Академический Документы

Профессиональный Документы

Культура Документы

Mosfet Scaling

Загружено:

Suhas NsИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mosfet Scaling

Загружено:

Suhas NsАвторское право:

Доступные форматы

MOSFET Scaling and Small Geometry Effects

The lateral geometric dimensions oI devices and interconnects are reduced. This

reduction in size is reIerred to as 'Scaling dimensions oI the integrated circuit

(IC).

Minimum Ieature size is smallest size oI object (interconnect line width) on IC.

Minimum Ieature size oI ICs has shrunk considerably over the time oI several

decades. As a consequence, the number oI transistors has increased over time.

What is Scaling?

O #eduction in size oI an MOS chip by reducing the dimensions oI MOSFETs

And interconnects.

O #eduction is symmetric and preserves geometric ratios which are important

to the Iunctionality oI the chip. Ideally, allows design reuse.

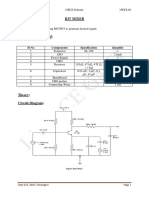

O Assume that S is the Scaling Iactor. Then a transistor with original

dimensions oI L and W becomes a transistor with dimensions L/S and W/S.

O Typical values oI S : 1.2 1.5 per biennium.

GATE

Figure 3.24 $.,3 of , typ., MO$ET by , s.,3 f,.tor of S.

Scallng

Two major Iorms oI scaling

Full scaling (constant-Iield scaling) - All dimensions are scaled by S

and the supply voltage and other voltages are so scaled.

Constant-voltage scaling - The voltages are not scaled and, in some

cases, dimensions associated with voltage are not scaled.

Full Scaling (Constant Field Scaling)

In this method the device dimensions (both horizontal and vertical) are

scaled down by 1/S, where S is the scaling Iactor. In order to keep the

electric Iield constant within the device, the voltages have to be scaled also

by 1/S such that the ratio between voltage and distance (which represents

the electric Iield) remain constant. The threshold voltage is also scaled down

by the same Iactor as the voltage to preserve the Iunctionality oI the circuits

and the noise margins relative to one another. As a result oI this type oI

scaling the currents will be reduced and hence the total power per transistor

(PIxV) will also be reduced, however the power density will remain

constant since the number oI transistors per unit area will increase. This

means that the total chip power will remain constant iI the chip size remains

the same (this usually the case).

W CaLe

L

Lox

x[

@e Lable below summarlzes ow eac devlce parameLer scales wlL S (S1)

arameLer 8efore scallng AfLer scallng

Cannel lengL L L/S

Cannel wldL W W/S

Cxlde Llckness Lox Lox/S

S/u [uncLlon depL x[ x[/S

ower Supply vuu vuu/S

@resold volLage

v

@C

v

@C

/S

uoplng uenslLy

n

A

n

u

n

A

*S and n

u

*S

Cxlde CapaclLance Cox S*Cox

uraln CurrenL

l

uS

l

uS

/S

ower/@ranslsLor /S

2

ower uenslLy/cm

2

Constant Voltage Scaling

In this method the device dimensions (both horizontal and vertical are scaled

by S, however, the operating voltages remain constant. This means that the electric

Iields within the device will increase (Iiled Voltage/distance). The threshold

voltages remain constant while the power per transistor will increase by S. The

power density per unit area will increase by S

3

! This means that Ior the same chip

area, the power chip power will increase by S

3

. This makes constant-voltage-

scaling (CVS) very impractical. Also, the device doping has to be increased more

aggressively (by S

2

) than the constant-Iield scaling to prevent channel punch-

through. Channel punch-through occurs when the Source and Drain Depletion

regions touches one another. By increasing the doping by S

2

, the depletion region

thickness is reduced by S (the same ratio as the channel length). However, there is

a limit Ior how much the doping can be increased (the solid solubility limit oI the

dopant in Silicon). Again, this makes the CVS impractical in most cases.

The Iollowing table summarizes the changes in key device parameters under

constant-voltage scaling:

arameLer 8efore scallng AfLer scallng

Cannel lengL L L/S

Cannel wldL W W/S

Cxlde Llckness Lox Lox/S

S/u [uncLlon depL x[ x[/S

ower Supply vuu vuu

@resold volLage

v

@C

v

@C

uoplng uenslLy

n

A

n

u

n

A

* S

2

and n

u

* S

2

Cxlde CapaclLance Cox S*Cox

uraln CurrenL

l

uS

l

uS

* S

ower/@ranslsLor *S

ower ueslLy/cm

2

* S

3

In almost all cases, the scaling is a combination oI constant-Iield scaling and

constant-voltage scaling, such that the number oI devices is increased and the total

power/chip does not increase much.

Short Channel Effects

As the channel length L is reduced to increase both the operation speed and the

number oI components per chip, the so-called short-channel eIIects arise.

The short-channel eIIects are attributed to two physical phenomena:

1. The limitation imposed on electron driIt characteristics in the channel,

2. The modiIication oI the threshold voltage due to the

shortening channel length.

Velocity Saturation and Surface Mobility Degradation

DriIt velocity vd Ior channel electrons is proportional to electric Iield along

channel Ior electric Iields along the channel oI 10`5 V/cm (as occur as becomes

small with JDD Iixed), vd saturates and becomes a constant vd(SAT) 10`7 cm/s.

This reduces ID(SAT) which no longer depends quadratically on JGS.

vd(SA1) unE(SA1)

unJD(SA1)/L

JD(SA1) L vd(SA1)/ un

Hence,

ID(SA1) ID(JDSJDSA1)

unCox(W/L)(JCS-J1) JDSA1-JDSA12/2]

vd(SA1) CoxW(JCS-J1 -JDSA1/2)

ThereIore, the drain current is linearly dependent on JGS when Iully velocity

saturated.

The vertical Iield (Ex) eIIects cause nn to decline represented by eIIective surIace

mobility nn(eff).

Empirical Iormulas Ior nn(eff) use parameters O and p.

Channel Depletion Region Charge Reduction

OIten viewed as the short channel eIIect

At the source and drain ends oI the channel, channel depletion region charge is

actually depletion charge Ior the source and drain region charge is actually

depletion charge Ior the source and drain.

For L large, attributing this charge to the channel results in small

errors

But Ior short-channel devices, the proportion oI the depletion

charge tied to the source and drain becomes large.

The reduction in charge is represented by the change oI the channel depletion

region cross-section Irom a rectangle oI length L and depth xdm to a trapezoid with

lengths L and L-ALS- ALD and depth xdm. This trapezoid is equivalent to a

rectangle with length :

Thus, the channel charge per unit area is reduced by the Iactor:

Next, need ALS and ALD in terms oI the source and drain junction depths and

depletion region junction depth using more geometric arguments. Once this is

done, the resulting reduction in threshold voltage JT due to the short channel eIIect

can be written as:

For 5 n, eIIect is negligible. But at 0.5 n, JT0 reduced to 0.43 Irom 0.76 volts

(AJT00.33V).

arrow Channel Effects

W is on the same order oI the maximum depletion region thickness xdm.

The channel depletion region spreads out under the polysilicon at its rises over the

thick oxide. Thus, there is extra charge in the depletion region.

The increase in JT0 due to this extra charge is

k is an empirical parameter dependent upon the assumed added charge cross-

section. This increase oI JT0 may oIIset much oI the short channel eIIect which

is subtracted Irom JT0.

Other Limitations Imposed by Small Geometry Effects

Subthreshold Condition

The potential barrier that prevents channel Iormation is actually controlled by

both the gate voltage JGS and the drain voltage JDS.

JDS lowers this potential, an eIIect known as DIBL (Drain-Induced Barrier

Lowering).

II the barrier is lowered suIIiciently by JGS and JDS, then there is channel

Iormation Ior JGS JT0.

Subthreshold current is the result.

Upward curvature oI the ID versus JGS curve Ior JGS JT with JDS= 0.

!unch-Through

Merging oI depletion regions oI the source and drain.

Carriers injected by the source into the depletion region are swept by the strong

Iield to the drain.

With the deep depletion, a large current under limited control oI JGS and JSB

results.

Thus, normal operation of devices in punch-through not feasible. Might cause

permanent damage to transistors by localized melting oI material.

Thinning of 9ox

As oxide becomes thin, localized sites oI nonuniIorm oxide growth (pinholes) can

occur, and can cause electrical shorts between the gate and substrate.

The dielectric strength oI the thin oxide may permit oxide breakdown due to

application oI an electric Iield in excess oI breakdown Iield. May cause

permanent damage due to current Ilow through the oxide.

ot Electron Effects

High electric Iields in both the channel and pinch-oII region Ior short channel

lengths occur Ior small L.

Particularly apparent in the pinch-oII region where voltage JDS - JD(SA1) large

with L - Leff small causes very high Iields.

High electric Iields accelerate electrons which have suIIicient energy with the

accompanying vertical Iield to be injected into the oxide and are trapped in deIect

sites or contribute to interIace states.

These are called hot electrons.

#esulting trapped charge increases J1 and otherwise aIIects transconductance,

reducing the drain current. Since these eIIects are concentrated at the drain end oI

the channel, the eIIects produce asymmetry in the I-J characteristics.

EIIect Iurther aggravated by impact ionization.

Вам также может понравиться

- VLSI Full Custom Mask LayoutДокумент18 страницVLSI Full Custom Mask LayoutRamanaButterflyОценок пока нет

- VLSI Design MethodologyДокумент72 страницыVLSI Design MethodologyMandovi BorthakurОценок пока нет

- Dynamic CMOS DesignДокумент30 страницDynamic CMOS DesignAllwyn Anand SОценок пока нет

- UNIT 4 - Switched CapacitanceДокумент75 страницUNIT 4 - Switched Capacitancerajasekarkpr100% (1)

- Questions and AnswersДокумент199 страницQuestions and AnswersRamesh100% (4)

- Ed & I Lab 18ecl37 ManualДокумент29 страницEd & I Lab 18ecl37 Manualcharan mОценок пока нет

- JLTsДокумент67 страницJLTsJawar SinghОценок пока нет

- Memories and PLDsДокумент47 страницMemories and PLDsHimanshu KhanduriОценок пока нет

- 04 - Second-Order Effects On MOSFET Small Signal ModelДокумент27 страниц04 - Second-Order Effects On MOSFET Small Signal ModelWinnie LahОценок пока нет

- CMOS Assignment QuestionsДокумент6 страницCMOS Assignment QuestionsAkhilGovindОценок пока нет

- Ray Theory Transmission in Optical FibersДокумент27 страницRay Theory Transmission in Optical FibersvardhanОценок пока нет

- Module 4Документ22 страницыModule 4Sushanth MОценок пока нет

- Carry Select AdderДокумент72 страницыCarry Select Adderharshithakr100% (1)

- VLSI Design Module 1 IntroductionДокумент119 страницVLSI Design Module 1 IntroductionPhanindra Reddy100% (2)

- Second Order Effects in MOSFETs ExplainedДокумент40 страницSecond Order Effects in MOSFETs ExplainedDhiraj Kumar100% (2)

- CMOS Fabrication and Layout RulesДокумент65 страницCMOS Fabrication and Layout Rulessasindhur r100% (2)

- Notes-Mixed Layout IssuesДокумент11 страницNotes-Mixed Layout Issuesthimmashetty100% (1)

- "Tunnel Field Effect Transistors (TFET) ": Prepared By:-Group 10Документ24 страницы"Tunnel Field Effect Transistors (TFET) ": Prepared By:-Group 10Rajesh Sharma50% (2)

- Viva Voce Questions On Communication SystemsДокумент3 страницыViva Voce Questions On Communication SystemsZealWolf100% (3)

- Twin Tub ProcessДокумент11 страницTwin Tub Processvmspraneeth33% (3)

- Serial Communication Bus-Interface (Unit3)Документ44 страницыSerial Communication Bus-Interface (Unit3)Surekha PittaОценок пока нет

- ComputerNetworksLAB 18ECL76 7thsemesterДокумент94 страницыComputerNetworksLAB 18ECL76 7thsemesterPhanindra ReddyОценок пока нет

- 15ecl48-VTU-raghudathesh-BJT MIXER PDFДокумент2 страницы15ecl48-VTU-raghudathesh-BJT MIXER PDFraghudatheshgp100% (1)

- EC8095-VLSI DesignДокумент11 страницEC8095-VLSI DesignfayikaliОценок пока нет

- ADVANCED ANALOG IC DESIGN Lab ManualДокумент27 страницADVANCED ANALOG IC DESIGN Lab ManualJahnavi Ratnam0% (1)

- Cross Talk Effect and Shielding: RSK DesignДокумент8 страницCross Talk Effect and Shielding: RSK DesignVamsi KrishnaОценок пока нет

- Stick Diagram and LayoutДокумент61 страницаStick Diagram and LayoutSwetha AbrahamОценок пока нет

- Rabaey Exercises Collected PDFДокумент64 страницыRabaey Exercises Collected PDFbatoolОценок пока нет

- Module 1 WCC NotesДокумент25 страницModule 1 WCC NotesMOHAMMED SUFIYAN100% (2)

- Microwave Solid State Devices And Measurements GuideДокумент52 страницыMicrowave Solid State Devices And Measurements GuideSnigdha SidduОценок пока нет

- VLSIДокумент107 страницVLSItamil selvam100% (1)

- Vlsi Design Question Bank EEC 703Документ10 страницVlsi Design Question Bank EEC 703selvi0412Оценок пока нет

- ORBITAL EffectsДокумент9 страницORBITAL EffectsAmit SinhaОценок пока нет

- OTA DesignДокумент18 страницOTA DesignAnandОценок пока нет

- VLSI & ASIC Digital Design Interview QuestionsДокумент6 страницVLSI & ASIC Digital Design Interview QuestionsRupesh Kumar DuttaОценок пока нет

- Low Voltage Low Power AddersДокумент24 страницыLow Voltage Low Power Addersrakesh100% (3)

- U I - Lecture 4 Basic Principle of Low Power DesignДокумент17 страницU I - Lecture 4 Basic Principle of Low Power Designbganeshsai50% (2)

- EI2403 - VLSI Design 2 Marks With AnswersДокумент23 страницыEI2403 - VLSI Design 2 Marks With AnswersAnand GvphОценок пока нет

- Low-Power Digital VLSI DesignДокумент530 страницLow-Power Digital VLSI DesignAllanki Sanyasi Rao50% (2)

- Types of Semiconductors (Intrinsic, ExtrinsicДокумент87 страницTypes of Semiconductors (Intrinsic, ExtrinsicRamadhurai100% (2)

- Cmos TestingДокумент22 страницыCmos TestingBharathi Muni100% (1)

- UNIT 1 Question BankДокумент6 страницUNIT 1 Question BankUjjwalОценок пока нет

- ARM CORTEX - M & OMAP ProcessorsДокумент34 страницыARM CORTEX - M & OMAP ProcessorsMaruthi Rao100% (1)

- Generic Process Design Kits (GPDK) DownloadsДокумент1 страницаGeneric Process Design Kits (GPDK) Downloadsbkgp1994Оценок пока нет

- VLSI Unit-IVДокумент87 страницVLSI Unit-IVUma Maheswari100% (2)

- Sagar Institute of Science and Technology Bhopal, M.P: 8051 Based Thyristor Firing CircuitДокумент3 страницыSagar Institute of Science and Technology Bhopal, M.P: 8051 Based Thyristor Firing Circuitsiddharth singh67% (3)

- Multiplier in Vlsi PDFДокумент23 страницыMultiplier in Vlsi PDFvmspraneeth100% (1)

- Telecommunication Switching Systems ComparisonДокумент31 страницаTelecommunication Switching Systems ComparisonKunal KucheriaОценок пока нет

- LPVLSI Unit 3 NotesДокумент49 страницLPVLSI Unit 3 NotesSai Sreeja100% (1)

- Hspice Simulation of SRAMДокумент65 страницHspice Simulation of SRAMYatheesh Kaggere100% (1)

- Mosfet ScalingДокумент0 страницMosfet ScalingKeith FernandesОценок пока нет

- 3.5 MOSFET Scaling and Small-Geometry EffectsДокумент19 страниц3.5 MOSFET Scaling and Small-Geometry Effectspraritlamba25Оценок пока нет

- MOSIC Amplifiers - Constant Current Source CircuitДокумент18 страницMOSIC Amplifiers - Constant Current Source CircuitNoorullah ShariffОценок пока нет

- Scaling of MOSFETs and Short Channel EffectsДокумент35 страницScaling of MOSFETs and Short Channel EffectsAnonymous zn5X2z0% (1)

- Short Channel Effects and ScalingДокумент23 страницыShort Channel Effects and ScalingskarthikpriyaОценок пока нет

- DiblДокумент25 страницDiblBasheer V.PОценок пока нет

- Mod1 (2) - EC464 Low Power VLSI Design-Ktustudents - inДокумент40 страницMod1 (2) - EC464 Low Power VLSI Design-Ktustudents - insurya sundarОценок пока нет

- Mod1 (2) - EC464 Low Power VLSI Design-Ktustudents - inДокумент40 страницMod1 (2) - EC464 Low Power VLSI Design-Ktustudents - insurya sundarОценок пока нет

- EE668: Electrical Scaling Trends in CMOS VLSI Systems: Madhav P. DesaiДокумент3 страницыEE668: Electrical Scaling Trends in CMOS VLSI Systems: Madhav P. DesaiChiquita WhiteОценок пока нет

- Matcon 2023 Wclop 2023Документ7 страницMatcon 2023 Wclop 2023RECОценок пока нет

- Syllabus Classification and Characteristics of Reservoir FluidsДокумент15 страницSyllabus Classification and Characteristics of Reservoir FluidsHaziq YussofОценок пока нет

- Org Chem LabДокумент7 страницOrg Chem LabCriselda CarinoОценок пока нет

- Monday 20 May 2019: ChemistryДокумент24 страницыMonday 20 May 2019: Chemistrymostafa barakat75% (4)

- Water Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaДокумент8 страницWater Jet Reed Best Manufacturer & Supplier in Ahmedabad, IndiaVijay PanchalОценок пока нет

- Me F211 1083 PDFДокумент3 страницыMe F211 1083 PDFPranjal SrivastavaОценок пока нет

- Product Data Sheet: Product Description Product Description Product Description Product DescriptionДокумент3 страницыProduct Data Sheet: Product Description Product Description Product Description Product DescriptionVaittianathan MahavapillaiОценок пока нет

- JBT Foodtech H1 Food Grade 460 Viscosity Gear OilДокумент5 страницJBT Foodtech H1 Food Grade 460 Viscosity Gear Oilandri putrantoОценок пока нет

- Outokumpu Stainless Steel Wall Chart PDFДокумент1 страницаOutokumpu Stainless Steel Wall Chart PDFcnaren67Оценок пока нет

- Wide-Lite Spectra VI Commercial Indoor Bulletin 1989Документ4 страницыWide-Lite Spectra VI Commercial Indoor Bulletin 1989Alan MastersОценок пока нет

- Electrical MatДокумент2 страницыElectrical Matmanoj_2027Оценок пока нет

- Masterseal Traffic 1330 TdsДокумент3 страницыMasterseal Traffic 1330 TdsSolomon AhimbisibweОценок пока нет

- Rheology Book PDFДокумент268 страницRheology Book PDFPaulo SouzaОценок пока нет

- Dow Science Paper-A Commercially Viable Solution Process To Control Long-Chain Branching in PolyethyleneДокумент1 страницаDow Science Paper-A Commercially Viable Solution Process To Control Long-Chain Branching in Polyethylenefengshaohua_gmailОценок пока нет

- Five Uses For NanotechnologyДокумент2 страницыFive Uses For NanotechnologyJailian Rhainne Delloso BretañaОценок пока нет

- Astm c1557Документ10 страницAstm c1557Roxana Elizabeth Valencia Navarrte100% (4)

- Module Outline 2011: Architects Need To Know But Can Never Find. Rockport: MassДокумент5 страницModule Outline 2011: Architects Need To Know But Can Never Find. Rockport: Massapi-115534435Оценок пока нет

- Metalkraft - Decking and Roofing Brochure - NEWДокумент6 страницMetalkraft - Decking and Roofing Brochure - NEWParthasarathi H RОценок пока нет

- Dual Filter: 20mm (/ ") - 200mm (8") Model OWДокумент4 страницыDual Filter: 20mm (/ ") - 200mm (8") Model OWJairo Andrés FAОценок пока нет

- Miscellaneous Treatment MethodsДокумент25 страницMiscellaneous Treatment Methodsjong LacОценок пока нет

- Refinery Presentation On 07th July 07Документ83 страницыRefinery Presentation On 07th July 07meenuОценок пока нет

- Caesar II Static TrainingДокумент312 страницCaesar II Static TrainingMed Rjeb100% (1)

- Chromatography Lab ReportДокумент6 страницChromatography Lab ReportMohamad MerhabiОценок пока нет

- NC-559-ASM Rev 0510Документ2 страницыNC-559-ASM Rev 0510electrosysro8560Оценок пока нет

- FICHA DE SEGURIDAD DE DE GRASA SANITARIA FM - CSC - EpДокумент6 страницFICHA DE SEGURIDAD DE DE GRASA SANITARIA FM - CSC - EpControl de Calidad MontefioriОценок пока нет

- ABS Fire Extinguisher CatalogueДокумент56 страницABS Fire Extinguisher CatalogueqwertyОценок пока нет

- MINIMUM TESTING REQUIREMENTS FOR CONSTRUCTION PROJECTSДокумент17 страницMINIMUM TESTING REQUIREMENTS FOR CONSTRUCTION PROJECTSAris TesoroОценок пока нет

- Programme CMSS17 2Документ18 страницProgramme CMSS17 2Mongi Ben OuezdouОценок пока нет

- Msds AluminaДокумент6 страницMsds AluminayaderОценок пока нет

- Clad Steel PlateДокумент4 страницыClad Steel PlateRobin GuОценок пока нет

- The Big, Bad Book of Botany: The World's Most Fascinating FloraОт EverandThe Big, Bad Book of Botany: The World's Most Fascinating FloraРейтинг: 3 из 5 звезд3/5 (10)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingОт EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingРейтинг: 5 из 5 звезд5/5 (4)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingОт EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingРейтинг: 3.5 из 5 звезд3.5/5 (32)

- Last Child in the Woods: Saving Our Children From Nature-Deficit DisorderОт EverandLast Child in the Woods: Saving Our Children From Nature-Deficit DisorderРейтинг: 4 из 5 звезд4/5 (283)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorОт EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorРейтинг: 4.5 из 5 звезд4.5/5 (137)

- Why Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeОт EverandWhy Fish Don't Exist: A Story of Loss, Love, and the Hidden Order of LifeРейтинг: 4.5 из 5 звезд4.5/5 (699)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildОт EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildРейтинг: 4.5 из 5 звезд4.5/5 (44)

- Wayfinding: The Science and Mystery of How Humans Navigate the WorldОт EverandWayfinding: The Science and Mystery of How Humans Navigate the WorldРейтинг: 4.5 из 5 звезд4.5/5 (18)

- The Mind of Plants: Narratives of Vegetal IntelligenceОт EverandThe Mind of Plants: Narratives of Vegetal IntelligenceРейтинг: 4.5 из 5 звезд4.5/5 (11)

- The Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanОт EverandThe Secret Life of Lobsters: How Fishermen and Scientists Are Unraveling the Mysteries of Our Favorite CrustaceanОценок пока нет

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsОт EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsРейтинг: 4 из 5 звезд4/5 (221)

- Soil: The Story of a Black Mother's GardenОт EverandSoil: The Story of a Black Mother's GardenРейтинг: 4.5 из 5 звезд4.5/5 (16)

- Spoiled Rotten America: Outrages of Everyday LifeОт EverandSpoiled Rotten America: Outrages of Everyday LifeРейтинг: 3 из 5 звезд3/5 (19)

- The Hummingbirds' Gift: Wonder, Beauty, and Renewal on WingsОт EverandThe Hummingbirds' Gift: Wonder, Beauty, and Renewal on WingsРейтинг: 4.5 из 5 звезд4.5/5 (60)

- The Hidden Life of Trees: What They Feel, How They CommunicateОт EverandThe Hidden Life of Trees: What They Feel, How They CommunicateРейтинг: 4 из 5 звезд4/5 (1002)

- Gathering Moss: A Natural and Cultural History of MossesОт EverandGathering Moss: A Natural and Cultural History of MossesРейтинг: 4.5 из 5 звезд4.5/5 (347)

- The Other End of the Leash: Why We Do What We Do Around DogsОт EverandThe Other End of the Leash: Why We Do What We Do Around DogsРейтинг: 5 из 5 звезд5/5 (63)

- Come Back, Como: Winning the Heart of a Reluctant DogОт EverandCome Back, Como: Winning the Heart of a Reluctant DogРейтинг: 3.5 из 5 звезд3.5/5 (10)

- A Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsОт EverandA Garden of Marvels: How We Discovered that Flowers Have Sex, Leaves Eat Air, and Other Secrets of PlantsОценок пока нет

- The Nature Fix: Why Nature Makes us Happier, Healthier, and More CreativeОт EverandThe Nature Fix: Why Nature Makes us Happier, Healthier, and More CreativeРейтинг: 4 из 5 звезд4/5 (157)

- Remnants of Ancient Life: The New Science of Old FossilsОт EverandRemnants of Ancient Life: The New Science of Old FossilsРейтинг: 4 из 5 звезд4/5 (2)