Академический Документы

Профессиональный Документы

Культура Документы

Logistics Int 1

Загружено:

Jacob RodriquesИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Logistics Int 1

Загружено:

Jacob RodriquesАвторское право:

Доступные форматы

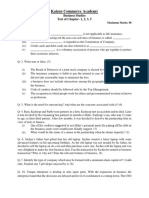

Elements of Logistics and Supply Chain Management

What is Logistics? Science of movement What is Movement? Human body? Economy? Movement is life Stagnation is death!

Where does the movement take place? Infrastructure What moves? Materials and information

What are Elements? Building blocks Constituents Elements of Logistics and Supply Chain Management Participants Processes and Activities Tools and techniques

Processes Planning Procurement Warehousing Distribution Outsourcing Activities Communication Packaging, material handling, Transportation Storage

Tools and Techniques

Operations Research Models MRP, DRP, SAP RFID EDI KANBAN

Participants

3PL

3PL

VENDOR

SUPPLIER

CUSTOMER

What? Where? When? Who? How much? How?

4PL

What are the objectives of Logistical Management? What is Logistical Management? Customer service Achieving logistical objectives at minimum cost What is Supply Chain? Evolved from the concept of Logistical management Looking beyond the organization to satisfy the end user A conceptual pipe line connecting source of raw material to end user What is there in this pipe line? What flows in this pipeline? ? ? ? - Procuring resources for production from where they are available (who is the customer?) - Distributing finished products where they are required in the market (who is the customer?)

The Supply Chain

Vendors vendor

Vendor

Supplier

Customer

Customers customer

Source of raw materials

End users

Genesis of modern logistics Logistics is as old as business but modern logistics (Logistical Management) is new Dark continent of economics in 60s.. Logistics is military planning, a military concept OR techniques like PERT/CPM, VA etc. came from military Battles are won or lost even before they are fought. Field Marshall Rommel Logistical Management? Performing physical movement of materials efficiently and effectively Ensuring availability of resources at minimum cost for production Ensuring availability of finished products at minimum cost to the customer A Function Of Business Management

Definition of Logistics management Logistics is the process of strategically managing procurement, storage and distribution of raw materials, parts, finished inventory and related information flow through organization and its marketing channels in such a way that current and future profits are maximized through cost effective fulfillment of order ? Logistics is the process of planning implementing and controlling efficient, effective flow and storage of goods, services and related information from the point of origin to the point of consumption for the purpose of confirming to customer requirements Council of Logistical Management What Causes Bad Logistics? Infrastructure : Bad roads, inefficient railways, poor communication lines, congested ports Government policies : Octroi Information : Inadequate information, bad communication Management decisions : Bad management decisions like carrier selection, out sourcing etc. Cost cutting in isolation What Does Bad Logistics Cause? Costly products - Poor logistics adds costs - Higher cost of capital (delayed deliveries) - Damaged products (bad roads, bad vehicles, bad packaging) - Excessive movement costs (wrong deliveries)

Shortages as product/service delivery fails - PDS and FCI stocks - Deteriorating economy - Law and order problems

Importance of Logistics Logistics is the bed rock of trade and business Leads to customer satisfaction, D & F expectations of customers Integrates logistical activities, which leads to cost reduction Competitive edge in a commodities market, where quality and costs are only qualifiers Supports critical functions like operations and marketing to be JUST IN TIME to the customer. Strong logistical support improves Lead time Product protection Logistical costs Logistical costs are 5% to 35% of sales depending on type of business, geographical areas of operation etc. Crucial to survival and prosperity in global business (longer supply lines, language, rules & regulations, taxes, holidays, beliefs!) Logistics experts are moving up in Corporate Ladder, great opportunities Leads to the concept of supply chain management Indian market is changing- shift from sellers market to buyers market Changing customer Competition, internal & external Logistics and Supply Chain Management, development of concepts. 1950s First post war decade - Decade of awareness Importance of physical movement of materials to customers Focus on costs of these activities & idea of total cost (Total cost and its components) Importance of mode of transport 1960s Integration of activities of outbound logistics and emergence of Physical Distribution Management Information as an important element of Physical Distribution Management Impact of electronics on information 1970s Integration of some aspects of financial subsystem recovery, cash flow Focus on activities of inbound logistics until considered to be vendors concern 1980s Concept of Logistics as a management function, internally integrating all activities of inbound and out bound logistics Focus on logistical operations Application of TQM, TPM & JIT philosophies

1990s Gradually concept is encompassing entire value chain as Supply Chain Management due to external integration Henry Fords [early 1890s] concept of mutual dependence of firms in a value chain Idea of control on entire supply chain for improving product delivery

LOGISTICAL FUNCTIONS :Inventory Management Neither stock-out nor stockpiling of inputs or outputs Minimum cost by minimum stock & high turns Just In Time to customer (internal and external) Inventory policies, models, systems Information management Importance in competitive business Response to customer Customer service The role Information Management function Accurate information Real time information Choice of Information technology phone, fax, internet, satellites, RFID (Radio Frequency Identification Device), EDI Transportation Physical movement of materials The most visible function of Logistics High contributor to costs of logistics Movement costs Preservation costs Cost of idle asset Administration costs Net work analysis Analysis of Logistical Network to retain or gain competitive edge Number of facilities and their locations Communication systems Operational decisions - What?Who?How much?Where? Warehousing Strategic storage storage as an activity in W/H Value Adding Activities in warehouses Switching facility rather than a storage facility Economic benefits (cost reduction) & service benefits (customer service) Material handling Receiving, moving, storing, dispatching activities Cost adding activity High capital cost as well as high running cost Packaging Product Protection Facilitation of transportation & material handling Types of packaging

Consumer packaging Logistical packaging

SUPPLY CHAIN MGT ;

Scope - Source of raw materials to end user - all upstream & downstream organizations & linkages Encompasses all logistical management activities involved Sourcing (procurement) Manufacturing support Distribution activities Includes coordination and collaboration with channel partners to finally deliver the product to end users Main objective - Supply chain profitability by value creation Focus - End User Origin - extension of scope of logistics management A set of several subsets Definition - Management of upstream and down stream relationships with suppliers and customers to deliver superior customer value at less cost to the supply chain as a whole How SCM creates value? Breaking the organizational barriers Sharing of sales information in real time Inventory visibility Reduces inventories by reducing uncertainties Compresses value chain by slashing lead-times thereby quickening cash flow The channel partners Suppliers product owners Intermediaries experts in international shipping who offer consultancy service to suppliers Third-party service providers those who offer logistics service for a fee Customers the recipients of service Manufacturers parts manufacturers Transporters 3PL companies who offer transportation service Handlers 3PL companies who offer material handling service Wholesalers who stock inventory and offer in small quantities to retailers Dealers who book orders and instruct wholesalers to supply to retailers Retailers offer products to consumers

Logistical performance cycles :Cycles are sets of logistical activities in logistical value chain Types of Logistical Performance Cycles Procurement Manufacturing support Physical distribution

Important features Logistical performance cycles link all participating firms (facilities) and organizations in the value chain up and down by information and product movement Input sensitive (customer order) & dynamic Sensitiveness determines efficiency of operating system

Operating Objectives Of Logistics :Rapid response Ability to respond rapidly to customers order High flexibility Short lead-times SMED and Kanban Real time information IT supported systems Minimum variance Any event that disrupts flow of supplies to customer is variance Problems in information flow, traffic snarls, acts of god, wrong dispatches, transit damage Interrupts product delivery Undermines OTD Objective How to maintain smooth, undisturbed flow of supplies to customer? Traditional approach stock piling Modern approach Minimum Variance

Minimum inventory Low inventory volume by high inventory turns Kanban as an inventory control tool Single piece flow as practiced by JIT companies Movement consolidation Movement planning to reduce costs Bulk volume, same product or collection Long runs, eliminating broken short runs Integrating interests of several players in business Quality Quality of logistics performance - complete fulfillment of order, product, place, time and quantity Life cycle support [cradle to cradle logistical support to product] After sales service Product delivery (cradle) Fault free installation Training (how to use) Repairs and maintenance Product replacement (cradle)

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Chapter 01 Ten Principles of EconomicsДокумент30 страницChapter 01 Ten Principles of EconomicsTasfia Rahman Riva100% (1)

- PERRUCI Millennials and Globalization 2012 PDFДокумент6 страницPERRUCI Millennials and Globalization 2012 PDFgomiuxОценок пока нет

- India Completing Inv UniverseДокумент16 страницIndia Completing Inv UniverseKushal ManupatiОценок пока нет

- The Affluent SocietyДокумент189 страницThe Affluent SocietyOtter1zОценок пока нет

- A Study On Impact of Foregin Stock Markets On Indian Stock MarketДокумент20 страницA Study On Impact of Foregin Stock Markets On Indian Stock MarketRaj KumarОценок пока нет

- Joint Stock CompanyДокумент2 страницыJoint Stock CompanybijuОценок пока нет

- Evaluasi Penerapan Perlakuan Akuntansi Psak 24 Pada PT Gudang Garam TBKДокумент9 страницEvaluasi Penerapan Perlakuan Akuntansi Psak 24 Pada PT Gudang Garam TBKphoechoexОценок пока нет

- Export Invoice: Item Description: Qty: UOM: Curr Unit PriceДокумент4 страницыExport Invoice: Item Description: Qty: UOM: Curr Unit PriceAdam GreenОценок пока нет

- Chapter 16 Macroeconomics Principle - The Monetary SystemДокумент52 страницыChapter 16 Macroeconomics Principle - The Monetary SystemNaufal Mohammad0% (1)

- Chapter 6 - Product and Service StrategiesДокумент32 страницыChapter 6 - Product and Service StrategiesralphalonzoОценок пока нет

- Calling DataДокумент54 страницыCalling DatainfoОценок пока нет

- Ceramic Tiles - Official Gazette 27 (10234)Документ16 страницCeramic Tiles - Official Gazette 27 (10234)NajeebОценок пока нет

- Panay Electric vs. NLRCДокумент1 страницаPanay Electric vs. NLRCsamme1010Оценок пока нет

- Entry Mode StrategyДокумент12 страницEntry Mode StrategyMetiya RatimartОценок пока нет

- Business Economics PPT Chap 1Документ18 страницBusiness Economics PPT Chap 1david sughapriyaОценок пока нет

- We Control The World's Wealth Twitter1.2.19Документ19 страницWe Control The World's Wealth Twitter1.2.19karen hudesОценок пока нет

- Revised Withholding Tax TablesДокумент2 страницыRevised Withholding Tax TablesReylan San PascualОценок пока нет

- Ethics Assignment 1 - Dedglis DuarteДокумент6 страницEthics Assignment 1 - Dedglis DuarteAnonymous I03Wesk92Оценок пока нет

- Kotler Chapter 11Документ41 страницаKotler Chapter 11Duc Trung Nguyen83% (6)

- Container Industry Value ChainДокумент14 страницContainer Industry Value ChainRasmus ArentsenОценок пока нет

- Business StudiesДокумент2 страницыBusiness StudiesSonal JhaОценок пока нет

- Placement Report 2023Документ9 страницPlacement Report 2023Star WhiteОценок пока нет

- The Birth Certificate: Rehabilitative Services" (HRS) - Each STATE Is Required To Supply The UNITED STATES WithДокумент4 страницыThe Birth Certificate: Rehabilitative Services" (HRS) - Each STATE Is Required To Supply The UNITED STATES Withpandabearkt50% (2)

- Population GrowthДокумент3 страницыPopulation GrowthJennybabe PetaОценок пока нет

- Indias Top 50 Best ItДокумент14 страницIndias Top 50 Best ItAnonymous Nl41INVОценок пока нет

- Markets and Commodity Figures: Total Market Turnover StatisticsДокумент6 страницMarkets and Commodity Figures: Total Market Turnover StatisticsTiso Blackstar GroupОценок пока нет

- Company Profile ManmulДокумент3 страницыCompany Profile ManmulAston Rahul Pinto50% (2)

- Li & Fung LimitedДокумент2 страницыLi & Fung Limitedeguno12Оценок пока нет

- List of The Top 10 Leather Manufacturers in BangladeshДокумент4 страницыList of The Top 10 Leather Manufacturers in BangladeshNasim HasanОценок пока нет

- Development and Fundraising - Independent SchoolsДокумент2 страницыDevelopment and Fundraising - Independent SchoolsHeadingtonОценок пока нет