Академический Документы

Профессиональный Документы

Культура Документы

12 Gauge

Загружено:

David HoffmanИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

12 Gauge

Загружено:

David HoffmanАвторское право:

Доступные форматы

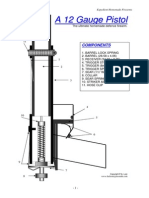

12 Gauge Pistol COMPONENTS 1. BARREL LOCK SPRING 2. BARREL (28.58 x 4.06) 3. RECEIVER (34.93 x 3.25) 4. TRIGGER STOP 5.

TRIGGER (8mm Allen Key) 6. TRIGGER SPRING/BOLT 7. SEAR (1 Washer) 8. COLLAR 9. SEAR SPRING/BOLT 10. STRIKER ASSEMBLY 11. HOSE CLIP 1.BREECH BLOCK The breech block is the only section of the pistol which cannot be made by hand. This component must be machined to the following dimensions using a lathe. A section of round steel bar is required, Figure A , 101mm in length and 28.5mm in diameter. The recess (Hole) to accommodate the Striker (Figure B ) is 12.70mm (1/2 ) in diameter and drilled to a depth of 95mm. The remaining length (Firing pin hole) is drilled to a diameter of 2.5mm. The entrance to the striker recess, (Figure to accept a short 5/8 C ) is enlarged and tapped

diameter hexagon head bolt.

A. Firing Pin Recess Dimensions B. ROUND BAR 101mm x 28.5mm (4 x 1-1/8 ) 28.5mm 2.5mm 12.70mm Tap hole to accept bolt. C. 2.STRIKER ASSEMBLY The Striker is nothing more than a section of 8mm diameter bolt with the threaded section removed. When shortened, the bolt should be 4

in length. The bolt head must be of the round variety with an allen key socket. The diameter of the bolt head must be measured. The one I used was in diameter and so the striker hole was machined

to a diameter of to accommodate it. The bolt used for the striker must be no heavier than 8mm in diameter. A 2mm diameter hole is drilled in the centre of the bolt head to a depth of 5/8 . The firing pin is a section of 2mm diameter drill shank 25mm in length. The pin should protrude 1 to 1.5 mm from the face of the bolt head when inserted. The pin is retained using bearing adhesive. Hole Insert pin Bolt head Pin Striker with pin fitted 3.STRIKER RETAINIG BOLT The striker retaining bolt is the next component to make. This bolt screws into the rear of the breech block and holds the striker assembly in place. The bolt consists of a short 5/8 diameter hexagon head bolt. A hole

of 8mm diameter must be drilled through the exact centre of the bolt to allow the striker to pass through it. This is best carried out using a lathe but it can be done by hand if enough care is taken. The striker spring should be coiled from 20 gauge spring wire around an 8mm diameter mandrel. The finished spring should be just under in diameter and 4 Drill 8mm hole THE STRIKER READY FOR ASSEMBLY Bolt Spring Firing PinStriker Collar Sear 4.ASSEMBLING THE BREECH BLOCK AND STRIKER ASSEMBLY in length.

Spring Firing Pin Collar Striker Bolt Sear Breechblock B. A. Screw in the retaining bolt smoothly. With the striker and breech block assembled the firing pin should protrude 1 to 1.5mm from the block face, as shown at 5.RECEIVER CONSTRUCTION The receiver is a B above.

A and check all parts are moving

Вам также может понравиться

- PPs Semi-Auto FCGДокумент5 страницPPs Semi-Auto FCGangelines12375% (8)

- DIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!От EverandDIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!Рейтинг: 4 из 5 звезд4/5 (4)

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsОт EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsРейтинг: 5 из 5 звезд5/5 (3)

- Avalon Hill The Longest Day - GeneralДокумент31 страницаAvalon Hill The Longest Day - GeneralMax CheeОценок пока нет

- 12g Shot PistolДокумент23 страницы12g Shot Pistolabhungry100% (1)

- Practical Guide to the Operational Use of the PPS-43 Submachine GunОт EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunОценок пока нет

- The Wolf by Philipp Meyer (The Iowa Review)Документ14 страницThe Wolf by Philipp Meyer (The Iowa Review)NouriОценок пока нет

- 22 PistolДокумент17 страниц22 PistolLambourghini100% (4)

- OBAS-12 Updated v2Документ89 страницOBAS-12 Updated v2Professor100% (2)

- V3 ECM Tutorial v1.0Документ40 страницV3 ECM Tutorial v1.0lmkkilo3Оценок пока нет

- 9mm PistolДокумент24 страницы9mm PistolGeorg WolfОценок пока нет

- ОружиеСтрелкаГермания9мая PDFДокумент11 страницОружиеСтрелкаГермания9мая PDF482358209596249420204458140058798324454948309300% (1)

- Maverick - 1.6 ManualДокумент6 страницMaverick - 1.6 ManualTimОценок пока нет

- 1911 Frame TutorialДокумент22 страницы1911 Frame Tutorialblackta6100% (6)

- Jaco Mini PistolДокумент4 страницыJaco Mini Pistolmistermo100% (2)

- Professional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopОт EverandProfessional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopРейтинг: 5 из 5 звезд5/5 (3)

- PM 01 CarbineДокумент9 страницPM 01 CarbineK Scott Wyatt100% (2)

- Professor Parabellum - The DIY STEN Gun - Practical Scrap Metal Small Arms Volume 3. 3-Professor ParabellumДокумент23 страницыProfessor Parabellum - The DIY STEN Gun - Practical Scrap Metal Small Arms Volume 3. 3-Professor Parabellumzaid hashem100% (3)

- Expedient .22 W. SilencerДокумент18 страницExpedient .22 W. Silencerjohn doe67% (3)

- 22lr Single Shot PistolДокумент20 страниц22lr Single Shot PistolMike Nichlos71% (7)

- How to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideОт EverandHow to Build a Children's Swing, Slide, Roundabout and Toboggan for the Garden - An Illustrated GuideОценок пока нет

- YEET22 V2 Manual Updated 2022 12 05Документ18 страницYEET22 V2 Manual Updated 2022 12 05hans landa100% (1)

- Jaco DerringerДокумент4 страницыJaco DerringerFunkpiratОценок пока нет

- COVID-22 Build GuideДокумент21 страницаCOVID-22 Build GuideGrant Markum100% (1)

- United States Patent (191: SeminianoДокумент2 страницыUnited States Patent (191: Seminianoomikami50% (2)

- MK 1Документ4 страницыMK 1Oscar AchtenveertigОценок пока нет

- Product Instructions - Flat Bending Jig InstructionsДокумент34 страницыProduct Instructions - Flat Bending Jig InstructionsDale WadeОценок пока нет

- Chimera ManualДокумент12 страницChimera ManualticocrazyОценок пока нет

- Browning Round Slide PistolДокумент9 страницBrowning Round Slide PistolHarrie Nak100% (2)

- Here Home Main Forums Hall of Freedom Here: This Is An Archive! Click To Go To The Live SiteДокумент19 страницHere Home Main Forums Hall of Freedom Here: This Is An Archive! Click To Go To The Live Sitejamesfletcher100% (1)

- Expedient .380 SMG - Impro GunsДокумент6 страницExpedient .380 SMG - Impro GunsВладимир Конев0% (1)

- Professor Parabellum - The DIY Sheet Metal Self Loading Pistol - Practical Scrap Metal Small Arms Volume 1. 1-Professor ParabellumДокумент15 страницProfessor Parabellum - The DIY Sheet Metal Self Loading Pistol - Practical Scrap Metal Small Arms Volume 1. 1-Professor ParabellumKobi Zada100% (1)

- Sent in To TFB Is Another Concept Design For AnДокумент5 страницSent in To TFB Is Another Concept Design For Aneduar laraОценок пока нет

- 12 Gauge Single-Shot ShotgunДокумент1 страница12 Gauge Single-Shot ShotgunGus Garcia50% (2)

- Sheet Metal Ar15 LowerДокумент12 страницSheet Metal Ar15 LowerCharles Keeney100% (4)

- Improvements Jaco Derringer 1A1Документ2 страницыImprovements Jaco Derringer 1A1Mike Nichlos100% (1)

- 22-Caliber Revolver PDFДокумент24 страницы22-Caliber Revolver PDFApril Bishop100% (5)

- 9mm BSP Machine Gun: Legal NoteДокумент29 страниц9mm BSP Machine Gun: Legal NoteLeonBackups100% (1)

- Bill Holmes Silencers From The Home WorkshopДокумент28 страницBill Holmes Silencers From The Home WorkshopWaltherPKОценок пока нет

- Polymer80: Phoenix Version - G150 80% Lower Receiver InstructionsДокумент13 страницPolymer80: Phoenix Version - G150 80% Lower Receiver InstructionsTimothy ScottОценок пока нет

- Checkmate II .22lr Manual.Документ2 страницыCheckmate II .22lr Manual.Griffin Armament SuppressorsОценок пока нет

- CZAR V2 Build TutorialДокумент20 страницCZAR V2 Build Tutorialgretschguy7081100% (1)

- 22 Silenced Pistol1Документ20 страниц22 Silenced Pistol1colompar80100% (1)

- Toy Derringer Handgun Firing Mechanism PDFДокумент5 страницToy Derringer Handgun Firing Mechanism PDFyuehan0% (1)

- Building a Home Defense Remington 870 ShotgunОт EverandBuilding a Home Defense Remington 870 ShotgunРейтинг: 3.5 из 5 звезд3.5/5 (5)

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsОт EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsОценок пока нет

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.От EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Рейтинг: 5 из 5 звезд5/5 (1)

- The Practical Guide to Man-Powered Weapons and Ammunition: Experiments with Catapults, Musketballs, Stonebows, Blowpipes, Big Airguns, and Bullet BowsОт EverandThe Practical Guide to Man-Powered Weapons and Ammunition: Experiments with Catapults, Musketballs, Stonebows, Blowpipes, Big Airguns, and Bullet BowsРейтинг: 5 из 5 звезд5/5 (1)

- Gunsmithing Made Easy: Projects for the Home GunsmithОт EverandGunsmithing Made Easy: Projects for the Home GunsmithРейтинг: 3 из 5 звезд3/5 (2)

- Practical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRОт EverandPractical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRОценок пока нет

- Stargate TV Series RulesДокумент9 страницStargate TV Series RulesSteven Taylor100% (1)

- Biggles Goes HomeДокумент98 страницBiggles Goes HomeAlan Tread100% (3)

- Ruma Dawn of Empire Quickstart RulesДокумент14 страницRuma Dawn of Empire Quickstart RulescameronhyndmanОценок пока нет

- GM Reference Burning WheelДокумент10 страницGM Reference Burning WheelMichele ToscanОценок пока нет

- DCUO Innate SkillsДокумент1 страницаDCUO Innate SkillsHulk SmashОценок пока нет

- VZ 58 BrochureДокумент2 страницыVZ 58 Brochureangelines123Оценок пока нет

- Chertezhi Pistoleta-Pulemeta STEN STEN MkIIДокумент22 страницыChertezhi Pistoleta-Pulemeta STEN STEN MkIISteven SanchezОценок пока нет

- Rapido River DisasterДокумент8 страницRapido River DisasterwingandaprayerОценок пока нет

- The PRO-Gram: PRO6 - LTC Jason JonesДокумент6 страницThe PRO-Gram: PRO6 - LTC Jason JonesPro RepОценок пока нет

- Tso PVP HelpДокумент22 страницыTso PVP Helprohit29agrawalОценок пока нет

- Moncure CowpensДокумент208 страницMoncure Cowpensbob01234Оценок пока нет

- Mod BritishДокумент36 страницMod Britishjohn_crawford_1100% (1)

- Twilight 2000Документ17 страницTwilight 2000Ryan Thomas100% (4)

- Iron Warriors Grand Company Warhammer 40K Homebrew SupplementДокумент24 страницыIron Warriors Grand Company Warhammer 40K Homebrew SupplementAlex Kratz100% (2)

- Army Combat Lessons Jul 1944Документ65 страницArmy Combat Lessons Jul 1944CAP History Library100% (2)

- An Army - Its Organization and Movements by Cornelus W. Tolles (1829 - 1864)Документ71 страницаAn Army - Its Organization and Movements by Cornelus W. Tolles (1829 - 1864)GAB-1955Оценок пока нет

- Objective EssayДокумент6 страницObjective Essayapi-550938033Оценок пока нет

- EmpireДокумент1 страницаEmpireMikołaj NowakОценок пока нет

- Pearl Harbor Air CombatsДокумент27 страницPearl Harbor Air CombatsMoulin KubisОценок пока нет

- TP350 9Документ94 страницыTP350 9Bojan Tanaskovski100% (1)

- Custom 1911Документ6 страницCustom 1911SayfGardezОценок пока нет

- ASL - VFTT 54Документ20 страницASL - VFTT 54deitti333Оценок пока нет

- A Lead Sling Bullet of The Macedonian King Philip V (221 - 179 BC) - Metodi ManovДокумент11 страницA Lead Sling Bullet of The Macedonian King Philip V (221 - 179 BC) - Metodi ManovSonjce Marceva100% (1)

- Da Pam 385Документ13 страницDa Pam 385Negrea PaulОценок пока нет

- New Weapons & Armor For D&D5eДокумент1 страницаNew Weapons & Armor For D&D5eJargogleОценок пока нет

- NES 179 Requirements For Lockers (Magazine, RU Magazine and Detonator) Used For Storage of Explosive StoresДокумент54 страницыNES 179 Requirements For Lockers (Magazine, RU Magazine and Detonator) Used For Storage of Explosive StoresJEORJEОценок пока нет

- O'Neill ThesisДокумент90 страницO'Neill Thesiswajahat408Оценок пока нет