Академический Документы

Профессиональный Документы

Культура Документы

Os Edited

Загружено:

Devu VijiИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Os Edited

Загружено:

Devu VijiАвторское право:

Доступные форматы

An organisation study at Vijayamohini mill]

1

Institute oI Management in Kerala, Poojappura

CHAPTER 1

INTRODUCTION

An organisation study at Vijayamohini mill]

2

Institute oI Management in Kerala, Poojappura

INTRODUCTION

The glorious Indian industrial past was related with cotton, silk

goods, jewels, embroideries etc. AIter independence, large scale industries especially in

consumer goods like cotton textiles, jute and sugar had registered signiIicant growth. Large scale

industries are those which require huge capital investment and long going period. Large scale

industrial sector is one oI those sectors that paved the way Ior economic growth in a country like

India, cotton textile industry is a major large sale industry and contributed one IiIth or 20 oI the

total industrial output oI the country.

In India there are number oI textile mills engaged in the

production oI yarn as well as clothes. Vijaya Mohini Mills at Thirumala in Thiruvananthapuram

is Iamous Ior the production oI yarns. Vijayamohini Mill is an undertaking oI Government oI

India.

The present study oI an organization like Vijaya Mohini Mill,

Thirumala, Thiruvananthapuram, one oI the leading national textiles corporation units in Kerala,

is an eye opener to the various obstacles being Iaced and the Iuture prospects oI the industry. The

importance oI the organisation study is to analyse in detail about the Iunctions oI the diIIerent

departments oI the organisation. The Iindings oI study would give valuable inIormation Ior

improving the overall perIormance oI the organisation.

An organisation study at Vijayamohini mill]

3

Institute oI Management in Kerala, Poojappura

SIGNIFICANCE OF THE STUDY

The most important objective is to get an organisational Iamiliarisation which will help to learn

more about the company, its diIIerent departments and sections, the delegation oI authority and

hierarchy. Moreover the study throws light on the various production process and products

together with company`s Iuture plans oI expansion.Moreover suggestions have been put Iorward

as to improve the satisIaction level oI workers in the organization.

OB1ECTIVES OF THE STUDY

Objectives:

To study in detail the overall Iunctions oI VijayaMohini Mills.

To know about the policies and procedures oI the organisation.

To study about the various stages oI manuIacturing process.

To interact with the managers oI various levels oI the organisational hierarchy as well as

the workers.

To make a SWOT analysis about the organisation.

An organisation study at Vijayamohini mill]

4

Institute oI Management in Kerala, Poojappura

RESEARCH METHODOLOGY

Both primary and secondary data have been used Ior the study.

Primary Data

irect Interview

Observation

xpert Opinion

Secondary Data

Annual Reports

Websites

ournals and Magazines

ompany Records

SCOPE OF THE STUDY

VijayaMohini Mills is a well reputed and experienced company,

that enjoyed monopoly Ior several years and it was Iound to be a good source oI study Ior me as

an MBA student. The company was running under various departments and had vast hierarchies

oI administration, which could be careIully studied Ior the well understanding oI how a

management works practically.

LIMITATIONS OF THE STUDY

O The time period allotted Ior the study was only 15 days.

O The availability oI data is limited.

O The conIidentiality restricted the collection oI Iinancial accounts.

An organisation study at Vijayamohini mill]

5

Institute oI Management in Kerala, Poojappura

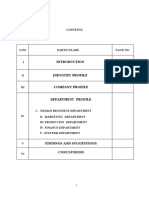

CHAPTERIZATION

The Organization Study conducted in Vijaya Mohini Mill is

reported in 8 chapters.

First chapter contains the Introduction oI the company, Objectives oI the study,

Methodology, Scope oI the study and hapterization.

Second chapter contains Industry ProIile World scenario, Indian scenario and State

scenario.

Third chapter contains ompany ProIile, History, modernisation, nature oI the activity

Product proIile, Main products etc.

Fourth chapter contains the structure oI the organisation.

Fifth chapter contains the various departments oI the organisation.

Sixth chapter contains ompetition and Industry analysis SWOT Analysis and

PORTR`S Model.

Sixth chapter contains Iindings, suggestions and conclusions.

Eighth chapter contains the bibliography.

An organisation study at Vijayamohini mill]

6

Institute oI Management in Kerala, Poojappura

CHAPTER 2

INDUSTRY PROFILE

An organisation study at Vijayamohini mill]

7

Institute oI Management in Kerala, Poojappura

INDUSTRY PROFILE

INTRODUCTION

ottontextile is one oI the oldest and largest industries oI our country. It has made rapid

progresses during the century oI its existence. India has the world`s highest land under cotton but

in terms oI production among 55 major countries it ranks only 4

th

being next to USA, USSR

(Iormer) and HINA. otton is grown in this country over an area oI about 8 million hectors and

average production during the last Iew seasons has been about 87 lakhs. In the modern world,

new materials are being produced and introduced into the market.

COTTON TEXTILE INDUSTRY

otton textile industry is an oldest one but also labour intensive and produces cloth which is one

oI the basic needs oI the human liIe. In India, this industry includes 3 diIIerent sectors namely

mills, power looms, and handlooms using diIIerent level oI equipment and technology. Among

the above mentioned sectors mill is most important because it provides a large quantity oI output

and it provides more employment opportunities and helps to earn a lion share oI Ioreign exchange

to national economy. The industry gives direct employment opportunities to about 20 oI all

industrial labourers and it earns 10 oI Ioreign exchange earnings. It also includes 20 oI the

total industrial production. The industry is supplying yarn to the decentralized sector, which gives

jobs to more than 4 million workers.

.

An organisation study at Vijayamohini mill]

8

Institute oI Management in Kerala, Poojappura

COTTON TEXTILE INDUSTRY IN INDIA

otton textile industry is the oldest and perhaps the largest in the country. otton

is believed to be grown and put to use Ior the Iirst time in India. otton industry is the most

important single industry in the country.

From about 1500 B to 1500 A Ior nearly 30 countries, India held the world

monopoly in the manuIacture oI cotton goods and even today the trade name oI the Indian cotton

goods is calico the product oI alicut.

The world owes in depth gratitude to India Ior the pioneer work it had done in

the cultivation and manuIacture oI cotton, which today has spreadwidely throughout the world. It

is estimated that at the beginning oI the 18

th

century, the annual import oI cotton goods into

urope were worth more than a million dollars.

Towards the end oI the 18

th

century, the ast India ompany realized the value

oI the invention in Lancaster especially the possibility oI spinning and weaving cotton by using

mechanical methods and developed to encourage the growth oI cotton in

India Ior the power looms oI the British.

Textile structure serve Irom 2 sources, ancient handcraIts and modern scientiIic

inventions. The earlier were not produced Irom one thread and employing a single repeated

movement to Iorm loops and inter layering oI Ilexible, reed, canes, or other suitable materials.

The earlier evidence oI weaving dates Irom about 5000 B. otton silk, wool and Ilax Iibers

were needed as textile materials in ancient gypt.otton was used in India by 3000 B and silk

production is mentioned in hinese chronicles dating to about the same period.

In India, the Iirst cotton textile mill was setup by British company in 1818 in

alcutta. The Iirst mill in India, the Bombay Spinning and Weaving ompany Ltd was set up by

MR Gawage Nanbhay evas in 1851. The mill commenced production by 1854. The cotton

An organisation study at Vijayamohini mill]

9

Institute oI Management in Kerala, Poojappura

textile industry was concentrated in and around Bombay during the initial period. Until 1870, the

industry development was at a slow pace. But during the 19

th

century, the industry grew rapidly.

Later on the cotton mill industry lost its dominant position in cloth production.

In 1981 the industry produced 40 cloth requirement against 80 in 1951.

COTTON TEXTILE INDUSTRY IN KERALA

The textile industry in Kerala is not only the oldest industry oI the state, but

also an industry which occupies an important position in the state economic development; the

earliest known registered Iactory is the Malabar Spinning and Weaving ompany at Ponnianwara

in alicut. The second important textile unit setup in the states is the Quilon Spinning Mills.

The development oI textile industry in the state took place only aIter

independence and during those days the development oI the textile industry in the state took place

mostly in the private sector. But some oI the mills became sick units and were taken over by the

NT. The Kerala state textile corporation was incorporated in 1972 with the objectives oI

promoting textile industry and assisting sick mills.

The peculiar Ieature oI cotton textile mills in Kerala is that, most oI them are

either in the hands oI government or in the co-operative sector. There are 33 textiles units in the

state which provide employment opportunities to about 23000 persons. OI these units, spinning

and composite mills number around 29 and out oI these 29 mills, 4 are in the state sector, 5 in the

central sector and 13 are in the private sector. The installed capacity oI the textile units in Kerala

is over 7 lakhs spindles and about 1900 looms.

According to the report oI the working group on the textile industry, State

Planning Board Thiruvananthapuram, the total production oI yarn is estimated to be more than 23

million kilograms valued at over Rs.100 crores. Also over 10 million meter oI clothes valued at

over about Rs.17 crores are produced.

An organisation study at Vijayamohini mill]

10

Institute oI Management in Kerala, Poojappura

CHAPTER 3

COMPANY PROFILE

An organisation study at Vijayamohini mill]

11

Institute oI Management in Kerala, Poojappura

COMPANY PROFILE

History of VijayaMohini Mills

Vijaya Mohini Mills is the Iirst textile mill that was started in

Thiruvananthapuram. It is located at the eastern side oI Thiruvananthapuram city. The unit is

surrounded by the Military ampus. The mill is started in a campus which is about 10.5 acres. It

was originally established under the rule no 6 oI the Textile Nationalization Act 1974.The mill is

now administered by the National Textile orporation.

Historical Development of the Company

Vijaya Mohini Mills spinning unit was started in the year 1946

by Mr. N. Nair with a paid up capital oI 12 lakhs. Though the Iirm was started in 1947,

production began only in 1948 with a spindle capacity oI 6720. Later the mill was handed over to

eva Ray Naidu, the owner oI many textile industries in South India. The spindle then increased

to 9360 in 1951 and mill was again taken over by N. Nair in1956. The spindle was expanded to

15080 in 1959. The management was transIerred to Sree Meenakshi Group in 1960. The

expansion programme they made increased the capacity oI spindle to 25016 in 1969. But

continuous loss and Iinancial diIIiculties made the closure oI the mill Irom May 1971 to

September 1971.

The growth oI the mill was aIIected by problems like repeated

change oI management and administration. Thus there arises a situation where there was no

managing agency.The administration was then directed to an organized Board oI irectors. The

Board then appointed an M to control all the administration oI the unit. Mr. Sundaram hettiyar

was the M up to 1974.

In 1974 the Nationalization oI the Textile Industry Act was

enacted. As per the rule no 6 Nationalization Act, the unit was undertaken by the entral

An organisation study at Vijayamohini mill]

12

Institute oI Management in Kerala, Poojappura

Government. Now NT is controlling the company. At present production capacity oI the mills is

around 4000 kg per day. The value oI the production per day at present is established at 2.6 lakhs.

NT had subsidiaries. Under every subsidiary 10-15 mills were Iunctioning. NT had 121 mills

Iunctioning all over India. The headquarters oI these subsidiaries were at Bangalore. Now, all the

subsidiaries are merged into one and NT Mills are controlled by its Head OIIice, through

Regional OIIice at various locations. The raw materials are purchased Irom the otton

orporation oI India. Vijayamohini Mills comes under the Southern Regional OIIice based at

oimbatore.

Modernisation

New proposals oI modernization with IBI, IFI, were

sanctioned in April 1990. It was with a total outlay oI Rs 666.03 lakhs, including theprovision oI

generators. As a part oI modernization, a new machine called auto-cornor was imported Ior

automatic winding.

Nature of Activity

This is a spinning mill engaged in the production and

distribution oI yarn to diIIerent parts oI the country.

Vision, Mission and Objective

Vision

To produce value added quality yarn and to be a competent enterprise in the Iield oI textile

industry.

An organisation study at Vijayamohini mill]

13

Institute oI Management in Kerala, Poojappura

Mission

.To provide employment

. To have competent work Iorce in the organization

Objective

The main aim oI the Vijayamohini Mills is the technology up gradation oI producing value added

yarn.

Product profile

The raw material yarn cotton is transIerred into the yarn through various processes. Yarn

produced at diIIerent qualities like 60s Pc and 50s P, the mill produces cotton polyester blended

yarn. That is cotton blended with polyester Iibred yarn, which is cotton blended with polyester in

the ratio oI 70 to 30 respectively.

Raw materials

Raw materials are purchased centrally by the head oIIice Irom the otton orporation oI

India, Reliance Ltd and some other parties and allocated to each mill according to the spin plan

by the head oIIice. The cotton received by the mill is Iirst weighted and then it records the weight

oI each bale. The cotton is issued to the production department on the basis oI moving average

cost. The cotton purchased is tested at the central testing laboratory in oimbatore.

An organisation study at Vijayamohini mill]

14

Institute oI Management in Kerala, Poojappura

CHAPTER 4

ORGANISATIONAL STRUCTURE

An organisation study at Vijayamohini mill]

15

Institute oI Management in Kerala, Poojappura

ORGANISATION STRUCTURE OF VI1AYA MOHININ MILLS

\

CN

&N AN

(Finance)

AN (HR)

A&N (N

AE

A&N (QC)

&'A

&'A

H'

Assistants

'" &;aff

QC&;aff

Peons S Drivers

&ecuri;

Wing

Maintenance

Wing

1obbers &

Workers

Engineering

Wing

Accountant

&;ore

Ass;

&

An organisation study at Vijayamohini mill]

16

Institute oI Management in Kerala, Poojappura

CHAPTER 5

FUNCTIONAL DEPARTMENTS

An organisation study at Vijayamohini mill]

17

Institute oI Management in Kerala, Poojappura

PRODUCTION DEPARTMENT

The head oI the department is the spinning manager, who is in eIIective control oI the production

process. There are three varieties in the production department. They are cotton, Polyester cotton,

Polyester staple Iiber.

The raw materials are obtained Irom the cotton corporations oI India and Reliance Industries Ltd.

Sometimes they purchase cotton Irom private parties also. The unit is working under the

instruction Irom head oIIice situated at Bangalore. The production department consists oI Iactory,

engineering and stores. The engineering section consists oI workshop and powerhouse.

An organisation study at Vijayamohini mill]

18

Institute oI Management in Kerala, Poojappura

PRODUCTION PROCESS

Mixing

Blow Room

Carding

Spinning

Simplex

Drawing

Comber, If any

Cone Winding

Packing

An organisation study at Vijayamohini mill]

19

Institute oI Management in Kerala, Poojappura

1) MIXING

AIter the cotton has been opened the raw cotton and the Polyester Spun Fibre (PSF)

will be mixed in a proportion oI 30: 70 i.e. 30 cotton and 70 PSF and it will be Ieeded to

the machine. The wastes and the seeds will be removed.

The two major raw materials used in the yarn production are:

1) Raw cotton Irom I

2) Polyester supplied by Reliance industries

The various steps in this process are as Iollows:

1) The bales oI cotton are taken out and accordingly to the mixing ratio, it is opened and

spread on a large Iloor.

2) Then another bale oI polyester is laid over the spread out cotton, thus making alternate

layers oI cotton and polyester.

3) AIter stock is made the material is allowed to stand Ior mixing up to 12 hours beIore

Ieeding into the blow room. This process is done in a mixing room, which is at a lower

temperature than that oI the room temperature.

An organisation study at Vijayamohini mill]

20

Institute oI Management in Kerala, Poojappura

2) BLOW ROOM

Here the impurities are removed and is converted into convenient package having the

uniIorm weight per unit length Ior Ieeding the next machine.

The diIIerent process taking place inside the blow rooms are as Iollows:

1) iIIerent types oI impurities present in the cotton Polyester mixer are removed.

2) To convert the loose and cleared mix into convenient package having uniIorm weight Ior

Ieeding the next machine.

3) Blending as mixing oI Iibre. Finally the process in the blow room helps to perIorm a

thorough mix.

The diIIerent types oI machines associated with this process and their

operations are given below.

a) Feed Lattice: The Iirst part through which cotton is passed, where bale is opened.

b) Step cleaner is used Ior more opening and cleaning.

c) Hooper Ieeder is used Ior uniIorm Ieeding and to make constant amount oI cotton to

pass into.

d) Porcupine opener is used to removethe minute particles.

Then through the bypass it reaches the condensing age which is the only way to the

second proper Ieeder. From here it goes to proper Ieeder Ior uniIorm Ieeding oI two

types and is extended to increase production.

The outputs that are obtained Irom the blow room are Lap. Lap looks like cotton coiled in

a thick rod.

The process oI delivering oI the mixture directly Irom the blow room to the carding

section is known as HUT FING SYSTM.

An organisation study at Vijayamohini mill]

21

Institute oI Management in Kerala, Poojappura

3) CARDING

The mix Irom the blow room will reach in the head oI the machines

in the carding section.

The main objective oI the carding machine is individualization oI the

Iibre to Iile separation.

1. Opening and cleaning.

2. Mixing and blending oI Iibre.

3. raIting

4. oiling

Reducing the thickness oI the lap to a Iilmy Iorm and together this web

is transIormed into condensed Iorm oI silver. The carding is done through carding engine. The

process helps to separate cotton Iibre Irom impurities and removes short and immature Iibre. The

carding engine delivers cotton as Iilmy webs which are collected in a coiler can. Here there are

35 high production carding machines and 7 high production carding machines.

The machines have three units namely

a) Licker In

b) ylinder

c) oIIer

The Iirst unit removes the waste Irom the mix. Then this mix passes through the cylinder

unit and then reaches the doIIer unit. In the doIIer unit loose Iibre will be collected and be

condensed and then transIormed into a rope Iorm.The raw material processed in this

An organisation study at Vijayamohini mill]

22

Institute oI Management in Kerala, Poojappura

department is known as carding silver. This carding silver will be collected in cans and each

can will be Iilled within a time oI halI an hour.

4) COMBER

The main objective oI the combing process is to remove the shoot Iibres,

limbs and impurities present in the card silver. The carding process helps the spinner to produce

cleaner yarn especially in counts which will be Iiner to be spun Irom the same cotton in the

carded state.

5) DRAWING

The silver lacks uniIormity oI thickness and Ior straightening the Iibre,

the carded silver is processed in the drawing Irame. Here silver gets uniIorm thickness through

doubling process and the Iibre get straightened by drawing in the draIting process. rawing

machines are the types oI machinery installed in this department. This silver Irom the carding

process are stretched or drawn out Irom the drawing machine and is aligned closely.

ight cans oI carded silver will be Ied to one machine in the drawing

session. In this, machine will be rolled in between 3 upper rollers Ior the purpose oI stretching.

ight cans oI carded silver will be converted to one can oI drawing silver.

) SIMPLEX SECTION/ FLY FRAME

Here in this section drawn silver will be Ied into machine. The machine will condense the Iibre

more and small twisting will be done to draw silver. Then the thread will be made thinner. The

level oI silver determines the quantity oI the yarn. In the simplex section the process oI ROVING

takes place.

First and second machines in the simplex section are Irom hina. It has a

better production capacity. In the case oI hinese machines each roving machine will have a

An organisation study at Vijayamohini mill]

23

Institute oI Management in Kerala, Poojappura

maximum capacity Irom 4000 to 4500 meters. These machines could produce 120 Roving`s in an

individual perIormance.The bundle oI the roving`s which will be Ied to the spinning section is

known as Bobin.

7) SPINNING

The spinning takes place in a ring Irame. Here driIting is done and twisting takes place to

give strength to the Iibre. The output produced here is the yarn.

The last stage in the manuIacturing oI yarn is called spinning. The ring

Irames convert the roving received Irom the simplex machine into yarn oI the required count.

The Iunctions oI the ring are:

1) rawing out oI roving by means oI rollers.

2) Twisting the roving around the ring.

3) Winding the twisted yarn into bobins where there are such machines which converts

roving`s into yarn.

In an individual perIormance 864 cops can be produced Irom each machine. op is the end

product oI spinning department. There are 29 machines in the spinning department. In this

department the size oI the thread will be Iurther reduced.

) WINDING DEPARTMENT

Winding oI the threads are done in two qualities.60 pc and 50 pc, in

which 60 pc is the best quality threads produced in the Vijaya Mohini Mills. This is doing Ior

exporting purpose.

The end product oI the winding section is known as cone. ach cone will have an average weight

oI 1.250 Kgs.

An organisation study at Vijayamohini mill]

24

Institute oI Management in Kerala, Poojappura

Another process in winding section is doubling. For making the Iibre convenient Ior weaving the

threads will be doubled in the doubler machine iI it is needed.

9) PACKAGING

In the packing section the threads will be suitably packed and will be

transported, and stored suitably Ior the domestic and exporting purpose. There are two types oI

packing. ach cone is covered using polythene bags. Such covered 50 cones are arranged as one

bag and stitched.

Gross weight is 52 kg (net weight 50 kg)

PROCESS OF POLYESTER /COTTON BLEND

TH FINISH YARN IS PAK IN 13 X 16 X 40 size bag.

While purchasing the material it should be cleared through an agent or directly. It is to be

veriIied in the main gate and allowed to store Ior the physical veriIication in the presence oI

intending person or the security guard.

AIter the physical veriIication the material is purchased as per the

order oI the department. Then in the Mill store purchasing oI the spare parts and the other

purchases is done.

An organisation study at Vijayamohini mill]

25

Institute oI Management in Kerala, Poojappura

The Mill store consists oI three procedures they are:

a) Procurement oI the material

b) onsumption

c) Payment

The persons in the Mill store consist oI Iour staII and are structured as Iollows:

PURCHASING PROCEDURE

The purchase material is recorded in the receipt book, which

consists oI:

1) Purchase Order

2) Store receipt

3) Rate entry

4) ate

5) Name oI the suppliers

6) Particular supplier

7) Invoice

The sale oI the yarn I are given to the industries like:

1) SHAH NTRPRISS

2) SANGTHA TRARS

3) PRIYANKA NTRPRISS

An organisation study at Vijayamohini mill]

26

Institute oI Management in Kerala, Poojappura

The spare parts oI the machinery are purchased Irom the companies like:

1) SUPRIYA HARWARS

2) KARTHIKA HARWARS

3) SURYA NTRPRISS

4) USHA LTRIALS

5) LKSHMI MAHIN

6) MM ARS

7) LMW LAP MAHIN

MAINTNAN SHM

ngineering section also comes under the production department.

The assistant engineer is in charge oI this section. The ngineering department comprises oI

the powerhouse and the workshops. They undertake all the maintenance and installation oI

the machinery.

QUALITY POLICY

We are committed to manuIacture and supply yarn conIorming to agreed speciIications and

ensure customer satisIaction. The above policy is implemented by adopting the Iollowing

measures.

By adhering to an eIIective quality management system and continually improving it.

By creating awareness among all the employees about the importance oI quality management

system.

By technology upgradation.

An organisation study at Vijayamohini mill]

27

Institute oI Management in Kerala, Poojappura

QUALITY CONTROL SECTION

There are two types oI raw materials used by VMM i.e. cotton and

polyester. The productionoI cotton yarn and polyester cotton yarn and 100 polyester yarn.

In polyester cotton yarn there is a blend oI polyester and cotton. It will be in the Iorm oI cone

each weighing 1.25 kgs.

Raw cotton is in bale Iorm. The Iollowing tests are conducted Ior

checking the quality oI bale (spin ability)

1) The test to Iind out the staple length

2) Strength test.

3) Fibre Iineness test

4) Maturity test

INVENTORY SECTION

In the stores department, only the spare parts oI the machines and other daily

requirements are maintained. They adopt bin card system Ior the receipt oI materials and a receipt

voucher is maintained. The procedures Ior the receipt are:

1) For purchasing a particular spare part the concerned department will spend on indent to

the store.

2) AIter receiving the indent, the store department will call Ior the quotation.

3) Quotation having the lowest price must be Iinalized.

4) The members oI the purchasing committee should sign to approve the quotation.

5) AIter that, a purchase order is placed and sent to the supplier.

6) Inspection oI the materials is done by the indent authority.

7) ReIlection oI goods can be made and it is send back to the parties.

An organisation study at Vijayamohini mill]

28

Institute oI Management in Kerala, Poojappura

But iI the materials are accepted a bill will be passed and payment is made aIter checking

Ior damages, deIaults etc.

Three copies oI receipt vouchers are prepared. Two copies are given to store, and one

copy is given in the accounts department.

For the issue oI materials, the department will send an issue slip to the store. AIter the

issue has been made, the closing balance in the bin card should match to the stock in the

stores. The goods are classiIied as:

a) Fast moving

b) Slow moving

c) Non moving

HR DEPARTMENT

HR Manager

Head Time

Keeper

P.F and

E.S.1

Time

Keepers

Security

Wing

Head Security

Inspector

An organisation study at Vijayamohini mill]

29

Institute oI Management in Kerala, Poojappura

The HR manager is in charge oI the department. Under him

there is a head time keeper and a security inspector. A general PF and SI section is successIully

working under the supervision oI the section oIIicer.

The HR department is working in liaison with other departments. In areas such as

recruitment , selection, placement, training, promotion, long term agreements, collective

bargaining industrial relations, discipline, administrative mills,quarters,disciplinary action. He

plays the main role in the organization.

TOTAL NUMBER OF EMPLOYEES

WORKERS

Permanent 214

Gate Badlis 14

Mill Staff 19

Officers

Total number of women workers 33+2

Total number of Trade Unions 4

An organisation study at Vijayamohini mill]

30

Institute oI Management in Kerala, Poojappura

RECRUITMENT

Recruitment is done through employment exchange under direct

recruitment. There are Iour categories such as A, B, , and , A and B are managerial categories

oI workers are selected only through employment exchange.

irect recruitment is done in the case oI managerial posts.

AIter receiving the list, the management will send memo under certiIicate

oI posting to the suitable candidate. The memo will contain date , time, and place oI the

interview. The selection committee consists oI:

1) General Manager

2) eputy HR Manager

3) Factory or Spinning Manager

4) Assistant Account Manager

SELECTION PROCEDURE

AIter recruitment procedure selection is done by ascertaining the

qualiIication oI the candidates with job requirement. The selection here is conducted on the basis

oI:

1) Test

2) Interview

3) Medical xam

4) Appointment

An organisation study at Vijayamohini mill]

31

Institute oI Management in Kerala, Poojappura

TIME OFFICE

This is the only administrative section Iunctioning Ior 24 hours

continuously over three shiIts. The Time Keeper, aIter collecting attendance cards oI the workers,

assesses the shortage oI labourers and lot overtime.PreIerence is given to permanent workers then

to badlis and apprentices. The senior Assistant calculates the number oI dates worked and their

wages is a very complicated procedure iI it isdone manually.

PROBATION

AIter placement the employees are given certain period oI probation. The

probation period is three months Ior workers and one year Ior general staII. Only aIter the

successIul completion oI probation, the employees are made permanent. II the perIormance is not

enough, the probation will be extended again. II the employees satisIactorily complete probation,

he will be conIirmed in that particular post.

TRAINING AND DEVELOPMENT

Training and evelopment becomes important as Iar as the growth oI the

company is concerned. As the mill does not have a separate training department, this Iunction is

perIormed by HR and Production epartments.

Training needs are assessed by consulting with various departments

which need trained labour reports into HR epartment and makes necessary arrangements Ior

training programme.

An organisation study at Vijayamohini mill]

32

Institute oI Management in Kerala, Poojappura

METHODS OF TRAINING

The workers are given only on the job training. The NT staII is sent to

the NT staII training ollege, oimbatore Ior training. The various other training programmes

have been given to managerial staII by diIIerent agencies.

PROMOTION AND TRANSFER

The Mill had Iollowed the SITRA standard oI promotion oI employees

which is speciIied in the Memorandum oI settlement. The matters related to the service

conditions oI the workmen oI the textile industry in Kerala as a whole was taken up by the

Industrial Relation ommittee (IR) Ior textiles, constituted by the Government oI Kerala and a

general Industry wide settlement between employers and workmen represented by the union oI

various textile mills in Kerala.

As provided in the IR Settlement dated 01-12-1994, Unit level

discussions were held at the Mill and aIter prolonged discussions, a Iinal agreement was reached.

As per the settlement, the principle to be Iollowed in case oI promotion is Merit- um-Seniority.

The promotion oI management staII is done at corporate level. It is the Supervision immediate to

the worker who certiIies that a worker is eligible Ior promotion.

The workmen becoming surplus in any category on account oI

implementation oI settlement shall be transIerred Irom one category to another category or

department. While doing so the person shall be treated as the junior-most workman in that

category.

PROMOTION

II two or more workmen have the same seniority in their designated

category oI service, then the seniority should be determined by total service. II the total service in

the mill also happens to be the same, Ior the competing workmen, then priority oI place in the

An organisation study at Vijayamohini mill]

33

Institute oI Management in Kerala, Poojappura

Master Rolls oI the designated category should be in a determining pattern. In Iuture, worker who

decline to proceed on promotion to higher post, should do so in writing. Where a workman Iails

to give in writing, the management shall notiIy surrendered and that he will not be eligible Ior

promotion in Iuture Iorever.

TRANSFER

The management reserves the right to transIer the employees Irom one

shiIt to another according to emergencies oI work at its complete discretion. Inter departmental

TransIer is done to both workers and clerical staII as per changes in count pattern , product mix,

break down oI machines, idling oI machines in order to adjust surplus labourers. For the unit staII

the TransIer is not acceptable. In normal circumstances, no staII member will be transIerred iI he

has three or less years oI service Irom his due date oI retirement.

COLLECTIVE BARGAINING

The collective bargaining process is taking place eIIiciently. The unions

are very much conscious about their rights in bargaining with the management. The unions are

not able to make the management to accept some oI their demands due to the poor Iinancial

conditions and strict compliance oI the rules and regulations as instructed by the mills HO.

The matters which need continuous negotiation to the mills are Iound to be the settlement oI

work load, revision oI wages and other beneIits. The present long term agreement oI the mill is

based in the recommendation the IR.

An organisation study at Vijayamohini mill]

34

Institute oI Management in Kerala, Poojappura

WELFARE FACILITIES

1) Statutory welfare measures

There are welIare measures that are required to be provided under various measures as speciIied

below.

WelIare measures under Factories Act are:

a) Provident Fund as per PF Act

This scheme is implemented according to the mployee`s

Provident Fund (PF) Act. It is a Iuture beneIit scheme by which employer along with

employees make regular contribution to Iund that will acquire to the employees on recruitment or

earlier. Under certain condition, all employees in the mill are covered under PF Act. The

employees must pay 12 oI wages excluding HRA.

b) Bonus as per Bonus Act

As per Bonus Act,the bonus is paid every year during Onam

seasons. Since the unit is suIIering Irom monitory loss, statutory bonus oI 8.33 was paid during

the last Iew years.

c) Family Pension Scheme

There is a Iamily pension scheme as per the PF and all the employees oI the mill get this aIter

their retirement. This amount is ranging Irom 1000 to 2000 Rs. Per month.

d) Gratuity as per Gratuity Act

Gratuity is payable to an employee who has rendered continuous

services Ior not less than 5 years, equivalent to 15 days wages Ior every completed years oI

service. In case oI death oI an employee, his/her dependent will be given the amount oI gratuity.

e) ESI Scheme as per ESI Act

An organisation study at Vijayamohini mill]

35

Institute oI Management in Kerala, Poojappura

The main intention behind SI is to provide the employee with Iine

medical beneIit and treatment through dispensaries and SI hospitals. All the employees oI the

mill who are drawing monthly salary oI less than Rs. 10000 are covered under the SI Act. The

total contribution oI the employer (SI 4.75 oI total wages) and employee (1.5 oI total

wages) are remitted to SI corporation every month. An employee has to work Ior minimum 78

days in an organization Ior becoming eligible Ior beneIits under the SI Act.

f) Welfare measures as per Factory Act

Factory Act 1948 provides the welIare measures Ior the industrial

workers

g) Canteen

The canteen provides the employees with good Iood at a subsidized rate.

anteen price will be discussed at the unit level by representatives oI both employer and

employees.

The prevailing canteen rates are as Iollows:

Meals-Rs.2

Snacks-50 Ps.

Tea and coIIee- 50 Ps.

An organisation study at Vijayamohini mill]

36

Institute oI Management in Kerala, Poojappura

h) Working Conditions

The working areas oI the employees are well maintained with suIIicient

space Ior Iree movement and working. The work areas are kept Iree Irom cotton dust, and have

suIIicient lighting and ventilation arrangement. Functioning oI the boiler is periodically checked.

Interval is given to all workers in such a way that no employee is required to work Ior more than

5 hours continuously.

An organisation study at Vijayamohini mill]

37

Institute oI Management in Kerala, Poojappura

VI1AYAMOHINI MILLS EMPLOYEES CO-OPERATIVE CREDIT SOCIETY

LTD.NO.T.390

PROFILE OF THE SOCIETY

BYLAWS OF THE SOCIETY

1. Name, Address, Area of operation

The name oI the society is Vijayamohini mills mployees o-operative

redit society Ltd.No.T.390. This society is registered according to The Kerala o-operative

Society Act oI 1969 under section 21.

The area oI operation oI this society is vested with Thiruvananthapuram

and the beneIit oI operation only leads to the staII oI Vijaya Mohini mills, Thirumala,

Thiruvananthapuram.

2. Objectives

a. A Iund should be created either Irom the members or other by the means oI shares deposits

etc.

b. Provide loans to members.

c. To execute activities allowed by the Registrar Ior the beneIit oI the members.

An organisation study at Vijayamohini mill]

38

Institute oI Management in Kerala, Poojappura

3. Share Capital

The share capital oI this society is Iixed with 2 lakhs. It includes Rs.

100000 by issuing 4000 A` class shares at Rs.25 each. Rs.50000 Irom 5000 ` class shares at

Rs.10 each and Rs.500000 by the way oI issuing 500 B` class shares at Rs.100 each.

4. Membership

a. The permanent staII oI this institution who is continuing Ior 5 years oI service can take A`

class membership. B` class shares can be issued by the State Government and Vijayamohini

mills. A staII who is permanent but who has not completed 5 years oI service can take ` class

membership.

b. A member should take at least one share but more than 100 shares can`t be kept in

possession.

5. Liability of the members

The liability oI a member is limited to the shares which are taken.

. Transfer of shares

A member can transIer his share to another member on certain conditions.

The transIeror and transIeree should sign on same transIer applications. The managing committee

has the power to receive or reject the applications.

7. Withdrawal of shares

a. A member can`t withdraw his shares within three years Irom which he takes the membership.

b. He should not have any liabilities to the society when the shares are withdrawn.

An organisation study at Vijayamohini mill]

39

Institute oI Management in Kerala, Poojappura

. Dismissal of membership

When a member deliberately deceives the society, then the general body can

terminate his membership. But in general body meeting 2/3 majority should ask Ior the dismissal.

9. Deposits

This society has three types oI deposits

1. Fixed eposit

2. Savings eposit

3. ThriIt eposit

10. Maximum loan limit

The total loan amount oI the society shall not exceed 10 times oI the share

capital with reserve Iund amount.

11. Management

The administrative powers oI the society are vested with the managing

committee. Under which consists oI 6 members Irom A` class and a nominee by the approval oI

TVM eputy Registrar oI o-operative society. Out oI these members a president and vice-

president should be elected.

12. Duration of managing committee

a. The managing committee members are elected Irom the general body Ior 3 years

b. The same committee can continue between the existences oI new committee on the approval

oI the Registrar.

An organisation study at Vijayamohini mill]

40

Institute oI Management in Kerala, Poojappura

13. Managing committee meetings

Managing committee should convene at least once in a month, but iI it

needs can meet many times.

a. The power oI conducting managing committee meeting is entrusted to the Secretary by the

approval oI the President.

b. Minimum 4 members should be present in the meeting.

c. ecision is taken on the basis oI majority. II voting members oI two sides have the same then

the President has the power to entertain crucial vote.

Relationship with the management

Introduction

Within the limitations oI an organizational study, I would like to explain some Iactors which

will substantiate the relationship between the employees and management in Vijaya Mohini

mills, Thirumala. In this study, I analyzed various aspects such as trade unionism, grievance

procedure, workers participation in management, wages and remuneration, industrial conIlicts

etc.

Data analysis and Interpretation

a) Trade unionism

There is some kind oI labor problems in Vijaya Mohini Mills. The workIorce is not

trusting in the transparency oI trade unions in this company. But the majority issupporting the

Iact that trade unions helps in maintaining a good relationship between management and

employees which indicates the bargaining power oI trade unions. All the respondents reported

that the representatives oI trade unions are recognized by the management.

An organisation study at Vijayamohini mill]

41

Institute oI Management in Kerala, Poojappura

b) Grievance Procedure

Study about the grievance procedure in Vijayamohini Mills show that a good process

oI grievance procedure is going on in this company. 80 oI workIorce is satisIied with grievance

procedure in the company. Most oI them reacted that their grievances are handled within a

reasonable time period.

c) Workers participation in decision making

There is not enough workers participation in the process oI decision making but the

management is ready to invite trade unions in the process oI decision making.

d) Wages and remuneration

Majority oI the employees in Vijayamohini Mills are not satisIied with structure oI wage

system and the beneIits and allowances provided by the company.

e) Conflicts

There is no conIlict between the co-workers which indicate a good co-worker relationship

in VMM, which in turn indicate a better recruitment process in this company. ven their

relationship with superiors is going smooth. They don`t Ieel any inconvenience, while working

under their superiors.

f) Inference

It is notable that in VMM there are no Irequent strikes. An interesting Iact that was heard

Irom the respondents was that they love to work in VMM even though they are not satisIied in

their wages and beneIits. They are also ready to accept slight changes in the responsibilities given

by the company.

Study in trade unionism indicates that the presence oI trade unions in this company

contributes something to maintain a good relationship between employees and management.

An organisation study at Vijayamohini mill]

42

Institute oI Management in Kerala, Poojappura

Majority oI the employees are satisIied with the grievance procedure which also contributes to

the maintenance oI a good relationship.

But the study on workers participation in decision making has shown a negative result, that

majority oI the employees are not satisIied in participating in the process oI decision making.

Another important aspect which hinders a better relationship between the employees and

management is the wages.

It is notiIied that Vijayamohini Mills is successIul in maintaining a better co-worker

relationship which in turn indicates an eIIective management in VMM.

WORKERS PARTICIPATION IN MANAGEMENT

A committee is constituted consisting oI

1) General Manager

2) Factory Manager

3) HR Manager

4)Three representatives oI workmen are to be decided by O/GM in consultation with the trade

unions concerned in any manner as per the local condition in the mill, iI any, will be ex- oIIicio

member oI the committee.

The committee is reconstituted on an annual basis or at any period as

per local requirements at the discretion oI the O/GM oI the mills.

FUNCTIONS OF THE COMMITTEE

1) Production programme

2) Utilization

3) IIiciency

4) Productivity

5) Quality oI products

An organisation study at Vijayamohini mill]

43

Institute oI Management in Kerala, Poojappura

6) ost oI reduction

7) Improving ProIitability

8) Purchase

9) Sales including disposal

PARTICIPATION OF MANAGEMENT

The management has good relation with the unions. They understand

the problem Iaced by the management and tries to adjust with the conditions oI the mills.

The majority oI the unions are oI the opinion that the management is

not willing to consider the problems and hazards Iaced by the workers. They blame the

management Ior its ineIIiciency in dealing with the day to day aIIairs oI the employees. The

workmen do not get any kind oI motivation which is an essential ingredient Ior the

improvement. Hence the management and the workers blame on each other without taking

responsibility.

Some workers do not have any Iaith in the unions as they change their

stand day by day. They are oI the opinion that the present unions are not best in handling their

day to day aIIairs and improving their working conditions. They have lost their Iaith in the

ability oI the trade unions leadership to bargain with the management Ior their welIare, saIety

and other problems oI workmen.

The view oI a large number oI workers is against the management, in its carelessness and

indiIIerence to the problem oI the workers, such as quality oI the raw materials, proper

maintenance oI the machine, saIety, health etc.

It is essential Irom the opinion oI the workers that the management

must change their attitude to the workers and consider them as important Ior the successIul

An organisation study at Vijayamohini mill]

44

Institute oI Management in Kerala, Poojappura

running oI the mill. For this purpose management should try to bring into minds a sense oI

belongingness.

As the trade unions compete themselves to get more strength and

excessive politicization, they cannot meet their objective, which is the welIare oI their

workers.

The mill has not experienced any major strikes or lock outs Ior the past

Iew years. The management tries its best to maintain a good and peaceIul relation with the

unions.

GRIEVANCE HANDLING PROCEDURE

1. WATH ON LABOUR SITUATION

The shiIt Supervisors, Assistant Spinning Masters and Spinning Master

will keep close watch about the labourers. Important inIormation will be directly and

conIidentially passed on to the General Manager by the quickest possible means. Labour WelIare

OIIicer will also collect inIormation by contracting union representatives and pass on the relevant

inIormation conIidentially to the General Manager over and above this. The general manager will

also Iind sources to collect inIormation directly to keep him well inIormedoI the developments in

the mill. Relevant inIormation will be passed on immediately to Manager ( HR and Industrial

Relations) ochin and General Manager (HR and Administration) NT, Bangalore.

General Manager will convene meetings oI the oIIicers Supervising StaII

members and variable intervals will be provided to discuss the labour situations.

An organisation study at Vijayamohini mill]

45

Institute oI Management in Kerala, Poojappura

2) PROMPT RRSSAL OF TH GRIVAN OF LABOUR

The probable grievance and demands oI the employees are grouped Ior the

convenient handling oI redressal steps.

PERFORMANCE APPRAISAL

The perIormance appraisal Ior the supervision is based on the grading

system

a) xcellent

b) Very Good

c) God

d) Average

e) UnsatisIactory.

ach staII member is assessed every year based on duty perIormance,

potential and character personality and health. The appraisal system helps to identity the training

needs oI the staII also the details oI the assessment is made in a conIidential report. The

perIormance oI the workers is reviewed by their immediate supervisors. The promotion oI the

workers to higher categories is based on their perIormance and seniority, which is strictly

Iollowed in the mill.

An organisation study at Vijayamohini mill]

46

Institute oI Management in Kerala, Poojappura

WAGES AND ADMINISTRATION

The personal department eIIects prompt and correct payment oI wages

/salary every month. The workers are paid their wages on the seventh oI every month while the

mill staII and NT are paid on the thirty oI every month.

WAGE STRUCTURE

In addition to the basic wages an employee`s earnings includes increment,

A, HRA etc. and other allowances.

The basic salary provided by the Vijaya Mohini Mill to the workers is given

below, which is likely to be revised in the coming months.Apart Irom this, they get earness

Allowance on the basis oI ost oI Living Index submitted by the Kerala conomics and Statistics

epartment, which enhances their salary by 6000-6500 Rs./month.

MIXING 1016.40

BLOWROOM 1010.40

OBBR UM FITTR 1090.40

ASSISTANT FITTR 1068.40

SPINNING FITTR 1090.40

OFING BOYS 1007.40

PAKR 1013.40

HARG MAN 1080.40

LIN OBBR 1105.40

An organisation study at Vijayamohini mill]

47

Institute oI Management in Kerala, Poojappura

SPECIAL ALLOWACES

They provide special allowances oI Rs 30 to the workers who work above

20 days per month.

HOUSE RENT ALLOWANCES

A total oI Rs 166 per month is paid as HRA to all the permanent and badli

workers.

For computation oI earned leave days as per the Factories Act, national

and Iestival holidays as per Kerala Industrial stablishment Act and days oI lay oII are treated as

days worked.

The workers who are occupying the mill quarters are not eligible Ior any

HRA.

LEAVE TRAVEL CONCESSION (LTC)

The worker drawing occupational wages are eligible Ior NT at Rs.1 per

day worked.

An organisation study at Vijayamohini mill]

48

Institute oI Management in Kerala, Poojappura

DEDUCTIONS

PF and ESI:

eductions towards PF and SI are common to all workers. A minimum

oI 10 oI total earnings excluding HRA and LT is deducted to the PF account and 1.75 oI

the total earnings are deducted towards SI scheme.

VARIABLE DEDUCTIONS

These include deductions towards SI, LI policies, Mill credit society

and consumer society, Union dues, Recreation club, WF, SWF, Festival advances. All this will

be deducted and recovered Irom the salary and it is also based on installments.

CALCULATION OF NET PAY

The total deductions will be subtracted Irom the gross earnings and it will

give the Net pay or home pay i.e. net pay (basicincrementAHRALTother earnings)-

(PFSIother deductions).

A worker should have worked 26 days in a month to claim his whole

monthly salary. For days not worked, salary will be reduced accordingly. Basic, A, HRA and

T are taken into account Ior reduction in salary.

The cashier in the account section handles the pay records oI the staII.

An organisation study at Vijayamohini mill]

49

Institute oI Management in Kerala, Poojappura

NTC STAFF ORGANIZATION

The managerial and supervisory staII oI the mill are recruited and managed by

the NT Ltd.

At present there are 8 oIIicers and 15 lerical StaII.

The oIIicers include GM, Spinning Manager, Assistant ngineer, two

Assistant Spinning Managers, HR Manager, and Finance Manager.

INCENTIVES

OIIicers and supervisory staII members in Appendix 1 who work beyond

the normal hours oI work during strike period will be provided the Iollowing incentives.

a. onveyance in mill vehicle or allowance in lieu thereoI.

b. Food and coIIee expenses will be met by the company.

MARKETING DEPARTMENT

The marketing Iunction oI an organization aim to promote its product

among wholesalers through substantial sales order. Marketing is considered as one oI the basic

need oI organization. It is the process oI planning and executing the conception, pricing,

promotion and distribution oI goods and organizational objectives.

An organisation study at Vijayamohini mill]

50

Institute oI Management in Kerala, Poojappura

CUSTOMERS

Yarn which is produced by Vijaya Mohini Mill is sold through

wholesalers.

PROMOTIONAL AND DISTRIBUTION ACTIVITIES

Sales are done by the members in the NT (TNP) Ltd oimbatore which is

the head oIIice.Once in a week they will conduct a meeting about the price and stock in each

mill. According to the market satisIaction they will decide the price. The product is sold to the

agencies according to the order. In the meeting they will decide the distribution oI the product.

And to the head oIIice a conIirmation letter will be sent about the distribution oI products to

several agencies. From the mill the product is distributed according to the order.

SOM AGNIS AR:

PRIYANKA AGNY

SHAW AGNY

SANGTHA AGNY

RAIV AGNY

COMPETITORS

ALAGAPA TXTILS MILLS, TRIHY

KRALA LAKSHMI MILLS, TRIHY

ANNANOR SPINNING MILLS, ANNANOR

An organisation study at Vijayamohini mill]

51

Institute oI Management in Kerala, Poojappura

UNION AND MANAGEMENT RELATIONSHIP

The union and management have a very good relationship. The main

problem is the work load. onIerences are held to maintain a good relationship. The union

leaders are included in the management committee which was Iormed in 1986. The chairman oI

the committee is the General Manager. The union leaders get wages and attendance oI the

conIerence day. II it is an oII day they will get overtime wages.

PURCHASE

Only aIter getting the permission Irom the head oIIice oI NT the mill can

purchase anything i.e.; they Iollow a centralized purchasing system. The raw material is provided

only aIter checking the quality. The cotton is purchased Irom Gujarat at Reliance Industries Ltd.

SALES

The sale oI yarn is done by the mill as prescribed by the NT Ltd, Bangalore.

The yarn is marketed through the depots oI NT and merchant depots at Mumbai, alcutta and

Burhanpur. The demand Ior yarn is ascertained through these depots. Sales are also centralized.

Fixed percentage oI sales commission is provided to agents appointed Irom the head oIIice.

There is no credit sale. The market Ior cotton textile is aIIected by seasonal

Iluctuation. The price is Iixed only aIter the goods are brought.

SALES PROMOTION

SuccessIul marketing depends on having the right product at the right time

at the right place oI the producer. Since yarn is a consumer product Ior making clothes, the

eIIective tool Ior the sales promotion is quality testing by experts.

An organisation study at Vijayamohini mill]

52

Institute oI Management in Kerala, Poojappura

SALES FORECASTING

In a competitive market there is Iluctuation in sales price thereIore proper sales

Iorecasting is not possible. The mill is having plans oI expanding its capacity but it is

handicapped due to non-availability oI Iunds. There are two types oI societies in this mill. redit

Society Ior getting loans and consumer Society Ior supplying Ior supplying provisions. There

apprentice training is compulsorily under the Labour Act.

SQC

There is a statistical quality control department to check the quality oI the yarn. The quality is

supervised Irom the blow room to the winding section.

ENGINEERING DEPARTMENT

ngineering section comes under the production department. The Assistant ngineer is in charge

oI this section. In this section there are 10workers (4 in the general shiIt and 6 in each oI the three

shiIts)

STORE

The storekeeper is in charge oI the stores department. Under him there is

senior assistant and unior Assistant. The store makes use oI the bin card system. A code number

is provided Ior each material. The records are maintained on weighted average method.

An organisation study at Vijayamohini mill]

53

Institute oI Management in Kerala, Poojappura

ACCOUNTS/FINANCE DEPARTMENT

The head oI the accounts department is the Assistant Account Manager. Under him

there is an Accountant, a senior Assistant (sales) and a senior Assistant (cotton) to assist the

Accountant there is a ashier, a senior Assistant and an Assistant. Proper books and records such

as sales and cost records etc. are maintained in this department.

Accounts

Manager

Dispatch

Sales

Section

Accounts

Section

Cotton

Assistants

Cashier

An organisation study at Vijayamohini mill]

54

Institute oI Management in Kerala, Poojappura

DISPATCH

This section oI the accounts department maintains the communication

system both inward and outward. The correspondence coming into the mill is entered into the

Inward register. Then the departments oI which they are meant are identiIied. Besides

correspondence, the Senior Assistant (ispatch) maintains telephone communication. The

outward calls are marked in a particular register which is meant Ior that purpose. A sum oI Rs

1300 is allowed to this section to buy stamps as per the requirements. Old correspondence to

NT is grouped together and is send through courier service.

SHARE CAPITAL

The Bangalore subsidiary has an authorized capital oI 6000000.Its equity

shares are oI Rs 1000 each. They have issued, subscribed and paid up capital oI Rs 582935.

quity shares were Iully paid. Financial accounts are prepared yearly.

COST ACCOUNTING PRACTICE

This section will come under the accounts department. The head oI this

section is the cost veriIier. The mill adapting UniIorm accounting system is as directed by the

head oIIice oI NT. There is an integrated account and the data are collected Ior cost accounting

purpose Irom the Iinancial books.

An organisation study at Vijayamohini mill]

55

Institute oI Management in Kerala, Poojappura

CHAPTER

COMPETITION AND INDUSTRY

ANALYSIS

An organisation study at Vijayamohini mill]

56

Institute oI Management in Kerala, Poojappura

PORTER`S FIVE FORCES & SWOT ANALYSIS

PORTER`S FIVE FORCES ANALYSIS

Porter`s Iive Iorce analysis is a Iramework Ior the industry analysis and

business strategy development developed by Michael . Porter oI Harvard Business School

in1979. It uses concepts developed in industrial Organization (IO) economics to drive Iive Iorces

which determine the competitive intensity and thereIore attractiveness oI a market. Attractiveness

in this context reIers to the overall industry proIitability. An 'unattractive industry is one where

the combination oI Iorces acts to drive down overall proIitability. A very attractive industry

would be one approaching 'pure competition.

According to Porter, the Iive Iorces model should be used at the

industry level; it is not designed to be used at the industry group or industry sector level. An

industry is deIined at a lower, more basic level: a market in which similar or closely related

products and services are sold to buyers. Porter makes clear that Ior diversiIied companies the

Iirst Iundamental issue in corporate strategy is the selection oI industries (lines oI business) in

which the company should compete; and each line oI business should develop its own, industry-

speciIic, Iive Iorces analysis. The average Global 1,000 ompany competes in approximately 52

industries.

An organisation study at Vijayamohini mill]

57

Institute oI Management in Kerala, Poojappura

The threat of substitute products

The existence oI close substitute products increases the propensity oI

customers to switch to alternatives in response to price increases (high elasticity oI demand).

The threat of the entry of new competitors

ProIitable markets that yield high returns will draw Iirms. This results in many new entrants,

which will eIIectively decrease proIitability. Unless the entry oI new Iirms can be blocked by

incumbents, the proIit rate will Iall towards a competitive level (perIect competition).

The intensity of competitive rivalry

For most industries, this A is the major determinant oI the

competitiveness oI the industry. Sometimes rivals compete aggressively and sometimes rivals

compete in non-price dimensions such as

The bargaining power of customers

The ability oI customers to put the Iirm under pressure and it also aIIects

the customer`s sensitivity to price changes.

The bargaining power of suppliers

Suppliers oI raw materials, components, labour, and services (such as

expertise) to the Iirm can be a source oI power over the Iirm. Suppliers may reIuse to work with

the Iirm, or e.g. charge excessively high prices Ior unique resources.

An organisation study at Vijayamohini mill]

58

Institute oI Management in Kerala, Poojappura

Porters Five Force Analysis in VMM

Competition in the Industry

O ompetition Irom subsidiaries and other private mills.

O High quality maintained by other companies.

O Low price oIIered by other mills.

O iversity oI competitors.

Potential of new entrants into the industry

O It is very diIIicult to accept new entrants because the existing channels have their own

brand in the market.

O apital requirement is high.

O Government regulations are high to start a new business.

Bargaining power of customers

O Switch to another company is very simple.

O The number oI customers and their inIluences is limited.

O The customers like to accept good quality at reduced price.

Bargaining power of suppliers

O The number oI suppliers is low

O ost oI input is high relative to the selling price oI the product.

Threat of substitute product

O The customer`s propensity to substitute other mills is very high.

O The prices oI synthetic Iibers are low.

An organisation study at Vijayamohini mill]

59

Institute oI Management in Kerala, Poojappura

SWOT Analysis

Strengths

a. The company has a well disciplined and skilled work Iorce.

b. It comprises oI an eIIicient quality control practice.

c. As a government organisation it gets various assistance, incentives and subsidiaries Irom

Government.

d. asy rail and road access, that helps eIIective transportation oI Iinished goods.

e. The company has very good industrial relations.

Weakness

a. The innovation eIIectiveness is low in the company.

b. Marketing department is not so strong.

c. The working Iacilities oI the company are poor.

Opportunities

a. oint venture with other companies helps to earn more market share.

b. High quality machines can be used.

Threats

a. The company is Iacing high competition in the market.

b. As a Government concern the changes in the market make adverse impact on the

productivity.

An organisation study at Vijayamohini mill]

60

Institute oI Management in Kerala, Poojappura

CHAPTER 7

FINDINGS, SUGGESTIONS AND

CONCLUSIONS

An organisation study at Vijayamohini mill]

61

Institute oI Management in Kerala, Poojappura

Findings

a. The study reveals that the recent expansion oI the mill has motivated the employees.

c. Under the supervision oI NT VijayaMohini Mills is one among the best two mills in Kerala.

d. It is Iound that the number oI shiIts have been reduced Irom three to two.

e. It is Iound that Ior the last two years the operations oI the company is good.

I. The interaction with the workers revealed that the scholarships provided Ior the children oI the

employees are bad.

j. Management is trying its best to keep a good relation with workers and unions.

l. Most oI the workers are not satisIied with the present wage system.

m.The study reveals that the Iacilities in the company are not good Ior the employees.

Suggestions

1. The process oI training and development could be improved more Ior the sake oI increasing

the output oI the company.

2. The attitude oI the workers about their duties and responsibilities has to be altered by proper

training.

3. Good quality machines should be used Ior speedy production.

4. The loss can be reduced iI good quality raw material is given to the unit at low price.

5. Increasing the manpower utility can help the Vijayamohini Mills to attain proIit.

6. Measures should be taken to reduce the absenteeism and to increase the motivational Iactors.

7. More medical Iacilities should be provided Ior the workers.

An organisation study at Vijayamohini mill]

62

Institute oI Management in Kerala, Poojappura

Conclusion

The organisation study has helped the researcher to get a lot oI knowledge about the company

and the Iunctions oI its various departments.

Vijayamohini Mills is a Government undertaking company having its oIIice at

Thirumala. The product yarn is the developing product oI Vijayamohini Mills. The company has

a highly proIessional management team and well-motivated employees and it also has an

eIIective public relation.

The loss can be reduced iI good quality raw material is given to the unit at low price. It

is sure that vijayamohini Mills will grow greater to the expectations oI the people by providing

new quality products by using latest technology in the coming years.

An organisation study at Vijayamohini mill]

63

Institute oI Management in Kerala, Poojappura

Bibliography

1. Aswathappa. K. (2005) Organizational Behaviour, Mumbai: Himalaya Publishing House,

Sixth revised edition.

2. Bose, . (2005) Financial Management, Quilon: ivya Publications.

3. Kanka, S.S Human Resource Management New elhi: S hand & ompany Ltd.

4. Kothari, .R (2004) Research Methodology Methods and Techniques, New elhi: New

Age International Publishers, Reprint dition.

5. Sekaran Uma, Research Methods Ior Business, ohn Wiley &Sons, Inc.

Вам также может понравиться

- Organization Study About The Ikon Exports Manufacture and Export of Garments at TirupurДокумент65 страницOrganization Study About The Ikon Exports Manufacture and Export of Garments at TirupurMeena SivasubramanianОценок пока нет

- Lokanath MarketingДокумент70 страницLokanath MarketingPrabiОценок пока нет

- Conte NTS: NO. Executive Summary 1Документ51 страницаConte NTS: NO. Executive Summary 1crashhelmet2444Оценок пока нет

- Performance AppraisalДокумент35 страницPerformance AppraisalR.SenthilОценок пока нет

- OS ReportДокумент29 страницOS ReportSuku Thomas SamuelОценок пока нет

- Lokanath MarketingДокумент69 страницLokanath MarketingGeethika K Marar100% (1)

- Org Study - OgДокумент44 страницыOrg Study - OgLuminance 2k21Оценок пока нет

- Subadra 1Документ55 страницSubadra 1Pushpa RituОценок пока нет

- Organisation Study On SitharamДокумент56 страницOrganisation Study On SitharamPreema Reghu78% (9)

- OS Original ReportДокумент61 страницаOS Original ReportJithin KottikkalОценок пока нет

- 08 - Chapter 1Документ23 страницы08 - Chapter 1Vijaya LakshmiОценок пока нет

- Sengundhar Mills Inplant Training ProjectДокумент69 страницSengundhar Mills Inplant Training ProjectMukesh kannan MahiОценок пока нет

- Malabar Spinning and Weaving MillsДокумент51 страницаMalabar Spinning and Weaving MillsMelvinОценок пока нет

- Rajapalayam MillДокумент53 страницыRajapalayam MillVijaya LakshmiОценок пока нет

- A Study On Sowmiya Spinning Mills at CoimbatoreДокумент91 страницаA Study On Sowmiya Spinning Mills at CoimbatoreMeena Sivasubramanian100% (2)

- Mudra Project ReportДокумент73 страницыMudra Project Reportmit200891Оценок пока нет

- Ojt ReportДокумент33 страницыOjt Reportpandim6477Оценок пока нет

- Industry ProfileДокумент13 страницIndustry ProfileMukesh kannan MahiОценок пока нет

- Colony Textile Mill Internship ReportДокумент39 страницColony Textile Mill Internship ReportEmman AsifОценок пока нет

- Central Silk BoardДокумент95 страницCentral Silk BoardManjesh KumarОценок пока нет

- Chapter-1 Introduction To The Study &industry ProfileДокумент55 страницChapter-1 Introduction To The Study &industry ProfileAshwini KumaranОценок пока нет

- An Analysis of Financial Feasibility of Lakshmi Mills in CoimbatoreДокумент9 страницAn Analysis of Financial Feasibility of Lakshmi Mills in CoimbatoreOUSMAN SEIDОценок пока нет

- Chapter-1: Alleppy Co-Operative Spinning MillДокумент61 страницаChapter-1: Alleppy Co-Operative Spinning MillPrejin T Radhakrishnan100% (3)

- Mahendra R & TДокумент73 страницыMahendra R & THarshith ShettyОценок пока нет

- Navdeep oSWAL FinalДокумент54 страницыNavdeep oSWAL FinalLovlesh RubyОценок пока нет

- A Report On Organizational Study Done at CHATHANNOR CO-OPERATIVE SPINNING MILLДокумент73 страницыA Report On Organizational Study Done at CHATHANNOR CO-OPERATIVE SPINNING MILLanoopvince123Оценок пока нет

- Internship ReportДокумент33 страницыInternship ReportMuhammad TaqiОценок пока нет

- Internship Report On ESMLДокумент43 страницыInternship Report On ESMLZaighum AliОценок пока нет

- Textile Internship (Compatibility Mode)Документ90 страницTextile Internship (Compatibility Mode)nalinkumar944Оценок пока нет

- My SoreДокумент38 страницMy SoreRa Hu L MalladiОценок пока нет

- Cotton Mills of IndiaДокумент16 страницCotton Mills of IndiakaviyaОценок пока нет

- Project ReportДокумент40 страницProject ReportNitika KatariaОценок пока нет

- A Project Report On LABOUR ABSENTEEISM at Gadag Co-Operative Textile MillДокумент91 страницаA Project Report On LABOUR ABSENTEEISM at Gadag Co-Operative Textile MillBabasab Patil (Karrisatte)Оценок пока нет

- 1002 Chapter 1 - 2 - 3Документ18 страниц1002 Chapter 1 - 2 - 3Harichandran KarthikeyanОценок пока нет

- Weaving MILL Summer Training ReportДокумент41 страницаWeaving MILL Summer Training ReportArjun100% (1)

- Os EditedДокумент66 страницOs EditedyyhteaohfnknjОценок пока нет

- Organisation Study of KAMCOДокумент62 страницыOrganisation Study of KAMCORobin Thomas100% (11)

- Ratio AnalysisДокумент85 страницRatio AnalysisAnup KannaОценок пока нет

- Textile IndustryДокумент6 страницTextile IndustryRenjitha rajuОценок пока нет

- Related TO THE Indian Textile IndustryДокумент113 страницRelated TO THE Indian Textile Industry55dilpreetОценок пока нет

- NRKR TextilesДокумент60 страницNRKR TextilesHariKrishna0% (1)

- INDUSTRY PROFILE Senkunthar New EditedДокумент10 страницINDUSTRY PROFILE Senkunthar New EditedMukesh kannan MahiОценок пока нет

- PCL Cotton Spinning Mills (2)Документ16 страницPCL Cotton Spinning Mills (2)Kawalpreet Singh MakkarОценок пока нет

- Shivu 1st YearДокумент10 страницShivu 1st YearHarsha VardhanОценок пока нет

- CottonДокумент17 страницCottonSakhamuri Ram's100% (1)

- DSM Textile Industry at KarurДокумент79 страницDSM Textile Industry at KarurMeena Sivasubramanian0% (1)

- A Study On Handloom Sector of India: Seema RawatДокумент33 страницыA Study On Handloom Sector of India: Seema RawatAnu PreetОценок пока нет

- Active Apparels InternshipДокумент40 страницActive Apparels InternshipprincegujarОценок пока нет

- Mangal TextileДокумент27 страницMangal TextileViral SarafОценок пока нет

- Chapter-1: Involvement of State AgriculturalДокумент42 страницыChapter-1: Involvement of State AgriculturalMohankumar MohankumarОценок пока нет

- It Provides Direct Employment To Over 35 Million People Who Include SubДокумент58 страницIt Provides Direct Employment To Over 35 Million People Who Include SubRajeev SivadasanОценок пока нет

- Jamuma Kumari BBAДокумент58 страницJamuma Kumari BBAMukesh SinghviОценок пока нет

- Summer Training Report On: "Consumer Perception Towards Online Shopping"Документ83 страницыSummer Training Report On: "Consumer Perception Towards Online Shopping"Swati TanwarОценок пока нет

- Implant Training Report FormatДокумент40 страницImplant Training Report FormatVinoth Vkr100% (1)

- Garden Sillk MillДокумент56 страницGarden Sillk MillrutikakulkarniОценок пока нет

- Sowdeswari Spinnng Mills EDITEDДокумент66 страницSowdeswari Spinnng Mills EDITEDMukesh kannan MahiОценок пока нет

- Cotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingОт EverandCotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingHua WangОценок пока нет

- MAP Report For MBAДокумент57 страницMAP Report For MBAMaulik TankОценок пока нет

- OS ReportДокумент72 страницыOS ReportPrasanth C NairОценок пока нет

- Sustainable Innovations in Textile Chemical ProcessesОт EverandSustainable Innovations in Textile Chemical ProcessesОценок пока нет

- ScribdДокумент27 страницScribdDevu VijiОценок пока нет