Академический Документы

Профессиональный Документы

Культура Документы

2-01201-N-T-019 R05 Diseño de Tuberias

Загружено:

narufredОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2-01201-N-T-019 R05 Diseño de Tuberias

Загружено:

narufredАвторское право:

Доступные форматы

tamsa

TUBOS DE ACERO DE MXICO S. A. GENERAL SEVICES ENGINEERING DEPARMENT PIPE SERVICES ENGINEERING STANDARDS PIPING SPECIFICATIONS GENERAL SPECIFICATIONS 2-01201-N-T-019 REV. 5

5

REV. N

JLH

CHECKED

01/20/97

DATE

1 A 55 DE 55

No. REVISED SHEET

ISSUED FOR TENDER PURPOSE

REASON

REVISION SHEET

MADE CHECKED APPROVED

JLH-VSJ JLH-VSJ RMO

H. VERACRUZ, VER., ENERO 20 DE 19 97 HOJA : 1 DE: 55

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 2 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

INDEX

1.2.3.4.5.6.7.8.9.10.-

INDEX AND SYMBOLS OF SERVICE ARRANGEMENT ACCESS AND CLEARANCES SUPPORTING PIPING IDENTIFICATION ENGLISH ABBREVIATIONS MITERED BENDS TYPICAL DRIP POCKET BRANCH CONNECTIONS PIPING MATERIAL SPECIFICATIONS

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 3 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

1.

INDEX AND SYMBOLS OF SERVICE

CLASS W1 W1 W1 W1 W1 W2 W3 W4 W1 W7 A1 A1 A1 A1 B1 G3 G4 L1 L2 H1 H2 H3 150# 150# 150# 150# 150# 150# 125# 150# 1# 3000# 150# 150# 150# 150# 150# 300# 150# 300# 3000# 1500# 3000# 150#

SYMBOL OF SERVICE RW DW IW SW EW BW PW FW SL HW IA PA N AR FO O NG LU GL OL1 OL2 OL3

SERVICE RAW WATER DIRECT COOLING WATER INDIRECT COOLING WATER SOFT WATER EMERGENCY WATER BOILER WATER POTABLE WATER (DRINKING) FIRE WATER SLURRY WATER HIGH PRESSURE WATER INSTRUMENT AIR PLANT AIR NITROGEN ARGON FUEL OIL GASEOUS OXYGEN NATURAL GAS LUBRICATION OIL LUBRICATION GREASE HYDRAULIC OIL 1500 # HYDRAULIC OIL 3000 # HYDRAULIC OIL ( T AND Dr.)

REVISION 0 1 2 3 4 5 6 X X X X X X X X X X X X X X X X X X X X X X

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 4 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

1.

INDEX AND SYMBOL OF SERVICE.

CLASS W1 W1 W1 W1 W1 W3 W1 W6 H2 H2 W8 150# 150# 150# 150# 150# 150# 150# 150# 3000# 6000# 150#

SYMBOL OF SERVICE CHW DWA IWB IWC DMW CDW STW ASL GW OL4 AH

SERVICE CHILLED WATER FOR AIR CONDITIONING DIRECT COOLING WATER A SYSTEM INDIRECT COOLING WATER B SYSTEM INDIRECT COOLING WATER C SYSTEM DEMINERALIZED WATER CHILLED DRINKING WATER SPRAY TOWER WATER ACID SLURRY GLICOL WATER SYSTEM HYDRAULIC OIL 6000 # ALKALINES AND HALOGENOUS DILUTE ACID

REVISION 0 1 2 3 4 5 6 X X X X X X X X X X X

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 5 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

2.

ARRANGEMENT All piping shall be installed in accordance with ANSI Code for pressure piping B 31.1 or B 31.3 as applicable and this TAMSA Engineering Standard. Overhead piping shall be grouped in banks and arranged to facilitate supporting and provide easy maintenance. Piping connecting equipment shall be designed to permit ready removal of equipment without additional support of pipe. Underground pipe lines shall be installed on solid fill and be kept clear of any major foundations.

3.

ACCESS AND CLEARANCES. All valves shall be located for ease of operation and accessibility. Where valves are not accessible, extension stems or chain wheels shall be used when valve center lines are longer than 2,150 mm above grade or floor. Sufficient clearance around control valves shall be provided to allow remotion of parts without removing valve body from line. Control valves shall be accessible from platforms, walkways or grade.

4.

SUPPORTING. Nomenclature PS- Pipe support, guide, hanger or anchor (see detail on particulars drawings). FS- Field support (suitable support shall be supplied in field). FG- Field guide (guide allowing only axial movement shall be supplied in field). All saddles and anchors shall be installed in field (unless otherwise shown) in accordance with the drawings. Piping to pumps, compressors and their drivers should be anchored close to the equipment to prevent thermal strain and misalignment. Location of pipe supports, guides, hangers and anchors are shown on piping drawings. Flanges and field welds will be so located as to leave a minimum clearance of 300 mm between pipe supports. Pipe suports, guides, hangers or anchors shall be identified by various tag numbers I.E. PS3PS4 etc., in which PS is the pipe support designator, 3 & 4 etc., are pipe support numbers. For convenience in detailing fabrication and erection, the tag numbers are shown on the structural steel and piping drawings. Pipe sleeves shall be provided for all piping passing through foundations, walls, floors, roofs, etc. weather shields shall be located at all openings throught the roof.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 6 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

5.

PIPING. Identification. All piping shall be identified by various service codes. Pipe lines shall be identified as follows:

15-DW-W1-10 LINE SEQUENCE NUMBER SERVICE Valves Identification. All valves shall be identified by variious service codes as follows: LINE SIZE CLASS

DW SERVICE

1 VALVE SEQUENCE NUMBER

The valves list will include: Valve identification. Diameter. Line number TAMSA valve code. Piping, Flanges & Fittings. No carbon steel pipe of the following sizes shall be used: 3/8, 1 1/4, 2 1/2, 3 1/2, 4 1/2, 5, & 7, except otherwise specifically required. Pipe wall thicknesses shall be calculated in accordance with ANSI B31.1.0 (present issue). Flanges shall be kept to a minimum except as indicated by the following service or location: At equipment valves. Spool pieces to allow easy maintenance or repairs without having to cut pipe lines. Other lines as indicated by Engineer.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 7 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

6.

ENGLISH ABBREVIATIONS. BALL JOINT BATTERY LIMIT BELL & SPIGOT BEVELLED END BLIND BOLT CIRCLE BOSS & TAP BOTTOM OF PIPE BUSHING BUTT WELD CARBON STEEL CAST IRON CAP CENTER TO FACE CENTER LINE CHAIN OPERATED CONCENTRIC CONTINUED ON DRAWING CONTINUED ON ISOMETRIC COUPLING DETAIL DIAMETER DIMENSION DRAIN DRAWING DRILL & TOP ECCENTRIC ELBOW ELEVATION ELECTRICAL RESISTANCE WELD EXPANSION JOINT FACE TO FACE BJ BL B&S BE BLD BC B&T BOP Bsg BW CS CI Cp C to F CL CHOP CONC COD COI Cplg DET DIA DIM Dr DWG D&T ECC ELL EL. ERW EXJ F to F Articulacin de rtula Lmites de una unidad Macho y hembra Terminacin biselada Ciego Circunferencia para barrenos saliente y toma Fondo del tubo Reduccin Soldadura de tope Acero al carbn Hierro colado Tapn De centro a cara de brida Lnea de centro Operado con cadena Concntrico Sigue en dibujo Sigue en isomtrico Cople Detalle Dimetro Dimensin Drenaje Dibujo Drill & Top Excntrico Codo Elevacin Soldadura por resistencia elctrica Junta de expansin Cara con cara

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 8 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

FLANGE FLAT FACE FIELD FIT WELD FIELD WELD FORGED STEEL FACE OF FLANGE GASKET HEADER HORIZONTAL HOSE CONNECTION INSIDE DIAMETER IRON PIPE SIZE LONG RADIUS LOCKED CLOSED LOCKED OPEN MALE AND FEMALE NIPPLE NOT FURNISHED OUTSIDE DIAMETER PLAIN END PLUG RAISED FACE REDUCER RING JOINT SAMPLE CONN. SCHEDULE SCREWED SEAMLESS SHORT RADIUS SLIP ON SOCKET WELD STAINLESS STEEL STUD BOLT SWAGE

FLG FF FFW FW FS FOF G HDR HOR HC ID IPS LR LC LO MF Np NF OD PE Pg RF RED RJ SC Sch Scd SML SR SO SW SS SB Swg

Brida Cara plana Ajuste para soldar en el campo Soldado en el campo Acero forjado Cara de la brida Empaque Colector Horizontal Conexion con manguera Dimetro interior Tamao de tubo de hierro Radio largo Cerrado con seguro Abierto con seguro Macho y Hembra Niple No suministrado Dimetro externo Terminacin plana Tapn macho Cara realzada Reduccin Junta de Anillo Conexin para muestreo Cdula Roscado Sin costura Radio Corto Deslizante Soldado en caja Acero inoxidable Esprrago Campanas reductoras

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 9 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

TEE THREADED END TYPICAL UNION VALVE VERTICAL WELDING NECK FLANGE WORKING POINT LARGE END PLAIN LARGE END BEVEL LARGE END THREADED SMALL END BEVEL SMALL END PLAIN SMALL END THREADED TOP OF PIPE

T RE TYP UN V VERT WN WP LEP LEB LET SEB SEP SET TOP

Conexin T Terminacin roscada Tpico Tuerca Unin Vlvula Vertical Brida de cuello soldable Punto de trabajo Terminacin larga y plana Terminacin larga y biselada Terminacin larga y roscada Terminacin corta y biselada Terminacin corta y plana Terminacin corta y roscada Nivel superior del tubo

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 10 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

7.

MITERED BENDS. 90 45 t 3/2

3/2

C/2 3

C

1115 2230 1115 F/2

F 30 30 15

15

A D

NOM. O.D.

4 6 8 10 12 14 16 18 20 22 24 30 36 42 48 114.3 168.3 219.1 273 323.8 334.6 406.4 457.2 508 558.8 609.6 762 914.4 1067 1719

A

245 307 337 399 460 460 491 521 583 613 675 920 1104 1285 1475

B

120 156 178 213 242 254 276 298 333 355 390 518 621 725 825

C

74 89 90 104 119 112 114 116 131 133 147 214 257 300 343

D

225 292 356 419 483 546 610 673 737 800 864 954 1245 1435 1626

E

153 202 249 285 346 388 436 433 531 575 626 769 912 1055 1158

F

92 111 132 151 172 197 218 238 259 279 300 361 422 483 545

NOTES: Extract from AWWA C-208.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 11 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

8.

TIPICAL DRIP POCKET.

300

B 400

500

150 150 2 x 3/4

A

2 3 4 5 8 10 12 14 16 18 20 24

B

---------6 6 6 8 8 8 10 10 10

C

---3 4 ----------------------------

D

2 ----------------------------------

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 12 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

RW - DW - IW - SW -EW - CHW - DWA - IWB - IWB - IWC DMW - STW - FW

CLASS:

ANSI 150# RF/FF CARBON STEEL

W1 - W4

MATERIAL: CORR. ALL FLUID VELOCITY

SERVICES LIMITES:

ITEM:

DIMENS. FROM TO

RATING:

ENDS:

DESCRIPTION:

CODE:

1/2 3/4

1 11/2 2 21/2

9.

BRANCH CONNECTIONS.

2 2 2 2 2 2 2 2 2 2

M A I N P I P E S I Z E

3 4 6 8 10 12 14 16 18 20 24 26 25 30 32 34 36 38 40 3

2 2

1/2" 3/4" 1 11/2 2 21/2 3

8 10 12 14 16 18 20 24 26 25 30 32 34 36 38 40

BRANCH PIPE SIZE 1. Straight or reducing tees (Threaded/Socket Welded) 2. Straight or reducing tees (B.W.) 3. Half coupling (Threaded/Socket Welded) 4. Pipe to Pipe Reinforcements, where necessary shalll be, designed according to ANSI B 31.3

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 13 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: POTABLE WATER (P.W.) SERVICES LIMITES:

CLASS:

ANSI 125# FF

W3

MATERIAL: CARBON STEEL GALVANIZED CORR. ALL FLUID VELOCITY

ITEM:

DIMENS. FROM TO

RATING:

ENDS:

DESCRIPTION:

CODE:

10. BRANCH CONNECTIONS.

1/2

M A I N P I P E S I Z E

3/4

11/2

21/2

1/2

3/4

11/2

21/2

BRANCH PIPE SIZE

1. Straight or reducing tees (Threaded)

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 14 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

PLANT AIR (PA) NITROGEN (N) INSTRUMENT AIR (IA) ARGON (AR) NATURAL GAS(NG)

CLASS: A1 - G4 * ANSI 150# RF MATERIAL: CORR. ALL FLUID VELOCITY CARBON STEEL

SERVICES LIMITES:

ITEM:

DIMENS. FROM TO

RATING:

ENDS:

DESCRIPTION:

CODE:

11. BRANCH CONNECTIONS.

1/2 3/4

M A I N P I P E S I Z E

1 11/2 2 21/2 3 4 6 8 10

2 2 4 2 2 2 2

1/2 3/4

1 11/2

21/2

10

BRANCH PIPE SIZE

1. Straight or reducing tees (threaded/Socket Welded)* 2. Straight tees (Butt Welded) 3. Half couplings (Threaded/Socket Welded) 4. Pipe to pipe without reinforcing For (NG) only socket welded

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 15 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

HIGH PRESSURE WATER (HW)

CLASS:

RATING 3000# R.F CARBON STEEL

W7

MATERIAL: SERVICES LIMITES: 250 Kg/cm2 AT 100 C ITEM: DIMENS. FROM TO RATING: ENDS: CORR. ALL

FLUID VELOCITY DESCRIPTION: CODE:

12. BRANCH CONNECTION.

1/2 3/4

M A I N P I P E S I Z E

1 11/2 2 21/2 3 4 6 8

1/2

4

3/4

11/2

21/2

BRANCH PIPE SIZE

1. Straight or reducing tees (socket Welded) 2. Straight or reducing tees (Butt Welded) 3. Half coupling (socket welded) 4. Welding Bevel coupling (Weldolet)

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 16 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: LUBRICATION OIL (LU) SERVICES LIMITES: 21 Kg/cm2 AT 80-C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: L1 RATING ANS 300# RF MATERIAL: CORR. ALL FLUID VELOCITY DESCRIPTION: CODE: CARBON STEEL

13. BRANCH CONNECTIONS.

1/2 3/4

M A I N P I P E S I Z E

1 11/2 2 21/2 3 4 6 8 10

1/2

3 4 2

3/4

11/2

21/2

10

BRANCH PIPE SIZE 1. Straight or reducing tees (socket welded) 2. Straight or reducing tees (Butt Welded) 3. Half couplings (Socket Welded) 4. Pipe to pipe without reforcing

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 17 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: LUBRICATION GREASE (GL) SERVICES LIMITES: 160 Kg/cm2 AT 100C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: L2 RATING 3000 # R.F MATERIAL: CORR. ALL FLUID VELOCITY DESCRIPTION: CODE: CARBON STEEL

14. BRANCH CONNECTIONS.

M A I N P I P E S I Z E

3/8 1/2

3/4 1 11/4 11/2 2

3/8 1/2 3/4 1 11/4 11/2 2

1 2

BRANCH PIPE SIZE

1. Straight or reducing tees (socket weld) 2. Half coupling (Socket Weld)

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 18 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: HYDRAULIC OIL (OL-1) SERVICES LIMITES: 110 Kg/cm AT 80 C. AND 1500 PSI AT 80 C. RATING: TO ENDS:

2

CLASS: H1-H3 RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION: CARBON STEEL 1/16 2.5 M/S

1500# R.F

ITEM:

DIMENS. FROM

CODE:

15. BRANCH CONNECTIONS.

3/8 1/2 3/4

M A I N P I P E S I Z E

1 11/4 11/2 2 21/4 3 4 6 8

3/8 1/2 3/4

3 4

11/4 11/2

21/4

BRANCH PIPE SIZE 1. Straight or reducing tees (Socket Welded) 2. Straight or reducing tees (Butt Welded) 3. Half coupling (Socket Welded) 4. Welding bevel coupling (Weldolet)

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 19 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: HYDRAULIC OIL (OL-2) SERVICES LIMITES 210 Kg/cm 3000 PSI

2

CLASS: H2 RATING ANSI MATERIAL:

2

3000# R.F.

CARBON STEEL

AT 100 C and 410 Kg. cm AT 100 C and 6000 PSC RATING:

CORR. ALL FLUID VELOCITY: DESCRIPTION: 2.5 M/S CODE:

ITEM:

DIMENS. FROM TO

ENDS:

16. BRANCH CONNECTIONS.

1/2 3/4

M A I N P I P E S I Z E

1 11/2 2 21/2 3 4 6 8

1/2

4

3/4

11/2

21/2

BRANCH PIPE SIZE 1. Straight or reducing tees (Socket Welded) 2. Straight or reducing tees (Butt Welded) 3. Half coupling (Socket Welded) 4. Welding bevel Coupling (Weldolet)

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 20 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: GASEOUS OXIGEN (O) SERVICES LIMITES: 17.5 Kg/cm2 ITEM: DIMENS. FROM TO at 40 C ENDS:

CLASS:

G3 ANSI 300 # R.F. CARBON STEEL 1/16 8.0 m/sec CODE:

MATERIAL: CORR.

FLUID VELOCITY: DESCRIPTION:

RATING:

1/2 1 3/4

1 3 1 2 2 2 4 2 2 6 2 5 2

1/2 3/4

M A I N P I P E S I Z E

1 11/2 2 21/2 3 4 6 8

11/2

21/2

BRANCH PIPE SIZE 1. Tee S.W. 2. Tee B.W. 3. Reducing Tee S.W. 4. Reducing Tee B.W. 5. Reducing Tee + Reduction 6. Half Coupling

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 21 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

RW - DW - IW - SW - EW - SLW - CHW DWA - IWB - IWC - DMW - STW

CLASS: WI RATING ANSI 150 LBS. RF MATERIAL: CORR. ALL CARBON STEEL 1/16 2.5 M/SEC CODE:

SERVICES LIMITES: 10.5 Kg/cm2 at 55C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

PIPE

1/2

80

Scd.

API STD 5L Gr. B, Seamless Steel pipe (to use for underground pipe only). API STD 5L Gr. B, Seamless Steel pipe. API STD 5L Gr. B, Seamless Steel or E.R.W. Carbon Steel Pipe. API STD 5L Gr. B, Seamless Steel or E.R.W. Carbon Steel Pipe. API STD 5L Gr. B, Seamless Steel or E.R.W. Carbon Steel Pipe. ASTM A 105 Gr, II forged carbon steel screwed fittings, conforming to ANSI B 2.1. ASTM A 105 Gr. II forged carbon steel socket welding fittings, conforming to ANSI B 16.11 (To use for underground pipe only). Concentric or eccentric swages made from pipe material and thickness same as pipe, screwed conforming to ANSI B 2.1. ASTM A 234 Gr. WPB carbon steel fittings conforming to ANSI B 16.9, thickness same as pipe. Mittered elbows made form pipe, material and thickness same as pipe: 90 ELBOW - 45 ELBOW

2 1/2 6

4 12

40 6.35 mm

B.E B.E.

14

24

7.92 mm

B.E.

26 38 FITTINGS 1/2

36 46 2

9.52 mm 12.7 mm 1500 Lbs

B.E. Scd.

1/2

1500 Lbs

S.W.

1/2

Scd.

2 1/2

18

B.E.

20

48

B.E.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 22 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

RW - DW - IW - SW - EW - SLW - CHW DWA - IWB - IWC - DMW - STW

CLASS: WI RATING ANSI 150 LBS. RF-FF MATERIAL: CORR. ALL: CARBON STEEL 1/16 2.5 M/SEC CODE:

SERVICES LIMITES: 10.5 Kg/cm2 at 55C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

FLANGES

1/2

150 Lbs.

R.F.

ASTM A 105 Gr. II, Forged carbon steel, socket welding type, as per ANSI B 16.5 ASTM A 105 Gr. II, forged carbon steel welding neck type, as per ANSI B 16.5 ASTM A 105 Gr. II, forged carbon steel welding neck type, as per ANSI B 16.5, (pumps and filters only). ASTM A 105 Gr. II, forged carbon steel, Slip-on type as per ANSI B 16.5 ASTM A 105 Gr. II, forged carbon steel, Slip-on type as per ANSI B 16.5, (for butterfly and Duo-check valves only). ASTM A 181 Gr. I, Forged or rolled carbon steel Slipon flange, stock finish, dimension according to AWWA-C 207 Class E. 1/8 Thick, BUNA N Nylon reinforced full-face type gasket as per ANSI B16-5. 1/8 thick BUNA N Nylon reinforced full face type gasket dimension according to AWWA-C-207 Class E.

2 1/2

12

150 Lbs.

R.F.

2 1/2

12

125 Lbs.

F.F.

14

24

150 Lbs.

F.F.

14

24

125 Lbs.

F.F.

26

36

150 Lbs.

F.F.

GASKETS

2 1/2

24

125 Lbs.

F.F .

26

36

125 Lbs.

F.F.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 23 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

RW - DW - IW - SW - EW - SLW - CHW DWA - IWB - IWC - DMW - STW

CLASS: WI RATING ANSI MATERIAL: CORR. ALL:

150 LBS. RF-FF

CARBON STEEL 1/16 2.5 M/SEC CODE:

SERVICES LIMITES: 10.5 Kg/cm2 at 55C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

BOLTS

ASTM A 307 grade B, carbon steel square head machine bolts with heavy duty coarse threads and semifinished heavy hexagonal nuts conforming to ANSI B 18.2.1 and B 18.2.2 for general USE. ASTM A-193 Gr B7, with two carbon steel ASTM-A194 Gr 2H hexagonal NUTS for butterfly and duocheck valves waffer type.

STUD BOLTS GATE VALVES

1/2 2 1/2

1 12

150 Lbs.

R.F.

Use ball valves. ASTM A 216 grade WCB, cast carbon steel gate valve, conforming to ANSI B 16.5 and 16.10, with bolted bonnet, O.S. & Y., rising stem, flexible wedge disc, ASTM A 182 Gr. F6 trimmed, flanges ends (Crane fig. No. 47X or equal). (To be used for pump suction and discharge valves only, except where specifically called for on drawings). ASTM A 216, grade WCB, cast carbon steel gate valve, conforming to ANSI B 16.5 and B 16.10, with bolted bonnet O.S. & Y., rising stem, solid wedge disc. ASTM A 182 Gr. F6 trimmed, flanged ends, gear operator (Crane fig. No. N 47X or equal).

18

24

150 Lbs.

R.F.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 24 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

RW - DW - IW - SW - EW - SLW - CHW DWA - IWB - IWC - DMW - STW

CLASS: WI RATING ANSI MATERIAL: CORR. ALL: CARBON STEEL 1/16

150 LBS. RF-FF

SERVICES LIMITES: 10.5 Kg/cm2 at 55C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

2.5 M/SEC CODE:

GLOBE VALVES

1/2

200 Lbs.

Scd.

ASTM B 61, bronze body globe valve, with union bonnet, inside screw, rising stem, with seat and plug type disc to be alloy steel and screwed ends conforming to ANSI B 2.1 (Crane fig. 212P or equal).

2 1/2

150 Lbs.

R.F.

ASTM A 216 grade WCB, cast carbon steel, globe valve conforming to ANSI B 16.5 and 16.10 with bolted bonnet, O.S. & Y.,rising stem, and trim to be alloy steel, renewable seat ring, plug type disc. (Crane fig. No. 143XR or equal).

CHECK VALVES

1/2

150 Lbs.

Scd.

Iron body lift check valves, ASTM A 126 class A, with union type cap. to be monel trimmed and screwed ends conforming to ANSI B 2.1 (Crane fig. 366 1/2 or equal).

2 1/2

12

150 Lbs.

R.F.

ASTM S 216, grade WCB, cast carbon steel, swing check valve conforming to ANSI B 16.5 and B 16.10 with bolted cap. and trim conforming to ASTM A 182, grade F6, renewable seat ring, flanged ends (Crane fig. No. 147X or equal)

14

36

150 Lbs.

F.F.

Tilting disc check valve, with weight lever, cast iron body, flange dimension according to ANSI B 16.5 and to AWWA C l207 class E. (VAG cat. fig. KAT153-002-A or equal)

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 25 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

RW - DW - IW - SW - EW - SLW - CHW DWA - IWB - IWC - DMW - STW

CLASS: WI RATING ANSI MATERIAL: CORR. ALL CARBON STEEL 1/16

150 LBS. RF-FF

SERVICES LIMITES: 10.5 Kg/cm2 at 55C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

2.5 M/SEC CODE:

2 1/2

12

150 Lbs.

R.F.

Body ASTM A-216 Gr. WCB plates ASTM A-216 Gr. WCB, Spring and Smuggler ASTM A-316, seat carbon steel, seal Buna N, for instalation between flanges R.F. according to ANSI B-16-5-S 150, type waffer. Duo-chek, mission or equal. Body ASTM A-278 cl. 40, plates ductil cast iron ASTM A-536 Gr. 65-4S-12 smuggler and spring ASTM A-316 (AISI 316) seag bronze ASTM B-61, seal Buna N, for instalation between flanges FF, according to ANSI B 16.5 S 125 Lbs. type waffer. Duo-chek-mission or equal (IBBM). Idem 14 to 24 for instalation between flanges according to AWWA C-207 class E. 150 Lbs. maximum working pressure ASTM A 126, class B, C.I., short laying length. Rubber seated butterfly valve conforming to AWWA C 504, class 150 B, with streamlined ni-resist type I cast iron disc, straight. Through stainless steel shaft, silicone lubricated bronze bearings. Leax proof packing a self loocking work gear operator conforming to AWWA handwheel shaft torque specifications. Wafer type (key stone model 111 with worm gear operator or electric motor operator). 150 Lbs. maximum working pressure, ASTM A 126, class B.C.I. short laying length, rubber seated betterfly valve conforming to AWWA C 504 class 150 B, with streamlined ni-resist type I cast iron disc or fabricated steel disc with stainless steel seating edge, straight through stainless steel shaft, adjustable rubber seat ring. Silicone lubricated bronze bearings, leak proof packing, a self loocking worm gear operator conforming to AWWA hand wheel shaft torque specification, flange dimension according to AWWA C 207 class E, (Keystone Model 105 with worm gear operator or electric motor operator).

14

20

125 Lbs.

F.F.

24

36

125 Lbs.

F.F.

BUTTERFLY

2 1/2

20

150 Lbs.

24

36

125 Lbs.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 26 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

RW - DW - IW - SW - EW - SLW - CHW DWA - IWB - IWC - DMW - STW

CLASS: WI MATERIAL: CORR. ALL

RATING ANSI CARBON STEEL 1/16

150 LBS. RF

SERVICES LIMITES: 10.5 Kg/cm2 at 55C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY DESCRIPTION:

2.5 M/SEC CODE:

GENERAL NOTES: 1. COATING AND WRAPPING OF STEEL PIPE AND FITTINGS The interior surface of all steel pipe and fittings 30 and larger shall be shop cleaned, primed and lined with coal-tar enamel in accordance with AWWA specifications C 203, prior to shipment. All underground steel pipe, irrespective of size, shall be shop cleaned, primed, covered with coal-tar enamel and wrapped with a bonded asbestos-felt wrapper,in accordance with AWWA specifications C 203, prior to shipment. All materials used and their application shall comply with the AWWA specifications C 203 together with sections A 1.2 A 2.2 A 3.2. The primer coat shall be AWWA C 203, type B primer. All pipe coatings shall have an electrical inspection conducted in accordance with section 3.13 and 4.3.5. of AWWA specifications C 203. An 8 cutback (uncoated section), both internal and external, shall be left at each field weld connection. After welding these cutback surfacess shall be thoroughly cleaned and coated (including wrapping) in accordance with AWWA specifications C 203, section 4.3. 2. FITTINGS. Do not use bushings, street elbows and crosses. Unions shall have ground integral seats. Plugs shall be round head and may be ASTM A 234 Gr. WPB hot rolled carbon steel bar stock. For branch connections see pag. 12.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 27 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: FIRE WATER SERVICES LIMITES: 10 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS: (F.W.)

CLASS: W 4 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION: CARBON STEEL 1/16 2.5 M/SEC

150 LBS. RF

CODE:

PIPE

1/2

80

Scd.

API STD 5 L Gr. B, seamless steel pipe. (1) API STD 5L Gr. B, seamless steel pipe.

See note

2 1/2 6

4 12

40 6.35 mm

B.E. B.E.

API STD 5L Gr. B.E.R.W. carbon steel pipe or seamless steel pipe. ASTM A 105 Gr, II forged carbon steel, screwed fittings conforming to ANSI B 2.1 See note (1) ASTM A 105 Gr. II forged carbon steel, socket welding fittings conforming to ANSI B 16.11 (must be used for underground pipe only). Concentric or eccentric swages made from pipe material and thickness same as pipe, screwed confoming to ANSI B 2.1 ASTM A 234 Gr. WPB, carbon steel, fittings, conforming to ANSI B 16.9 thickness same as pipe. ASTM A 105 Gr. II forged carbon steel, socket welding type, conforming to ANSI B A 16.5 (Must be used for underground pipe only). ASTM A 105 Gr. II forged carbon steel welding neck type conforming to ANSI B 16.5 ASTM A 105 Gr. II forged carbon steel threaded type conforming to ANSI B 16.5 See note (1)

FITTINGS

1/2

2000 Lbs

Scd.

1/2

2000 Lbs

S.W.

1/2

Scd.

2 1/2

12

B.E.

FLANGES

1/2

150 Lbs.

R.F.

2 1/2

12

150 Lbs.

R.F.

1/2

150 Lbs.

R.F.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 28 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: FIRE WATER SERVICES LIMITES: 10 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS: (F.W.)

CLASS: W 4 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION: CARBON STEEL 1/16

150 LBS. RF

2.5 M/SEC CODE:

GASKETS

1/2

12

(*)

(*)

1/16 thick compressed asbestos, ring type or full face as required.

BOLTS

ASTM A 307grade B, carbon steel square head machine bolts with heavy duty coarse threads and semi-finished heavy hexagonal nuts, conforming to ANSI B 18.2.1 and B 18.2.2

ASTM A 193 Gr. B7 with two carbon steel ASTM A 194 Gr. 2H. hexagonal nuts. For butterfly and duo-check valves waffer type.

GATE VALVES

1 1/4

125 Lbs.

Scd.

ASTM B 62, cast bronze, gate valve with screwed bonnet, inside screw, rising stem, integral seats, solid wedge disc and screwed ends conforming to ANSI B 2.1 (Crane fig. No. 428 or equal).

2 1/2

12

150 Lbs.

R.F.

ASTM A 216 grade WCB, cast carbon steel gate valve conforming to ANSI B 16.5 AND B 16.10 with bolted bonnet, O.S.& Y. rising stem, flexible wedge disc, ASTM A 182 Gr. F6 trimmed, flanged ends (Crane fig.No. 47X or equal).

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 29 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: FIRE WATER SERVICES LIMITES: 10 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS: (F.W.)

CLASS: W 4 - RATING ANSI 150 LBS. RF MATERIAL: CORR. ALL: FLUID VELOCITY: DESCRIPTION: CARBON STEEL 1/16 2.5 M/SEC CODE:

BUTTERFLY VALVES

2 1/2

12

150 Lbs.

150 Lbs. maximum working pressure, ASTM A 126, class B.C.I. short laying length, rubber seated butterfly valve conforming to AWWA C 504 class 150 B, with streamlined ni-resist type I cast iron disc or fabricated steel disc with stainless steel seating edge, straight through stainless steel shaft, adjustable rubber seat ring. Silicone lubricated bronze bearings, leak proof packing, a self loocking worm gear operator conforming to AWWA hand wheel shaft torque specification, flange dimension according to C 207 class E, (Keystone Model 105 with worm gear operator or electric motor operator)

GLOBE VALVES

1/2

200 Lbs.

Sc.

ASTM B 61, bronze body globe, valve, with union bonnet, inside screw, rising stem, with seat and plug type disc, to be alloy steel and screwed ends conforming to ANSI B 2.1. (Crane fig. 212P or equal).

2 1/2

150 Lbs.

R.F.

ASTM A 216 grade WCB, cast carbon steel, globe valve conforming to ANSI B 16.5 and B 16.10 with bolted bonnet, OS & Y, rising stem ASTM A 182 Gr. F6 trimmed, renewable seat ring, plug type disc, flanged ends (Crane fig. No. 143XR or equal).

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 30 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: FIRE WATER SERVICES LIMITES: 10 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS: (F.W.)

CLASS: W 4 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY DESCRIPTION: CARBON STEEL 1/16

150 LBS. RF

2.5 M/SEC CODE:

CHECK VALVES

1/2

200 Lbs.

Scd.

ASTM B 61 bronze swing check valve, Y pattern with screwed ends conforming to ANSI B 2.1 (Crane Fig. 36 or equal). ASTM A 216 grade WCB, cast carbon steel, swing check valve conforming to ANSI B 16.5 and B 16.10 with bolted cap. and trim conforming to ANSI A 182 grade F6, renewable seat ring, flanged ends (Crane fig.No. 147X or equal). Body ASTM-216 Gr. WCB, plates ASTM A-216 Gr. WCB, Spring ends smuggler ASTM A-316, carbon steel, seal Buna N, for instalation between flanges F.F. according to ANSI B-16.5 S-150, type waffer. Duo-check. Mission or equal.

2 1/2

12

125 Lbs.

R.F.

CHECK VALVES

2 1/2

12

150 Lbs.

R.F.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 31 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: FIRE WATER SERVICES LIMITES: 10 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS: (F.W.)

CLASS: W 4 MATERIAL: CORR. ALL

RATING ANSI CARBON STEEL 1/16

150 LBS. RF

FLUID VELOCITY: DESCRIPTION:

2.5 M/SEC CODE:

GENERAL NOTES. 1. For transformers fire protection only galvanized pipe shall be used and fittings conforming to piping specification class W 3 COATING AND WRAPPING OF STEEL PIPE AND FITTINGS. All underground steel pipe, irrespective of size, shall be shop cleaned, primed, covered with coal tar enamel and wrapped with a bonded asbestos felt wrapper in accordance with AWWA specifications C 203 prior to shipment. Application of all materials shall comply with the AWWA specifications C203 together with sections A 1.2 A 2.2 and 3.1 of the appendix of those specifications the primer coat shall be AWWA C203, type B primer. All pipe coatings shall have an electrical inspection conducted in accordance with section 3.13 and 4.3.5 of AWWA specifications C 203. An 8 cutback (uncoated section), both internal and external, shall be left at each field weld connection, after welding these cutback surfaces shall be thoroughly cleaned and coated (including wrapping) in accordance with AWWA Specifications C 203, Section 4.3 3. FITTINGS. Do not use bushings, street elbows and crosses. Unions shall have ground integral seats. Plugs shall be round head and may be ASTM A 234 Gr. WPB hot rolled carbon steel bar stock. For branch connections see page 12.

2.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 32 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: POTABLE WATER SERVICES LIMITES: 7 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS: (P.W.)

CLASS: W 3 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

150 LBS. RF

CARBON STEEL GALV. 1/16 2.5 M/SEC CODE:

PIPE

1/2

1 1/2

40

Scd.

ASTM A 120 seamless or with seam carbon steel, galvanized, threaded. ASTM A 53 Gr B seamless or with seam, galvanized, threades and coupled. ASTM A 105 Gr. II galvanized forged carbon steel, as per ANSI B 16.5 screwed. Malleable, Galvanized, Gray Iron screwed fittings conforming ANSI B 16.3 Forged carbon steel ASTM A 105 Gr. II, screwed galvanized reducers or reducing fittings. Carbon steel screwed round bar stock, galvanized. Malleable iron, screwed ends, bronze to iron seat, galvanized ANSI B 16-3 1/16 thick Buna N, fullface type. Carbon steel machine bolts ASTM A 307 Gr. B with heavy hex. nuts, conforming to ANSI B 18.2.1 and 18.2.2 ASTM B 62 Cast bronze, gate valve with screwed bonnet inside screw rising stem integral seats, solid wedge disc and screwed ends (Crane No. 428)

40

Scd.

FLANGES

1/2

125 Lbs.

F.F

FITTINGS

1/2

150 Lbs.

Scd.

BUSHINGS

1/2

150 Lbs.

Scd.

PLUGS UNIONS

1/2 1/2

4 3

150 Lbs. 150 Lbs.

Scd. Scd.

GASKETS BOLTING

1/2 -

4 -

125 Lbs. -

GATE VALVES

1/2

125 Lbs.

Scd.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 33 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: POTABLE WATER SERVICES LIMITES: 7 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS: (P.W.)

CLASS: W 3 RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

150 LBS. RF

CARBON STEEL GALV. 1/16 2.5 M/SEC CODE:

GLOBE VALVES

1/2

200 Lbs.

Scd.

ASTM B 61 bronze, union bonnet, inside screw rising stem, plug type disc, screwed ends, (Crane fig. No. 212P or equal). ASTM B 62 bronze, swing type, screwed ends, installation in horizontal or vertical position for upward flow (Crane fig. No. 34 or equal). ASTM-A-126 class B half steel, bronze inside, non rising stem, solid wedge disc. (Crane fig. No. 461). ASTM-&-126 class B half steel, bronze inside, screw rising stem, solid wedge disc (Crane fig. No. 351).

CHECK VALVES

1/2

200 Lbs.

Scd.

GATE VALVES GLOBE VALVES

125 Lbs.

F.F.

125 Lbs.

F.F.

NOTES: All threads shall be in accordance with ANSI B 2.1 and made up with suitable thread lubricant. For branch connections see pag. 13.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 34 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

PLANT AIR (PA) NITROGEN (N) INSTRUMENT AIR (IA) ARGON (AR)

CLASS: A1 - RATING ANSI MATERIAL: CORR. ALL

150 LBS. RF

CARBON STEEL. 1/16 10 M/SEC CODE:

SERVICES LIMITES: 10 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

PIPE

1/2 2 1/2

2 8 2

80 40 3000 Lbs

Scd. B.E. Scd.

API Std. 5L Gr. B seamless carbon steel pipe. API Std. 5L Gr. B seamless carbon steel pipe. ASTM A 105 Gr. II forged carbon steel, screwed fittings, conforming to ANSI B 16-11 ASTM A 105 Gr. II forged carbon steel socket welding fittings, conforming to ANSI B 16.11 (must be used for underground pipe only) ASTM A 234 Gr. WPB, seamless carbon steel fittings conforming to ANSI B 16.9 ASTM A 105 Gr. II forged steel, socket welding type conforming to ANSI B 16.5 (Must be used for underground pipe only). ASTM A 105 Gr. II forged steel threaded type, conforming to ANSI B 16.5 ASTM A 105 Gr. II forged steel, welding neck type conforming to ANSI B 16.5 1/16 thick compressed asbestos, flat ring type. ASTM A 307 Gr. B carbon steel square head machine bolts. with heavy duty coarse threads and semifinished heavy hexagonal nuts conforming to ANSI B 18 2.1 and B 18 2.2

FITTINGS

1/2

1/2

3000 Lbs

S.W.

2 1/2

40

B.E.

FLANGES

1/2

150 Lbs.

R.F.

1/2

150 Lbs.

R.F.

2 1/2

150 Lbs.

R.F.

GASKET BOLTS

1/2 -

8 -

150 Lbs. -

R.F. -

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 35 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

PLANT AIR (PA) NITROGEN (N) INSTRUMENT AIR (IA) ARGON (AR)

CLASS: A1 - RATING ANSI 150 LBS. RF MATERIAL: CORR. ALL CARBON STEEL 1/16 10 M/SEC CODE:

SERVICES LIMITES: 10 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

GATE VALVES

1/2

Use globe valve.

1 1/4

125 Lbs.

Scd.

ASTM B 62, cast bronze gate valve with screwed bonnet, inside screw. Rising stem, integral seats, solid wedge disc and screwed ends conforming to ANSI B 2.1. (Crane fig. 428 or equal). ASTM A 216, Gr. WCB, cast carbon steel, gate valve conforming to ANSI B 16.5 and B 16.10 with bolted bonnet, OS & Y, rising stem flexible wedge disc, ASTM A 182 Gr. F 6 trimmed flanged ends (Crane fig. No. 47X or equal). ASTM B 61, bronze body globe valve with union bonnet, inside screw rising stem, with seat and plug type disc, to be alloy steel and screwed ends conforming to ANSI B 2.1 (Crane fig. 212 P or equal). ASTM A 216, grade WCB cast carbon steel globe valve conforming to ANSI B 16.5 and B 16.10 with bolted bonnet, OS & Y, rising stem, trim to be alloy steel renewable seat ring, plug type disc, flanged ends (Crane fig. No. 147X or equal). ASTM B 61 bronze body check valve, and pattern with plug type cap, bronze internals and screwed ends conforming to ANSI B 2.1 (Crane Fig. 36 or equal).

2 1/2

150 Lbs.

R.F.

GLOBE VALVES

1/2

200 Lbs.

Scd.

2 1/2

150 Lbs.

R.F.

CHECK VALVES

1/2

200 Lbs.

Scd.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 36 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

PLANT AIR (PA) NITROGEN (N) INSTRUMENT AIR (IA) ARGON (AR)

CLASS: A1 - RATING ANSI MATERIAL: CORR. ALL CARBON STEEL 1/16

150 LBS. RF

SERVICES LIMITES: 10 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

10 M/SEC CODE:

2 1/2

150 Lbs.

R.F.

ASTM A 216 grade WCB, cast carbon steel, swing check valve conforming to ANSI B 16.5, and B 16.10 with bolted cap, and trim conforming to ASTM A 182, grade F 6, renewable seat ring, flg. ends (Crane fig. N 147X or equal). Body ASTM A-106 Gr. II chrome, ball ASTM A-182 Gr. F6, seat and seats teflon screwed ends Worcester econ-o-miser or equal.

BALL VALVES

1/2

600 WOG

Scd.

NOTES: FITTINGS. Do not use bushings, street elbows and crosses. Unions shall have ground integral seats. Plugs shall be round head and may be ASTM A 234, Gr. WPB hot rolled carbon steel bar stock For branch connections see page 14.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 37 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: NATURAL GAS SERVICES LIMITES: 18 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: G4 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION: CARBON STEEL 1/16

150 LBS. PF

15 M/SEC. MAX CODE:

PIPE

1/2

80

P.E.

API Std. 5L Gr. B seamless carbon steel pipe.

2 1/2

40

B.E.

API Std. 5L Gr. B seamless carbon steel pipe.

FITTINGS

1/2

3000 Lbs

S.W.

ASTM A 105 II forged carbon steel, socket welding fittings, conforming to ANSI B 16.11

2 1/2

40

B.E.

ASTM A 234 WPB, seamless carbon steel fittings conforming to ANSI B 16.9

FLANGES

1/2

150 Lbs.

R.F.

ASTM A 105 Gr. II, forged carbon steel, socket welding type conforming to ANSI B 16.5

2 1/2

150 Lbs.

R.F.

ASTM A 105 Gr. II forged carbon steel, welding neck type, conforming to ANSI B 16.5

GASKETS

1/2

150 Lbs.

R.F.

1/16 thick compressed asbestos, flat ping gasket.

BOLTS

ASTM A 307, grade B. carbon steel square head machine, bolts with heavy duty coarse theads and semi-finished heavy hexagonal nuts conforming to ANSI B 18.2.1. and 18.2.2

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 38 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: NATURAL GAS SERVICES LIMITES: 18 Kg/cm2 at 40C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: G4 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

150 LBS. PF

CARBON STEEL 1/16 15 M/SEC. MAX CODE:

PLUG VALVES

1/2

300 Lbs.

S.W.

Carbon steel body ASTM A 105 Gr. II or ASTM-A216 Gr. WCB socket welding ends rockwell nordstrom No. 2024 or resembling. Body ASTM A-105 Gr. II Chrome, ball ASTM A-182 Gr. F6 seat and seal teflon screwed ends, Worcester econ-o-miser or equal. ASTM A 216 grade WCB, cast carbon steel body, lubrificated plug, flanged ends with 1/18 R.F. wrench operated lockwell nordstrom No. 1925 powell 1559 or resembling.

1/2

600 WOG

S.W.

2 1/2

150 Lbs.

R.F.

For branch conections see page 14.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 39 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: HIGH PRESSURE WATER (HW) SERVICES LIMITES: 250 Kg/cm2 at 100C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: W7 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION: CARBON STEEL 1/16 --

2500 LBS. RF

CODE:

PIPE

1/2 2 1/2

2 8 2

XXS XXS 6000 Lbs

P.E. B.E. S.W.

ASTM-A-106 Gr. B, seamless carbon steel pipe. ASTM-A-106 Gr. B, seamless carbon steel pipe. ASTM-A-105 Gr. II, forged carbon steel, socket welding fittings conforming to ANSI B 16.11 ASTM-A-234 Gr. WPB, carbon steel, conforming to ANSI B 16.9, Butt welded. ASTM-A-105 Gr. II, forged carbon steel, welding neck, conforming to ANSI B 16.5, same thickness to pipe Smooth finish surface roughness 125 AARH for spiral Wound gasket.

FITTINGS

1/2

2 1/2

XXS

B.E.

FLANGES

1/2

3000 Lbs

R.F.

GASKETS

1/2

3000 Lbs

R.F.

3/16 thick, compressed asbestos, spiral wound, type 304 stainless steel, for raised face flanges. Dimension TOAP1 601 4.5 mm thickness. ASTM-A-193 Gr. B7, with two carbon steel ASTM-A194 Gr, 2H hexagonal nuts. Obteined from ASTM-A-105Gr. II forged carbon steel block, with seat and stem to be 13% Cr. stainless steel, including flanges and nozzle.

BOLTS

BLOCK VALVES

1 1/2

3000 Lbs

B.E.

NOTES: For 1/2 to 1 1/2 flanges, shall be used four holes square type flanges with ORing. For branch connections see page 15.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 40 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: LUBRICATION OIL (LU) SERVICES LIMITES: 21 Kg/cm2 at 55C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: L1 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

300 LBS. RF

CARBON STEEL 0.05 2.5 M/SEG CODE:

PIPE

1/2 2

1 1/2 6 1 1/2

80 40 3000 Lbs

P.E. B.E. S.W.

ASTM-A-53 Gr. B seamless carbon steel pipe. ASTM-53 Gr. B seamless carbon steel pipe. ASTM-A-105 Gr. II forged carbon steel, socket welded. ANSI B.16.11 ASTM-A-234 Gr. WPB, carbon steel, butt welded. ANSI B 16.9 ASTM-A-105 Gr. II, forged carbon steel, socket welded. ASTM-A-105 Gr. II, forged carbon steel, socket welded. ASTM-A-105 Gr. II, forged carbon steel, socket welded. 125 AARH ASTM-A-105 Gr. II forged carbon steel, welding neck internal bore in according with rating. Smooth finish 125 AARH for spiral wound gasket. 1/16 thick compressed asbestos spiral wound, type 304 stainless steel, for raised face flanges, flexitalic type CGP or equal. ASTM-A-193 Gr B7, with two carbon steel ASTM-A194 Gr. 2H, hexagonal nuts.

FITTINGS

1/2

40

B.W.

UNIONS

1/2

1 1/2

3000 Lbs

S.W.

COUPLINGS

1/2

1 1/2

3000 Lbs

S.W.

FLANGES

1/2

1 1/2

300 Lbs.

R.F.

300 Lbs.

R.F.

GASKETS

1/2

300 Lbs.

R.F.

BOLTS

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 41 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: LUBRICATION OIL (LU) SERVICES LIMITES: 21 Kg/cm2 at 55C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: L1 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

300 LBS. RF

CARBON STEEL 0.05 2.5 M/SEG CODE:

GATE VALVES

1/2

1 1/2

800 Lbs.

S.W.

ASTM-A-105 Gr. II, forged carbon steel body, standards stem, solid wedge disc, hancock 950 WO, vogt SW 12113117 or equal-socket welded. ASTM-A-216 Gr. WCB, cast carbon steel body, standards stem seat and gasket, rising stem, solid wedge disc crane 33X or equal rised face flanges 125 AARH. ASTM-A-105 Gr. II, socket welded, forged carbon steel body, standards stem seat and gasket, rising stem, plug type disc, crane 151X or equal. ASTM-A-216 Gr. WCB, cast carbon steel body, rised face flanges, standards stem seat and gasket, rising stem, plug type disc, crane 151X or equal 125 AARH. ASTM-A-105 Gr. II, socket welded, forged carbon steel body, ball type, installation in horizontal or vertical position, VOGT-S-W-5 4853147 or equal. ASTM-A-216 Gr. WCB, cast carbon steel body, raised faces flanges, crane 159 X or equal 125 AARH.

300 Lbs.

R.F.

GLOBE VALVES

1/2

1 1/2

800 Lbs.

S.W.

300 Lbs.

R.F.

CHECK VALVES

1/2

1 1/2

600 Lbs.

S.W.

300 Lbs.

R.F.

NOTE: For branch connection see page 16.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 42 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: LUBRICATION GREASE (GL) SERVICES LIMITES: 160 Kg/cm2 at 100C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: L2 - RATING MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

2500 LBS.

CARBON STEEL

CODE:

PIPE

1/8

3/8

40

P.E.

ASTM-A-106 Gr. B, seamless carbon steel pipe.

1/2

80

P.E.

ASTM-A-106 Gr. B, seamless carbon steel pipe.

1/8 CONNECTION

6000 Lbs

S.W.

ASTM-A-105 Gr. II, socket welded, forged carbon steel, ANSI B.16.11

NOTE: For branch connections see page 17.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 43 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: HYDRAULIC OIL (OL1) SERVICES LIMITES: 110 Kg/cm2 at 80 C 1500 PSI at 80 C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: H1 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

1500 LBS. R.F.

CARBON STEEL 1/16 2.5 M/S CODE:

PIPE

3/8

80

B.E.

ASTM-A-53 Gr. B seamless carbon steel pipe.

2 1/2

160

B.E.

ASTM-A-53 Gr, B seamless carbon steel pipe.

FITTINGS

3/8

3000 Lbs

S.W.

ASTM-A-105 Gr. II, forged carbon steel, socket welded, in according with ANSI B.16.11 (See note No.1)

1 1/4 2 1/2 UNIONS 3/8

2 8 -

80 B.E. 160 3000 Lbs S.W.

ASTM-A-234 WPB seamless carbon steel butt welded, in according with ANSI-B. 16.9

ASTM-A-105 Gr. II, forged carbon steel, socket welded, in according with ANSI B.16.11

FLANGES

3/8

3000 Lbs

R.F.

ASTM-A-105 Gr. II, forged carbon steel, socket welded. (See Note 2)

2 1/2

3000 Lbs

R.F.

ASTM-A-105 Gr. II, forged carbon steel, welding neck conforming to ANSI B.16.5, same thickness to pipe R.F. 125 AARH.

GASKET

2 1/2

3000 Lbs

R.F.

3/16 thick, compressed asbestos, spiral wound, type 304 stainless steel for raised face flanges.

BOLTS

ASTM-A-193 Gr. B7, with two carbon steel ASTM-A194 Gr 2 hexagonal nuts.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 44 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: HYDRAULIC OIL (OL1) SERVICES LIMITES: 110 Kg/cm2 at 80 C 1500 PSI at 80 C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: H1 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

1500 LBS. R.F.

CARBON STEEL 1/16 2.5 M/S CODE:

GATE VALVES

3/8

1500 Lbs

S.W.

ASTM-A-105 Gr. II, forged carbon steel body, standards stem seat and gasket, rising stem, solid wedge disc, hancock 950 W.O. Vogt 12111 or equal, socket welded.

2 1/2

900 Lbs.

R.F.

ASTM-A-216 Gr. WCB, cast carbon steel body, standards stem seat and gasket, rising stem, solid wedge disc, crane 83 XR or similar, rised face flanges.

GLOBE VALVES

3/8

1500 Lbs

S.W.

ASTM-A-105 Gr. II, forged carbon steel body, standards stem seat and gasket, rising stem, plug type disc, hancock 5520 W, socket welded.

2 1/2

900 Lbs.

R.F.

ASTM-A-216 Gr WCP, cast carbon steel body, standards stem seat and gasket, rising stem, plug type disc crane 183 XR or equal, rised face flanges.

CHECK VALVES

1/2

1500 Lbs

S.W.

ASTM-A-105 Gr. II, forged carbon steel, body, ball type installation in horizontal or vertical position, Vogt-SW-5-4853/47 or equal, socket welded.

2 1/2

900 Lbs.

R.F.

ASTM-A-216 Gr. WCB, cast carbon steel body, rised face flanges, crane 187X or equal.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 45 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: HYDRAULIC OIL (OL1) SERVICES LIMITES: 110 Kg/cm at 80 C 1500 PSI at 80 C ITEM: DIMENS. FROM TO RATING: ENDS:

2

CLASS: H1 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

1500 LBS. R.F.

CARBON STEEL 1/16 2.5 M/S CODE:

NOTES: As possible, the pipe shall be cold bended with a four times or more diameter pipe radius. For 1/2 to 2 flanges, shall be used four holes square type flanges with ORing (SAE). Pipes joint shall be butt welded. For branch connections, see page 18.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 46 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: HYDRAULIC OIL (OL2) SERVICES LIMITES: 210 Kg/cm2 at 100 C and 3000 PSI at 100 C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: H2 - RATING ANSI MATERIAL: CORR. ALL FLUID VELOCITY DESCRIPTION:

3000 LBS. R.F.

CARBON STEEL 1/16

CODE:

PIPE

3/8 2 1/2

2 4 4 2 4

XXS XXS 3000 Lbs

P.E. B.E.

ASTM-A-106 Gr. B, seamless carbon steel pipe. ASTM-A-106 Gr. B, seamless carbon steel pipe. ASTM-A-105 Gr II, forged carbon steel, socket welding fittings conforming to ANSI B 16.11

FITTINGS

1/2 1/2 2 1/2

S.W. 6000 Lbs XXS B.E.

ASTM-A-234 Gr. WPB, carbon steel, conforming to ANSI B 16.9 butt weld. ASTM-A-105 Gr. II, forged carbon steel, socket welded, in acording with ANSI B.16.11 AISI 1018 carbon steel socket weld conforming SAE Code 61 or 62 (Main or equal).

UNIONS

3/8

6000 Lbs

S.W.

FLANGES

1/2 1/2

4 4" 4 4 -

3000 Lbs S.W. 6000 Lbs 3000 Lbs 6000 Lbs -

GASKET

1/2 1/2

BUNA N ORing seals (main or equal).

BOLTED

ASTM A-193 Gr. B.7, with two carbon steel ASTM A194 Gr. 2 hexagonal nuts. (main equal). Valves will used in accordance with Rexroth, vogt or hancock.

VALVES

3/8

3000 Lbs 6000 Lbs

NOTES: As possible, the pipe shall be cold bended with a four times or more diameter pipe radius. For brahck connections, see page 19.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 47 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

HYDRAULIC OIL (OL3) (T - DR.)

CLASS: H3 - RATING ANSI MATERIAL: CORR. ALL CARBON STEEL 1/16 2.5

150 LBS. R.F.

SERVICES LIMITES: 16 Kg/cm2 at 80 C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

CODE:

PIPE

3/8 2 1/2

2 10 1

80 40 3000 Lbs

B.E. B.E. S.W.

ASTM-A-53 Gr. B seamless carbon steel pipe. ASTM-A-53 Gr. B seamless carbon steel pipe. ASTM-A-105 Gr.II, forged carbon steel, socket welded, ANSI B. 16.11 ASTM-A-234-WPB, carbon steel butt welded, ANSI B.16.9 butt welded.

FITTINGS

3/8

1 1/4 2 1/2 UNIONS 3/8

2 10 -

80 B.E. 40 3000 Lbs S.W.

ASTM-A-105 Gr. II, forged carbon steel, ANSI B.16.11 socket welded. ASTM-A-105 Gr. II, forged carbon steel, See Note 2, socket welded ASTM-A-105 Gr.II, forged carbon steel, ANSI B.16.5, welding neck, same thickness to pipe. 1/16 thick, compressed asbestos, spiral wound, for raised face flanges. ASTM-A-193 Gr B7, with two carbon steel ASTM-A194 Gr. 2H hexagonal nuts. ASTM-A-105 Gr. II, forged carbon steel body, standards stem seat and gasket, rising stem, solid wedge disc, hancock 950 W.O. Vogt SW-12111 or equal, socket welded.

FLANGES

3/8

150 Lbs.

R.F.

2 1/2

10

150 Lbs.

R.F.

GASKET

2 1/2

10

150 Lbs.

R.F.

BOLTS

GATE VALVES

3/8

900 Lbs.

S.W.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 48 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

HYDRAULIC OIL (OL4) (T - DR.)

CLASS: H3 - RATING ANSI MATERIAL: CORR. ALL

150 LBS. R.F.

CARBON STEEL 1/16 2.5 M/S CODE:

SERVICES LIMITES: 16 Kg/cm2 at 80 C ITEM: DIMENS. FROM TO RATING: ENDS:

FLUID VELOCITY: DESCRIPTION:

GATE VALVES

2 1/2

10

150 Lbs.

R.F.

ASTM-A-216 Gr. WCB, cast carbon steel body, standards stem seat and gasket, rising stem, solid wedge disc, crane 47 XR or equal, rised face flanges. ASTM-A-105 Gr. II, forged carbon steel body, standards stem set and gasket, rising stem, plug type disc, handcock 552OW, socket welded. ASTM-A-216 Gr. WCB, cast carbon steel body, standards stem plug type disc, crane 143XR or equal, rise. ASTM-A-105 Gr. II, forged carbon steel body, ball type installation in horizontal or vertical position, Vogt-SW-5/4853/47 or equal, socket welded. ASTM-A-216 Gr. WCB, cast carbon steel body, raised face flanges, crane 147X or equal.

GLOBE VALVES

3/8

1500 Lbs

S.W.

2 1/2

150 Lbs.

R.F.

CHECK VALVES

1/2

1500 Lbs

S.W.

10

150 Lbs.

R.F.

NOTES: As possible, the pipe shall be cold bended with a four times or more diameter pipe radius. For 1/2 to 2 flanges, shall be used four holes square type flanges with ORing. Pipes joint shall be butt weld. For branch connections, see page 18.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 49 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: GASEOUS OXIGEN (O) SERVICES LIMITES: 17,5 Kg/cm2 at 40 C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: G3 - ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

300 LBS. R.F.

CARBON STEEL 1/16 80 M/SEC CODE:

PIPE

1/2 1 1/2 2 1/2

1 2 8 1

80 80 40 3000 Lbs

P.E. B.E. B.E. S.W.

API Std. 5L Gr. B, seamless steel pipe. API Std. 5L Gr. B, seamless steel pipe. API Std. 5L Gr. B, seamless steel pipe. ASTM A 105 Gr. II, forged carbon steel, socket welding fittings, conforming to ANSI B 16.11 ASTM A 234 Gr. WPB seamless carbon steel, conforming to ANSI B 16.9

FITTINGS

1/2

1 1/2 2 1/2 FLANGES 1/2

2 8 1

80 B.E. 40 300 Lbs. R.F.

ASTM A 105 Gr. II forged carbon steel, socket welding type, conforming to ANSI B 16.5 smooth finish surface roughness 125 AARH for spiral wound gasket. ASTM A 105 Gr. II, forged carbon steel, welding neck type conforming to ANSI B 16.5 smooth finish surface roughness 125 AARH for spiral wound gasket. ASTM A 105 Gr. II forged carbon steel, blind type conforming to ANSI B 16.5 smooth finish surface roughness 125 AARH for spiral wound gasket. Spiral wound type 304 stainless steel asbestos 100% gaskets Suitable for oxigen, dimensions to API 601 - 4,5 mm. thickness.

300 Lbs.

R.F.

1/2

300 Lbs.

R.F.

GASKETS

1/2

300 Lbs

R.F.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 50 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: GASEOUS OXIGEN (O) SERVICES LIMITES: 17,5 Kg/cm2 at 40 C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: G3 - ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

300 LBS. R.F.

CARBON STEEL 1/16 80 M/SEC CODE:

BOLTS

Stud bolts, alloy steel ASTM A 193 Gr. B 7 threaded full length to ANSI B 1.1 CL 2A. Carbon steel ASTM A 194 Gr. 2H Std. heavy hex. nuts dimension to ANSI B 18.2.2 thread as for ANSI B1.1 CL. 2B. Ball valve for oxygen service, fire safe type, stainless, steel body AISI B 16, teflon seat ring, packing stem for oxygen service, lever operator, socket welding ends, (Jamesbury Model. A Z.0 or equal). Ball valve for oxygen service, fire safe type, stainless steel body, AISI B16, ball and stem AISI 316, teflon seat ring, packing stem for oxygen service, 4 and smaller lever operator, 6 and larger gear operator, flanged ends R.F. for ANSI B 16.5, Smooth finish surface roughness 125 AARH for spiral wound gaskets. (Jamesbury Model 5306 or equal). Ball check valve for oxygen service, horizontal operation, stainless steel body AISI 316, ball AISI 316, bolted Cap. AISI 316, seat AISI 316, socket welding ends. Swing check valve for oxygen service, stainless stell body AISI 316, disc AISI 316, bolted cover AISI 316, seat AISI 316, flanged ends for ANSI B 16.5 R.F. type, smooth finish surface roughness 125 AARH for spiral wound gaskets.

BALL VALVES

1/2

1 1/2

600 Lbs.

S.W.

300 Lbs.

R.F.

CHECK VALVES

1/2

1 1/2

800 Lbs.

S.W.

300 Lbs.

R.F.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 51 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: GASEOUS OXIGEN (O) SERVICES LIMITES: 17,5 Kg/cm2 at 40 C ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: G3 - ANSI MATERIAL: CORR. ALL FLUID VELOCITY: DESCRIPTION:

300 LBS. R.F.

CARBON STEEL 1/16 80 M/SEC CODE:

GENERAL NOTES: 1. All pipes, fittings and accesories shall be pickled, washed, degreased and plugged before despatch, so as to be suitable for oxygen service. 2. FITTINGS: Do not used crosses. Use unions with socket welding ends where required by frequent routine maintenace. For branch connection see page 20.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 52 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: ACID SLURRY SERVICES LIMITES: Atmospheric - 110 F ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: ACE2. PTA.

W6

MATERIAL: PVC (Polyvinyl clorure) CORR. ALL -------------------0.5 M/SEG CODE:

FLUID VELOCITY: DESCRIPTION:

Nom. PIPE 1 1/2

In. 2

Sch 80

Ends. B.E. ASTM D 1785 pipe, in CPVC (Chlorinated Polyvinyl clorure)

2 1/2

4.25

B.E.

ASTM D 1785 Pipe in PVC, (Polyvinyl clorure).

FITTINGS

1/2

80

S.W.

ASTM D 2467 IN CPUC (Chlorinated Polyvinyl clorure) Socket-type schedule 80 fittings.

2 1/2

4.25

S.W.

PVC-Industrial Drainage, In ASTM D1785 material, hub X hub or spigotxhub as catalog PPS 1980 Volume I sheet 39 to 47) Quick couplings, conforms MIL-C-27487 (Catalog PPS Volume I 1980 sheet 54 to 55) Bulkhead fitting catalog PPS PVC fig. 0261136

FLANGES

SLIP, figure 02001120 and 0122100 Catalog PPS1980 Volume I, material ASTM D 1785, CPVC (for 0 upper 2 1/2 use transition pipe sch 40 for connection with pipe 4.25 PVC).

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 53 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE: ACID SLURRY SERVICES LIMITES: Atmospheric - 110 F ITEM: DIMENS. FROM TO RATING: ENDS:

CLASS: ACE2. PTA. MATERIAL: CORR. ALL

W6

PVC and CPVC --------------------------0.5 M/SEG or Gravity CODE:

FLUID VELOCITY: DESCRIPTION:

Nom. GASKETS 1/2

In. 8

Sch ALL

Thicknes 1/8 Use o Rings or (fluoroelastomer). face gaskets of VITON

VALVES

1/2

True union ball valves in CPVC (Catalog PPS sheet 62 volume 1980, fig. 0332322) Seats of teflon, handle in ABS ORings in VITON.

2 1/2

Single union ball valves (catalog PPS sheet 61, volume I 1980 fig. 0312331) Seats of teflon, ORing in Viton Body and Ball in CPVC-Handles in ABS.

CHECK VALVES

1/2

S.W.

Diaphragm check valves, body in PVC, Diaphragm in Viton. Catalog PPS Volume I 1980 fig. 0861323

1 1/2

S.W.

Ball check valve, body in CPVC ORings In Viton (Catalog PPS Volume I 1980 fig. 0832323).

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 54 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

Alkalines and halogenous dilute acid NaOH50%-SO4H296%-HCL36% CL70,GS334,CS,H2515

CLASS: ACE2. PTA.

W8

MATERIAL: PVC (Polyvinyl clorure) CORR. ALL ---------------------0.8 M/SEG CODE:

SERVICES LIMITES:

FLUID VELOCITY: ITEM: DIMENS. FROM TO RATING: ENDS: DESCRIPTION:

Nom. PIPE 1 1/2

In. 2 1/2

Sch 80

Ends B.E. ASTM D 1785 Pipe, in CPVC (Chlorinated Polyvinyl clorure).

FITTINGS

1/2

2 1/2

80

S.W.

ASTM D 2467 IN CPVC (Chlorinated Polyvinyl clorure) Socket-type schedule 80 fittings. Quick couplings, conforms mil C27487 catalog. PPS Volume I 1980 sheet 54 to 55 Bulkhead fitting catalog PPS PVC fig. 0261136 and 0122100.

FLANGES

1/2

2 1/2

80

S.W.

SLIP, figure 02001120 Material ASTM D 1785 CPVC, Catalog PPS, Volume I 1980.

GASKETS

1/2

2 1/2

1/8

Use ORings or (Fluoroelastomer)

face

gaskets

of

Viton

VALVES

1/2

2 1/2

True union Ball valves in CPVC (Seats of Teflon, ORings in VITON Handle in ABS). Catalog PPS Volume 1, sheet 62, fig. 0332322.

TITLE:

No. OF DOCUMENT 2-01201-N-T-019

SHEET: 55 OF: REV. 55

PIPING SPECIFICATIONS

tamsa

SERVICE:

Alkalines and halogenous dilute acid NaOH50%-SO4H296%-HCL36% CL70,

CLASS: ACE2. PTA. MATERIAL: CORR. ALL

W8

PVC and CPVC ---------------------0.8 M/SEG CODE:

SERVICES LIMITES:

FLUID VELOCITY: ITEM: DIMENS. FROM TO RATING: ENDS: DESCRIPTION:

CHECK VALVES

1/2

2 1/2

S.W.

Ball check valve, body in CPVC ORings in Viton. (Catalog PPS Volume I 1980 fig. 0832323).

FLEXIBLE TUBBING

1/4

5/8

Polyethylene tubing series EHB High Density. Catalog Parker Parflex EHB-4-0250 to 60500 and GT 86-0500-GT1080500. For connections pumps and others, use fluid connectors fast y tite in black polypropylene NPT tread parflex No. 3312484 - P4MC2 to P10MC12.

Вам также может понравиться

- 80valve Data SheetsДокумент82 страницы80valve Data SheetsOscarin1978Оценок пока нет

- Brochure 3Документ12 страницBrochure 3Gohilakrishnan ThiagarajanОценок пока нет

- 3-Way Valve - ThreadedДокумент4 страницы3-Way Valve - ThreadedAhrian BenaОценок пока нет

- 11422Документ10 страниц11422balajivangaruОценок пока нет

- BallValues PDFДокумент12 страницBallValues PDFDevdatt WaghuleОценок пока нет

- rc18011 f09Документ7 страницrc18011 f09Trayo AyangbayiОценок пока нет

- Series 411 Specification SheetДокумент2 страницыSeries 411 Specification SheetWattsОценок пока нет

- Virgo Welded Valve BrochureДокумент8 страницVirgo Welded Valve BrochureHerrera Jorge AgustínОценок пока нет

- RTDДокумент68 страницRTDMaria DenetОценок пока нет

- STD PipingДокумент51 страницаSTD PipingRodrigo Iván Latorre AlmirallОценок пока нет

- Series 406NRSRW Specification SheetДокумент2 страницыSeries 406NRSRW Specification SheetWattsОценок пока нет

- Compact solenoid valves for commercial applicationsДокумент16 страницCompact solenoid valves for commercial applicationsJorge Jarpa VОценок пока нет

- A09Документ1 страницаA09liviu_dovaОценок пока нет

- Flowserve Valvulas de Bolas y Valvulas YДокумент148 страницFlowserve Valvulas de Bolas y Valvulas YJuan Gutierrez CastilloОценок пока нет

- Comeval Cast Steel Gate Valve ANSI 150 PDFДокумент5 страницComeval Cast Steel Gate Valve ANSI 150 PDFblizanacОценок пока нет

- Piping Material Specification RatingsДокумент4 страницыPiping Material Specification RatingsPrasanta Kumar BeheraОценок пока нет

- PL 008748Документ10 страницPL 008748ronaldxmenОценок пока нет

- Lunkenheimer Cast Steel Valves Bulletin CS096Документ28 страницLunkenheimer Cast Steel Valves Bulletin CS096Alex WilmerОценок пока нет

- 6oilccopdngglobal2152008 Voll III 20piping 20 20 MechanicalДокумент643 страницы6oilccopdngglobal2152008 Voll III 20piping 20 20 Mechanicaldinesh2u85Оценок пока нет

- 61502YДокумент9 страниц61502YbalajivangaruОценок пока нет

- Anderson Separator: Fuel Gas Skid General Arrangment - 250 PsigДокумент2 страницыAnderson Separator: Fuel Gas Skid General Arrangment - 250 PsigJhonny Rincones100% (1)

- Butterfly ValveДокумент14 страницButterfly ValveSingSareblakKanaManahОценок пока нет

- TDS For Y-StrainerДокумент2 страницыTDS For Y-StrainerRAGHVENDRA PRATAP SINGHОценок пока нет

- Mech Van Catalogue PDFДокумент26 страницMech Van Catalogue PDFVan Nguyen Huu VanОценок пока нет

- Bolt Length TableДокумент16 страницBolt Length TablePrasanta Kumar BeheraОценок пока нет

- Swagwlok Lap Flange PDFДокумент6 страницSwagwlok Lap Flange PDFPraveen KumarОценок пока нет

- 310-1512715 Bilge System H01Документ11 страниц310-1512715 Bilge System H01buturca sorinОценок пока нет

- Ball Valve Flange TypeДокумент7 страницBall Valve Flange TypeperoooОценок пока нет

- Computer Rack, Version 1 CustoerДокумент1 страницаComputer Rack, Version 1 CustoerVinodh Kumar LОценок пока нет

- Valves Reference PDFДокумент35 страницValves Reference PDFJulio RodriguezОценок пока нет

- Bombas Goulds 4NS Aguas ResidualesДокумент6 страницBombas Goulds 4NS Aguas ResidualescamatuteОценок пока нет

- ASV 10 20 BrochureДокумент8 страницASV 10 20 BrochureThomas Duane DavidsonОценок пока нет

- Ep31492 PDFДокумент11 страницEp31492 PDFJilJilОценок пока нет

- Valve Procurement SpecsДокумент39 страницValve Procurement Specsjoseph.maquez24100% (2)

- MasterSeries 850 Specification SheetДокумент2 страницыMasterSeries 850 Specification SheetFEBCOОценок пока нет

- 185-170-5-300-M44-0058 RevDДокумент1 страница185-170-5-300-M44-0058 RevDVashish RamrechaОценок пока нет

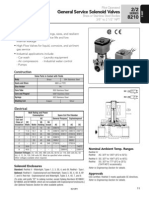

- 8210 General Solenoid Valve ASCOДокумент6 страниц8210 General Solenoid Valve ASCOyuri0527Оценок пока нет

- AGIP STD - Valves Specification SheetДокумент1 страницаAGIP STD - Valves Specification Sheethalim_kaОценок пока нет

- Fluid Components Full CatalogДокумент464 страницыFluid Components Full Catalognegg 348Оценок пока нет

- Process & Piping Design Section Plug Valves Technical SpecificationДокумент14 страницProcess & Piping Design Section Plug Valves Technical Specificationashish.mathur1100% (1)

- Index: Product List SR. NOДокумент40 страницIndex: Product List SR. NOch_yustinusОценок пока нет

- Pressure Pipe FittingsДокумент52 страницыPressure Pipe FittingslissandovalОценок пока нет

- Condenser BushingДокумент4 страницыCondenser BushingSanthosh RMОценок пока нет

- Series TDV Specification SheetДокумент2 страницыSeries TDV Specification SheetWattsОценок пока нет

- KVC 01Документ35 страницKVC 01hamidreza_m85Оценок пока нет

- Dual-Plate Check Valve DesignДокумент5 страницDual-Plate Check Valve Designmusaismail8863Оценок пока нет

- Grundfos NKДокумент121 страницаGrundfos NKSam Wang Chern PengОценок пока нет

- MPVN BrochureДокумент32 страницыMPVN Brochurefernando_naciamentОценок пока нет

- MepДокумент44 страницыMepdush_qs_883176404Оценок пока нет

- Cast Steel and Stainless Steel Y StrainersДокумент13 страницCast Steel and Stainless Steel Y StrainersNinad SherawalaОценок пока нет

- 1 1610 110Документ4 страницы1 1610 110MuhammedHafisОценок пока нет

- Bermad - Filtro en y 70fДокумент2 страницыBermad - Filtro en y 70fYadir BojacaОценок пока нет

- Modular Dual Line SystemДокумент6 страницModular Dual Line Systemangela_draguОценок пока нет

- All-in-One Manual of Industrial Piping Practice and MaintenanceОт EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceРейтинг: 5 из 5 звезд5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsОт EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Finolex Cables Ltd - Leading ManufacturerДокумент13 страницFinolex Cables Ltd - Leading ManufacturerDeobrat SahayОценок пока нет

- A Neoteric Funerary Design Approach: Sustainable Modular Entombment in Baguio CityДокумент15 страницA Neoteric Funerary Design Approach: Sustainable Modular Entombment in Baguio CityEd dela Pena100% (1)

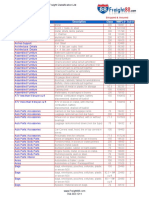

- Freight88 Freight Class CheatsheetДокумент11 страницFreight88 Freight Class Cheatsheetexamen707160% (5)

- Woodward, Jon - Off The Grid Hydroponics - No Power Needed (2013) PDFДокумент22 страницыWoodward, Jon - Off The Grid Hydroponics - No Power Needed (2013) PDFTrixie BellОценок пока нет

- Presentation FRPДокумент35 страницPresentation FRPANKESH SHRIVASTAVAОценок пока нет

- HP Color Laserjet Pro MFP M477 Series: Stunning Speed. Solid SecurityДокумент5 страницHP Color Laserjet Pro MFP M477 Series: Stunning Speed. Solid Securitygem lihanshОценок пока нет

- Raft (Mat) Foundation: - A) Flat Plate - B) Flat Plate Thickened Under ColumnsДокумент18 страницRaft (Mat) Foundation: - A) Flat Plate - B) Flat Plate Thickened Under ColumnsProf. N. El-SakhawyОценок пока нет

- VHDL DmaДокумент5 страницVHDL DmaPuneet DubeyОценок пока нет

- Ed M 01.00 I 05Документ18 страницEd M 01.00 I 05joseellargo100% (1)

- Instruction Codes Computer Registers Computer Instructions Timing and Control Instruction Cycle Memory Reference Instructions Input-Output and Interrupt Complete Computer DescriptionДокумент38 страницInstruction Codes Computer Registers Computer Instructions Timing and Control Instruction Cycle Memory Reference Instructions Input-Output and Interrupt Complete Computer DescriptionYash Gupta MauryaОценок пока нет

- 2 Storey PDFДокумент23 страницы2 Storey PDFcollins unankaОценок пока нет

- Ping Trace HostsДокумент2 страницыPing Trace HostsJnt MFОценок пока нет

- Cleanroom Design in 10 Easy StepsДокумент5 страницCleanroom Design in 10 Easy StepsWerner SchrammelОценок пока нет

- American Style ISVS 2022Документ22 страницыAmerican Style ISVS 2022Nishan WijetungeОценок пока нет

- Chief Architect x8 Users Guide Roof TutorialДокумент44 страницыChief Architect x8 Users Guide Roof TutorialcharlieaizaОценок пока нет

- Slicehost API: April 1, 2008Документ8 страницSlicehost API: April 1, 2008Oleksiy KovyrinОценок пока нет

- Operation Manual: Smart-UPS On-Line SRTДокумент36 страницOperation Manual: Smart-UPS On-Line SRTHarry RincónОценок пока нет

- EmpanelHospList HelpFAQДокумент13 страницEmpanelHospList HelpFAQaditi001Оценок пока нет

- Index To SpecificationДокумент29 страницIndex To Specificationsat palОценок пока нет

- Costing of Steelwork From Feasibility Through To Completion 1996 - Australian Institute of Steel ConstructionДокумент53 страницыCosting of Steelwork From Feasibility Through To Completion 1996 - Australian Institute of Steel ConstructionKakoDa100% (2)

- Mapxtreme V7.2.0 Release Notes: List of TopicsДокумент7 страницMapxtreme V7.2.0 Release Notes: List of TopicstruycaptudoОценок пока нет

- Aurora Logger Install GuideДокумент25 страницAurora Logger Install GuideAlejandro Pedraza GiraldoОценок пока нет

- Apks Count ListДокумент5 страницApks Count ListKevin Moreno MancinazОценок пока нет

- Sunlite GigeДокумент2 страницыSunlite GigeJhon SendokОценок пока нет

- Frankenstein: Penguin Readers FactsheetsДокумент4 страницыFrankenstein: Penguin Readers FactsheetsPatrícia MartinsОценок пока нет

- ETAG 025: Guideline For European Technical Approval OFДокумент49 страницETAG 025: Guideline For European Technical Approval OFSerban RaduОценок пока нет

- FidelisUserGuide 60Документ158 страницFidelisUserGuide 60T AnnapooraniОценок пока нет

- Hvac Survey & Calculation Report: Site NameДокумент17 страницHvac Survey & Calculation Report: Site NameMehdi Hasan TararОценок пока нет

- Sap Terp10Документ7 страницSap Terp10naifnОценок пока нет

- BN-DS-C01 Overview of The Piping Design StandardsДокумент4 страницыBN-DS-C01 Overview of The Piping Design Standardsyulianus_srОценок пока нет