Академический Документы

Профессиональный Документы

Культура Документы

BALANCES DE MATERIA Y ENERGíA I

Загружено:

Tozkano DeyabuИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

BALANCES DE MATERIA Y ENERGíA I

Загружено:

Tozkano DeyabuАвторское право:

Доступные форматы

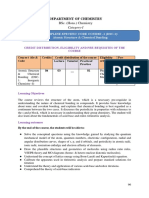

BALANCES DE MATERIA Y ENERGA I (l1p)

Material Balance Project EthanolProductlon

A new ethanol production facility within a refinery complex is de~gned to produce 5,000,000 gallons per year of liquid chemical grade ethanol which is 95 vol% pure. The ethanol is made by reacting ethylene with steam over a catalyst. The ethylene feed is 99.99% pure. High-purity steam, suitable for the process, is available within the refinery. The reactor in the chemical plant is designed to operate at 227C and produce an equilibrium mixture of ethanol, ethylene and water.

The reaction is

C H + H O ~ C H OH 24225

In the temperature range of normal operations, there are no side reactions.

Process Description

A simplified process flow diagram for the ethanol facility is shown in Figure l. The fresh ethylene and steam are mixed with a recycle stream and sent to a reactor. The reactor operates at 227C and 40 atm pressure. The reactants and products are at chemical equilibrium within the reactor. The effluent in Stream 5 is at the same composition as the reactor. The effluent pressure is reduced to 5 atm and is cooled to condense ethanol and water. The liquid and vapor phases are separated in the flash unit. For simplicity, it is assumed that all ofthe ethanol and water are condensed, and that all ofthe ethylene is in the vapor phase. The liquid product is sent to a distillation column for purification. The overhead. stream produces a liquid containing 95 volume% ethanol. The bottoms stream, containing a negligible amount of ethanol, is sent to a wastewater treatment facility. The vapor phase from the separator is recycled to the reactor. A compressor increases the pressure of the recycle stream from 5 atm to 40 atm before it is mixed with fresh feed.

AdditionaJ Process Information

Stream 1 - Can be considered as essentially pure ethylene. Stream 2 - Pure water vapor. This stream is saturated steam at 600 psig. Stream 4 - The water/ethylene feed ratio can be adjusted from 1: 1 to 5: l. R-201 - The reactor operates at 227C and in the 10-40 atm pressure range. The contents are mixed and are always at equilibrium in this model. Heat for the process comes from the steam and from the heat of the exothermic reaction. At steady state, heat has to be removed from the reactor to maintain constant temperature. This detail is not considered in this project. The equilibrium constant at 227C is K = 0.01306 eq Stream 5 - Contents are at the same temperature, pressure and concentrations as in the reactor. Stream 6 - Pressure is red~"'d to 5 atm. Stream 7 - Stream is c0cf?~ to s~ra4 temperature. O ~ '1)

Stream 8 - Ethylene only. Stream 9 - Ethanol and water only. Stream 10 - Purge stream. Consider operation with no purge stream. Stream 11 - Recycle stream: Since no purge stream is being considered, Stream 11 is actualIy a continuation of Stream 8.

Stream 12 - Ethanol product containing 95 volume% liquid ethanoI. Stream 13 - Waste water stream sent to treatment plant assumed to contain negligible ethanol (read as no ethanol). .

Stream 14- Recycled ethylene.

Problem You, the engineering team, are to plan the operation ofthe ethanol production unit in order to produce 5,000,000 gallon per year. Y our goal is to minimize operating costs and maximize profit. Y ou have some flexibility in the operation of this unit in that the reactor pressure can be varied from 10-to-40 atm, and the steam-to-ethylene ratio can be adjusted from i: 1 to 5: 1. Each of these variable parameters involves trade-offs. Increasing the reactor pressure increases equilibrium conversion but also increases compression costs for the recycIe loop. Increasing the steam-toethylene ratio increases equilibrium conversion, but increases the costs of effluent cooling and the costs of distilIation.

y ou may not use CAD software, but you are encouraged to use spreadsheet caIculations since variables may be changed and operating profit or loss caIculated immediately. Prior to setting up a spreadsheet, you must tum in hand calculations for two cases to demonstrate that the spreadsheet is set up correctly. The first case will be due Wednesday, July 6. Conditions for the first hand caIculation are: P(reactants) = 10 atm; steam-to-ethylene ratio = 2. The second set of hand calculations, due Monday, July 11, are for P(reactants) = 40 atm; steam-to-ethylene ratio =1.

Operating Costs Value ofFeeds and Products Ethylene fresh feed $0.35/Ib High purity steam at 600 psig $0.03/lb Fuel gas $0.18/lb 95 vol% ethanol (SG = 0.807) $2.90/gal

Variable Operating Costs Distillation $0.47 /lb-mol Cooling after reactor $0.03/lb-mol Recycle compressor $0.003(M in atm)/lb-mol 3 Wastewater treatment $100/1 000 m

Fixed Operating Costs

Operating the ethanol production unit involves additional costs such as labor, maintenance and debt service which should remain nearly constant as operating parameters change. Assume that these fixed costs are $0.30/gal of ethanol produced.

BALANCES DE MATERIA Y ENERGA I (llp)

Profit (Loss) on Unit At a selling price of $2.90/gal, the value of 5-million gallons of ethanol is $14.5 million. In estimating profit or loss for various operating conditions, the significant figure for profit or loss . . . should be $0.01 million.

Group Formation A student design group will consist of 3 or 4 group members. Y ou are encouraged to choose a partner for this project to form a pair. When you have formed a pair, please send your names to Email: rsruiz2000@yahoo.com.mx.beforeJune13.Dr.Ruiz will combine pairs to form groups ofthree or four. Group assignments will be made on June 17.

Report Authors Although work on a group report can never be divided equally, only those members making substantial contributions to the final report should be listed as authors.

Reporte El equipo deber entregar un reporte por escrito en el que se expongan las mejores condiciones de operacin del proceso analizado. El reporte ser entregado el da 20 de julio a las 3:00 PM en el cubculo T-158. Se recomienda que base sus conclusiones en resultados reportados en forma de tablas y grficas, ya que estos sirven para condensarlos y hacerlos ms sencillos de entender. Su reporte deber contener:

l. Hoja de clculo que calcule balances de masa y los correspondientes gastos totales de materias primas, productos y de operacin. a) Un ejemplo donde se proponga un valor de la relacin vapor de agua/etileno en la corriente 4, y a partir de ello se determinen la presin del reactor y los flujos de cada corriente. b) Presentar los resultados del inciso anterior en forma de tabla.

Corriente

Flujo molar I Presin

Flujo de etileno

Flujo de al!Ua

Flujo de etanol 12 Etc. c) Una tabla que presente los costos diversos asociados a la operacin del proceso y la rentabilidad expresada como ganancia anual. 2. Graficas y comentarios sobre: a) la variacin de la rentabilidad con respecto a la relacin Vapor de agua/etlineno a la entrada del reactor; b) Efecto de la presin de operacin del reactor sobre la rentabilidad del proceso.

Вам также может понравиться

- Proyecto Ethanol AДокумент4 страницыProyecto Ethanol Aacte90Оценок пока нет

- Energy Balances and Numerical Methods Design Project Ethanol ProductionДокумент9 страницEnergy Balances and Numerical Methods Design Project Ethanol ProductionFatima Manzano OrtizОценок пока нет

- Dee CДокумент15 страницDee CAnderson David ValenciaОценок пока нет

- Produce Acetone from Isopropyl AlcoholДокумент13 страницProduce Acetone from Isopropyl AlcoholGustavo Vasquez100% (1)

- Acetone BДокумент9 страницAcetone BIrdani IdrisОценок пока нет

- Ethanol Production Process OptimizationДокумент8 страницEthanol Production Process Optimizationarnold30Оценок пока нет

- Project 6 - Ethylene Oxide PDFДокумент13 страницProject 6 - Ethylene Oxide PDFStephanie Hawkins100% (1)

- Production of Formaldehyde From MethanolДокумент13 страницProduction of Formaldehyde From MethanolAugusto Mohr Christmann100% (1)

- Fluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of StyreneДокумент12 страницFluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of StyrenezarceloОценок пока нет

- Project 4 Acrylic AcidДокумент16 страницProject 4 Acrylic AcidN193746100% (3)

- Acrylic Acid ProductionДокумент8 страницAcrylic Acid ProductionAhmad MuzammilОценок пока нет

- CHE655 - Formalin Production DesignДокумент13 страницCHE655 - Formalin Production DesignAhmed Ali100% (1)

- Ilovepdf MergedДокумент39 страницIlovepdf MergedmoheedОценок пока нет

- Project 1 Acetone PDFДокумент13 страницProject 1 Acetone PDFvanesaОценок пока нет

- Allyl CДокумент15 страницAllyl CTengku Mohd Imran0% (1)

- Fluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of CumeneДокумент11 страницFluid Mechanics, Heat Transfer, Thermodynamics Design Project Production of CumeneCarlos Benavidez AranibarОценок пока нет

- Ethyl Acetate Design ProjectДокумент60 страницEthyl Acetate Design ProjectAhmed Ali100% (4)

- Ethanol 3Документ6 страницEthanol 3Fedi ChennaouiОценок пока нет

- Styrene AДокумент4 страницыStyrene AIng QuimОценок пока нет

- FormalinДокумент5 страницFormalinDipankar KalitaОценок пока нет

- Design of An Ethylene Oxide Production ProcessДокумент13 страницDesign of An Ethylene Oxide Production ProcessGie100% (4)

- Ethyl Acetate ProjectДокумент60 страницEthyl Acetate ProjectBaskarrajaОценок пока нет

- Exp 2 Bubble Cap DistillationДокумент7 страницExp 2 Bubble Cap DistillationFaris HamirОценок пока нет

- Examen 1 Diseño de Procesos Químicos IДокумент29 страницExamen 1 Diseño de Procesos Químicos IDavid Tovar HernándezОценок пока нет

- Allyl BДокумент9 страницAllyl BDemet AcargilОценок пока нет

- Project 2 CumeneДокумент9 страницProject 2 CumeneUmar Alijandro50% (2)

- EvaporatorsДокумент17 страницEvaporatorsOmprakash VermaОценок пока нет

- Alpha OlefinsДокумент3 страницыAlpha OlefinsAnkit ModiОценок пока нет

- Project 3 Phthalic AnhydrideДокумент15 страницProject 3 Phthalic AnhydrideAhmed Ali100% (1)

- Styrene Production Process OptimizationДокумент4 страницыStyrene Production Process Optimizationppluk-s100% (1)

- Allyl Chloride OptimizationДокумент37 страницAllyl Chloride Optimizationmoheed100% (1)

- Cumene ProductionДокумент9 страницCumene ProductionDrVedprakash MishraОценок пока нет

- Assignment Question bank-PEPE - HUKДокумент10 страницAssignment Question bank-PEPE - HUKDhananjay pathareОценок пока нет

- Exp 1 Packed Column DistillationДокумент12 страницExp 1 Packed Column DistillationLuqman WasirОценок пока нет

- CHE655 - Plant Design Project #4 Summer 2011 Design of A Styrene Production ProcessДокумент11 страницCHE655 - Plant Design Project #4 Summer 2011 Design of A Styrene Production ProcessAhmed Ali67% (3)

- Simulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017Документ5 страницSimulation Lab Problem-1: Chem 2002 - Process Systems Analysis - 2016-2017ajali1957Оценок пока нет

- PROJECT 5. Problems at The Cumene Production Facility, Unit 800Документ14 страницPROJECT 5. Problems at The Cumene Production Facility, Unit 800migelОценок пока нет

- Aspen Example Test - EO v2018Документ2 страницыAspen Example Test - EO v2018marij233Оценок пока нет

- Ammonia B PDFДокумент9 страницAmmonia B PDFmehrdad_k_rОценок пока нет

- Dme BДокумент8 страницDme Bdewi xiaОценок пока нет

- Eo AДокумент4 страницыEo AiwansaputratekimОценок пока нет

- Design of An Plant For Manufacturing of AcetaldehydeДокумент4 страницыDesign of An Plant For Manufacturing of AcetaldehydeClaudio Martinez BernalОценок пока нет

- AmoniaДокумент35 страницAmonianoelia cossio0% (1)

- Thermodynamic Analysis of Rajby Industries Power and Boiler HouseДокумент20 страницThermodynamic Analysis of Rajby Industries Power and Boiler HouseSyed AhmedОценок пока нет

- Final ReportДокумент17 страницFinal ReportFahad KhokharОценок пока нет

- Acetone ProjectДокумент8 страницAcetone ProjectYo MarhoonОценок пока нет

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОт EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGОценок пока нет

- Ethanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesОт EverandEthanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesОценок пока нет

- Sustainable Retail RefrigerationОт EverandSustainable Retail RefrigerationJudith A. EvansРейтинг: 5 из 5 звезд5/5 (1)

- Working Guide to Reservoir Rock Properties and Fluid FlowОт EverandWorking Guide to Reservoir Rock Properties and Fluid FlowРейтинг: 3 из 5 звезд3/5 (1)

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentОт EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentОценок пока нет

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingОт EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingРейтинг: 5 из 5 звезд5/5 (1)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesОт EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesРейтинг: 1 из 5 звезд1/5 (2)

- Chapter 1: The Quantum Theory of The Submicroscopic WorldДокумент28 страницChapter 1: The Quantum Theory of The Submicroscopic WorldHun Qiu LimОценок пока нет

- RonNielsen NuclearReactionsДокумент471 страницаRonNielsen NuclearReactionsr_nielsenОценок пока нет

- TH-L32C10R2: Model NoДокумент121 страницаTH-L32C10R2: Model Nozerson13Оценок пока нет

- Lightening ArresterДокумент13 страницLightening Arresterrohanlagad10Оценок пока нет

- Reactor Design Sample ExamДокумент7 страницReactor Design Sample ExamAugustine BrockОценок пока нет

- Model-A Physics (3) 2 PDFДокумент16 страницModel-A Physics (3) 2 PDFk bhuvanОценок пока нет

- Eges485 DTCДокумент9 страницEges485 DTCeng_hamada_4uОценок пока нет

- Syllabus of Chemistry H NEP 96 105 1Документ10 страницSyllabus of Chemistry H NEP 96 105 1Vijay Kumar VishvakarmaОценок пока нет

- Mock Test 4 Paper Neet SolДокумент16 страницMock Test 4 Paper Neet Solspamhater566Оценок пока нет

- Water Purification Experiment Dissolved OxygenДокумент2 страницыWater Purification Experiment Dissolved OxygenJunОценок пока нет

- Air Conditioning and Refrigeration: Muhammad Bilal KhanДокумент25 страницAir Conditioning and Refrigeration: Muhammad Bilal KhanMuzammalRehmanОценок пока нет

- Underground Power Transmission Insulation MaterialsДокумент31 страницаUnderground Power Transmission Insulation MaterialsnandhakumarmeОценок пока нет

- 10biology Practical - StomataДокумент2 страницы10biology Practical - StomataHridaan SherawatОценок пока нет

- PZC of Titanium DioxideДокумент14 страницPZC of Titanium DioxideSuja GeorgeОценок пока нет

- Pogil Photosynthesis and Respiration-SДокумент6 страницPogil Photosynthesis and Respiration-Sapi-2623786400% (1)

- Asam Mefenamat EmulgelДокумент5 страницAsam Mefenamat EmulgelVi Vian HiuОценок пока нет

- Sensors 3Документ59 страницSensors 3zubairawОценок пока нет

- ESAS-Lindeburg Terms (Dreamforce)Документ14 страницESAS-Lindeburg Terms (Dreamforce)e5865domingoascotbaguioОценок пока нет

- Game PhysicsДокумент31 страницаGame Physicscabella_pasaporteОценок пока нет

- 9.0 Corrosive Material IndexДокумент66 страниц9.0 Corrosive Material IndexMaria Laura PonceОценок пока нет

- Daily Lesson Log TemplateДокумент64 страницыDaily Lesson Log TemplateArlene ChavezОценок пока нет

- Review Article Barium HexaferriteДокумент11 страницReview Article Barium HexaferriteIngrid Bena RiaОценок пока нет

- Flowmetter KytolaДокумент4 страницыFlowmetter Kytolason tran lamОценок пока нет

- What Is Organic ChemistryДокумент4 страницыWhat Is Organic Chemistrybas haОценок пока нет

- FUTO Post UTME Past Questions 2005 2006 - 2010 2011Документ29 страницFUTO Post UTME Past Questions 2005 2006 - 2010 2011Dider DrogbaОценок пока нет

- Iare RRS Notes PDFДокумент588 страницIare RRS Notes PDFmohan reddyОценок пока нет

- Copernican PrincipleДокумент7 страницCopernican Principlemaddy555Оценок пока нет

- Water Treatment TechnologyДокумент10 страницWater Treatment TechnologynickОценок пока нет

- Estimating water hardnessДокумент9 страницEstimating water hardnessAruldharshan SaravananОценок пока нет

- Quantum Anharmonic Oscillator, A Computational ApproachДокумент3 страницыQuantum Anharmonic Oscillator, A Computational ApproachInternational Journal of computational Engineering research (IJCER)Оценок пока нет