Академический Документы

Профессиональный Документы

Культура Документы

Refrigerant Unit

Загружено:

Alif Aikal Che HatИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Refrigerant Unit

Загружено:

Alif Aikal Che HatАвторское право:

Доступные форматы

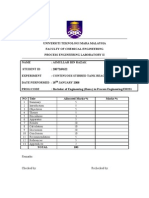

UNIVERSITI TEKNOLOGI MARA

FAKULTI KEJURUTERAAN KIMIA

ENGINEERING CHEMISTRY LABORATORY

(CHE485)

No. Title Allocated Marks () Marks

1 Abstract/Summary 5

2 Introduction 5

3 Aims 5

4 Theory 5

5 Apparatus 5

6 Methodology/Procedure 10

7 Results 10

8 Calculations 10

9 Discussion 20

10 Conclusion 5

11 Recommendations 5

12 ReIerence / Appendix 5

TOTAL MARKS 100

Remarks:

Checked by : Rechecked by:

--------------------------- ---------------------------

Date : Date :

NAME : NUUR ALIF AIKAL B. CHE HAT

STUDENT NO. : 2010403024

GROUP : 3A

EXPERIMENT : REFRIGERANT UNIT

DATE PERFORMED : 19

OCTOBER 2011

SEMESTER : 3

PROGRAMME / CODE : EH221

SUBMIT TO : MISS HABSAH BINTI ALAWI

[Z`WZ`_

ABSTRACT ............................................................................................................................... 3

INTRODUCTION ...................................................................................................................... 4

OBJECTIVES ............................................................................................................................. 6

THEORY .................................................................................................................................... 7

APPARATUS ............................................................................................................................. 8

PROCEDURES .......................................................................................................................... 8

RESULT ..................................................................................................................................... 9

DISCUSSION ........................................................................................................................... 19

CONCLUSION ........................................................................................................................ 20

RECOMMENDATIONS .......................................................................................................... 21

REFERENCES ......................................................................................................................... 21

ABSTRAT

A reIrigeration apparatus was used to evaluate the perIormance oI a reIrigeration cycle. There

are Iour parts in this experiment. Experiment 1 is mainly about determining power input, heat

output and coeIIicient oI perIormance oI a vapor compression heat pump system. From the

calculation made, the value oI heat output Irom the experiment is 229.9 W, the power input

which is taking Irom the reading is 179 W, and the coeIIicient oI perIormance oI heat pump is

1.28. The coeIIicient oI perIormance oI heat pump is calculated Irom the Iormula

C

H

heat rejected at the higher temperature

COP

compressor net work

"

.

Second part oI the experiment is to produce the perIormance oI heat pump over a range oI source

and delivery temperatures. The graphs oI COP

H

, power, and heat output vs temperature was

plotted. All the graphs shows similar pattern. The third experiments are to plot vapor

compression cycle on p-h diagram and compare with the ideal cycle and to perIorm energy

balances Ior the condenser and compressor. The graph oI p-h was plotted by Iinding the value oI

h Ior the whole cycle. The last part oI the experiment is to determine the compression ratio and

volumetric eIIiciency. The value oI compression ratio and volumetric eIIiciency are 0.35 and

0.62 respectively. In real liIe, ideal cycle cannot be achieved because oI so many Iactors that can

aIIect the system.

TRUDUTU

The SOLTEQ Mechanical Heat Pump (Model: HE165) has been designed to provide students

with a practical and quantitative demonstration oI a vapour compression cycle, and is suitable

Ior all course levels (intermediate and undergraduate). ReIrigerators and heat pump both apply

the vapour compression cycle, although the applications oI these machines diIIer, the

components are essentially the same.

The Mechanical Heat Pump is capable oI demonstrating the heat pump applications where a

large Ireely available energy source, such as the atmosphere is to be upgraded Ior water

heating. The unit will be particular interest to those studying Mechanical Engineering, Energy

Conservation, Thermodynamics, Building Services, Chemical Engineering, Plant and Process

Engineering, ReIrigeration and Air Conditioning.

ReIrigerators and heat pumps are devices that absorb heat at a low temperature and reject

heat at a higher temperature. Both reIrigerators and heat pumps operate in the same way using a

reversed heat engine cycle, but are labeled separately according to their purpose. Devices that are

used to maintain a temperature below ambient are known as reIrigerators (or air conditioners)

while devices that are used to supply heat at a higher temperature than ambient are known as heat

pumps. Some devices, in particular those used Ior space cooling, may be used as both a heat pump

and a reIrigerator.

The vapor compression cycle is the most commonly used reIrigeration/heat pump cycle and

involves the same Iour processes as a heat engine cycle but in the reverse order (i.e. evaporation

compression condensation expansion/throttling). Figure 1 gives a schematic representation oI

the Iour essential mechanical components in this cycle; Iigure 2 shows the ideal cycle on a

pressure-enthalpy diagram.

Heat out

3 2

Condenser

Throttle Work in

Valve

Evaporator Compressor

4 1

Heat in

Figure 1: Vapor Compression Cycle components

Figure 2: Ideal cycle on pressure enthalpy diagram.

In ideal vapor compression cycle the reIrigerant vapour is compressed isentropically to a higher

temperature and pressure (12). The compressed vapour is then condensed isobarically which

results in heat rejection to the surroundings (23). The next step is the adiabatic throttling oI the

3

2

4

1

Superheating

Subcooling

Critical Point

Liquid

Pressure

Enthalpy

reIrigerant to the low temperature and pressure (34). The Iinal step is where the reIrigerant is

evaporated isobarically at low temperature and pressure, which results in the absorption oI heat

Irom its surroundings (41). In an actual cycle states 1 and 3 should not lie on the saturation line

as there is subcooling (helpIul to obtain state 3 in the diagram) and superheating (necessary to

avoid droplets (two phase region!) in the compressor).

The usual measure oI perIormance oI a reIrigerator or heat pump is the Coefficient of Performance

COP which Ior a reIrigerator COP

R

is deIined as:

E

R

heat absorbed at the lower temperature

COP

compressor net work

"

(1a)

For a heat pump COP

H

:

C

H

heat rejected at the higher temperature

COP

compressor net work

"

(1b)

where E, C, R, H stand Ior Evaporator, Compressor, ReIrigeration, and Heat pump respectively.

UB)ETES

Experiment 1: to determine the power output, heat output and coeIIicient oI perIormance oI a

vapor compression heat pump system.

Experiment 2: to produce perIormance oI heat pump over a range oI source and delivery

temperatures.

Experiment 3: a) to plot vapor compression cycle on p-h diagram and compare with the ideal

cycle.

b) to perIormed energy balances Ior the condenser and compressor.

Experiment 4: to determine the compression ratio and volumetric eIIiciency.

THEURY

A heat pump is a machine or device that transIers heat Irom one location at a lower temperature

to another location at a higher temperature using mechanical work or a high-temperature heat

source. The diIIerent between a heat pump and a normal air conditioner is heat pump can be used

to provide heating or cooling whereas air conditioner is only Ior cooling. Although heat pump is

use to heating but it still work using the same basic reIrigeration cycle. The basic idea oI all

pumps is that the heat is absorbed using a medium, which releases the heat at a required

temperature which is higher aIter a physical or chemical transIormation.

Generally, there are three types oI heat pump system:

1. Closed cycle vapor compression heat pump (electric and engine driven)

2. Heat transIormer (a type oI absorption heat pump)

3. Mechanical vapor recompression heat pump operating at about at 200C

The coeIIicient oI perIormance, (COP) oI a heat pump cycle is an expression oI the cycle

eIIiciency and is stated as the ratio oI the heat removed in the heated space to the heat energy

equivalent oI the energy supplied to the compressor.

COPH Heat produced inside the room / Power consumed by the compressor

Thus, the theoretical simple cycle, it may write as:

COPH

hcutng o] ]cct

hcut o] compcsson

(h

2

-h

3

)

(h

2

-h

1

)

The cooling water and reIrigerant Ilow rate display is in percentage (). The Iormula to convert

cooling water and reIrigerant Ilow rate to LPM are:

1. Cooling water Ilow rate (LPM)

cooIng wutc ]Iow utc (%)

100%

5 LPM

2. ReIrigerant Ilow rate (LPM)

c]gcunt ]Iow utc (%)

100%

1.26 LPM

APPARATUS

1) SOLTEQ Mechanical Heat Pump (Model: HE165)

2) Stop watch.

PRUEDURES

General start-up

1) All the unit and instruments were checked so that in good condition.

2) Both water source and drain are connected then water supplies were opened and the

cooling water Ilowrate were set at 1.0 LPM.

3) The drain hose at the condensate collector was connected.

4) Main power was switched on Iollows by switch at control panel.

5) ReIrigerant compressor was switched on.

Experiment 1

1) General start-up procedures were perIormed.

2) The cooling water Ilowrate was set to 40.

3) All the necessary data were recorded aIter the system running Ior 15 minutes.

Experiment 2

1) General start-up procedures were perIormed.

2) The cooling water Ilowrate was set to 70.

3) All the necessary data were recorded aIter the system running Ior 15 minutes.

4) The experiments were repeated by reducing the cooling water Ilowrate so that the water

outlet temperature, TT6, increases by about 3

o

C.

5) Similar steps were repeated until the compressor delivery pressure reaches around 2.6

bars.

Experiment 3

1) General start-up procedures were perIormed.

2) The cooling water Ilowrate was set to 40.

3) All the necessary data were recorded aIter the system running Ior 15 minutes.

Experiment 4

1) The experiment is similar to experiment 3, thereIore the procedures were repeated.

RESULT

Experiment 1: determination of power input, heat output and coefficient of performance.

Cooling water Ilow rate, FT 1 40.1

Cooling water inlet temperature, TT 5 C 26.4

Cooling water outlet temperature, TT 6 C 29.7

Compressor power input W 179

For reading 1,

Cooling water Ilow rate, LPM

cooIng wutc ]Iow utc (%)

100%

x 5 LPM

40.1 x 5

100

2.005 LPM

Calculation:

Heat output

1.0 L

mn

1 L

kg

1 mn

60 s

4180 ]

kg.K

(9. - .)

229.9 W

COP

H

Hcut 0utput

Powc Input

229.9 w

179 w

1.28

Experiment 2: production of heat pump performance curve over a range of source and

delivery temperatures.

Reading 1 Reading 2 Reading 3

Cooling water Ilow rate, FT 1 70.8 19.0 20.7

Cooling water inlet temperature, TT

5

C 26.4 26.3 26.4

Cooling water outlet temperature,

TT 6

C 28.4 31.6 32.9

Compressor power input W 175 185 185

Heat output W 139.3 369.2 452.8

COP

H

0.80 2.00 2.45

From the value calculated, graphs can be constructed,

1rlal

1

(

0

C)

CC

hp

ower

(W)

C

h

(W)

1 26.4 0.80 175 139.3

2

26.3 2.00 185 369.2

3 26.4 2.45 185 452.8

0

03

1

13

2

23

28 283 29 293 30 303 31 313 32 323 33 333

C

C

coo||ng water out|et temperature (deg C)

performance of heat pump aga|nst coo||ng

water out|et temperature

0

03

1

13

2

23

2628 263 2632 2634 2636 2638 264 2642

C

C

coo||ng water |n|et temperature (deg C)

performance of heat pump aga|nst coo||ng

water |n|et temperature

Experiment 3: production of vapor compression cycle on p-h diagram and balance study.

ReIrigerant Ilow rate, FT2 47.1

ReIrigerant pressure (low), P1 Bar (abs) 2.5

ReIrigerant pressure (high), P2 Bar (abs) 7.4

ReIrigerant temperature, TT1 C 20.8

ReIrigerant temperature, TT2 C 72.9

ReIrigerant temperature, TT3 C 28.6

ReIrigerant temperature, TT4 C 17.7

Cooling water Ilow rate, FT1 40.8

Cooling water inlet temperature,

TT5

C 26.5

Cooling water outlet temperature ,

TT6

C 30.3

Compressor power input W 179

The reIrigeration cycle is constructed Irom the data in the table

Figure 1: Example reIrigeration cycle

1 atm 101.325 kPa 1.01325 bar

ReIrigerant pressure (low), P1,

.TS^

1 atm

1.01325 bar

101.325 kPa

1 atm

250kPa

ReIrigerant pressure (high), P2,

7.4 TS^

1 atm

1.01325 bar

101.325 kPa

1 atm

740 kPa

Calculation at 1 and 2,

Find h

1

and h

2

using interpolation Irom saturated R-134a pressure table

P (kPa) h (kJ/kg)

240 202.62

250 201.85

280 199.54

P (kPa) h (kJ/kg)

700 176.21

740 174.43

750 173.98

Calculation 3 and 4,

Find h

3

and h

4

using interpolation Irom saturated R-134atemperature table

T (C) h (kJ/kg)

28 90.69

28.6 91.63

30 93.58

T (C) h (kJ/kg)

16 73.73

17.7 76.00

18 76.52

From the value that calculated, p-h diagram can be constructed,

h (k!/kg)

ressure

(ka)

20183 250

17443 740

9163

740

7600 250

20183 250

p-h diagram of ideal cycle

0

100

200

300

400

300

600

700

800

0 30 100 130 200 230

p

r

e

s

s

u

r

e

(

k

a

)

h(kI]kg)

h d|agram of k134a

Experiment 4: estimation of the effect of compressor pressure ratio on volumetric

efficiency

ReIrigerant Ilow rate , FT2 47.2

ReIrigerant pressure (low) , P1 Bar (abs) 2.6

ReIrigerant pressure (high) , P2 Bar (abs) 7.4

ReIrigerant temperature ,TT1 C 22.4

Compressor pressure ratio

tIon prcrc oI rcIrIgcrant

dIargc prcrc oI rcIrIgcrant

2.6 bar

7.4 bus

0.35

Volumetric eIIiciency

ctuuI oIumctc ]Iow utc

1hcoctcuI oIumc o] compcsso

ReIrigerant Ilow rate, LPM

c]gcunt ]Iow utc (%)

100%

x 1.26 LPM

0.472 1.26 LPM

0.595 LPM

Change LPM to the kg/s

Mass Ilow rate 0.595 LPM x

1000 cm

3

1 L

x

1m

3

(100cm)

3

x

1 mn

60 s

x 4.25

kg

m

3

4.215 x 10

-5

kg

s

Density oI reIrigerant 134a 4.25

kg

m

3

Actual volume Ilow rate

muss ]Iowutc

dcnst o] c]gcunt 134u

4.215 x 10

-5

kg

s

x

m

3

4.25 kg

9.918 x 10

-6

m

3

s

Volumetric eIIiciency

9.98 x -

1.61 x 10

-S

0.62

DSUSSU

All the experiment need to perIorm start-up procedure Iirst beIore doing the Iollowing

experiments. The start-up procedure was to make sure that the entire component is in proper

condition to avoid any mistakes. The hoses need to be connected to both at sources and drain.

Experiment 1 is conducted to determine the power output, heat output and coeIIicient oI

perIormance oI a vapor compression heat pump system. To take the necessary data, the system

was running Ior 15 minutes and let the Ilowrate oI cooling water be about 40.in this

experiment; we had made it 40.1 because it is diIIicult to set Ior the exact value. For the power

output, we get the reading was 179 W, heat output is 229.9 W and coeIIicient oI perIormance is

1.28. We can determine the value oI coeIIicient oI perIormance by applying Iormula COP

H

Hcut 0utput

Powc Input

and the power input is just by reading it at the control panel oI the apparatus. The

coeIIicient oI perIormance was a small value so iI we want to improve the coeIIicient oI

perIormance, we need to decrease temperature diIIerence. %e Coefficient of Performance

(amount of eat moved per unit of input work required) decreases wit increasing temperature

difference.

1

Experiment 2 is about producing the perIormance oI heat pump over a range oI source and

delivery temperatures. This time, we adjust the cooling Ilowrate to about 70 let it run Ior 15

minutes again. Then, we repeated the same procedure by reducing water Ilow rate so that water

outlet temperature increases by about 3

o

C then all the necessary data were collected. These

procedures were made to plot graphs oI perIormance oI heat pump against cooling water outlet

and inlet. The graph shows the perIormance oI heat pump decreases with increasing temperature

even it increase Ior a value, then it decrease back. ThereIore, the statement above was right that

the coeIIicient oI perIormance decreases with increasing temperature diIIerence.

1

PeaL pump

hLLp//enwlklpedlaorg/wlkl/PeaL_pump

Experiment 3 is to construct p-h diagram Ior the cycle and compare it to the ideal cycle. There

are diIIerences between this cycle and the ideal one because oI many Iactors that aIIect it.

Frictional pressure drop in the system, slight thermodynamic irreversibility during the

compression oI the reIrigerant vapor, or non-ideal gas behavior are most common Iactor that

aIIect the system. Conclusion Ior this experiment is there are no ideal cycle can be achieve in

real liIe because even the most perIect cycle can have slight diIIerence.

In experiment 4, we want to determine the compression ratio and volumetric eIIiciency. From the

calculation, we Iound that the compression ratio is 0.35 and the volumetric eIIiciency is 0.62.

'olumetric efficiencies of at least 0.8 are desirable and are acievable.

2

Even the value is slight diIIerence Irom the desirable value, it can be considered.

ULUSU

The conclusion that can be made Irom this experiment is that this cycle is not an ideal cycle. We

do not achieve the desirable value Ior volumetric eIIiciency, the p-h diagram that have been

made Irom the experiment and calculation is diIIerent Irom the ideal cycle and the value oI

coeIIicient oI perIormance is small that are 0.8, 2.0 and 2.4 as in experiment 2. ThereIore, to

improve the coeIIicient oI perIormance, we need to decrease the temperature diIIerence.

2

ueslgn of a refrlgeraLlon cycle claymoreenglneergvsuedu

REUMMEDATUS

1. Make sure the machine is in the good condition beIore start the experiment.

2. Make sure the data is stabilizing beIore taking the reading as it can aIIect the result.

3. Make sure that the both water source and drain are connected beIore start the experiment.

4. Make sure the amount oI water supply is enough Ior entire experiment.

5. Make sure the water Ilowrate is set on 1.0 LPM.

REFEREES

1. Date oI access:02 November 2011

http://en.wikipedia.org/wiki/Heatpump

2. Date oI access:30 October 2011

http://www.scribd.com/doc/37740504/Lab-1-ReIrigeration-Cycle

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Center of Gravity CalculatorДокумент2 страницыCenter of Gravity CalculatorAalekh PrajapatiОценок пока нет

- KEC International Limited: Pile FoundationДокумент49 страницKEC International Limited: Pile FoundationDinesh Kumar100% (1)

- TMS Energy Calculations (V2.0g)Документ5 страницTMS Energy Calculations (V2.0g)Alif Aikal Che HatОценок пока нет

- 8) Honeywell Actuator PDFДокумент13 страниц8) Honeywell Actuator PDFAlif Aikal Che HatОценок пока нет

- Bar Q Salaries Part 2Документ5 страницBar Q Salaries Part 2Brigette DomingoОценок пока нет

- Lecture Notes (Financial Economics)Документ136 страницLecture Notes (Financial Economics)americus_smile7474100% (2)

- Philippine Multimodal Transportation and Logistics Industry Roadmap - Key Recommendations - 2016.04.14Документ89 страницPhilippine Multimodal Transportation and Logistics Industry Roadmap - Key Recommendations - 2016.04.14PortCalls50% (4)

- Fastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Документ3 страницыFastener Grades A1, A2, A3 & A4, A5 To BS en ISO 3506Paul OnionsОценок пока нет

- ABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Документ18 страницABMOM q2 mod5OrgAndMngmnt Motivation - Leadership and Communication in Organizations-V2Zoren Jovillanos EmbatОценок пока нет

- Media and Information Literacy Quarter 3 Module 1Документ67 страницMedia and Information Literacy Quarter 3 Module 1Joshua Catequesta100% (1)

- Filcar vs. EspinasДокумент2 страницыFilcar vs. EspinasBrian ThunderОценок пока нет

- U-Blox Parameters Setting ProtocolsДокумент2 страницыU-Blox Parameters Setting Protocolspedrito perezОценок пока нет

- Successfully Allocating Risk and Negotiating A PPP ContractДокумент12 страницSuccessfully Allocating Risk and Negotiating A PPP ContractWilliam Tong100% (1)

- CPE615 Tutorial 1Документ3 страницыCPE615 Tutorial 1Alif Aikal Che HatОценок пока нет

- CPE615 Tutorial 1Документ3 страницыCPE615 Tutorial 1Alif Aikal Che HatОценок пока нет

- Trelleborg Fender CatalogueДокумент34 страницыTrelleborg Fender CatalogueIgnatius SamrajОценок пока нет

- BSNL Project MBA NitishДокумент92 страницыBSNL Project MBA NitishAnkitSingh0% (2)

- OSN 8800 6800 3800 V100R011C00 Alarms and Performance Events Reference 01Документ1 544 страницыOSN 8800 6800 3800 V100R011C00 Alarms and Performance Events Reference 01Oscar Behrens ZepedaОценок пока нет

- Instructions!!Документ1 страницаInstructions!!Alif Aikal Che HatОценок пока нет

- MSL Foundry Bollard CatalogueДокумент6 страницMSL Foundry Bollard CatalogueAlif Aikal Che HatОценок пока нет

- Catalogue Fenders ParameterДокумент28 страницCatalogue Fenders ParameterAlif Aikal Che HatОценок пока нет

- Kaspersky Key and InstructionДокумент4 страницыKaspersky Key and InstructionAlif Aikal Che HatОценок пока нет

- Fender Design GuideДокумент4 страницыFender Design GuideAlif Aikal Che HatОценок пока нет

- Customer: Bme Logistic SDN BHD PROJECT: STUV 250H X 1100L: Work ScheduleДокумент1 страницаCustomer: Bme Logistic SDN BHD PROJECT: STUV 250H X 1100L: Work ScheduleAlif Aikal Che HatОценок пока нет

- Chain AnalysisДокумент4 страницыChain AnalysisAlif Aikal Che HatОценок пока нет

- Weak Acid Base NotesДокумент49 страницWeak Acid Base NotesJankel L PahuyoОценок пока нет

- Confidential CS/APR 2008/MAT405/483 2: 0 X 2 For) X 2 (X) X (FДокумент3 страницыConfidential CS/APR 2008/MAT405/483 2: 0 X 2 For) X 2 (X) X (FAlif Aikal Che HatОценок пока нет

- DR Strange CoG Article Part 2Документ23 страницыDR Strange CoG Article Part 2Amar_IbsОценок пока нет

- RP1 Briefing - Student 2Документ25 страницRP1 Briefing - Student 2Alif Aikal Che HatОценок пока нет

- Lab RPRT (CSTR)Документ21 страницаLab RPRT (CSTR)Black White80% (5)

- Lab Pendulum 2Документ15 страницLab Pendulum 2Alif Aikal Che Hat100% (5)

- Result Shell N Tube ExchangerДокумент10 страницResult Shell N Tube ExchangerAlif Aikal Che HatОценок пока нет

- Che571 Che584 Che594Документ7 страницChe571 Che584 Che594Alif Aikal Che HatОценок пока нет

- Drying of Processes MaterialsДокумент25 страницDrying of Processes MaterialsAlif Aikal Che HatОценок пока нет

- Male Are More in TechnicalДокумент2 страницыMale Are More in TechnicalAlif Aikal Che HatОценок пока нет

- Chap 1Документ2 страницыChap 1Alif Aikal Che HatОценок пока нет

- Assignment ElectricДокумент2 страницыAssignment ElectricAlif Aikal Che HatОценок пока нет

- StatusДокумент1 страницаStatusAlif Aikal Che HatОценок пока нет

- New Text DocumentДокумент1 страницаNew Text DocumentAlif Aikal Che HatОценок пока нет

- Geometric Entities: Basic Gear TerminologyДокумент5 страницGeometric Entities: Basic Gear TerminologyMatija RepincОценок пока нет

- Comprehensive Case 2 - QuestionДокумент7 страницComprehensive Case 2 - QuestionPraveen RoshenОценок пока нет

- Memorandum of AgreementДокумент6 страницMemorandum of AgreementJomar JaymeОценок пока нет

- Chapter 01Документ26 страницChapter 01zwright172Оценок пока нет

- Analytical Profiles Drug Substances and Excipien T S: Harry G. BrittainДокумент693 страницыAnalytical Profiles Drug Substances and Excipien T S: Harry G. BrittainNguyen TriОценок пока нет

- Human Resource Management - Introduction - A Revision Article - A Knol by Narayana RaoДокумент7 страницHuman Resource Management - Introduction - A Revision Article - A Knol by Narayana RaoHimanshu ShuklaОценок пока нет

- D.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Документ5 страницD.E.I Technical College, Dayalbagh Agra 5 III Semester Electrical Engg. Electrical Circuits and Measurements Question Bank Unit 1Pritam Kumar Singh100% (1)

- LIC Form - Intimation of Death Retirement Leaving ServiceДокумент1 страницаLIC Form - Intimation of Death Retirement Leaving ServicekaustubhОценок пока нет

- 1 General: Fig. 1.1 Industrial RobotДокумент40 страниц1 General: Fig. 1.1 Industrial RobotArunОценок пока нет

- BW-Africa 2023 BrochureДокумент12 страницBW-Africa 2023 BrochureDanial DarimiОценок пока нет

- Ababio v. R (1972) 1 GLR 347Документ4 страницыAbabio v. R (1972) 1 GLR 347Esinam Adukpo100% (2)

- Water Cooled Centrifugal Chiller (150-3000RT)Документ49 страницWater Cooled Centrifugal Chiller (150-3000RT)remigius yudhiОценок пока нет

- Good Practice On The Project "Improve The Food Security of Farming Families Affected by Volatile Food Prices" (Nutrition Component) in CambodiaДокумент2 страницыGood Practice On The Project "Improve The Food Security of Farming Families Affected by Volatile Food Prices" (Nutrition Component) in CambodiaADBGADОценок пока нет

- Zone Controller: Th-LargeДокумент1 страницаZone Controller: Th-LargeIsmat AraОценок пока нет

- Business Works Student User GuideДокумент14 страницBusiness Works Student User GuideAkram UddinОценок пока нет

- COST v. MMWD Complaint 8.20.19Документ64 страницыCOST v. MMWD Complaint 8.20.19Will HoustonОценок пока нет

- Hyster Forklift Class 5 Internal Combustion Engine Trucks g019 h13xm h12xm 12ec Service ManualsДокумент23 страницыHyster Forklift Class 5 Internal Combustion Engine Trucks g019 h13xm h12xm 12ec Service Manualsedwinodom070882sad100% (71)

- Google-Analytics 01Документ28 страницGoogle-Analytics 01Smm Store24Оценок пока нет

- SecureCore Datasheet V2Документ2 страницыSecureCore Datasheet V2chepogaviriaf83Оценок пока нет