Академический Документы

Профессиональный Документы

Культура Документы

1581 GB 03

Загружено:

hasan2525Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1581 GB 03

Загружено:

hasan2525Авторское право:

Доступные форматы

Autogenous mills, semi-autogenous mills and ball mills for wet grinding.

A company of ThyssenKrupp Technologies

Polysius

tk

High-performance systems for wet grinding applications.

The comprehensive range of wet grinding systems from Polysius comprises of:

x x x x

Ball mill in iron ore benefication plant.

Autogenous and semiautogenous mills, Ball mills, Rod mills and Scrubbers.

Polysius offers dry grinding systems comprising of the following equipment:

x AEROFALL type dry SAG mills, x Dry grinding ball mills, x Air separators, x Dryers, x POLYCOM high-pressure grinding rolls.

Ball mill with COMBIFLEX drive for lead zinc ore grinding.

High-pressure grinding rolls can be supplied to work in dry grinding as well as in wet grinding plants. They can be used for green field plants as well as for plant upgrades. Plant supply Our organisation is designed to handle system supply on a turnkey basis. We can draw upon professionals in offices all around the world to provide process engineering design & layout, contract management, inspection, shipping, expediting, purchasing, equipment erection, start up, training and customer service. Simulation of grinding circuits The capability to design entire grinding circuits with aid of state-ofthe-art simulation tools allows Polysius to design and build complete grinding lines to meet the high standards demanded by our clients in the minerals and cement industries. The in-house expertise allows Polysius to provide application-specific solutions for economical, reliable and energy efficient grinding of ores, cement clinker, coal and other materials. Polysius has been successfully designing and building grinding plants since 1880. The resulting global know how of process and plant technology, together with the extensive grinding test facilities in our research and development centre provide the basis for an optimum design. Grinding plants from Polysius have a long track record in wet grinding applications. They are operating in open or closed circuit mode. Polysius grinding mills can be of the overflow type or of grate discharge design. In 1976 Polysius adopted the design of shell-supported grinding mills using slide shoe bearings. Since this time, the design has been perfected based on the experience of more than 180 units operating all over the world in various industries. Today Polysius grinding mills are exclusively built as shell-supported units.

Ring motor driven SAG mill for gold ore grinding.

SAG and ball mills for comminuting gold / copper ore.

Site assembly of a large mill shell.

SAG and ball mill for gold ore grinding.

One of three SAG mills with 9.75 m diameter and 2 x 4000 kW drive power. These mills operate in conjunction with ball mills for iron ore grinding in Iran.

The design offers such benefits as:

x Elimination of castings and the structural risk associated with

Polysius standard range of grinding mills Polysius has established a standard for grinding mills, which covers the requirements for a variety of applications in the minerals industry. The grinding mills can be equipped with ring gear pinion drives as well as with the COMBIFLEX drive. The standardisation allows for short delivery times and minimisation of spare part inventory. If required, ring motor drives can be fitted to shellsupported grinding mills up to the largest sizes.

them. x Feed and discharge designed to process requirements rather than to restrictions imposed by trunnion bearings. x Minimised risk of feed blockage through short trunnions. x Quick accessibility to mill interior. x Lighter weight and lower number of flanges for ease of transport and erection. x Lower space requirement for less foundation and civil cost. x Ideal for ring motor drives. Polysius grinding mills can be driven via ring gear pinion drives or the COMBIFLEX drive for drive capacities of up to 16,000 kW. Higher drive power is reliably transmitted via ring motor drives.

SAG / ball mill circuit incorporating pebble crushers and a POLYCOM high-pressure grinding roll.

Reagent preparation systems for FGD from limestone handling through to grinding.

Ball mill for grinding limestone for a flue gas desulphurisation system in a Korean power station.

Polysius brings the benefits of its vast experience in limestone processing to provide an optimised total solution for FGD reagent preparation systems. The project scope can vary from the supply of a ball mill to the installation of a comprehensive system for limestone grinding or lime slaking. We have the capabilities and expertise to take and expand the scope of a system to include all the limestone / lime handling, storage and product storage complete with automation. The system can be ordered as equipment supply or turn-key to best tailor the solution to your needs.

Limestone storage.

Ball mill for grinding limestone for flue gas desulphurisation systems in power stations.

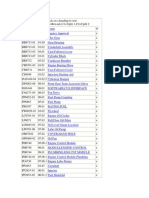

Di [m] 1.6 1.8 2.0 2.2 2.4 2.6 2.8 3.0 3.2 3.4 3.6 3.8

EGL [m] 2.4 3.2 2.7 3.6 3.0 4.0 3.3 4.4 3.6 4.8 3.9 5.2 4.2 5.6 4.5 6.0 4.8 6.4 5.1 6.8 5.4 7.2 5.7 7.6

P* [kW] 50 70

... small diameter ball mills.

60 100 90 120 150 250 175 300 250 350 350 550 400 650 500 750 700 1000 800 1200 950 1350

*Motor power at 35 % ball charge

The standard range of...

...autogenous and semi-autogenous mills.

Di [m] 8.0 8.6 9.2 9.8 10.4 11.0 11.6 12.2 12.8 13.4

EGL [m] 3.9 4.2 4.5 4.8 5.1 5.4 5.7 6.0 6.4 6.8

P [kW] 3800 5000 6400 8400 9900 12100 14700 17600 21300 25400

Di [m] 4.3 4.6 4.9 5.2 5.5 5.8 6.1 6.4 6.7 7.0 7.3

EGL [m] 6.1 7.6 6.4 8.0 6.7 8.6 7.3 8.9 7.6 9.5 8.0 10.1 8.3 10.4 8.9 11.0 9.2 11.6 9.5 12.2 10.1 12.5

P* [kW] 1600 2100 2000 2600 2500 3300 3200 3900 3800 4800 4600 5900 5500 6900 6700 8300 7700 9900 9000 11600 10000 13300

... medium size and big ball mills.

*Motor power at 35 % ball charge

Mill drive systems.

Shell-supported grinding mills supplied by Polysius offer the flexibility for equipping with all drive systems available on todays market. The motor torque can be transmitted to the mill shell via a ring gear or a ring motor. The ring gear meshes either with a pinion in the case of a conventional drive or with the COMBIFLEX reducer. Self-aligning pinion A self-aligning pinion can be applied if the ring gear is a spur type. Such drives then need no realignment of the ring gear and pinion mesh after the installation of the components. These casehardened and precision ground-pinions can be either grease or oil lubricated.

tored by infrared devices. The pinion can be driven either via a reducer or a low speed motor. COMBIFLEX drive The COMBIFLEX drive unit combines the advantages of a ring motor drive, such as minimal maintenance requirement and high availability, with the advantages of a normal girth gear and pinion drive system, such as reasonable capital cost. The gearing with drive pinions, the girth gear and the sliding shoe bearing with slide ring and axial guide are integrated into a single unit enclosed in a common housing. Each COMBIFLEX unit is equipped with its own auxiliary drive. High reliability: The selfcentring hardened and ground pinions and the simple oil lubrication system create optimum operating conditions. Minimal maintenance requirement and low operating costs: no subsequent adjustment of the drive system is necessary. A central oil supply system lubricates the girth gear and pinion, substantially reducing the amount of oil used and thus also cutting the disposal costs. Standardised design: Just four types cover a power range from approx. 1,200 kW to 8,000 kW. By using a dual drive system, drive powers of up to 16,000 kW can be transferred. Maximum use of identical components drastically reduces the required spare parts inventory.

Quality control: A portable gear involute measuring device allows on-the-spot manufacturing-quality control of the gear toothing

Two SAG mills with rigid pinion drives.

Ring motor drive The ring motor transmits the motor torque to the mill shell through a magnetic gap. As no wear and tear occurs, high availability and long drive service life are assured. The variable speed capability comes with the drive as an inherent feature. Due to the investment cost the ring motor drive is usually applied for drive powers above 10 MW. Shell-supported grinding mills offer special benefits to ring motor drives:

x Shell-supported grinding

SAG mill with DOUBLECOMBIFLEX drive.

Selfaligning drive pinions compensate wobbling and faulty alignment of the girth gear.

Rigid pinion drive With this type of drive, the mill shell is driven via one or two pinions which transmit the motor power to the mill shell. Ring gear and pinion are usually of the helical type. Lubrication is effected through a greasing system. The operating conditions can be moni-

mills offer a high system stability to withstand the magnetic forces developed by

Synchronous motor drive with air clutch.

COMBIFLEX drive (5,400 kW) with highspeed synchronous motor and fluid coupling.

the motor and which have to be accepted by the mill structure. x The hydraulic jack incorporated into the slide shoe support enables easy centring of motor stator and motor poles, which are attached to the mill shell. Drive motors In the case of ring gear drives, either wound rotor induction motors or synchronous motors can be used. Induction motors Wound rotor induction motors are usually equipped with starters for a controlled ramp up of mill speed with modest inrush currents. Motor speeds usually require the application of a speed reducer.

Synchronous motors Synchronous motors are usually of the low torque type in order to reduce the inrush current and the load of the mill drive train. A starting coupling is required to limit the motor torque during mill start. In the case of a high-speed synchronous motor a hydraulic coupling can be used. Low-speed low-torque motors use air clutches for a controlled mill start.

Installation of a ring motor on a SAG mill.

Ring motor drive.

Oil lubricated standardised pinion arrangement with induction motor.

Hydrodynamic slide shoe bearing for individual requirement profiles.

Slide shoe bearing Depending on the size of mill, its shell is supported at the periphery by two, four or six slide shoes. The self-aligning support of the slide shoes compensates any slide ring wobbling and eccentricity caused by mill sag, thermal distortion and manufacturing tolerances. Hydrodynamic or hydrostatic lubrication systems can be used for this type of bearing. The mill can be lifted and positioned by hydraulic jacks installed in the base of the bearing to compensate for foundation settlements and allow replacement of bearing shoes without complicated supporting of the mill shell. It is also possible to install load cells in the base of the bearing in order to determine the weight of the mill. Well-proven seals keep dirt and water out of the bearing housing and reliably prevent oil leaks. The mill shell is a welded structure without heavy and complicated end disc castings. The straight end disc design provides significant advantages: simple liner plate shape, quick replacement of the mill lining and free design

Preparation of measuring in a hydrodynamic slide shoe bearing.

of the mill inlet and outlet to suit process requirements instead of structural constraints.

Measuring compaign at hydrodynamic slide shoe bearing.

Assembly of slide shoe bearing.

Mounted slide shoe.

Pressure [bar]

Reliable detail engineering maximises plant availability.

Polysius utilises the most modern Computer Aided Engineering tools in order to design top-performance products quickly and reliably. Furthermore, the companys high quality standard is overseen and approved by an independent certification institute in accordance with ISO DIN 9000. CAD programs parameterise sub-assemblies and machines, ensuring efficient preparation of design documentation without transcription errors. Thanks to unified data transfer, geometry data can subsequently be taken directly from the plantdesign department for use in calculations. Safe and reliable dimensioning of the grinding plants supplied by Polysius is ensured by stateof-the-art hardware and software, combined with comprehensive calculation know-how. Polysius carries out:

Pressure distribution in a hydrodynamic slide shoe bearing.

Stress calculation of a SAG-mill using the Finite Element method.

Field measurements at installed plants back up the calculations. The findings also provide a database for the safe calculation of machines and the development of new components.

x stress calculations using

the Finite Element method,

x torsion and vibration

Lea ding edg e

analyses,

x heat transfer calculations, x seismic analyses and x field measurements at

installed plants.

10

Erection, commissioning and comprehensive service from a single source.

Undertaking the project engineering for a grinding plant is one thing erecting and commissioning a grinding plant is another. But customers know that for these important activities they can also totally rely on Polysius knowhow.

Erection of a ball mill with flanged mill shell.

Erection / Commissioning Our experienced specialists assemble the plant with an expertise and care that assures successful commissioning and achievement of the contractually agreed performance data, regardless of whether a flanged, site-welded or one-piece mill shell is involved. The very large number of plants that Polysius has put into operation bears witness to this success. Research and Development The basis for the final design of the plant is usually provided by extensive material testing in the Polysius Research Centre during the project-planning stage. Our Research and Development Centre with its diverse facilities is also available to customers for the performance of their own tests and analyses. Spare parts /Maintenance Maintenance and service contracts provide customers with the certainty of obtaining high plant availability and operating economy despite the tough day-to-day operating condi-

Last inspection before the commissioning.

11

tions. This naturally also includes the Polysius spare parts service, because our customer-specific database assures quick availability of the right spare parts. Plant optimisation Even in the case of older plants that have been in operation for a long time it is still important to permanently keep an eye on the operating economy and competitiveness of the production process. If necessary, it can be upgraded to a futureoriented condition by integrating the latest technical developments. For this purpose, Polysius records the current operating condition of the plant and works out an optimisation concept that is tailored to the individual requirements of the customer.

Erection of a one-piece mill shell.

Field welding of a large mill shell.

Вам также может понравиться

- FLENDER Vertical Mill DrivesДокумент16 страницFLENDER Vertical Mill DrivesGaetan Berlin100% (2)

- Sag MillingДокумент21 страницаSag MillingNaren KumarОценок пока нет

- Motor 12V140-3 PDFДокумент596 страницMotor 12V140-3 PDFRAMON CALDERON100% (2)

- OC442012e FN72-00 (F2000) SPECIFICATIONS 11-00Документ7 страницOC442012e FN72-00 (F2000) SPECIFICATIONS 11-00profistarОценок пока нет

- Suplemento Manual de Taller Yamaha YFS 200 BlasterДокумент25 страницSuplemento Manual de Taller Yamaha YFS 200 BlasterVicente Manuel Vidal ValdesОценок пока нет

- C7 ACERT 454 BHP SpecyjyДокумент4 страницыC7 ACERT 454 BHP SpecyjyAdhem El SayedОценок пока нет

- Autogenous SPДокумент16 страницAutogenous SPMichael Mateo CerveraОценок пока нет

- KHD Tube MillДокумент2 страницыKHD Tube MillKeynes de SavaОценок пока нет

- Ball Mill Machine Guide - Less than 40 CharactersДокумент2 страницыBall Mill Machine Guide - Less than 40 Characterspadma26327Оценок пока нет

- 8 Crusher Rod MillДокумент4 страницы8 Crusher Rod MillvvananthОценок пока нет

- Everything You Need to Know About Ball MillsДокумент14 страницEverything You Need to Know About Ball MillsLaxman Kumar100% (1)

- High Pressure Grinding RollsДокумент12 страницHigh Pressure Grinding RollsJorge EduardoОценок пока нет

- Gears Their Designs & Uses: Andrei Lozzi 2012Документ23 страницыGears Their Designs & Uses: Andrei Lozzi 2012atulsemiloОценок пока нет

- Wear Rate Calculator MonoДокумент2 страницыWear Rate Calculator MonoBùi Hắc HảiОценок пока нет

- Mineral Processing UG2 Concentrator Process Flow ReportДокумент41 страницаMineral Processing UG2 Concentrator Process Flow ReportPortia ShilengeОценок пока нет

- Mill Ops AusIMM Kirsch and DanielДокумент7 страницMill Ops AusIMM Kirsch and DanielMicheael JohnОценок пока нет

- Ball GrindingДокумент10 страницBall Grindingmahreza189Оценок пока нет

- Paper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit DesignДокумент13 страницPaper # 153 - The Appropriateness of The Transfer Size in Ag and Sag Mill Circuit Designcuberbill1980Оценок пока нет

- Teoria de BondДокумент8 страницTeoria de BondMarcelaChavezОценок пока нет

- Power-based comminution calculations using AusgrindДокумент13 страницPower-based comminution calculations using AusgrindMarcos Bueno100% (1)

- Simulation of A Proposed Grinding Circuit Change To Reduce PB SlimingДокумент345 страницSimulation of A Proposed Grinding Circuit Change To Reduce PB SlimingH Marquez R Graciela100% (1)

- The Application of High Chrome Grinding Media at MMG Century Mine For Improved Grinding Media Consumption and Metallurgy PerformanceДокумент15 страницThe Application of High Chrome Grinding Media at MMG Century Mine For Improved Grinding Media Consumption and Metallurgy PerformanceYaser Mohamed Abas100% (1)

- Ball Mill Bearing Design OverviewДокумент32 страницыBall Mill Bearing Design OverviewJoel Miguel Angel PachecoОценок пока нет

- GOLDEN FIRESTONE SAG MILLДокумент5 страницGOLDEN FIRESTONE SAG MILLNovei Almane GorresОценок пока нет

- Raw Material Handling and GrindingДокумент78 страницRaw Material Handling and GrindingmkpqОценок пока нет

- Design of The 40 Foot Diameter SAG Mill Installed at The Cadia Gold Copper Mine, R. DunneДокумент8 страницDesign of The 40 Foot Diameter SAG Mill Installed at The Cadia Gold Copper Mine, R. DunneNicolas MirandaОценок пока нет

- Section 3C: GrindingДокумент3 страницыSection 3C: GrindingLM100% (1)

- PeletizadoДокумент8 страницPeletizadoJavier GómezОценок пока нет

- 1 - Grinding Media Catalogue PDFДокумент14 страниц1 - Grinding Media Catalogue PDFmahreza189Оценок пока нет

- Energy efficient mineral liberation using HPGR technologyДокумент236 страницEnergy efficient mineral liberation using HPGR technologyMarcos BuenoОценок пока нет

- MAV Comminution TestsДокумент16 страницMAV Comminution TestsNilson Ariel Gálvez OlguinОценок пока нет

- 00 Introduction Polysius-HistoryДокумент17 страниц00 Introduction Polysius-HistoryEnrique BandaОценок пока нет

- Top SAG Mill ManufacturersДокумент2 страницыTop SAG Mill ManufacturersRodrigo GarcíaОценок пока нет

- Grinding Plants-Optimization and ModellingДокумент12 страницGrinding Plants-Optimization and ModellingaghilifОценок пока нет

- PallaДокумент16 страницPallaJuan Alberto Giglio FernándezОценок пока нет

- Hofmann BrochureДокумент88 страницHofmann BrochureJorge VillalobosОценок пока нет

- Kobelco Grate - Kiln ProcessДокумент11 страницKobelco Grate - Kiln ProcessJb Koffi KadjoОценок пока нет

- Cyclone Processing GuideДокумент10 страницCyclone Processing Guideboanerges wino pattyОценок пока нет

- Power-Based Comminution Calculations Using AusgrindДокумент12 страницPower-Based Comminution Calculations Using AusgrindW ZuoОценок пока нет

- Some Observations Regarding SAG MillingДокумент5 страницSome Observations Regarding SAG MillingLevent ErgunОценок пока нет

- Selection of Comminution Circuits for Improved EfficiencyДокумент19 страницSelection of Comminution Circuits for Improved EfficiencyKroya HunОценок пока нет

- Better Grinding Systems with V-Separator and VSK-SeparatorДокумент5 страницBetter Grinding Systems with V-Separator and VSK-SeparatorGerman Gabriel Anaya VegaОценок пока нет

- Collaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurДокумент4 страницыCollaboration Cuts Costs and Increases Capacity by 35%: CASE: India Cements Limited, ChilamkurjmpbarrosОценок пока нет

- Ball MillДокумент8 страницBall MillHumbulaniОценок пока нет

- Pulse-Jet Parts ListДокумент5 страницPulse-Jet Parts ListIngeniero mecanico F.N.I.Оценок пока нет

- Grinding The Primary ConditionerДокумент18 страницGrinding The Primary ConditionerAkshay Pookat RammohanОценок пока нет

- Grinding MediaДокумент4 страницыGrinding Mediasempatik721Оценок пока нет

- The Rhodax® Process For Dry Mix Preparation in Anodes PlantsДокумент37 страницThe Rhodax® Process For Dry Mix Preparation in Anodes PlantsGupta AnacoolzОценок пока нет

- Ball MillДокумент9 страницBall MillTaufik AchmadОценок пока нет

- Ball Mill For Cement GrindingДокумент5 страницBall Mill For Cement GrindingNkosilozwelo Sibanda100% (1)

- Grinding With Ball Mill SystemsДокумент47 страницGrinding With Ball Mill SystemsaghilifОценок пока нет

- An Overview of Single Stage Autogenous and Semiautogenous Grinding MillsДокумент12 страницAn Overview of Single Stage Autogenous and Semiautogenous Grinding Millsjosesejo123Оценок пока нет

- Grinding and Classifying Technology For Slag: Replacement Factors DryingДокумент6 страницGrinding and Classifying Technology For Slag: Replacement Factors DryingGerman Gabriel Anaya Vega100% (1)

- HPGR Faq PDFДокумент9 страницHPGR Faq PDFfran01334Оценок пока нет

- Auditoría Molino 5Документ22 страницыAuditoría Molino 5ElZeroMJОценок пока нет

- 02 Comminution TheoryДокумент28 страниц02 Comminution TheoryPham tony1604Оценок пока нет

- Determination of The Nip Zone Angle in High-Pressure Grinding RollsДокумент12 страницDetermination of The Nip Zone Angle in High-Pressure Grinding RollsKroya HunОценок пока нет

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОт EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementОценок пока нет

- 1568 GB 02Документ7 страниц1568 GB 02Andra EneОценок пока нет

- Modular Mill With Modular DriveДокумент6 страницModular Mill With Modular DriveFran JimenezОценок пока нет

- Caterpillar Cat Mining Shovel Excavators Spec 9a5887Документ32 страницыCaterpillar Cat Mining Shovel Excavators Spec 9a5887Gholamreza GholipourОценок пока нет

- Cat6030fs PDFДокумент36 страницCat6030fs PDFDiego Domínguez AriasОценок пока нет

- Unit8.2 Cement MillДокумент30 страницUnit8.2 Cement MillRevati MotagiОценок пока нет

- Shovel Starting Current PDFДокумент32 страницыShovel Starting Current PDFamrit90320100% (1)

- Motor Rotax 912/914Документ581 страницаMotor Rotax 912/914Mariano RigottiОценок пока нет

- Ebs3 - Electronic Braking SystemДокумент44 страницыEbs3 - Electronic Braking SystemMile Martinov100% (3)

- 8127280a002 GBДокумент129 страниц8127280a002 GBLuci Lucian100% (3)

- TM 9-6115-464-34 Mep-004a, - 103a, - 113aДокумент493 страницыTM 9-6115-464-34 Mep-004a, - 103a, - 113aAdvocateОценок пока нет

- Parts For CraftДокумент13 страницParts For Craftfaisal jawadОценок пока нет

- Brakes NotesДокумент7 страницBrakes NotesAakash KumarОценок пока нет

- Limited Slip Differential: Submitted byДокумент13 страницLimited Slip Differential: Submitted byPranav SinghОценок пока нет

- Manual de Pulsar Rs 200 - Set15Документ78 страницManual de Pulsar Rs 200 - Set15Anonymous iaqwR2gZ2867% (3)

- Casar Special Wire RopesДокумент48 страницCasar Special Wire RopesmarketakisioannisОценок пока нет

- Fabia Mechanics - Steering Brakes TyresДокумент10 страницFabia Mechanics - Steering Brakes TyresbuerebistaОценок пока нет

- Chapter Two D.C. Motors: Fleming's Left Hand RuleДокумент20 страницChapter Two D.C. Motors: Fleming's Left Hand Rulenoor aliОценок пока нет

- Sc4127-4535ta-Ca GB 6053.111Документ95 страницSc4127-4535ta-Ca GB 6053.111Rachid Smaili100% (1)

- Tecumseh Engine Parts Manual TVS100 44050GДокумент7 страницTecumseh Engine Parts Manual TVS100 44050Greply-to-addОценок пока нет

- Tower Crane Load ChartДокумент1 страницаTower Crane Load ChartDahanTowerCraneОценок пока нет

- 2015 Dodge Grand Caravan SE 3.6L, V6, Gas, VIN GДокумент6 страниц2015 Dodge Grand Caravan SE 3.6L, V6, Gas, VIN GRafael Zuñiga TellezОценок пока нет

- At - Automatic TransaxelДокумент400 страницAt - Automatic TransaxelIlarion CiobanuОценок пока нет

- Spare Parts Manual of AM6 SHN RH VERSION, Doc - No. 80154016, Edition - Jun'10 PDFДокумент107 страницSpare Parts Manual of AM6 SHN RH VERSION, Doc - No. 80154016, Edition - Jun'10 PDFMohammad Aslam100% (1)

- TDP InfoДокумент7 страницTDP InfoEN LeedОценок пока нет

- S 353 Ih 6 RДокумент68 страницS 353 Ih 6 Rmkbuilder2003Оценок пока нет

- Parking Brake System: SectionДокумент10 страницParking Brake System: SectionPiyapong SaerimОценок пока нет

- MECHATRONICS IN ROBOTICS: ELECTRICAL DRIVESДокумент34 страницыMECHATRONICS IN ROBOTICS: ELECTRICAL DRIVESDeepa Ragav RОценок пока нет

- Cat C32 ACERT Spec Sheet - Pleasure CraftДокумент8 страницCat C32 ACERT Spec Sheet - Pleasure CraftSteven Wong100% (1)

- QSK45C HTC2500Документ137 страницQSK45C HTC2500Nova kurniawan 34Оценок пока нет

- Series: Hydraulic ExcavatorДокумент16 страницSeries: Hydraulic ExcavatorForomaquinas50% (4)

- Engine Power G.V.W. Payload Body Heaped (SAE 2:1) : English 09-2014Документ6 страницEngine Power G.V.W. Payload Body Heaped (SAE 2:1) : English 09-2014César PérezОценок пока нет

- Johnson Demountable Bearing BrochureДокумент20 страницJohnson Demountable Bearing BrochureJulio FerrerОценок пока нет