Академический Документы

Профессиональный Документы

Культура Документы

Örnek Deney Raporu

Загружено:

Ali AtikИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Örnek Deney Raporu

Загружено:

Ali AtikАвторское право:

Доступные форматы

Research Institute for Thermal Insulation e.V.

Munich

Research and test operations in the field of thermal and humidity insulation in construction and technical process facilities Recognised test, control and certification authority for construction products Managing Board: Dr.-Ing. J. Achtziger, Dipl.-Ing. H. Zehendner

Examination Report

(Translation from German)

Applicant:

Lambda-Metechnik GmbH Dresden at the Technology Centre of the Technical University Dresden at Zellescher Weg 24 01217 Dresden Germany Performance test of thermal conductivity test system consisting of hermal conductivity test tool -Meter WMG 2 and the hot plate apparatus EP 500

Contents of Application:

Report-Nr.: Report date: No of text pages: Graphs: Tables:

CE1-1/99 03.09.1999 4 1

Forschungsinstitut fr Wrmeschutz Lochhamer Schlag 4 82166 Grfelfing Germany

Forschungsinstitut fr Wrmeschutz e.V. Mnchen

examination-no.: CE.1-1/99 page 2 of 5

1. Scope of Examination The thermal conductivity test tool with the hot plate apparatus is to be tested on its test accuracy. To this end, flat samples of various insulating materials will be tested. Their thermal conductivity is simultaneously being verified in the FIW-laboratory on a two-plate tool in accordance with DIN 51612 (pr EN 12667 respectively)

2. Brief Description of the Test Tool Hot plate apparatus (Poensgen apparatus) according to DIN 52612-1, Measurement zone 200 mm in diameter with protective rings. Tool dimensions with corresponding sample dimensions are 500 x 500 mm. The tool verifies the thermal conductivity for a given temperature of e.g. 10 C. Alternatively it can do up to 3 thermal conductivity tests at randomly selected mean temperatures in the range of 10 C to 40 C in automatic sequence. The temperature within the apparatus can be controlled by thermostat in the range between 0 C and 50 C. This is done by air-cooled Peltier elements. The temperature measurement on both plate surfaces is integral by nature and done across the entire test area. In order to prevent disruptive currents between the measurement zone and the protective heating the protective heating ring next to the measurement zone is enclosed by another protective ring and a cooling (temperature control) ring, which again is enclosed by another protective ring. This enables the testing of quite large specimen thicknesses at a given size of the heating area even without a thermostat controlled test chamber or environment.

Forschungsinstitut fr Wrmeschutz e.V. Mnchen

examination-no.: CE.1-1/99 page 3 of 5

3. Test samples The samples available for testing all have outer edge lengths of 500 x 500 mm but with different thicknesses. The selection the different materials covers the range of common thermal conductivities in various material structures. The following materials were tested: polystyrol particle foam (EPS); extruded polystyrol foam (XPS), elastified polystyrol (EPS-TS), mineral wool (MW), hemp and lightweight concrete.

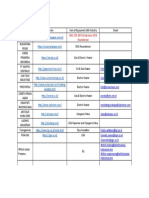

4. Test Results The test results are summarised in table 1. The results show a good compliance in the thickness range of 20 to 120 mm for the tested materials. The original test was done on a double-plate tool. Therefore the comparative test on the hot plate apparatus EP 500 was carried out with 2 single samples stacked on top of one another (see test 1 to 3 and 7). Alternatively each sample was tested its own (see 10/11, 23/13, 14/15 and 16/17) and the mean value then compared to the results of the double-plate tool. The time for test no. 5 was too short. The test was terminated before stationary thermal conditions were reached. Therefore the results must be regarded as error values. Sample no. 237 was then tested again in test no. 10/11. For test no. 1 the hot plate apparatus is bound to yield increased thermal conductivity values. This is due to the total thickness of 2 x 19.6 mm and the radiation-related thickness effect. Therefore a single material sheet of sample 485 (thickness 19.6 mm) was tested again in test no. 6. The compliance of these test results with the FIW double plate tool confirms that the effect of radiation was correctly accounted for. Test no. 4 to 6, 8, 9, 18 and 19 with a test of a single sample can also be used for comparative purposes de to the homogeneity of the material. Columns 8, 9 and 10 show the thermal conductivity values adjusted to the mean temperatures of 10, 25 and 40. The corresponding values of the hot plate apparatus are included in columns 11, 12 and 13.

Forschungsinstitut fr Wrmeschutz e.V. Mnchen

examination-no.: CE.1-1/99 page 4 of 5

The deviations for those three mean temperatures are given in columns 14, 15 and 16. The increase in thermal conductivity is practically identical with the FIW values.

5. Summary The comparative tests were essentially done by FIW. Sample insertion, operations and evaluation were done by staff of Lambda-Metechnik GmbH. The FIW test values for the comparative test samples were not known to the operator prior to the test. The samples which were used for testing had been tested by FIW on a standard Poensgen double-plate apparatus. The test error of standard tools (FIW) ranges between 2 % form test value. A statistical correlative evaluation of the test error trend was nor done. The deviation of the test values verified on the hot plate apparatus EP 500 from the values recorder by FIW lie within the acceptable error range of both test procedures. The test apparatus was located in a room with air-conditioning for the time of testing. All test values are valid only for the time of testing. Grfelfing on 03.09.1999 The Board of Directors

Signed and Stamped Dr.-Ing. J. Achtziger

Table 1: Summary of Test Results LAM 10, LAM 25 and LAM 40 refer to the thermal conductivity at 10C, 25C and 40C mean temperature respectively

1 N 1 2 3 4 5 6 7 8 9 10 11

2 Material EPS EPS EPS XPS MW EPS EPS EPS-TS EPS MW MW

3 Specimen 485 507 511 1113 237 485 451 514 451 237 237

4 Plate 1+2 1+2 1+2 1 1 1 1+2 1 1 1 2

5 Test 26.05. 26.05. 27.05. 28.05. 29.05. 31.05. 31.05. 01.06. 03.06. 03.06. 05.06.

6 Thickness 39,2 98,2 102 81,1 81,3 19,6 119 30,6 59,5 81,3 81,3

7 Density 35,4 14,8 16,2 33,3 158 35,4 30,1 16,4 30,1 158 158 Median:

8 Lam 10 31,5 37 36,5 37,72 39,5 31,5 32,26 35,95 32,26 39,5 39,5 39,50 32,9 32,9 32,90 139 139 139,00 36 36 36,00 36,5 33

9 FIW values Lam 25 32,75 39,1 38,6 40,25 41,48 32,75 33,86 38,56 33,86 41,48 41,48 41,48 35,1 35,1 35,10 142 142 142,00 39 39 39,00 38,6 34

10 Lam 40 41,2 40,82 42,78 43,5 35,47 41,17 35,47 43,5 43,5 43,50 37,2 37,2 37,20 143 143 143,00 42 42 42,00 40,82 36

11 Lam 10 32,12 37 35,9 36,95 39,8 31,84 32,5 36,8 32,7 40,4 39,15 39,77 32,3 32,1 32,20 139,5 140,7 140,10 35,7 35,6 35,65 36,1 33

12 Lam 25 34,11 39,16 38,15 39,61 42,5 33,43 34,2 39,2 34 42,7 41,05 41,88 35,3 34,8 35,05 142,4 143 142,70 38,8 39,4 39,10 38 34,5

13 Lam 40 36,11 41,82 40,45 42,77 45,3 35,9 41,9 35,7 44,7 42,75 43,73 37,7 37 37,35 145,9 146,9 146,40 42 42,9 42,45 40,6 36

14 Dev. 10 1,96 -0,01 -1,64 -2,03 1,07 0,74 2,36 1,36 2,28 -0,89 0,69 -1,82 -2,43 -2,13 0,36 1,22 0,79 -0,83 -1,11 -0,97 -1,1 0

15 Dev. 25 4,16 0,16 -1,17 -1,58 2,07 1 1,66 0,41 2,95 -1,04 0,96 0,57 -0,85 -0,14 0,28 0,7 0,49 -0,51 1,03 0,26 -1,55 1,47

16 Dev.40 1,5 -0,91 -0,03 1,21 1,77 0,65 2,77 -1,72 0,53 1,34 -0,54 0,40 2,03 2,73 2,38 0 2,14 1,07 -0,54 0

17 end of test 1 hour 1 hour 2 hours 1 hour 3 hours 1 hour 2 hours 2 hours 1 hour 6 hours 6 hours

hot plate apparatus "EP 500"

12 13

MW MW

490 490

1 2

07.06. 08.06.

99 99

23,6 23,6 Median:

2 hours 2 hours

14 15

Concrete Concrete

368 368

1 2

10.06. 12.06.

570 570 Median:

6 hours 6 hours

16 17

Hemp Hemp

428 428

1 2

13.06. 14.06.

100 100

44,4 44,4 Median:

2 hours 2 hours

18 19

EPS EPS

511 453

1 1

14.06. 15.06.

51 100

16,2 34,6

2 hours 2 hours

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Fire HeatДокумент231 страницаFire HeatprabhuarunkumarОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Energy Performance Assessment of Heat Exchangers: Overall Heat Transfer Coefficient, UДокумент18 страницEnergy Performance Assessment of Heat Exchangers: Overall Heat Transfer Coefficient, USATISH PAWARОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Objective Food Science 2013 Sanjeev Kumar SharmaДокумент839 страницObjective Food Science 2013 Sanjeev Kumar SharmaDivya Bharathi100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Risk Assessment of Fire Damper InstallationsДокумент43 страницыThe Risk Assessment of Fire Damper Installationsalan.edwards7282100% (1)

- Green Living Roof Simulation Model ReviewДокумент8 страницGreen Living Roof Simulation Model ReviewGogyОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Training Manual (TSE2D) : SAMSUNG TMF RefrigeratorДокумент31 страницаTraining Manual (TSE2D) : SAMSUNG TMF RefrigeratorCesar Calderon GrОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Example of Heat Exchanger TEMA SheetДокумент3 страницыExample of Heat Exchanger TEMA SheetHandyОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- DuraSystems - 2012 AHR Expo Product Line CardДокумент2 страницыDuraSystems - 2012 AHR Expo Product Line CardDuraSystemsОценок пока нет

- MAE 4171: Principles of Heat Transfer Solution-Assignment #1Документ4 страницыMAE 4171: Principles of Heat Transfer Solution-Assignment #1Bo100% (5)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- CCW Intercoolers (Tube & Shell Type) : Maintenance ManualДокумент38 страницCCW Intercoolers (Tube & Shell Type) : Maintenance ManualPenjual AirОценок пока нет

- List LNG CompanyДокумент1 страницаList LNG CompanyAndi Yassa0% (1)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- CryocarДокумент21 страницаCryocarSrikanth Adepu67% (3)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Cassette FCU (One Way) PDFДокумент16 страницCassette FCU (One Way) PDFHadi Khajouee NejadОценок пока нет

- Thermoeconomic Analysis and Optimization of Energy SystemsДокумент31 страницаThermoeconomic Analysis and Optimization of Energy Systemsjhugo_mirandaОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Assignment4 PDFДокумент2 страницыAssignment4 PDFVijay VijayОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Flue Gas Heat Recovery in Power Plants, Part IДокумент12 страницFlue Gas Heat Recovery in Power Plants, Part IknsaravanaОценок пока нет

- Ad 01202010214Документ14 страницAd 01202010214theijesОценок пока нет

- RTHD Catalog RLC Prc020 enДокумент32 страницыRTHD Catalog RLC Prc020 enCharles Lee50% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Chapter 3Документ28 страницChapter 3Anonymous lOMOpX3Оценок пока нет

- Vaibhav Rakde BS Principles of RefrigrationДокумент1 страницаVaibhav Rakde BS Principles of RefrigrationKscsiddhant KscsiddhantОценок пока нет

- PC 03 Marine Air Handling Units PDFДокумент18 страницPC 03 Marine Air Handling Units PDFhautamakiОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Design and Fabrication of Thermo Electric RefrigeratorДокумент6 страницDesign and Fabrication of Thermo Electric RefrigeratorEditor IJTSRDОценок пока нет

- Heat Work and EnergyДокумент4 страницыHeat Work and EnergyHelma Jabello AriolaОценок пока нет

- Name Plate WEG-w22 PDFДокумент1 страницаName Plate WEG-w22 PDFPranay KharbeОценок пока нет

- Underground Floor Ventilation Report PDFДокумент23 страницыUnderground Floor Ventilation Report PDFNor Azman AmrilОценок пока нет

- Energy Valve TechДокумент50 страницEnergy Valve Techchiong cjОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- HEAT TRANSFER PYQ (2000-2020) by Yogesh Tyagi Sir: IIT KharagpurДокумент33 страницыHEAT TRANSFER PYQ (2000-2020) by Yogesh Tyagi Sir: IIT KharagpurRomil GandhiОценок пока нет

- ICMIEE-Published Paper ListДокумент6 страницICMIEE-Published Paper ListSajidОценок пока нет

- 134 519 1 PB PDFДокумент8 страниц134 519 1 PB PDFL Fattih Diwa ModeonОценок пока нет

- Tissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoДокумент14 страницTissue Paper Hot Air Balloon: Andrea Badua Period 2 Physics Ms. BuenconsejoAndrea BaduaОценок пока нет