Академический Документы

Профессиональный Документы

Культура Документы

420 F 04019

Загружено:

Sachin RaneИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

420 F 04019

Загружено:

Sachin RaneАвторское право:

Доступные форматы

Innovation that Works

Clean Automotive Technology

www.epa.gov/otaq/technology

Worlds First Full Hydraulic Hybrid SUV Presented at 2004 SAE World Congress

In collaboration with its partners, the U.S. Environmental Protection Agency (EPA) has been researching advanced technology for the past ten years. EPA has had research partnerships with several organizations including Ford Motor Company, Eaton Corporation, Armys National Automotive Center and Parker Hannifin Corporation. Hydraulic hybrid technology is one of the EPA research areas, with the vehicle presented at SAE being the first-ever SUV with a fully hydraulic drivetrain. Hydraulic hybrids increase vehicle fuel economy in two main ways: they allow the engine to be operated at much more efficient modes and they permit the recovery of energy that is otherwise wasted in vehicle braking. The vehicle displayed was a diesel hydraulic hybrid with a projected 55% improvement in fuel economy due to the hydraulic hybrid technology. The hydraulic hybrid technology is projected to increase the cost of a large SUV by about $600, which would be quickly recouped by the consumers lower fuel and maintenance costs. Another 30-40% improvement is available through the conversion of the gasoline engine to a diesel engine. Improved fuel economy reduces greenhouse gas emissions, lowers dependence on imported oil, as well as saves consumers money. Full hydraulic hybrid technology means that the conventional transmission and transfer case have been removed and replaced with a hydraulic drivetrain; EPA has also replaced the large gasoline engine with a small diesel engine. The hydraulic components are easily packaged in this vehicle because the conventional transmission and transfer case were deleted. Hydraulics are an exciting alternative to batteries for making a hybrid vehiclewhile electric hybrids add a battery pack, electric generator/motor, and power electronics, hydraulic hybrids add an accumulator (which stores energy as highly compressed nitrogen gas) and one or more hydraulic pump/motors. EPA and its partners have active programs to demonstrate the commercial potential of hydraulic hybrids.

Innovation that Works

Clean Automotive Technology

www.epa.gov/otaq/technology

Full Hydraulic Hybrid SUV

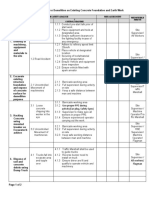

Projected Design Examples

Large 4WD SUV Diesel Engine Accumulators Weight Increase Medium Engine Package Small Engine Package

3.8-liter (170 kw) 15 gals 360 lbs (163 kg)

Fuel Economy label values

1.9-liter (95 kw) 22 gals 125 lbs (57 kg)

Fuel Economy label values

City Highway Combined

32 mpg 22 mpg 27 mpg

Cost/Payback

33 mpg 23 mpg 28 mpg

Cost/Payback

Cost Increase Consumer Payback Net Lifetime Savings

$2,200 2.5 years $4,800

Performance

$1,000 1.1 years $6,300

Performance

0-to-60 mph acceleration

(at test weight)

8.9 seconds 108 mph 9.1% 12,000 lbs

11.4 seconds 90 mph 3.5% 6,900 lbs

Max sustained speed

(at GVWR)

Max sustained grade

(at 70 mph at GVWR)

GVWR plus towing

(at 65 mph at 5% grade)

Economic assumptions: For more information:

Mature high-volume production, vehicle life of 14 years and 188,000 miles, $1.50 per gallon fuel price, 7% discount rate, and 26% retail price mark-up

See Progress Report on Clean and Efficient Automotive Technologies Under Development at EPA, Interim Technical Report, January 2004, at

www.epa.gov/otaq/technology

Innovation that Works

Clean Automotive Technology

www.epa.gov/otaq/technology

Full Hydraulic Hybrid SUV

Projected Performance Examples

0-70 MPH Acceleration

Full Hydraulic Hybrid SUV

80 70 60 Vehicle Speed (mph) 50 40 30 20 10 0 0 2 4 6 8 10 12 Time (s) 14 16 18 20 22 24

Conventional Expedition (5.4L gas) 95 kW, 4-cyl engine, 22 gal accum, 5000 psi max 95 kW, 4-cyl engine, 22 gal accum, 7000 psi max 170 kW, 6-cyl engine, 15 gal accum, 5000 psi max 170 kW, 6-cyl engine, 22 gal accum, 5000 psi max

55 - 70 MPH Passing Acceleration

Full Hydraulic Hybrid SUV

75

70 Vehicle Speed (mph)

65

60

55

Conventional Expedition (5.4L gas) 95 kW, 4-cyl engine, 22 gal accum, 5000 psi max 95 kW, 4-cyl engine, 22 gal accum, 7000 psi max 170 kW, 6-cyl engine, 15 gal accum, 5000 psi max 170 kW, 6-cyl engine, 22 gal accum, 5000 psi max

50 0 1 2 3 4 Time (s) 5 6 7 8

Innovation that Works

Clean Automotive Technology

www.epa.gov/otaq/technology

EPA Advances in Hydraulic Components

Charge/Discharge Cycle Efficiency Overall Weight Weight Reduction Specific Energy Energy Density Power Density Specific Costs Operating Pressure Next Generation - Operating Pressure Peak Efficiency 90+% Efficiency Power Density Next Generation - Power Density

Composite Accumulators

95 % to 99% 240 pounds (22 gallon system) 80 to 90% (from steel piston type accumulators) ~8 kW-sec/kg >50 kW-sec/gallon 3 kW/kg $10/kg 5000 psi 7000 psi

Pump Motors

95+% over 60% of the operating map 5 kW/kg (w/integrated mode valve) 7 kW/kg (w/integrated mode valve)

This hydraulic system can store and re-deliver about 80% of braking kinetic energy back to the wheels.

Regenerating Mode Propulsion Mode 82% Efficiency

Pump Shaft Accumulator Vehicle Braking Kinetic Energy 100

92

(92%)

100 Wheel

Reservoir

(98%)

Hydraulic Motor

Shaft

90

82

(91%)

Wheel

EPA420-F-04-019 March 2004

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Automobile EngineeringДокумент44 страницыAutomobile EngineeringSachin Rane100% (2)

- SSP421 Body BasicsДокумент76 страницSSP421 Body Basicsmamuko100% (3)

- ULSADO-JSA-Demolation Existing Concrete FoundationДокумент2 страницыULSADO-JSA-Demolation Existing Concrete FoundationKelvin Tan75% (4)

- 501 Quantitative Comparison QuestionsДокумент168 страниц501 Quantitative Comparison Questionsjnanmol00793% (15)

- Physics and Chemistry of Micro NanotribologyДокумент290 страницPhysics and Chemistry of Micro NanotribologySachin RaneОценок пока нет

- FUJI FRONTIER 340E - PartslistДокумент172 страницыFUJI FRONTIER 340E - Partslistvitprint22Оценок пока нет

- An Introduction To Orgone Matrix Material (Jon Logan)Документ42 страницыAn Introduction To Orgone Matrix Material (Jon Logan)Jose CiprianiОценок пока нет

- Heating Value of Gases FRM Biomass GasificationДокумент61 страницаHeating Value of Gases FRM Biomass GasificationSai PremОценок пока нет

- Hager Protection Devices TechnicalДокумент70 страницHager Protection Devices TechnicalerreagaaОценок пока нет

- πДокумент290 страницπSachin RaneОценок пока нет

- Aptitude Questions: Ans - TIEДокумент53 страницыAptitude Questions: Ans - TIEkumargpalaniОценок пока нет

- AsdfasdfДокумент1 страницаAsdfasdfSachin RaneОценок пока нет

- Calculus For BeginnersДокумент21 страницаCalculus For BeginnersJay LawsonОценок пока нет

- Master of Body Language PDFДокумент10 страницMaster of Body Language PDFreversoОценок пока нет

- Tree List RecursionДокумент11 страницTree List RecursionKranthi Kiran GuduruОценок пока нет

- Putting Big Data: To WorkДокумент6 страницPutting Big Data: To WorkSachin RaneОценок пока нет

- Numerical RecipesДокумент3 страницыNumerical RecipesVinay GuptaОценок пока нет

- Painless Conjugate GradientДокумент64 страницыPainless Conjugate GradientBlanca Gomez OrozcoОценок пока нет

- Aptitude Questions: Ans - TIEДокумент53 страницыAptitude Questions: Ans - TIEkumargpalaniОценок пока нет

- C Language Reference Manual - 5th EditionДокумент208 страницC Language Reference Manual - 5th Editionioana100% (3)

- C EssentialsДокумент45 страницC EssentialssuchitraprasannaОценок пока нет

- MEMSДокумент1 страницаMEMSSachin RaneОценок пока нет

- A Review of Solar-Powered Stirling EnginesДокумент24 страницыA Review of Solar-Powered Stirling EnginesadrianunteaОценок пока нет

- Six Pack Ab WorkoutДокумент7 страницSix Pack Ab Workouthp910Оценок пока нет

- IntroFinance 2012 SyllabusДокумент8 страницIntroFinance 2012 SyllabusParidhi AggarwalОценок пока нет

- Sor FeldДокумент1 страницаSor FeldSachin RaneОценок пока нет

- Creativity QuotesДокумент4 страницыCreativity QuotesSachin RaneОценок пока нет

- Master of Body Language PDFДокумент10 страницMaster of Body Language PDFreversoОценок пока нет

- Creativity QuotesДокумент4 страницыCreativity QuotesSachin RaneОценок пока нет

- American Idioms PDFДокумент19 страницAmerican Idioms PDFSachin RaneОценок пока нет

- Velocity and Acceleration DiagramsДокумент31 страницаVelocity and Acceleration Diagramsjohn_max03Оценок пока нет

- ASMEДокумент2 страницыASMESachin RaneОценок пока нет

- American Idioms PDFДокумент19 страницAmerican Idioms PDFSachin RaneОценок пока нет

- Physical Properties of Lubricants and Their CompositionДокумент85 страницPhysical Properties of Lubricants and Their CompositionSachin RaneОценок пока нет

- Infinite Long Rayleigh Step Bearing-Rev1Документ19 страницInfinite Long Rayleigh Step Bearing-Rev1Sachin RaneОценок пока нет

- Tsi 20040109 PDFДокумент2 страницыTsi 20040109 PDFenache_marian0% (1)

- Price ListДокумент2 страницыPrice ListCHeng SOngco TAlosigОценок пока нет

- 7216Документ8 страниц7216siicmorelosОценок пока нет

- INA FAG Water Pump BearingsДокумент31 страницаINA FAG Water Pump Bearings2bjornОценок пока нет

- Durability Analysis 101Документ4 страницыDurability Analysis 101fkaram1965Оценок пока нет

- Strength Calculation and Dimensioning of Joints: Prepared By: Samson Yohannes Assistant ProfessorДокумент45 страницStrength Calculation and Dimensioning of Joints: Prepared By: Samson Yohannes Assistant ProfessorBK MKОценок пока нет

- Materials System SpecificationДокумент8 страницMaterials System Specificationnadeem shaikhОценок пока нет

- Connector CatalogДокумент60 страницConnector CatalogYadira De De Ciam100% (1)

- TL2 Number SystemsДокумент78 страницTL2 Number SystemsKhushbu SavaliyaОценок пока нет

- DTH Drilling MachineДокумент8 страницDTH Drilling MachineREL PromoОценок пока нет

- Geotech Final ReportДокумент38 страницGeotech Final Reportapi-320590292Оценок пока нет

- SPECIFICATION WRITING MODULEДокумент3 страницыSPECIFICATION WRITING MODULEHana YeppeodaОценок пока нет

- Compressed Air Fittings & Equipment Catalogue: Importers and Direct Sellers of Quality Hand ToolsДокумент18 страницCompressed Air Fittings & Equipment Catalogue: Importers and Direct Sellers of Quality Hand ToolsVin KenОценок пока нет

- Home water pressure booster pumpДокумент3 страницыHome water pressure booster pumpbadaasaabОценок пока нет

- Sangshad BhabanДокумент21 страницаSangshad Bhabanuniqueboy6050% (2)

- MPTO Charts566662Документ25 страницMPTO Charts566662andres ortizОценок пока нет

- Dell Operation ManagementДокумент13 страницDell Operation ManagementIsha GosainОценок пока нет

- How Objects Are Discovered and Monitored in Operations ManagerДокумент2 страницыHow Objects Are Discovered and Monitored in Operations ManagerAkhilesh NandanwarОценок пока нет

- Inverting Power Supply Using A TPS54202 BuckДокумент25 страницInverting Power Supply Using A TPS54202 Buckg4okkОценок пока нет

- White Paper c11 737101Документ13 страницWhite Paper c11 737101Aleksandar PopovicОценок пока нет

- 72.core Cut Reference SP-24Документ1 страница72.core Cut Reference SP-24DMJ NagpurОценок пока нет

- System 1: Bently NevadaДокумент4 страницыSystem 1: Bently Nevadanabil160874Оценок пока нет

- HOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsДокумент12 страницHOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsJo PatrickОценок пока нет

- 90ma012 - CarrierДокумент32 страницы90ma012 - Carrierrafaelpaiva871531Оценок пока нет