Академический Документы

Профессиональный Документы

Культура Документы

Catalog Gear Couplings

Загружено:

Dev MisraИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Catalog Gear Couplings

Загружено:

Dev MisraАвторское право:

Доступные форматы

Fenner Gear Couplings

MISALIGNMENT :

The crowning of the teeth allows the coupling to withstand

parallel misalignment upto a maximum of 10.25 mm and

O

angular misalignment upto a maximum of 1.5 per gear

mesh. The coupling can also absorb axial displacement of

the shafts upto a maximum of 3 mm.

SELECTION OF THE COUPLINGS:

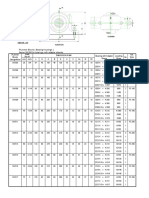

Gear Couplings

The following details are required for selection of the

coupling :

1. Type of driven machine.

2. Power absorbed by the driven machine and Peak load.

3. Speed and Diameter of the connecting shafts and

space available for accommodating the coupling.

4. Maximum misalignment to be compensated.

5. Surrounding temperature.

6. Any other special feature of the drive.

Angular

Parallel

MISALIGNMENTS

Example : A gear couplings is required to transmit 250 KW

from an Electric Motor running at 730 rev/min to a Pulper

Machine. Considering the peak load as 180% of full load,

the Motor shaft as 100 mm and the Pulper shaft as 110

mm, select a suitable gear coupling.

a)

b)

c)

d)

Service factor : 2 (for heavy duty application)

Peak load

: 180% of full load.

Design power : 250 x 180/100 x 2 = 900 KW

Power to be transmitted at 100 rev/min :

900 x 100 / 730 = 123.3 KW

e) Coupling size : By referring to the Table, coupling

size FGC 5, has got a rating of 150 KW at 100 rev/min

which exceeds the required power of 123.3KW. The

bore range is 60 mm to 110 mm. Hence, size FGC 5 is

selected for the application.

Custom built Gear Spacer Couplings and Torsion Shaft Gear Couplings are

also manufactured & supplied as per requirements. Please contact Fenner

with all details.

Corporate Office :

Khivraj Complex II, V Floor, 480, Anna Salai, Nandanam,

Chennai-600 035 Tel: 24312450 to 57, Fax: 044 -24349016, 24320193.

E.mail: ptd_mhq@fennermail.com Website: www.fennerindia.com

Registered Office:

3, Madurai - Melakkal Road, Kochadai, Madurai - 625 016. Tel: 2383801, 2383802

Fax : 0452 -2383822.

Branches at : Ahmedabad : Shreeji House, 3rd Floor, Behind M.J.Library, Ellis Bridge, Ahmedabad - 386 006. Tel: 079-26578572, 26578590.

Bangalore : No.20, New Timber Yard Layout, Mysore Road, Bangalore - 560 026. Tel: 080-26756330, 26756333, Fax : 080-22225223.

Indore: 24, Sitabagh Colony, Dhenu Market, Indore - 452 001,Tel : 0731 -2538248. Fax: 0731-4043935 Jaipur : A-21, Opp. State Bank of

India, Bais Godown, Industrial Area, Jaipur-302006, Tel:0141-2211075, 93148 70878. Kanpur : 112/371 (A), Swaroop Nagar, Kanpur - 208

002, Tel : 0512-2525304, 2540915, Fax: 0512-2294071. Kochi : 266-A & B, Temple Road, Koonamthai, Changampuzha Nagar, Kalamassery,

Kochi-682033 Tel : 93492 56054. Kolkata : 56-D, Mirza Ghalib Street, Kolkata-700 016. Tel : 033-22297880, 22298791, 22298792, Fax :

033 -22290701, 22297880. Ludhiana : B-XVII/ 2820/48, Opp to Adam Park, Jammu Colony, Link Road, Ludhiana -141 003. Tel : 01612410214, Telefax:0161-2443791. Madurai : 117/6E, Madurai - Usilampatti Road, Meenakshipuram, Madurai-625 016. Tel : 0452-2383920,

Telefax : 0452-2383921. Mumbai : 19/21, Manohardas Street, P.B. No.1307, Opp. G.P.O., Fort, Mumbai-400 001. Tel : 022-22695040,

22696329, 22697041, Fax : 022-22695199. New Delhi : 7th Floor, 'Hansalaya', 15, Barakhamba Road, New Delhi -110 001. Tel : 01123314053, 23317016, 23314428, Fax : 011-23314429. Secunderabad : No.156/8, Plot No.147, A. P. Text Book Colony, Transport Road,

Secunderabad -500 015 Tel : 040-27845443, 27845444.

All rights reserved by Fenner (India) Limited. No portion of the Catalogue can be reproduced in any form without authorisation of the copyright owner.

11/09/2007

Fenner (India) Limited

Dependable Power Transmission Accessories

Fenner Gear Couplings

Fenner Curved Tooth Flexible Gear Couplings

are the result of many years of experience in the field of

Mechanical Power Transmission.

These Gear Couplings are distinguished by their mechanical

flexibility and compensation of Angular, Parallel and Axial

misalignments of the connected shafts. They are made for

extensive use in Metal Rolling Mills, Paper Machinery, Cranes,

Dredgers, Rubber and Plastic Industries, Cement Plants,

Conveyors and Elevators, Compressors, Fans and Blowers,

Screens and other general industries.

Flexible Gear Couplings basically consist of two hubs, with

crowned external teeth and two outer sleeves with internal

spur teeth.

Fenner Gear Couplings

LUBRICATION :

The coupling must be filled with grease or oil. It is recommended

to use grease where the maximum temperature is within 80OC

and for temperature above 80OC, oil should be used. When

using grease it is suggested to fill the coupling completely with

Lithium based grease with EP additives (NLGI-No.1

consistency). When the coupling is to be filled with oil, fill half the

coupling with EP Gear Oil.

SLEEVES :

The internal teeth of the sleeves are generated to ensure correct

profile. The coupling sleeves are joined together with high

tensile steel bolts (class 8.8 IS : 1367) fitted using a gasket in

between them.

'O' RINGS :

The setting of special 'O' Rings at the ends of coupling hubs

prevents leakage of lubricants and entry of dust. The 'O' rings

can also withstand high degree of temperature upto 120O C

Minimum Clearance required for aligning

POWER RATINGS :

The normal power ratings are given in the Table. For selection of

the correct size of couplings, proper service factor depending on

the type of machines and the peak load should be considered.

HUBS :

The teeth of Gear Hubs are crowned and are generated by

involute system. The amount of crowning and backlash values

are so chosen as to ensure the best results in torque

transmission, greater flexibility and smooth operations.

SERVICE FACTOR :

Generally, for medium duty use a service factor of 1.5. For

heavy duty use a factor of 2 and for extra heavy duty a factor of 3

should be used. For special applications please contact

Fenner with full details.

Hub Bore (mm)

Rigid

Flex

Min.

Max

Max

Minimum Clearance required for aligning

Gasket

Sleeve

G1

A

F

'O' Ring

Rigid Half

Flex. Half

D D

D D

D D

Maximum

Speed

G1

E

G

Fitted

Bolts

Dimensions (mm)

A

HALF FLEXIBLE COUPLINGS

Power at Maximum

100 rpm

Torque

in Kw

in Nm

: Indian Oil - Servomesh

SP 680 or equivalant.

Hub

Gear Hubs and the outer sleeves are manufactured from

carbon steel and are hardened to the required degree. They are

machined to fine tolerances for proper meshing of the gears as

well as for inter-changeability.

Coupling

No /

Size

Oil

Minimum Clearance required for aligning

SEAL CARRIERS :

Seal carriers have been provided for sizes from FGC 11 to FGC

19 facilitate inspection and replacement of 'O' rings without

disturbing the alignment.

RECOMMENDATION FOR GREASE & OIL:

Grease : Indian Oil - Servogem

EP 1 or equivalent.

RPM

Approx. Weight

in Kg.

Full Flex

Half Flex

COUPLINGS SIZES 1 To 10

Approx. Gd2 Value

2

in Kg M

Full Flex

Half Flex

Clamping

Bolt

Size

No.

Of

Bolts

COUPLINGS SIZES 11 To 19

Max. Misalignment Capacity

Amount of

Grease / Oil

Parallel

(mm)

Kg.

Ltr.

Axial Float Angular per

(mm)

Gear Mesh

FGC 1

11.5

1100

14

55

60

170

115

17

55

78

90

110

65

6700

11

10.5

0.14

0.11

M12 X 50

0.80

0.25

0.20

FGC 2

28.5

2720

20

60

75

185

145

17

70

85

110

125

85

6100

16

15

0.21

0.18

M12 X 50

0.95

0.50

0.40

FGC 3

51.5

4920

30

75

90

220

175

20

85

107

130

150

105

5200

26

26

0.45

0.44

M16 X 60

1.10

0.80

0.60

FGC 4

96.5

9220

40

100

110

250

215

20

105

138

160

178

125

4500

41

42

0.98

0.88

M16 X 60

1.30

1.00

0.80

FGC 5

150

14320

46

120

130

290

240

25

115

10

166

185

204

140

3950

63

63

1.90

1.90

M20 X 75

1.45

1.80

1.50

FGC 6

230

21960

50

125

150

320

260

25

125

10

176

215

230

155

3500

86

87

3.05

3.06

M20 X 75

1.55

2.40

2.00

FGC 7

390

37250

60

145

170

350

290

25

140

10

208

240

260

175

3250

120

120

5.25

5.20

M20 X 75

10

1.80

3.50

3.00

FGC 8

515

49180

70

165

200

380

330

25

160

10

230

285

290

200

3000

165

170

8.52

8.63

M20 X 75

12

1.90

4.00

4.00

FGC 9

644

61500

80

200

220

430

340

25

165

10

270

315

332

210

2600

210

220

15.00

15.00

M24 X 80

10

2.25

5.50

5.00

FGC 10

930

88800

100

230

260

490

370

25

180

10

315

370

390

230

2300

310

320

28.67

29.00

M24 X 80

12

2.60

8.50

8.00

FGC 11

1265

120800

110

260

280

545

410

30

200

10

350

380

445

270

2100

454

430

52.00

46.18

M24 X 90

12

3.30

12.50

12.00

FGC 12

1600

152800

150

300

310

590

490

30

240

10

404

420

490

300

1900

630

590

88.60

76.57

M24 X 90

14

3.50

14.00

16.00

FGC 13

2880

275000

160

330

340

680

535

35

260

15

442

480

555

320

1550

887

850

155.00

140.00

M30X110

14

6.65

16.00

20.00

FGC 13A

3980

380000

200

340

370

730

575

35

275

25

470

520

595

350

1400

1050

1050

215.00

203.00

M30X110

16

7.35

18.00

24.00

FGC 14

3980

380000

200

370

370

730

575

35

280

15

500

520

610

340

1400

1097

1050

230.00

203.00

M30X110

16

7.35

18.00

24.00

FGC 14A

4765

455000

230

360

400

780

635

35

305

25

510

560

640

375

1350

1310

1350

300.00

305.00

M30X110

18

8.15

25.00

33.00

FGC 15

4765

455000

230

410

400

780

655

40

320

15

540

560

660

385

1350

1440

1350

352.00

305.00

M30X110

18

8.15

25.00

33.00

25

40.00

49.00

55.00

64.00

0.5

1.0

2.0

1.5O

FGC 16

6800

650000

260

450

460

900

720

40

350

630

650

750

425

1150

2120

2000

670.00

611.20

M36X120

18

8.55

FGC 16A

8375

800000

300

490

530

1000

815

40

395

25

700

750

855

470

1050

3057

2900

1210.00

1132.00

M36X120

20

9.15

FGC 17

9000

850000

300

520

530

1000

820

40

400

20

720

750

855

490

1050

3100

2900

1275.00

1132.00

M36X120

20

9.15

55.00

64.00

FGC 17A

10730

1025000

320

540

580

1100

920

40

440

40

750

820

955

525

950

4196

4050

2030.00

1913.00

M36X120

20

9.65

60.00

72.00

FGC 18

11800

1120000

320

620

580

1100

920

55

450

20

820

820

950

535

950

4370

4050

2198.00

1913.00

M36X150

20

9.65

60.00

72.00

FGC 18A

12700

1200000

400

600

700

1250

1000

55

475

50

840

920

1050

560

825

5430

5200

3410.00

3179.00

M48X160

20

10.25

70.00

80.00

FGC 19

15500

1470000

400

710

700

1250

1000

55

485

30

915

920

1050

560

825

5590

5200

3588.00

3179.00

M48X160

20

10.25

70.00

80.00

All dimensions are subject to alteration without notice.

3.0

Вам также может понравиться

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyОт EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyРейтинг: 5 из 5 звезд5/5 (1)

- House Designs, QHC, 1959Документ64 страницыHouse Designs, QHC, 1959House Histories92% (13)

- Design CalculationДокумент26 страницDesign Calculationtawas20100% (1)

- D&H Sécheron Electrodes Private Limited: Approximate Comparison WithДокумент5 страницD&H Sécheron Electrodes Private Limited: Approximate Comparison WithmahaveenОценок пока нет

- Pre Concreting ChecklistДокумент1 страницаPre Concreting ChecklistFahmi ZahariОценок пока нет

- ELECON GEAR Elign CouplingДокумент14 страницELECON GEAR Elign Couplingsatish kumar reddy100% (1)

- Flender Manual GeneralДокумент42 страницыFlender Manual GeneralYenny LaraОценок пока нет

- Medellin Apartments DescriptionsДокумент16 страницMedellin Apartments DescriptionsMedellinApartmentsОценок пока нет

- Elecon ET Catalogue PDFДокумент42 страницыElecon ET Catalogue PDFVisnu Sankar86% (7)

- Commonwealth Stadium PlansДокумент62 страницыCommonwealth Stadium Plansnob_pdfsОценок пока нет

- Chain Breaking Load CalculationДокумент1 страницаChain Breaking Load CalculationDebkumar958Оценок пока нет

- Perhitungan Gearbox Part-1 PDFДокумент32 страницыPerhitungan Gearbox Part-1 PDFHermawan SuwantoОценок пока нет

- SKF NameДокумент26 страницSKF NameIslam Fawzy100% (1)

- Elecon Gear CouplingДокумент7 страницElecon Gear CouplingVipul Chaudhari100% (4)

- Elecon GearboxДокумент19 страницElecon GearboxShirley Farrace100% (3)

- Fenaflex Tyre CouplingsДокумент12 страницFenaflex Tyre CouplingsGUZMANОценок пока нет

- Elecon Gear Box CatalogueДокумент15 страницElecon Gear Box CatalogueKARTHIGEYAN.R79% (14)

- KilnДокумент17 страницKilnprashant mishraОценок пока нет

- Masta Bearing Housing CatalogДокумент89 страницMasta Bearing Housing Catalogpranav manjunath100% (1)

- Premium All Products 2019 PricelistДокумент35 страницPremium All Products 2019 PricelistShyam J VyasОценок пока нет

- Example 1 For Gearbox SelectionДокумент11 страницExample 1 For Gearbox SelectionNakkolop100% (1)

- Safety in Working at HeightДокумент106 страницSafety in Working at HeightVaibhav Vithoba Naik100% (12)

- Apron Feeder Spare Part ListДокумент17 страницApron Feeder Spare Part ListParmeshwar Nath TripathiОценок пока нет

- Barrel Reclaimers TRFДокумент4 страницыBarrel Reclaimers TRFkaustavОценок пока нет

- CM-3.01INP0316 - SERIES M GEARED MOTORS AND REDUCERS GUIDEДокумент121 страницаCM-3.01INP0316 - SERIES M GEARED MOTORS AND REDUCERS GUIDEshivanandr2481100% (6)

- Premium Transmission Gear BoxДокумент80 страницPremium Transmission Gear BoxShipra Shalini83% (6)

- CE-marked industrial doorsДокумент7 страницCE-marked industrial doorskhaireddinОценок пока нет

- B.ARCH Abcm Question Paper PDFДокумент33 страницыB.ARCH Abcm Question Paper PDFshreenu211204Оценок пока нет

- Geared MotorДокумент96 страницGeared MotorSaurabh jain50% (2)

- Belt Pulley Is.3142.1993 PDFДокумент14 страницBelt Pulley Is.3142.1993 PDFchidambaram kasiОценок пока нет

- Horizontal Shaft Impact CrusherДокумент6 страницHorizontal Shaft Impact CrusherPuzzolana Foundation For ExcellanceОценок пока нет

- Naga House Construction SpecificationsДокумент6 страницNaga House Construction SpecificationsJason HallОценок пока нет

- Hopper Volume Calculation PDFДокумент1 страницаHopper Volume Calculation PDFAnonymous 5XvUbWynn50% (2)

- Aditya Tech Diary PDFДокумент155 страницAditya Tech Diary PDFSiddhant SatpathyОценок пока нет

- Mill Liner Bolt Torque SpecificationsДокумент1 страницаMill Liner Bolt Torque SpecificationsAugusto TorresОценок пока нет

- Module 1 Residential Site Planning (Arcstudio Reference)Документ56 страницModule 1 Residential Site Planning (Arcstudio Reference)CliffordJamesSabiganОценок пока нет

- Gear BoxДокумент6 страницGear Boxprashant mishra100% (1)

- Is 2708 - Manganize Steel CastingДокумент6 страницIs 2708 - Manganize Steel CastingJanak MistryОценок пока нет

- Mat 3810 For Suppliers PDFДокумент3 страницыMat 3810 For Suppliers PDFbaskaran ayyapparajОценок пока нет

- Mat 5850 For Suppliers PDFДокумент3 страницыMat 5850 For Suppliers PDFgraduateОценок пока нет

- Chairpad ShimДокумент2 страницыChairpad Shimsarat kumar mondal100% (1)

- Elecon Gear Box O&M ManualДокумент38 страницElecon Gear Box O&M ManualSrinivasa Rao PallelaОценок пока нет

- Gear Coupling FGCДокумент4 страницыGear Coupling FGCMandar PundeОценок пока нет

- MAAG GEAR - Techinal and Commercial Considerations Related To The Cement Mill ProductionДокумент43 страницыMAAG GEAR - Techinal and Commercial Considerations Related To The Cement Mill Productionrecai100% (1)

- Centrifugally Cast Inserted Grinding Rollers SpecificationДокумент6 страницCentrifugally Cast Inserted Grinding Rollers Specificationsiva100% (1)

- Conveyor Idlers PDFДокумент10 страницConveyor Idlers PDFDhirendraRaviОценок пока нет

- Indian Habitat CentreДокумент20 страницIndian Habitat CentrePrakriti GoelОценок пока нет

- Elecon KCN Gear BoxДокумент43 страницыElecon KCN Gear BoxGourav Choudhuri100% (12)

- Lindal Living Dreams SampleДокумент23 страницыLindal Living Dreams SampleAdriana Zamora100% (1)

- Dependable Power Transmission Gear CouplingsДокумент4 страницыDependable Power Transmission Gear CouplingsananthdevaОценок пока нет

- Gear Coupling 2014Документ4 страницыGear Coupling 2014Dado Maja ArseninОценок пока нет

- SKF Spherical Roller Bearing ClearanceДокумент2 страницыSKF Spherical Roller Bearing ClearanceKumaran GopalОценок пока нет

- Type SDFC Sizes 290 To 1040 - EngДокумент2 страницыType SDFC Sizes 290 To 1040 - EngKUNALJAYОценок пока нет

- Usha Company Profile Product & CatloguesДокумент29 страницUsha Company Profile Product & Catloguesvipul bhatt100% (1)

- Iom DSM100-36Документ27 страницIom DSM100-36rogueatdoorОценок пока нет

- Is 3815Документ15 страницIs 3815mishra_198250% (2)

- Masta Pillow Blocks PDFДокумент26 страницMasta Pillow Blocks PDFAnonymous W3Kdy4pr100% (1)

- L&T O&M ManualДокумент156 страницL&T O&M Manualranajoy71971Оценок пока нет

- J J Plum Block-PlДокумент6 страницJ J Plum Block-Plmanoj_doshi_1Оценок пока нет

- Indian Standard 276Документ9 страницIndian Standard 276sdmelОценок пока нет

- Wet Scrapper Equipment SpecificationДокумент1 страницаWet Scrapper Equipment Specificationprashant mishraОценок пока нет

- Is 8598Документ8 страницIs 8598rajeevkumarrajeevОценок пока нет

- Coal InjectorsДокумент2 страницыCoal Injectorsprashant mishraОценок пока нет

- Jingjin Filter Press Operation ManualДокумент57 страницJingjin Filter Press Operation ManualRobin PОценок пока нет

- Centralised lubrication system guideДокумент32 страницыCentralised lubrication system guideShivakumar PattarОценок пока нет

- Gear CouplingsДокумент2 страницыGear Couplingsersanjeeb_456Оценок пока нет

- Tyre Coupling CatalogДокумент9 страницTyre Coupling CatalogKariem R NoweerОценок пока нет

- Geared Motor Catalogue-2018-19Документ20 страницGeared Motor Catalogue-2018-19velhankar.pushОценок пока нет

- Gorman Star Winding Machine Operator'S ManualДокумент32 страницыGorman Star Winding Machine Operator'S Manualshafqat ullahОценок пока нет

- Cable Reeling DrumДокумент4 страницыCable Reeling DrumBanamali NaskarОценок пока нет

- Alwasy Step Ahead in TechnologyДокумент4 страницыAlwasy Step Ahead in TechnologyDxFxОценок пока нет

- GEARED MOTOR GUIDEДокумент7 страницGEARED MOTOR GUIDEJaynil GunarkarОценок пока нет

- BUPRG - Emergency Sinter StorageДокумент4 страницыBUPRG - Emergency Sinter StorageDev MisraОценок пока нет

- Pulley Shaft SelectionДокумент6 страницPulley Shaft SelectionDev MisraОценок пока нет

- Working Point of ConveyorДокумент3 страницыWorking Point of ConveyorDev MisraОценок пока нет

- Debabrata Mishra: Ticketadmin@irctc - Co.inДокумент3 страницыDebabrata Mishra: Ticketadmin@irctc - Co.inDev MisraОценок пока нет

- Kobelco Pelletizing ProcessДокумент11 страницKobelco Pelletizing ProcessP.S.J.SarmaОценок пока нет

- Development of Pellet-Sinter Composite Agglomerate For Blast FurnaceДокумент8 страницDevelopment of Pellet-Sinter Composite Agglomerate For Blast FurnaceDev MisraОценок пока нет

- Ib Valley Jharsuguda 22-10-16Документ108 страницIb Valley Jharsuguda 22-10-16Dev MisraОценок пока нет

- Pressure Drop CalculationДокумент11 страницPressure Drop CalculationDev MisraОценок пока нет

- Take Care in TBAДокумент1 страницаTake Care in TBADev MisraОценок пока нет

- Care With Drinking BottlesДокумент6 страницCare With Drinking BottlesDev MisraОценок пока нет

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Документ1 страницаIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Dev MisraОценок пока нет

- WWW - Irctc.co - in Cgi-Bin bv60.dll Irctc Services Printticket - JSP BV SessionID @@@@1607339675.1319120485@@@@&BV EngineIDДокумент2 страницыWWW - Irctc.co - in Cgi-Bin bv60.dll Irctc Services Printticket - JSP BV SessionID @@@@1607339675.1319120485@@@@&BV EngineIDshri2512Оценок пока нет

- Living conditions of Roman inhabitants in OstiaДокумент3 страницыLiving conditions of Roman inhabitants in OstiaGayatri GogoiОценок пока нет

- ELC120 - Grammar Task 1Документ1 страницаELC120 - Grammar Task 1Khairunnisa Abd WahabОценок пока нет

- Tributary Load and Load PathДокумент14 страницTributary Load and Load PathPandal RajОценок пока нет

- mh50-20 MOTOMANДокумент78 страницmh50-20 MOTOMANLiferi ConstantinОценок пока нет

- The extent of Black TownДокумент63 страницыThe extent of Black TownPrarthana roy RОценок пока нет

- CWC Engineering Specifications 211011Документ6 страницCWC Engineering Specifications 211011Parthasarathy KMОценок пока нет

- Focus2 2E Grammar Quiz Unit4 2 GroupBДокумент1 страницаFocus2 2E Grammar Quiz Unit4 2 GroupBsashabatiuk2010Оценок пока нет

- 970 Taken by Surprise 0tДокумент10 страниц970 Taken by Surprise 0ttwinkle00033% (6)

- Generator Power Application Guide: Blue Star 145/185 Bobcat 225Документ16 страницGenerator Power Application Guide: Blue Star 145/185 Bobcat 225Younus BakshiОценок пока нет

- 8 Petaling (Zone K)Документ24 страницы8 Petaling (Zone K)danielwwcheong8981Оценок пока нет

- Excavation and concrete framingДокумент18 страницExcavation and concrete framingRubbyRdОценок пока нет

- Le Corbusier's Domino Housing SystemДокумент5 страницLe Corbusier's Domino Housing SystemNasha BahasoeanОценок пока нет

- Calculate Earthquake Forces On Buildings and StructuresДокумент4 страницыCalculate Earthquake Forces On Buildings and Structurespallavi guptaОценок пока нет

- The Vault of DestiniesДокумент17 страницThe Vault of Destiniesdloaizav1Оценок пока нет

- MaterialsДокумент47 страницMaterialsjjОценок пока нет

- FR430Документ18 страницFR430dreamyson1983Оценок пока нет

- Sample-Problems For Flexure, Shear and Floor FramingДокумент24 страницыSample-Problems For Flexure, Shear and Floor FramingMaan Valencia - RevillaОценок пока нет

- Hengshui Jingtong Engineering Rubber Co., Ltd.Документ9 страницHengshui Jingtong Engineering Rubber Co., Ltd.jixie898Оценок пока нет