Академический Документы

Профессиональный Документы

Культура Документы

Controlador Danfoss

Загружено:

frank.marcondes2416Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Controlador Danfoss

Загружено:

frank.marcondes2416Авторское право:

Доступные форматы

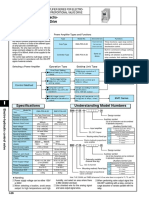

EKD 316 Controller for evaporators in water chillers and rooftop air conditioning units

The EKD 316 controller for electronic expansion valves can operate as a standalone controller or as interface (driver) between a central system and an electronic expansion valve. The EKD 316 controller is compatible with all Danfoss ETS and KVS valves. It is designed specifically for evaporator control in water chillers and rooftop units. Only parameters needed for those applications are shown in the menus. Once the parameters are set with an EKA 164A Universal Setting Module, they can be read via the EKA 164A or via Modbus communication protocol.

REFRIGERATION AND AIR CONDITIONING

EKD 316 Controller

Advantages

Refrigerant delivery to the evaporator is optimal even under wide variations in load and suction pressure Energy savings - adaptive regulation of refrigerant injection ensures that evaporator utilization is optimally efficient. Superheat is maintained at the lowest level consistent with efficient operation. Thus, suction pressure can be higher. The result is less compressor run time and lower operating and maintenance costs. Compatible with all Danfoss ETS and KVS stepper motor valves 24 Volt a.c or d.c. Quick, easy plug-in connectors Modbus communication Can be remote from valve Mounts on DIN rail Standalone or slave using any standard voltage or current analog signal Battery backup terminals Ratiometric pressure transmitter input connection User programmable for any of 31 common refrigerants

Functions

Superheat control MOP function ON-OFF input allows manual valve closing Valve opening degree can be manually set User programmable alarm output Single or double loop (using extra sensor) PI regulation Bipolar constant current stepper motor driver

Technical data

Supply voltage Power consumption Input signal Digital (on-off ) input Analog sensor inputs Alarm relay Step motor output Data communication Environments Enclosure Weight Mounting Operation Approvals 24 V a.c. +/-15% 50/60 Hz, 10 VA (supply voltage galvanically isolated from input and output signals) Controller 5 VA ETS step motor 1.3 VA Current 4-20 mA or 0-20 mA Voltage 0-10 V or 1-5 V Digital input from external contact function 1 for switched valve shutdown 2 for Pt1000 temperature sensors 1 for AKS 32R pressure transmitter AC-1: 4 A (ohmic) 1 pcs. SPDT AC-15: 3 A (inductive) 30 mA - 300 mA , pulse modulated MODBUS 0 to 131F (0 to +55C), during operations -40 to 158F (-40 to +70C), during transport 20 - 80% Rh, not condensing Shockproof, vibration- proof IP 20 0.6 lb (300 g) DIN rail External display type EKA 164A EU Low Voltage Directive and EMC demands re CE-marking complied with. LVD-tested acc. to EN 60730-1 and EN 60730-2-9 EMC-tested acc. to EN50081-1 and EN 50082-2

Battery backup 18 V dc min. 100 mAh required Max. distance between 16.4 ft (5 m) controller and valve

Valve operation

ETS valves are modulated by an electronically controlled 2-phase bipolar stepper motor (AST). The stepper stays in position unless power pulses from a driver initiate one of the two discrete sets of motor windings that operate respectively in the opening and closing directions. The direction of motor rotation depends on the phase relationship of the power pulses. The distance traveled depends on the number of pulses transmitted for a given move. The motor drives a lead screw, whose rotating motion is transformed into linear motion by a transmission in the cage assembly. The AST motor housing has a glass sealed 6.5 feet (2 m) cable connection as standard. Cable length and connections can be customized. The valve cone is an exponential V-port design that provides best part load efficiency with zeroresistance maximum capacity The cage and orifice design is fully power balanced, so that bi-flow operation has equal performance and capacity in either direction. The port design includes a shut-off function with solenoid tightness in both flow directions. Closed position is also the mechanical stop acting as reference point to reset the controller. The zero reference point is reset at each closing, with accuracy ensured by a slight overdrive.

Electrical data

Parameter Stepper motor type Step mode Phase resistance Phase inductance Holding current Step angle ETS 50-400 Bi-polar 2 phase full step 52 10% 85 mH Depends on application. Full current allowed (100% duty cycle) 7.5 (motor), 0.9 (lead screw), Gearing ratio 8.5:1. (38/13)2:1 (Constant voltage drive) 12 V dc - 4% +15%, 150 steps/sec. (Using chopper drive) 100 mA RMS - 4% +15% Voltage / current drive: 5.5 / 1.3 W (UL: NEC class 2) 150 steps/sec. (constant voltage drive) 0-300 steps/sec. 300 recommended (chopper current drive) ETS 50: 2625 [+160 / -0] steps ETS 100: 3530 [+160 / -0] steps ETS 250 and 400: 3810 [+160 / -0] steps ETS 50: 17 / 8.5 sec. (voltage / current) ETS 100: 23 / 11.5 sec. (voltage / current) ETS 250 and 400: 25.4 / 12.7 sec. (voltage / current) ETS 50: ETS 100: ETS 250-400: 0.5 in. (13 mm) 0.6 in. (16 mm) 0.7 in. (17.2 mm)

Nominal voltage Phase current Maximum total power Step rate

Total steps

Full travel time

Lifting height

Reference position Overdriving against the full close position Electrical connection 4 wire 0.02 in2 (0.5 mm2), 6.5 ft (2 m) long cable

Stepper motor switch

STEP 1 CLOSING 2 3 4 1 Coil I Red + + + Green + + Coil II White + + + Black + + OPENING

Danfoss, Inc., Refrigeration & Air Conditioning Division, 7941 Corporate Drive, Baltimore, MD 21236 Tel.: 410-931-8250, Fax: 410-931-8256, www.danfoss.com/North _America

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products already on order provided that such alternations can be made without subsequential changes being necessary in specifications already agreed. All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

DKRCC.PB.R1.A1.22 / 520H1934

Produced by Danfoss DE-BD 01-2007

Вам также может понравиться

- PCS 9705Документ3 страницыPCS 9705elkhalfi50% (2)

- Analog Circuit Design Volume Three: Design Note CollectionОт EverandAnalog Circuit Design Volume Three: Design Note CollectionРейтинг: 3 из 5 звезд3/5 (2)

- Truwater - TCM SeriesДокумент12 страницTruwater - TCM SeriesnkhhhОценок пока нет

- 1 1 6 Blood Splatter Analysis Experimental DesignДокумент4 страницы1 1 6 Blood Splatter Analysis Experimental Designapi-343751193100% (1)

- Corrective MaintenanceДокумент12 страницCorrective MaintenanceMohammed Nerissa100% (1)

- 111-300 Trans Temp MonДокумент4 страницы111-300 Trans Temp MonLucian2001Оценок пока нет

- ARI Armaturen ARI SteviДокумент12 страницARI Armaturen ARI SteviCaptain98Оценок пока нет

- Ari PremioДокумент0 страницAri PremioCandiano PopescuОценок пока нет

- Transferencias Automaticas ABBДокумент24 страницыTransferencias Automaticas ABBCesar BorregoОценок пока нет

- 3.72.e.el Linear Electric ActuatorsДокумент10 страниц3.72.e.el Linear Electric ActuatorsSon Trinh PhuongОценок пока нет

- Moog D633Документ16 страницMoog D633Balu M100% (1)

- D 633 Series Valves eДокумент16 страницD 633 Series Valves ehaggОценок пока нет

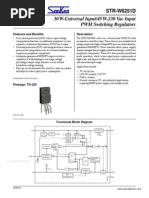

- 60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsДокумент14 страниц60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsIBSDIALLO0% (1)

- Trasduttore Lineare InternoДокумент6 страницTrasduttore Lineare InternoankvepeОценок пока нет

- DKRCC - pd.Vd1.d5.02 Ets6 SWДокумент16 страницDKRCC - pd.Vd1.d5.02 Ets6 SWJaroslav BiresОценок пока нет

- DatasheetДокумент13 страницDatasheetebertecnicoОценок пока нет

- Astat PlusДокумент13 страницAstat Pluspayolin77Оценок пока нет

- DeviceCraftDCmotorController 1015BДокумент24 страницыDeviceCraftDCmotorController 1015BbetortitaОценок пока нет

- H1000e I Ema-Emc PDFДокумент4 страницыH1000e I Ema-Emc PDFNguyen Van ChungОценок пока нет

- ATV32HU75N4Документ11 страницATV32HU75N4bmshivakumarОценок пока нет

- Danfoss MCD3000 BrosuraДокумент2 страницыDanfoss MCD3000 BrosurazvekoslavОценок пока нет

- ATV32HD15N4Документ12 страницATV32HD15N4gasm22Оценок пока нет

- ElectrovalvulasДокумент8 страницElectrovalvulasRaul Guevara TorresОценок пока нет

- 1SCC301020C0201 PDFДокумент116 страниц1SCC301020C0201 PDFlagm54Оценок пока нет

- Re29564 2007-011Документ12 страницRe29564 2007-011engineer86Оценок пока нет

- Consumption: Flow Direction Switch For Compressed AirДокумент2 страницыConsumption: Flow Direction Switch For Compressed AirKelvin NgОценок пока нет

- ETSДокумент4 страницыETSGiorgos PapadopoulosОценок пока нет

- V Series Rectifier 102407 PDFДокумент6 страницV Series Rectifier 102407 PDFchiquilin2Оценок пока нет

- NOAH KatalogДокумент6 страницNOAH KatalogtalayОценок пока нет

- 67relay - Elr W3 400 500Документ2 страницы67relay - Elr W3 400 500maghagxxxОценок пока нет

- Dse7310 20 Data SheetДокумент2 страницыDse7310 20 Data SheetRICKYBLACKОценок пока нет

- Lin 1.3 TC 80310Документ32 страницыLin 1.3 TC 80310MohanakrishnanОценок пока нет

- Stogra Stepper Motor ControlsДокумент24 страницыStogra Stepper Motor Controlscatalin_constantinescu100% (2)

- Avr Newage mx321 PDFДокумент4 страницыAvr Newage mx321 PDFLiya MahagamaОценок пока нет

- TSI Bravo EPC 48 230 Data Sheet V07Документ2 страницыTSI Bravo EPC 48 230 Data Sheet V07Yashveer TakooryОценок пока нет

- Automatic Transfer SwitchesДокумент20 страницAutomatic Transfer SwitchesgianmantОценок пока нет

- Altivar 71 ATV71HD11N4Документ13 страницAltivar 71 ATV71HD11N4Dagostino GigiОценок пока нет

- Maxon 145391Документ2 страницыMaxon 145391Mathieu BrasseurОценок пока нет

- LM2596 LM2596 SIMPLE SWITCHER Power Converter 150 kHz3A Step-Down Voltage RegulatorДокумент33 страницыLM2596 LM2596 SIMPLE SWITCHER Power Converter 150 kHz3A Step-Down Voltage RegulatorFremont Navarro GottliebОценок пока нет

- DC/DC C 28 V I: Onverters OLT NputДокумент21 страницаDC/DC C 28 V I: Onverters OLT Nputnpadma_6Оценок пока нет

- Datasheet ATV61EXS5C63N4Документ8 страницDatasheet ATV61EXS5C63N4flake03Оценок пока нет

- Avr MX321Документ3 страницыAvr MX321Ahmad ArpaniОценок пока нет

- EuroSMC Let Range - BrochureДокумент4 страницыEuroSMC Let Range - BrochurersgrsgrsgОценок пока нет

- Substation / Switchyard EquipmentДокумент10 страницSubstation / Switchyard EquipmentVenkatesh VenkyОценок пока нет

- Copley Controls Power AmplifiersДокумент6 страницCopley Controls Power AmplifiersSiva Srinivas RangavajhalaОценок пока нет

- Pneumatic and Apm Liquid Level ControlДокумент12 страницPneumatic and Apm Liquid Level Controlyuri0527Оценок пока нет

- NXe 10-20 kVA (V. 1.0) - Tech SpecДокумент5 страницNXe 10-20 kVA (V. 1.0) - Tech SpecChathura DharmasenaОценок пока нет

- Electrical System Data SheetДокумент9 страницElectrical System Data SheetpmlikrishnaОценок пока нет

- Altistart 22 ATS22C14QДокумент9 страницAltistart 22 ATS22C14QJavier SaireОценок пока нет

- TSI Nova 48 230 Data Sheet V10Документ2 страницыTSI Nova 48 230 Data Sheet V10ThanosEleftheroudisОценок пока нет

- Altivar71 HU22N4 - Variabile Speed Drive Atv71-2.2kw 3hp-480vДокумент13 страницAltivar71 HU22N4 - Variabile Speed Drive Atv71-2.2kw 3hp-480vMutu DanielОценок пока нет

- GSE CONTROL 400 + BMZ Poland IESSДокумент5 страницGSE CONTROL 400 + BMZ Poland IESSJakub VonkomerОценок пока нет

- Commander SE: Simple and EasyДокумент8 страницCommander SE: Simple and EasyRitesh SharmaОценок пока нет

- Pillar MK17 Power SupplyДокумент2 страницыPillar MK17 Power SupplyManoj RaijadaОценок пока нет

- 62 SeriesДокумент8 страниц62 SeriesDevendra BangarОценок пока нет

- AMS1117 SeriesДокумент8 страницAMS1117 SeriesMauricio Raul RotmanОценок пока нет

- 3730-2 Positioner SamsonДокумент8 страниц3730-2 Positioner SamsonKashif JamalОценок пока нет

- KA7500 DatasheetДокумент6 страницKA7500 DatasheetSergio Daniel BarretoОценок пока нет

- Datasheet PDFДокумент15 страницDatasheet PDFperro sОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Рейтинг: 2.5 из 5 звезд2.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsОт EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsРейтинг: 3.5 из 5 звезд3.5/5 (6)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Fan Motor Basic PartsДокумент7 страницFan Motor Basic PartsMARIO BULANADIОценок пока нет

- Swot Analysis of PTCLДокумент5 страницSwot Analysis of PTCLM Aqeel Akhtar JajjaОценок пока нет

- Project TimesheetДокумент2 страницыProject TimesheetAmanpreet SinghОценок пока нет

- Walk inДокумент1 страницаWalk inCHATHURОценок пока нет

- Contamination ControlДокумент5 страницContamination ControlPadmanabhan DhanasekaranОценок пока нет

- Life-Saving Rules: Tool Box Talk SeriesДокумент86 страницLife-Saving Rules: Tool Box Talk SeriesSalahBouzianeОценок пока нет

- Unit 9 Computer NetworksДокумент8 страницUnit 9 Computer NetworksDaniel BellОценок пока нет

- Pursuit ManualДокумент26 страницPursuit Manualhunter9903Оценок пока нет

- MK7850NДокумент6 страницMK7850NkherrimanОценок пока нет

- CMP Tutorial PDFДокумент83 страницыCMP Tutorial PDFMax HaroutunianОценок пока нет

- HIV Sero-Status and Risk Factors of Sero-Positivity of HIV Exposed Children Below Two Years of Age at Mityana General Hospital in Mityana District, UgandaДокумент14 страницHIV Sero-Status and Risk Factors of Sero-Positivity of HIV Exposed Children Below Two Years of Age at Mityana General Hospital in Mityana District, UgandaKIU PUBLICATION AND EXTENSIONОценок пока нет

- Washing MachinesДокумент6 страницWashing MachinesAnonymous wK36hLОценок пока нет

- 01-25 OB Bbs 3 Year Preboard 2076Документ1 страница01-25 OB Bbs 3 Year Preboard 2076Reestam SD100% (1)

- R&D Division BrochureДокумент4 страницыR&D Division BrochureShai WeissОценок пока нет

- Ancient Civilizations AssignmentДокумент3 страницыAncient Civilizations Assignmentapi-240196832Оценок пока нет

- Database Testing: Prepared by Sujaritha MДокумент21 страницаDatabase Testing: Prepared by Sujaritha Mavumaa22Оценок пока нет

- Brake Actuator Instruction - ManualДокумент32 страницыBrake Actuator Instruction - ManualJoeОценок пока нет

- (DOC) Makalah Sistem Endokrin - YENNA PUTRI - Academia - Edu183414Документ13 страниц(DOC) Makalah Sistem Endokrin - YENNA PUTRI - Academia - Edu183414dominggus kakaОценок пока нет

- Online Assignment - Aritificial LiftДокумент10 страницOnline Assignment - Aritificial LiftfatenamiraОценок пока нет

- Atoll 3.3.2 Technical Reference Guide RadioДокумент912 страницAtoll 3.3.2 Technical Reference Guide Radioratelekoms100% (4)

- Astm C-743Документ4 страницыAstm C-743IyaadanОценок пока нет

- Active Suspension System of Quarter CarДокумент70 страницActive Suspension System of Quarter CarMarcu SorinОценок пока нет

- Model Space & Layout (Paper) SpaceДокумент7 страницModel Space & Layout (Paper) SpaceIonela Lioara TutaОценок пока нет

- 1 1 6 A-VariableRolesIIДокумент5 страниц1 1 6 A-VariableRolesIIRocket FireОценок пока нет

- Guidelines For Layout and Format of The Proposal: 1. Page Margins (For All Pages) - Use A4 Size PaperДокумент3 страницыGuidelines For Layout and Format of The Proposal: 1. Page Margins (For All Pages) - Use A4 Size PaperAummy CreationОценок пока нет

- High Impact Papers in Power Engineering, 1900 1999: Celebration 2000Документ7 страницHigh Impact Papers in Power Engineering, 1900 1999: Celebration 2000nooralhudОценок пока нет