Академический Документы

Профессиональный Документы

Культура Документы

MODAPTS Course Brochure

Загружено:

EngAhmed80Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MODAPTS Course Brochure

Загружено:

EngAhmed80Авторское право:

Доступные форматы

TRAINING SEMINAR

MODAPTS

An Easy To Learn, Easy To Use Work Management System

September 24-27, 2007 Blacksburg, Virginia

METHOD ANALYSIS ERGONOMIC ANALYSIS PRODUCTION MANAGEMENT

Introduction to MODAPTS

This interactive training course will provide the opportunity to become fluent in the predetermined work measurement, ergonomic analysis system MODAPTS. MODAPTS is similar to other predetermined time systems such as MTM or MOST. MODAPTS is a system for measuring work, without the use of a stopwatch. It is based on analyzing the body motions required in a work task or work process. It is an accurate and quick work analysis system that can be applied to production activities, non-cycle work environments and safety management. It is currently being utilized by automotive manufacturers and suppliers, government organizations, not-for-profit workshops, shipping and transportation industries, as well as office and data processing organizations. This system can be used for contract bidding, direct labor cost estimating, quality control, safety analysis and establishing productivity standards for work stations and manufacturing processes.

Course Overview

Learning Objectives of this 3 Day Hands-On Workshop:

Become fluent in the language and the use of the MODAPTS work measurement system; Gain the knowledge required to become a Certified MODAPTS practitioner by the International MODAPTS Assocaiation.; Learn alternative methods of setting standards which will aid in developing computer based standards; Learn to provide fast and accurate direct labor costs, assist quality improvement and control; Learn to improve the ergonomics and productivity of work tasks.

What Makes MODAPTS a Powerful Work Task Productivity Analysis System?

Build A Foundation - Compatible with other work management and productivity tools such as LEAN Manufacturing, JIT System and Six Sigma,MODAPTS is the base analysis tool, producing time and movement based studies that can be applied to any work study.

Its benefits include: Easy to Use and Quick Application Rapid Derivation of Objective Standards Increased Utilization of Work Management Personnel Work Task Analysis Regarding People and Their Capacities Accuracy and Consistency In Costing

(+/-5% at the 95% confidence level of the true mean)

Improved Communication and Productivity Added Potential For Analytical Evaluations Quick Determination of Rates and Plant/Department Capacity Quantitative Basis for Analysis of Work Center Design Determines Which Tasks Can Be Automated and Which Aspects Require Human Interaction Data and Analysis for Human Systems Integration Builds stronger working relationships by defining job tasks and expectations Physically stressful work can be identified and reduced or eliminated to reduce work related injuries

QUICK AND LONGLASTING ECONOMIC & ERGONOMIC BENEFITS! SAVE TIME & MONEY PLANT WIDE WHILE IMPROVING QUALITY!

DYNAMICS RESEARCH GROUP www.drshinnick.com drg@drshinnick.com 540.951.1950 FAX 540-951-0519

Who Should Attend

The training program is competency-based and interactive. Each participant is encouraged to bring a videotape of workstations and of an assembly process and, if feasible, samples or components of products produced. Work standards for these processes and products will be developed during the training. At the conclusion of the training, an International MODAPTS Association (IMA) Practitioner Certification Examination will be administered. This provides the opportunity to obtain certification required by the U.S. Department of Labor for utilization of MODAPTS. During the training, each participant will develop an action plan, which will serve as a post-training strategy for MODAPTS application and implementation. In addition, following the training course, participants are expected to complete an application project. These applied projects will help to ensure fluency in the MODAPTS language, as well as assist in facilitating integration of MODAPTS into production management, bidding, and costing systems.

This is a an Excellent Opportunity For

Operations and Production Managers & Ergonomic Directors and Staff Maintenance Managers and Supervisors Safety Managers, Supervisors & Engineers Human Resource Managers Procurement Offices Government Contractors Facility Managers Dept. of Defense Contractors

(req. by DOD, Pub. 50-01-02)

Why Does MODAPTS Work

Simplicity and Accuracy. MODAPTS is easy to explain and employs a small number of values, a review of standards by interested parties is simple and the possibility of controversy is reduced. MODAPTS analyses motion patterns and subjective operator ratings. Its MOD based system is accurate and easy to interpret.

You Have Questions, We Have Answers. The MODAPTS System Answers Questions Such As:

- What is a reasonable productivity expectation given a specific amount of work and time? - How can productivity standards and expectations be established quickly and accurately? - How can reasonable productivity goals be established? - How can inefficient work methods and procedures be identified and corrective action taken and results measured? How can an effective ergonomic and work safety program be established and maintained.

MODAPTS can be adapted to virtually any industry: Manufacturing, Distribution, Retail, Transportation, Hospitals, Banks, Insurance, Public Utilities, Government Contractors of Any Kind

MODAPTS is equally valuable to firms currently using formalized work measurement programs as well as those considering such a program. It puts work measurement capability in the hands of small firms that do not have the technical staff required for traditional measurement. In large firms, existing work measurement specialists can use MODAPTS to increase the effectiveness of standard coverage, and reduce the costs of standards development. Users of MODAPTS include Abbott Laboratories, Motorola, General Electric, Nestle, Siemens, Commonwealth Bank, Monash University, Clairol, TRW, Whirlpool, ANZ Bank, National Australia Bank, University of Melbourne.

Endorsements include the U.S. Department of Labor and Labor Unions such as United Steel Workers and United Auto Workers.

DYNAMICS RESEARCH GROUP www.drshinnick.com drg@drshinnick.com 540.951.1950 FAX 540-951-0519

Meet Your Instructor

One of the Best Known MODAPTS Specialists

Lead Trainer, Dr. Michael D. Shinnick, Director of Dynamics Research Group, has provided consultation and directed projects in work assessment, disability management, and ergonomics for the past 20 years. He learned MODAPTS from the developer Christopher Heyde in Australia and was the founding director and president of the International MODAPTS Association (IMA). His dynamic and interactive teaching style makes the MODAPTS system accessible and immediately productive for any course attendee. Please visit our website at www.drshinnick.com for a complete listing of Dr. Shinnicks qualifications, publications and experience.

Course Notes

The effective implementation of MODAPTS is enhanced when two or more individuals from an organization or department participate in the training. Commitment from management is necessary for effective implementation and utilization of the MODAPTS system. Course Tuition is $625.00 The Tuition includes: the International MODAPTS Association's (IMA) MODAPTS training manual; the Practitioners Certification Examination; one year membership in IMA, and an opportunity to purchase TaskMaster 2000 Plus at a discounted price. E-mail based followup consultation available. Upon receipt of the tuition, the manual will be mailed to the participant for pre training review and study. For additional information call Dynamics Research Group at 540-951-1950 or E-Mail at DRG@drshinnick.com, www.DrShinnick.com.

Streamline your Work Studies Save Time and Resources

INTRODUCING

TaskMaster 2000 Plus

MODAPTS based Work Study Software

For sales and information, contact

540-951-1950 drg@drshinnick.com

Ergonomic and MODAPTS Training Programs Available

Registration

Please fill out the registration form and mail completed form and check to Dynamics Research Group, 670 Sunshine Farm Lane, Research Park, Suites 201-203, Blacksburg, VA 24060. Name:_______________________________________________________________ Company: _________________________ Title: __________________ Dept.: ______________________________ Type of Business: _________________________ Address: ________________________________________________________________________________________________ City:___________________________________________ ST: _____________ Zip Code: _____________________________ Phone: _________________________ Alt. Phone: _________________________ E-mail: _________________________ Course Date: ___________________________________________ Course Location: _________________________________________ Method of Payment: Please pay by check or money order, made payable to Dynamics Research Group. Total enclosed: ______________

DYNAMICS RESEARCH GROUP www.drshinnick.com drg@drshinnick.com 540.951.1950 FAX 540-951-0519

Вам также может понравиться

- What Is ModaptsДокумент8 страницWhat Is ModaptsBayu Saputra0% (1)

- Current State ModaptДокумент1 страницаCurrent State Modaptsukhpreet SinghОценок пока нет

- MODAPTS PRIMER SLIDESHOW - Modular Arrangement of Predetermined Time StandardsДокумент24 страницыMODAPTS PRIMER SLIDESHOW - Modular Arrangement of Predetermined Time StandardsGuger27Оценок пока нет

- 10 - Predetermined Time Systems PDFДокумент42 страницы10 - Predetermined Time Systems PDFRoberto De La PazОценок пока нет

- Work Study and MeasurementДокумент31 страницаWork Study and MeasurementAleemОценок пока нет

- Process Improvement & Performance Management Made Simple: The Fasttrack Approach to Getting Results QuicklyОт EverandProcess Improvement & Performance Management Made Simple: The Fasttrack Approach to Getting Results QuicklyОценок пока нет

- Lean Six Sigma QuickStart Guide: The Simplified Beginner's Guide to Lean Six SigmaОт EverandLean Six Sigma QuickStart Guide: The Simplified Beginner's Guide to Lean Six SigmaРейтинг: 4 из 5 звезд4/5 (1)

- Software Quality Assurance Research Paper PDFДокумент4 страницыSoftware Quality Assurance Research Paper PDFegya6qzc100% (1)

- Brochure For CAPДокумент2 страницыBrochure For CAPAnonymous Uqrw8OwFWuОценок пока нет

- Cost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsОт EverandCost Estimation in Agile Software Development: Utilizing Functional Size Measurement MethodsОценок пока нет

- Mobile Device Management MDM A Complete Guide - 2020 EditionОт EverandMobile Device Management MDM A Complete Guide - 2020 EditionОценок пока нет

- IBM Test Data Management V0.4Документ7 страницIBM Test Data Management V0.4Rosário CunhaОценок пока нет

- Group Project Software Management: A Guide for University Students and InstructorsОт EverandGroup Project Software Management: A Guide for University Students and InstructorsОценок пока нет

- A Study of the Supply Chain and Financial Parameters of a Small BusinessОт EverandA Study of the Supply Chain and Financial Parameters of a Small BusinessОценок пока нет

- Lean Six Sigma Black Belt NadeemДокумент4 страницыLean Six Sigma Black Belt NadeemSyedNadeemAhmedОценок пока нет

- FMEA 4th Edition & Control PlanДокумент4 страницыFMEA 4th Edition & Control PlanadobactОценок пока нет

- Human Resource Management Systems HRMSДокумент81 страницаHuman Resource Management Systems HRMSgovindarajn67% (3)

- Software Quality Assurance Term PaperДокумент4 страницыSoftware Quality Assurance Term Paperc5rnbv5r100% (1)

- Thesis Production Operations ManagementДокумент5 страницThesis Production Operations Managementlynnwebersaintpaul100% (2)

- Software Testing Interview Questions You'll Most Likely Be AskedОт EverandSoftware Testing Interview Questions You'll Most Likely Be AskedОценок пока нет

- Pro ModelДокумент6 страницPro ModelUrmil KhamarОценок пока нет

- Aerospace Lean Six Sigma NadeemДокумент4 страницыAerospace Lean Six Sigma NadeemSyedNadeemAhmedОценок пока нет

- Information System of Managers 3yywmnДокумент8 страницInformation System of Managers 3yywmnAkki ChoudharyОценок пока нет

- Douglas Montgomery's Introduction to Statistical Quality Control: A JMP CompanionОт EverandDouglas Montgomery's Introduction to Statistical Quality Control: A JMP CompanionОценок пока нет

- Plant Maintenance Cost Reduction Nov KL NadeemДокумент5 страницPlant Maintenance Cost Reduction Nov KL NadeemSyedNadeemAhmedОценок пока нет

- Managed M2M Service Providers A Complete Guide - 2019 EditionОт EverandManaged M2M Service Providers A Complete Guide - 2019 EditionОценок пока нет

- AUDITДокумент7 страницAUDITErnest Kamrad BndОценок пока нет

- Information Governance And MDM A Complete Guide - 2019 EditionОт EverandInformation Governance And MDM A Complete Guide - 2019 EditionОценок пока нет

- SumTotal Recruiting Hiring ManagementДокумент2 страницыSumTotal Recruiting Hiring ManagementSumTotal Talent ManagementОценок пока нет

- Enabling World-Class Decisions for Asia Pacific (APAC): The Executive’s Guide to Understanding & Deploying Modern Corporate Performance Management Solutions for Asia PacificОт EverandEnabling World-Class Decisions for Asia Pacific (APAC): The Executive’s Guide to Understanding & Deploying Modern Corporate Performance Management Solutions for Asia PacificОценок пока нет

- Shaping A New Era in Energy PDFДокумент4 страницыShaping A New Era in Energy PDFRafael FernandezОценок пока нет

- W6 CaseStudyДокумент6 страницW6 CaseStudyEric GiamОценок пока нет

- Job-Schedulers-CONTROLM - Changing Schedulers Is Easier Than You ThinkДокумент6 страницJob-Schedulers-CONTROLM - Changing Schedulers Is Easier Than You ThinkHowe LaiОценок пока нет

- Agile 1 PDFДокумент5 страницAgile 1 PDFGARLAPATI VIVEK SAIОценок пока нет

- Coursework It Project and Quality ManagementДокумент6 страницCoursework It Project and Quality Managementzug0badej0n2100% (2)

- Online Recruitment System Final Year Project1 PDF FreeДокумент53 страницыOnline Recruitment System Final Year Project1 PDF FreeKïñg Øf ÇrïsОценок пока нет

- A Practical Guide For Implementing Operator Driven ReliabilityДокумент4 страницыA Practical Guide For Implementing Operator Driven Reliabilitytiu4tonОценок пока нет

- Project Online Job Placement SystemДокумент96 страницProject Online Job Placement SystemManish SharmaОценок пока нет

- Quality Circles and Its Importance and Aid of CAD and CIM in Reducing To Market TimeДокумент18 страницQuality Circles and Its Importance and Aid of CAD and CIM in Reducing To Market TimeHina KhanОценок пока нет

- MDM Of Customer Data Solutions A Complete Guide - 2020 EditionОт EverandMDM Of Customer Data Solutions A Complete Guide - 2020 EditionОценок пока нет

- Research Papers On Production and Operations ManagementДокумент6 страницResearch Papers On Production and Operations ManagementyvunfevgfОценок пока нет

- Rockwell Automation TechED 2018 - PR26 - Endress+HauserДокумент33 страницыRockwell Automation TechED 2018 - PR26 - Endress+HauserAlex Rivas100% (1)

- Source Code Ijtima Falakiyin NUsanataraДокумент187 страницSource Code Ijtima Falakiyin NUsanataraUlum NiОценок пока нет

- PNP Switching Transistor: FeatureДокумент2 страницыPNP Switching Transistor: FeatureismailinesОценок пока нет

- Wayne Patterson, Cynthia E. Winston-Proctor - Behavioral Cybersecurity - Applications of Personality Psychology and Computer Science (2019, Taylor & Francis - CRC) - Libgen - LiДокумент291 страницаWayne Patterson, Cynthia E. Winston-Proctor - Behavioral Cybersecurity - Applications of Personality Psychology and Computer Science (2019, Taylor & Francis - CRC) - Libgen - Lisor ronОценок пока нет

- Management Reporter Integration Guide For Microsoft Dynamics® AX - DynAXDataProvInstGuide - ENUSДокумент17 страницManagement Reporter Integration Guide For Microsoft Dynamics® AX - DynAXDataProvInstGuide - ENUSUmesh PanditОценок пока нет

- Feature Evaluation For Web Crawler Detection With Data Mining TechniquesДокумент11 страницFeature Evaluation For Web Crawler Detection With Data Mining TechniquesSlava ShkolyarОценок пока нет

- Security Alarm SystemДокумент32 страницыSecurity Alarm SystemAnamika Yadav100% (2)

- Detailed List and Syllabuses of Courses: Syrian Arab Republic Damascus UniversityДокумент10 страницDetailed List and Syllabuses of Courses: Syrian Arab Republic Damascus UniversitySedra MerkhanОценок пока нет

- LM78S40 Switching Voltage Regulator Applications: National Semiconductor Application Note 711 March 2000Документ17 страницLM78S40 Switching Voltage Regulator Applications: National Semiconductor Application Note 711 March 2000Pravin MevadaОценок пока нет

- 9000-41034-0100600 - Data Sheet - enДокумент2 страницы9000-41034-0100600 - Data Sheet - endAvId rObLeSОценок пока нет

- Opamp ProjectДокумент10 страницOpamp Projectbirla_sОценок пока нет

- Fan ManualДокумент389 страницFan ManualkarkonОценок пока нет

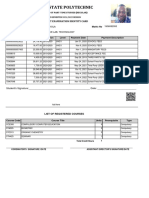

- Lagos State Polytechnic: Student Examination Identity CardДокумент1 страницаLagos State Polytechnic: Student Examination Identity CardSunday PeterОценок пока нет

- Advances in Computer NetworkДокумент26 страницAdvances in Computer NetworkSandesh RameshОценок пока нет

- MATLAB and Simulink: Prof. Dr. Ottmar BeucherДокумент71 страницаMATLAB and Simulink: Prof. Dr. Ottmar BeucherShubham ChauhanОценок пока нет

- Statistical Analysis With R - A Quick StartДокумент47 страницStatistical Analysis With R - A Quick StartPonlapat Yonglitthipagon100% (1)

- OQLДокумент16 страницOQLVikram KarkiОценок пока нет

- College Brochure ProjectДокумент2 страницыCollege Brochure Projectapi-275943721Оценок пока нет

- CSEC Information Technology June 2015 P02Документ18 страницCSEC Information Technology June 2015 P02SiennaОценок пока нет

- PACSystems RX3i CPU Quick Start GuideДокумент54 страницыPACSystems RX3i CPU Quick Start GuideHaz ManОценок пока нет

- (PPT) Digital Electronics 2 For StudentsДокумент6 страниц(PPT) Digital Electronics 2 For StudentsJONNA ACABOОценок пока нет

- Bharat Heavy Elelctricals Limited: Operation & Maintenance Manual of Bhelscan Flame Scanner System (Bn10)Документ25 страницBharat Heavy Elelctricals Limited: Operation & Maintenance Manual of Bhelscan Flame Scanner System (Bn10)MukeshKrОценок пока нет

- Java ProgrammingДокумент134 страницыJava ProgrammingArt LookОценок пока нет

- Codesys Professional Developer Edition: Professional Add-On Tools For The IEC 61131-3 Development SystemДокумент3 страницыCodesys Professional Developer Edition: Professional Add-On Tools For The IEC 61131-3 Development SystemPauloRpindaОценок пока нет

- VoyeurismДокумент9 страницVoyeurismsaurabhosaurus100% (1)

- Free License Keys of Kaspersky Internet Security 2017 Activation Code PDFДокумент20 страницFree License Keys of Kaspersky Internet Security 2017 Activation Code PDFCaesar Catalin Caratasu0% (1)

- Girbau, S.A.: STI-54 / STI-77 Parts ManualДокумент72 страницыGirbau, S.A.: STI-54 / STI-77 Parts ManualoozbejОценок пока нет

- CCNA Exploration 2 - Module 4 Exam Answers Version 4.0Документ3 страницыCCNA Exploration 2 - Module 4 Exam Answers Version 4.0fun kollaОценок пока нет

- Projection of Points &lineДокумент25 страницProjection of Points &lineSai Radha KrishnaОценок пока нет

- THE Football Analytics HandbookДокумент26 страницTHE Football Analytics HandbookAlvaro Zabala100% (2)