Академический Документы

Профессиональный Документы

Культура Документы

Material Challenges For The North Sea-1

Загружено:

Isoboye HarrisonИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Material Challenges For The North Sea-1

Загружено:

Isoboye HarrisonАвторское право:

Доступные форматы

Mining Institute of Scotland IOM3 Petroleum and Drilling Engineering Division

Material Challenges for North Sea Oil & Gas Production

A Well Engineers Perspective

ITF Advanced Materials Workshop Steve Bedford February 21st 2008

Agenda

Material Challenges for North Sea Oil and Gas Production

Business Environment Operating Environment Opportunities for Advanced Materials ? Conclusions

Business Environment

Global Energy Demand: 1970 to 2030

UK Energy Demand and North Sea Prize

Business Environment

UK Electricity Generation

99% of UK transport requires oil UKCS could deliver another 27 bn boe Potential investment of 300bn

Source UK Oil & Gas

Business Environment

Costs and Returns

High global demand for oilfield equipment, people and services Offshore supply costs up c68% on 2000 Production sharing agreements and windfall taxes Trend to divest mature fields/acreage to new entrants

Business Environment

Increasing Public Concern

Material Challenges for North Sea Oil and Gas Production

Agenda Business Environment Operating Environment

Operating Environment

Basins and Infrastructure

Operating Environment

Onshore Oilfield: Kimmeridge Bay, Dorset

First Dorset exploration well drilled in 1934 Field on stream in 1959 Producing from the naturally fractured Cornbrash Limestone Production rate declined from 500 to current 80 bbl/day Beam pumped Sweet, light crude with very little gas

Operating Environment

Southern North Sea Gas

Typically sandstone reservoirs, often hydraulically fractured to stimulate rates First fields on stream in the mid 1960s As the larger fields were developed, smaller fields have been developed with subsea wells and unmanned small platforms. Move towards multi lateral wells, under balanced drilling and de-liquification technologies

Operating Environment

Large Integrated North Sea Oil Platforms

Typically sandstone reservoirs with highly prolific wells and water flood Platforms typically accommodate 150 to 250 people with facilities for: drilling, primary processing, export and life support As fields age upgrades typically required to reduce discharges, artificially lift wells and access adjacent smaller fields e.g. subsea wells

Operating Environment

CRINE (Cost Reduction In the New Era)

Novel designs to reduce development costs and thereby access smaller Reservoirs Example is the Harding Field where a jack up on a concrete storage base is used for drilling, production, storage and export. Once the Field is exhausted the facility will be moved to the next field

Operating Environment

Post Piper Alpha Facilities

Move to separate living accommodation from process and drilling facilities Example is the Bruce Platform with three bridge linked structures: Quarters/Utilities: Drilling/Process and Export. Subsea wells tied back to the Drilling/Process platform

Operating Environment

Subsea Developments

Increasing subsea well count in the North Sea to reduce capital costs Use of floating production systems and mobile drilling rigs, particularly in deep water areas e.g. Foinaven and Scheihallion Fields in 550m of water in the North East Atlantic.

Operating Environment

Supply Boat: Northern North Sea January 2007

Agenda

Material Challenges for North Sea Oil and Gas Production

Business Environment Operating Environment Opportunities for Advanced Materials ?

Opportunities for Advanced Materials ?

Corrosion / Erosion

Many miles of pipework in place surface, subsea and downhole Corrosion/erosion may not be an issue until conditions change e.g. CO2 content increases Internal and external corrosion a major issue Coatings/materials to prevent or repair corrosion ? Intelligent materials to provide information or react to change in condition ?

Opportunities for Advanced Materials ?

Material Deposition

Organic scale, hydrocarbon deposits, sand, rust are major production issues Non stick coatings ? Materials that destroy unwanted deposits ?

Opportunities for Advanced Materials ?

People

Protective equipment ? Location devices ? Health monitoring ?

Lighter / stronger tools ? Lighting ?

Material Challenges for North Sea Oil and Gas Production

Conclusions Increasing demand for Oil and Gas with significant reserves remaining in the UK and multiple opportunities to export services/equipment internationally Pressure on margins, mature facilities, challenging geology and the emphasis on health, safety and environmental protection are driving operators to look for alternative materials in the UKCS Many possibilities for advanced materials

Mining Institute of Scotland IOM3 Petroleum and Drilling Engineering Division

Material Challenges for North Sea Oil & Gas Production A Well Engineers Perspective ITF Advanced Materials Workshop Steve Bedford February 21st 2008

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Crude Oil Assay ManualДокумент41 страницаCrude Oil Assay Manualman45039Оценок пока нет

- 01 Gas GradesДокумент20 страниц01 Gas GradesRadu CerneaОценок пока нет

- Natural Gas ProcessingДокумент5 страницNatural Gas ProcessingĐoàn TrangОценок пока нет

- Unit 02 NHT Operator Training Material - 20210626 REV1Документ72 страницыUnit 02 NHT Operator Training Material - 20210626 REV1ضياء محمدОценок пока нет

- Base Aromatics Production Processes: P A R T 2Документ12 страницBase Aromatics Production Processes: P A R T 2Ashraf SeragОценок пока нет

- Sunflower OilДокумент13 страницSunflower OiljayОценок пока нет

- 08 - Source Rock EvaluationДокумент76 страниц08 - Source Rock EvaluationJose Prima Boang Manalu50% (2)

- Refinery Overview FinalДокумент65 страницRefinery Overview FinalasifОценок пока нет

- AbtngДокумент5 страницAbtngSushant PaiОценок пока нет

- J18 780 PEC Chapter 5 Project DescriptionДокумент43 страницыJ18 780 PEC Chapter 5 Project DescriptionAjlaa Rahim100% (1)

- TOTAL: New Oil Discovery in Nigeria's Offshore OML 102 - 4-TradersДокумент2 страницыTOTAL: New Oil Discovery in Nigeria's Offshore OML 102 - 4-TradersBJAkinolaОценок пока нет

- Chapter 2 Petroleum ReservoirsДокумент23 страницыChapter 2 Petroleum ReservoirsFatima Al-nОценок пока нет

- Applications of AlkanesДокумент2 страницыApplications of AlkanesAira Jane SembranОценок пока нет

- API 617 - Centrifugal and Axial CompressorsДокумент291 страницаAPI 617 - Centrifugal and Axial CompressorsmacarenapurtichОценок пока нет

- 3218MS Gear CouplingДокумент6 страниц3218MS Gear Couplingmanuel1122Оценок пока нет

- Feed AspenHYSYS TransformДокумент20 страницFeed AspenHYSYS Transform李天Оценок пока нет

- 9 - Bhattiacademy - Com - Chemistry - 1. Scholar Series PDFДокумент14 страниц9 - Bhattiacademy - Com - Chemistry - 1. Scholar Series PDFSumair Khan MasoodОценок пока нет

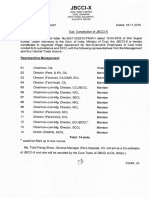

- COAL INDIA Constitution of JBCCI-XДокумент3 страницыCOAL INDIA Constitution of JBCCI-Xrajat304shrivastavaОценок пока нет

- En - Wykaz Towarów - CN Od 20230812Документ8 страницEn - Wykaz Towarów - CN Od 20230812Юрий АндреевОценок пока нет

- India - A New Growth Engine of Petrochemicals?: Threat or Opportunity For Asian Producers?Документ21 страницаIndia - A New Growth Engine of Petrochemicals?: Threat or Opportunity For Asian Producers?PRASENJIT CHAKRABORTYОценок пока нет

- BFNMSДокумент6 страницBFNMSNicolas SosaОценок пока нет

- Malaysian Oil and Gas StatisticДокумент1 страницаMalaysian Oil and Gas StatisticAnonymous 6ZljVVvETОценок пока нет

- Conrad Press ReleaseДокумент2 страницыConrad Press ReleaseFritzОценок пока нет

- Bhai AssignmentДокумент4 страницыBhai AssignmentAun RazaОценок пока нет

- Myanmar Oil Gas Trends Market Opportunities andДокумент8 страницMyanmar Oil Gas Trends Market Opportunities andKhin Maung KyuОценок пока нет

- A Comparison Between The Microbial & ThermogenicДокумент4 страницыA Comparison Between The Microbial & Thermogenicاحمد حمید کارسول عزیزОценок пока нет

- Science9 q2 Clas6 General Classes and Uses of Organic Compounds v4 For RO QA Carissa Calalin 1Документ14 страницScience9 q2 Clas6 General Classes and Uses of Organic Compounds v4 For RO QA Carissa Calalin 1XTlucidОценок пока нет

- Competitive Profile Matrix of Petron: Critical Success Factors WeightДокумент3 страницыCompetitive Profile Matrix of Petron: Critical Success Factors WeightLOUISE ANTHONY APOSTOLОценок пока нет

- Tugas Bahasa InggrisДокумент2 страницыTugas Bahasa InggrisGloriaОценок пока нет

- Multi-Genre ProjectДокумент15 страницMulti-Genre Projectapi-269004027Оценок пока нет