДокумент1 страницаShreyas Pawale ResumeRahulRajGoldyОценок пока нет

- Sam Townsend CV 2011Документ2 страницыSam Townsend CV 2011Sam TownsendОценок пока нет

- Solutions To I E Irodov Problems in General PhysicsДокумент3 страницыSolutions To I E Irodov Problems in General Physicsakshit14nov1996Оценок пока нет

- File E300 Electronic Overload Relays 193-UM015 EN 1 PDFДокумент546 страницFile E300 Electronic Overload Relays 193-UM015 EN 1 PDFAlvaro S. CáceresОценок пока нет

- Transline Part 2Документ97 страницTransline Part 2Haw-ChyunОценок пока нет

- 342 B.sc.b.ed. Mdsu PDF 4yrДокумент135 страниц342 B.sc.b.ed. Mdsu PDF 4yrDINESH SALVIОценок пока нет